Filter medium and filter unit

A filter material and single fiber technology, applied in the field of filter material and filter units using the filter material, can solve the problems of undisclosed fiber physical properties, small elongation, practical filter material, high air permeability, etc., and save energy. , low noise, high air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The method for producing the nonwoven fabric may, for example, be a wet papermaking method, an air-laid method, a dry chemical bonding method, a thermal bonding method, or a spunbonding method. The wet papermaking method or the air-laid method is a method of aggregating short non-curled staple fibers with a fiber length of several mm-10mm to obtain a nonwoven fabric. The dry chemical bonding method is a method in which crimped short fibers are formed into a web through a carding machine, then impregnated with an emulsified resin, dried, and fixed between the fibers to prepare a nonwoven fabric. The thermal bonding method is a method in which short fibers containing crimped hot-melt-adhesive short fibers are formed into a web through a carding machine, and then the fibers are thermally melt-bonded to prepare a non-woven fabric. The spunbond method is a method in which the polymer is pulled out of a small hole in a dissolved state, and then solidified to directly make a n...

Embodiment 1

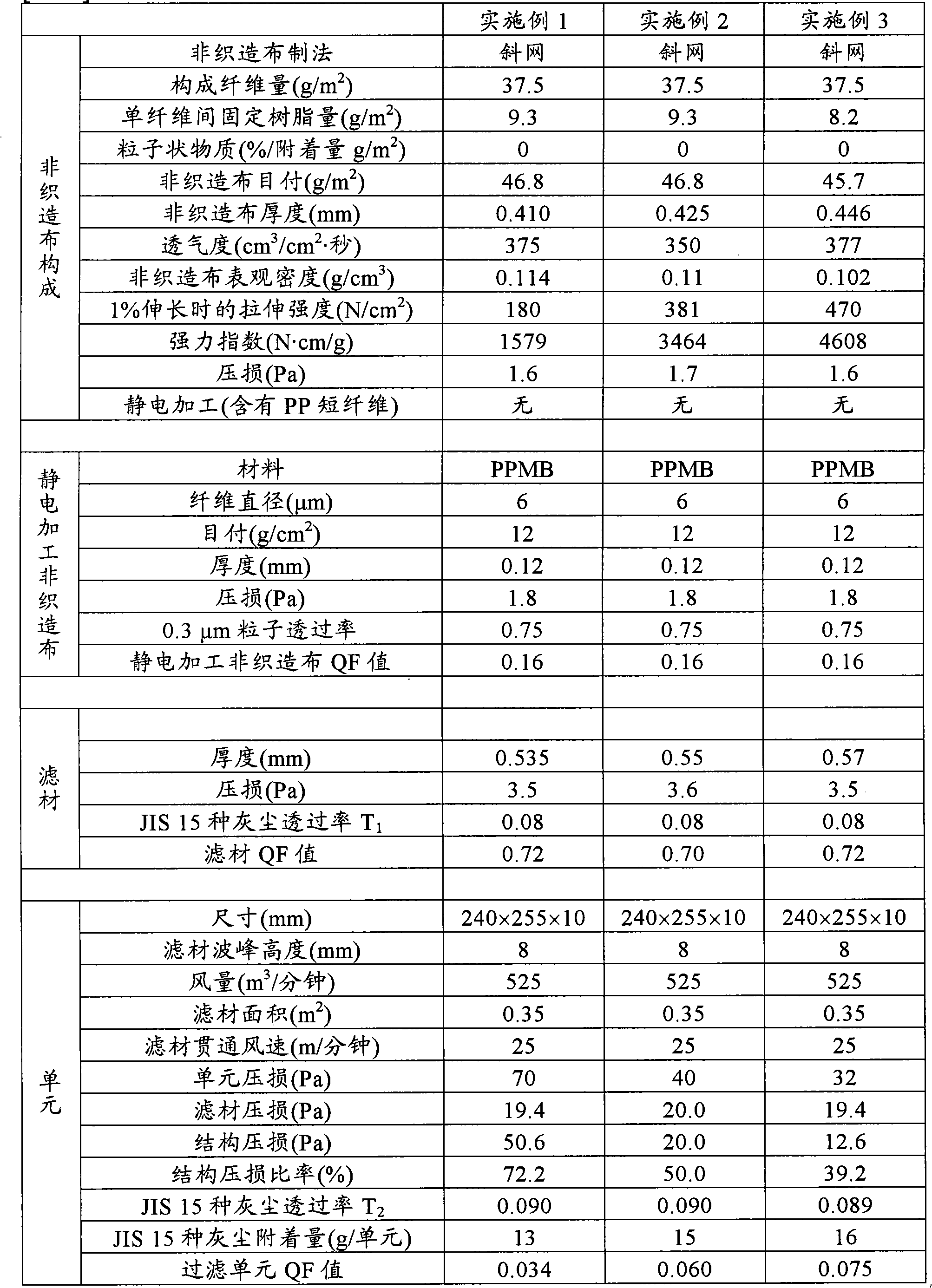

[0147] By the wet papermaking method of inclined net mode, prepare by non-crimp vinylon fiber (contain the fiber of 20 mass % Young's modulus 180cN / dtex, denier 7dtex, fiber length 10mm), non-crimp polyester fiber ((1) contains 21% by mass of fibers with a Young's modulus of 65 cN / dtex, a fineness of 10 dtex, and a fiber length of 10 mm, (2) containing 49% by mass of fibers with a Young's modulus of 65 cN / dtex, a fineness of 17 dtex, and a fiber length of 18 mm), pulp (10% by mass ) composed of 37.5g / m 2 of fiber aggregates. Then, the fiber aggregate was impregnated in a liquid with a solid content of 30% of styrene / acrylic polymer (glass transition temperature Tg 30°C, film-forming temperature 45°C), and dried and heat-treated to prepare mesh weight 46.8g / m 2 , thickness 0.410mm, air permeability 375cm 3 / cm 2 Seconds (2 pieces overlap), apparent density 0.114g / cm 3 , Tensile strength at 1% elongation 180N / cm 2 , Non-woven fabric with a strength index of 1579N·cm / g. The...

Embodiment 2

[0153] Except for changing the constituent fibers of the nonwoven fabric as shown in Table 1 and Table 2, it was carried out in the same manner as in Example 1. As a result, a filter unit can be made in which structural pressure loss occurs less. The filter unit is also proven to be a low pressure drop high capture, long life filter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com