Nanofiber aggregate, polymer alloy fiber, hybrid fiber, fibrous structures, and processes for production of them

A nanofiber and alloy fiber technology, applied in the direction of single-component synthetic polymer rayon, fiber treatment, fiber chemical characteristics, etc., can solve the problems of nanofiber application prospect restrictions, difficult operation, and drawing out fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0304] The melt viscosity is 53Pa s (262 ℃, shear speed 121.6 seconds -1 ), the end of the amine with a melting point of 220°C is capped with acetic acid, and the amount of the end group of the amine reaches 5.0×10 -5 Molar equivalent / g of N6 (20% by weight); and a melt viscosity of 310 Pa·s (262°C, shear rate 121.6 seconds -1 ), 8 mol% of isophthalic acid with a melting point of 225°C, and 4 mol% of bisphenol A are copolymerized into a copolymerized PET (80% by weight) with a melting point of 225°C, and are mixed at 260°C with a twin-screw extrusion mixer , get b * Polymer alloy slices with value=4. In addition, the copolymerized PET at 262 ° C, 1216 seconds -1 The melt viscosity is 180Pa·s. The mixing conditions at this time are as follows:

[0305] Screw type Full engagement in the same direction, 2 screws

[0306] Screw diameter 37mm, effective length 1670mm, L / D=45.1

[0307] The length of the mixing section is 28% of the effective length of the screw

...

Embodiment 2

[0319] Except for N6, the melt viscosity is 212Pa·s (262°C, the shear speed is 121.6 seconds -1 ), the end of the amine with a melting point of 220°C is capped with acetic acid, and the amount of the end group of the amine reaches 5.0×10 -5 Except the N6 (20% by weight) of molar equivalent / g, operate in the same way as in Example 1, obtain b with twin-screw extrusion mixer * Polymer alloy slices with value=4. In addition, except that the discharge rate of each single hole is 1.0g / min, the shear stress between the nozzle hole wall and the polymer is 0.071MPa (the viscosity of the polymer alloy is 170Pa·s, 262°C, and the shear speed is 416 seconds -1 ) except that melt spinning was carried out in the same manner as in Example 1 to obtain undrawn polymer alloy yarns. The spinnability at this time was good, and the yarn was broken once during 1 t of spinning. And except that the draw ratio of the undrawn polymer alloy fiber is 3.0 times, drawing is carried out in the same manne...

Embodiment 3

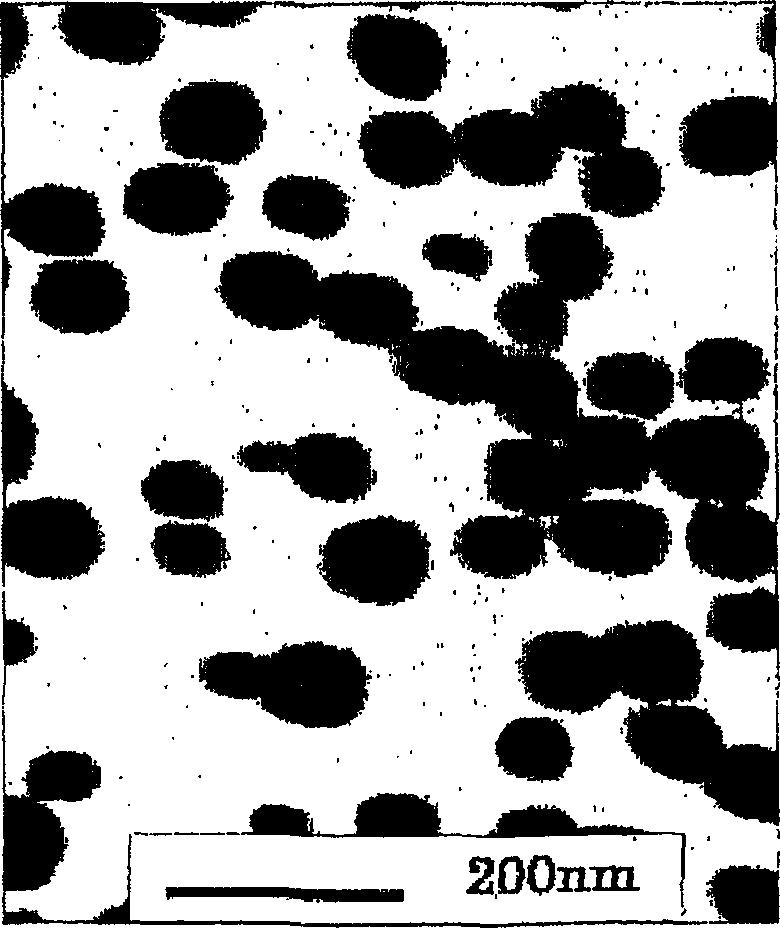

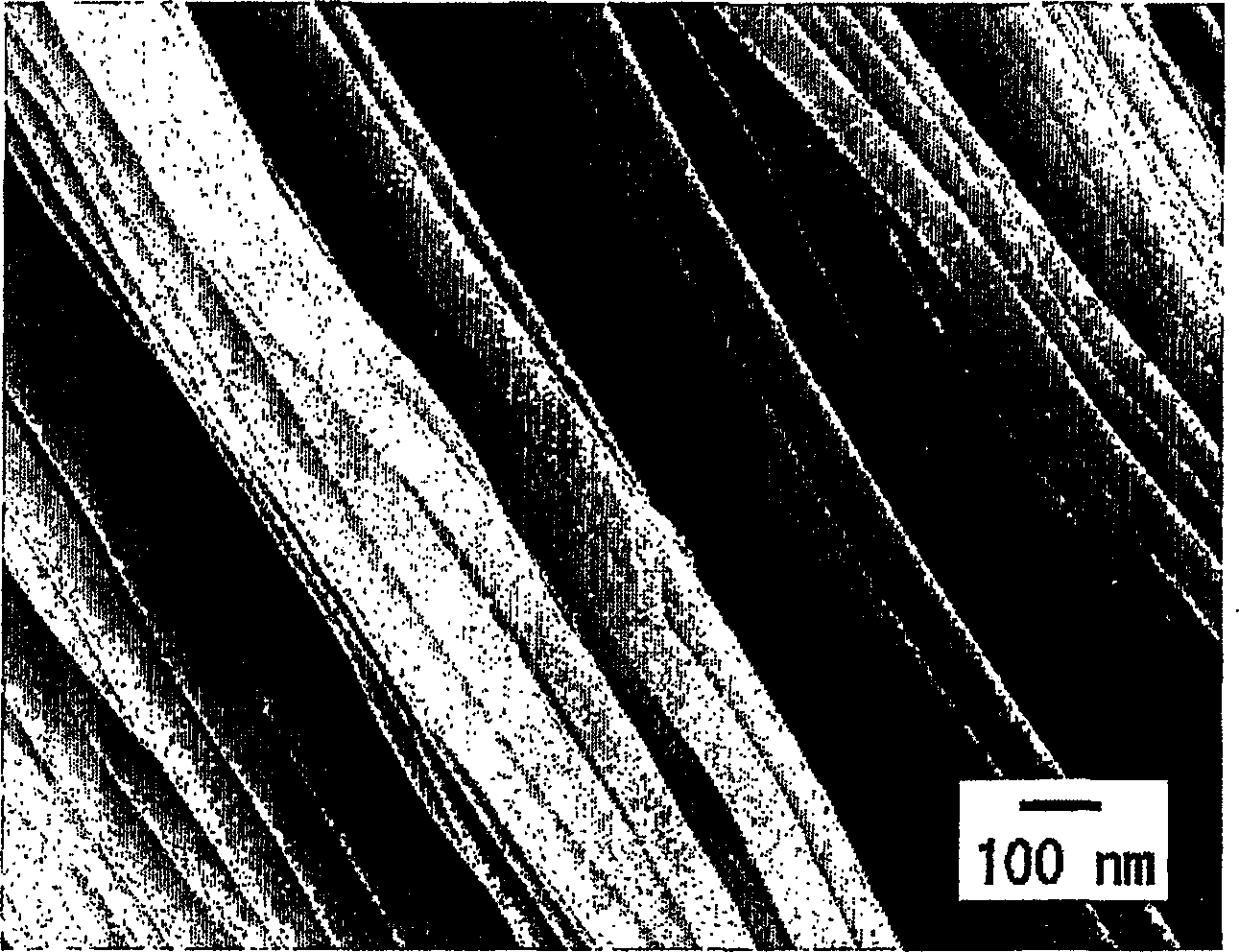

[0324] Except for N6, the melt viscosity is 500Pa·s (262°C, the shear speed is 121.6 seconds -1 ) and N6 (20% by weight) with a melting point of 220° C. were melt-spun in the same manner as in Example 2. Then, except that the shear stress between the nozzle hole wall and the polymer is 0.083MPa (the viscosity of the polymer alloy is 200Pa·s, 262°C, 416 seconds -1 ) except that melt spinning was carried out in the same manner as in Example 1 to obtain undrawn polymer alloy yarns. The spinnability at this time was good, and the yarn was broken once during 1 t of spinning. Moreover, stretching and heat treatment were carried out in the same manner as in Example 2, and the obtained polymer alloy fiber had 128 decitex, 36 filaments, a strength of 4.5cN / dtex, an elongation of 37%, U%=1.9%, and a shrinkage in boiling water 12% excellent characteristics. The results of TEM observation of the cross-section of the obtained polymer alloy fiber show that, as in Example 1, a sea-island ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com