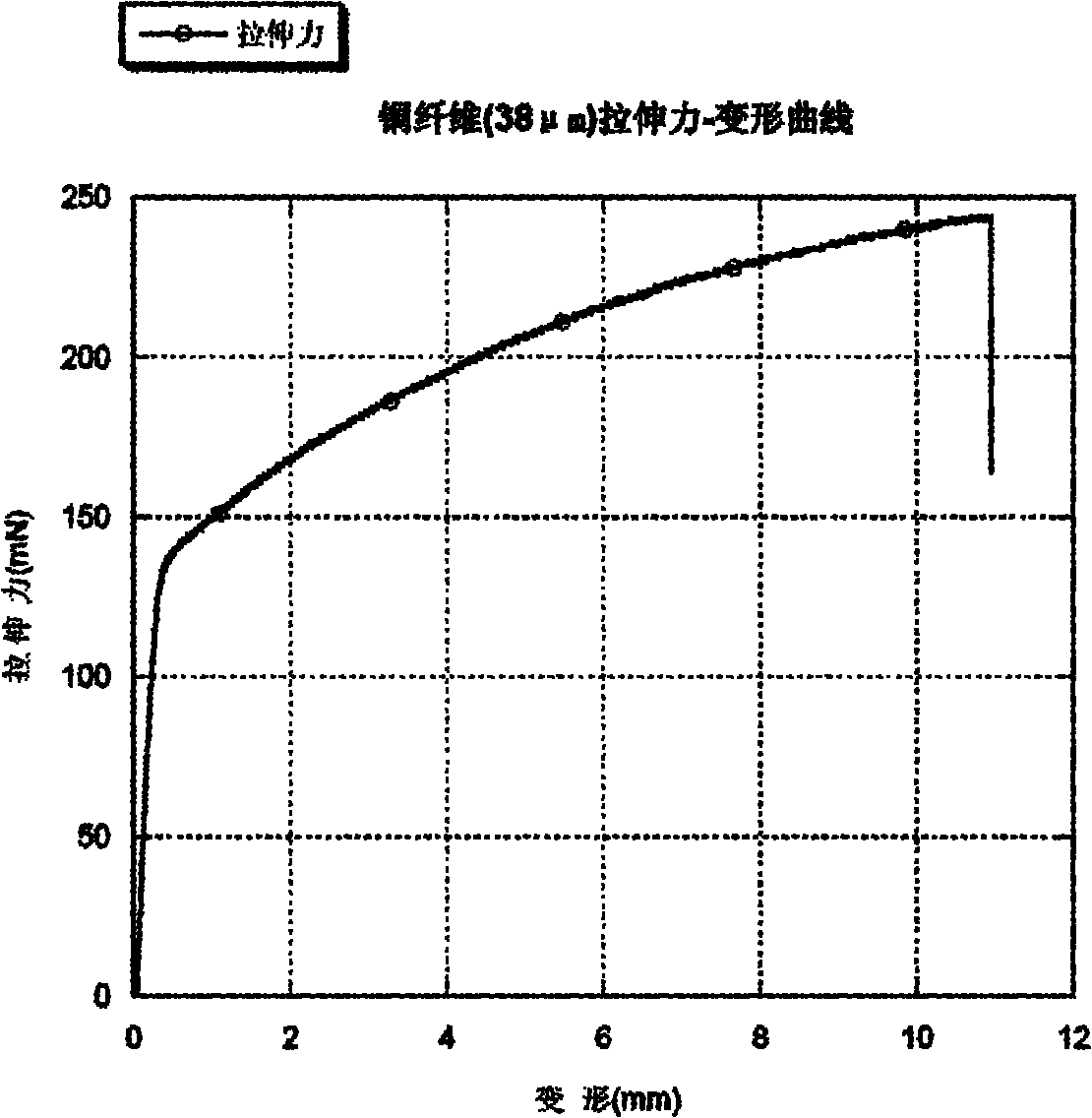

Method and device for testing micro-tensile mechanical properties of metal fiber

A metal fiber, micro-stretching technology, used in measuring devices, optical devices, tension measurement, etc., can solve the problems of high price, complex structure, contact interference, etc., and achieve compact device structure, stable measurement system, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

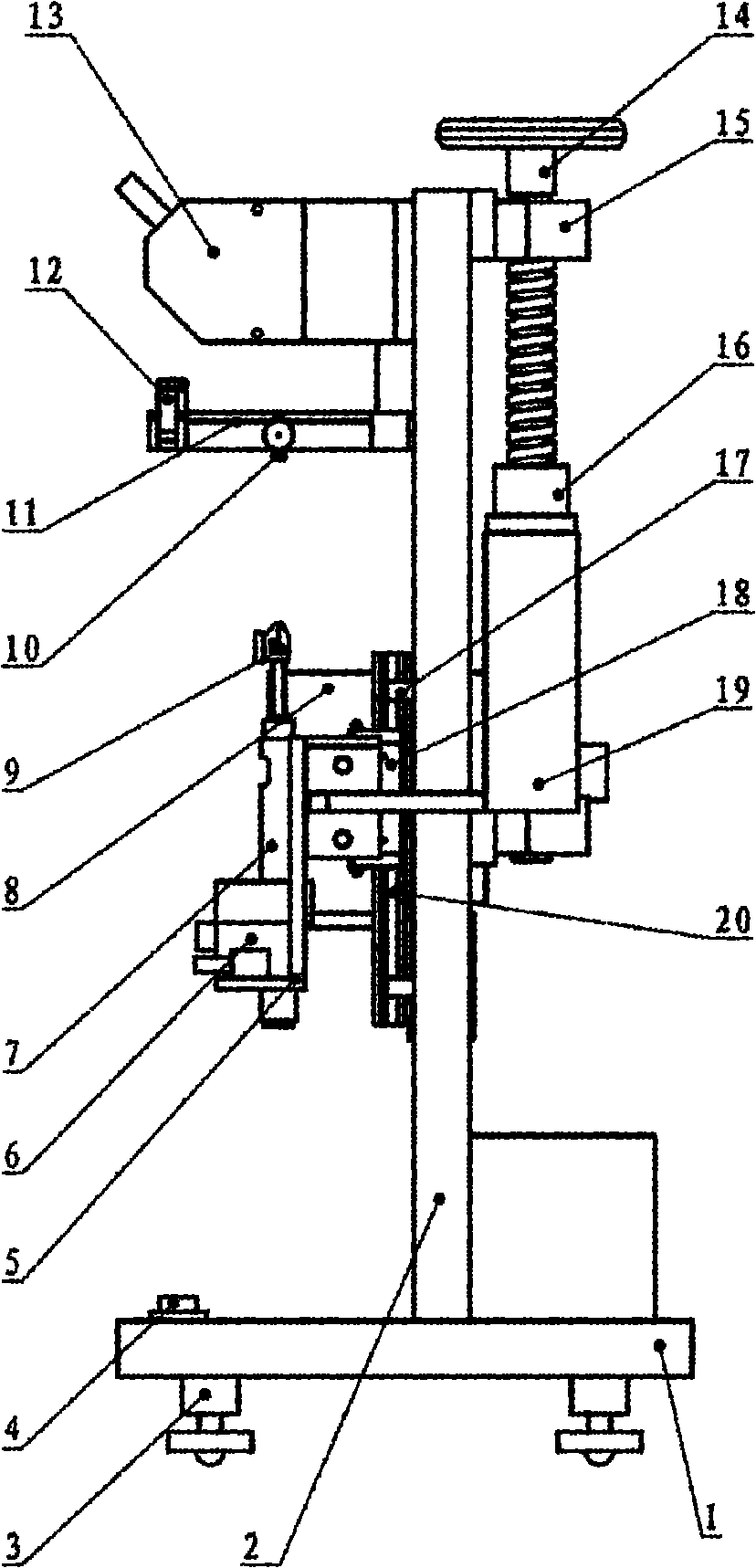

[0016] Attached below Figure 1~5 Detailed description of the present invention: The measuring device of the present invention generally includes six parts in terms of functions: a force sensor unit, a drive unit, a displacement adjustment mechanism, a specimen fixture assembly, a machine base unit, and a data acquisition and testing system. Its structure and working principle are as follows:

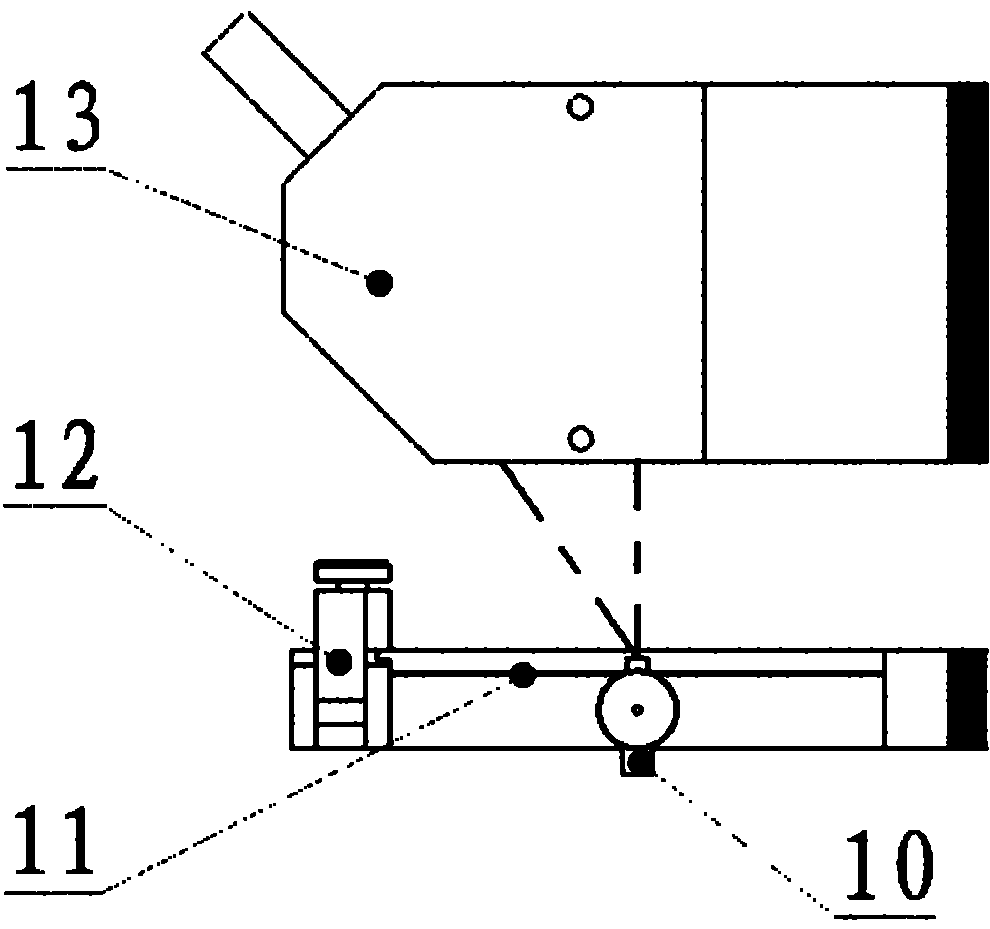

[0017] a. The force sensor unit consists of a high-precision photoelectric displacement sensor and an elastic element 11. The photoelectric displacement sensor includes a sensing head 13 (with an accuracy of 0.1 μm and a measuring range of ±5mm) and a photoelectric displacement controller 8. The photoelectric displacement sensor adopts the triangulation measurement principle (as attached image 3 As shown), the deformation of the laser irradiation point of the elastic element can be measured non-contact, and the deformation is converted into a force value signal through calibration, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com