Waterproof non-woven heat-preservation material making method and waterproof non-woven heat-preservation material

A technology of water repellent and glue, which is applied in the direction of non-woven fabrics, textiles and papermaking, and liquid-repellent fibers, etc., which can solve problems affecting warmth retention, safety and environmental issues, and increase costs, and achieve excellent warmth retention effects. Increased wash fastness, low-cost manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Adopt 2D / 51mm polyester low melting point fiber (Huvis 2080 produced by Huvis Company) 2kg, 2D / 51mm solid polyester fiber (2D solid fiber of Yizheng Chemical Fiber) 8kg. After opening, carding and cross-lapping, it is made into a fiber web. Then spray water repellent (3M Scotchgard) on the surface of the fiber net TM PM-3633), the fiber web enters a three-layer oven, and when it enters the second layer of drying, the water repellent is sprayed on the lower surface of the fiber web. The spray ratios on the upper and lower sides are 0.5gsm, 5gsm and 20gsm respectively. The oven temperature is 120 degrees Celsius, and the drying time is 6-9 minutes. Then the dried non-woven material is wound and packaged. Samples 1-3 of the water-repellent nonwoven thermal insulation material of the present invention were obtained.

Embodiment 2

[0037] Adopt 4D / 51mm polyethylene / polypropylene low-melting point fiber (the ES fiber produced by Guangzhou Yiai Si Company) 2kg, cotton fiber 8kg, after opening, make fiber web by air-laid. Then according to the technique in embodiment 1, adopt organic fluorine water-repellent agent (as a kind of water-repellent agent of Hunstman company, ), the oven temperature is 145 degrees Celsius, and the drying time is 5-8 minutes. There are three kinds of spraying ratios: 1. Spraying on one side, 2gsm; 2. Spraying on both sides, 8gsm; 3. Spraying on both sides, 15gsm; make samples 1'-3' of the water-repellent non-woven thermal insulation material of the present invention.

Embodiment 3

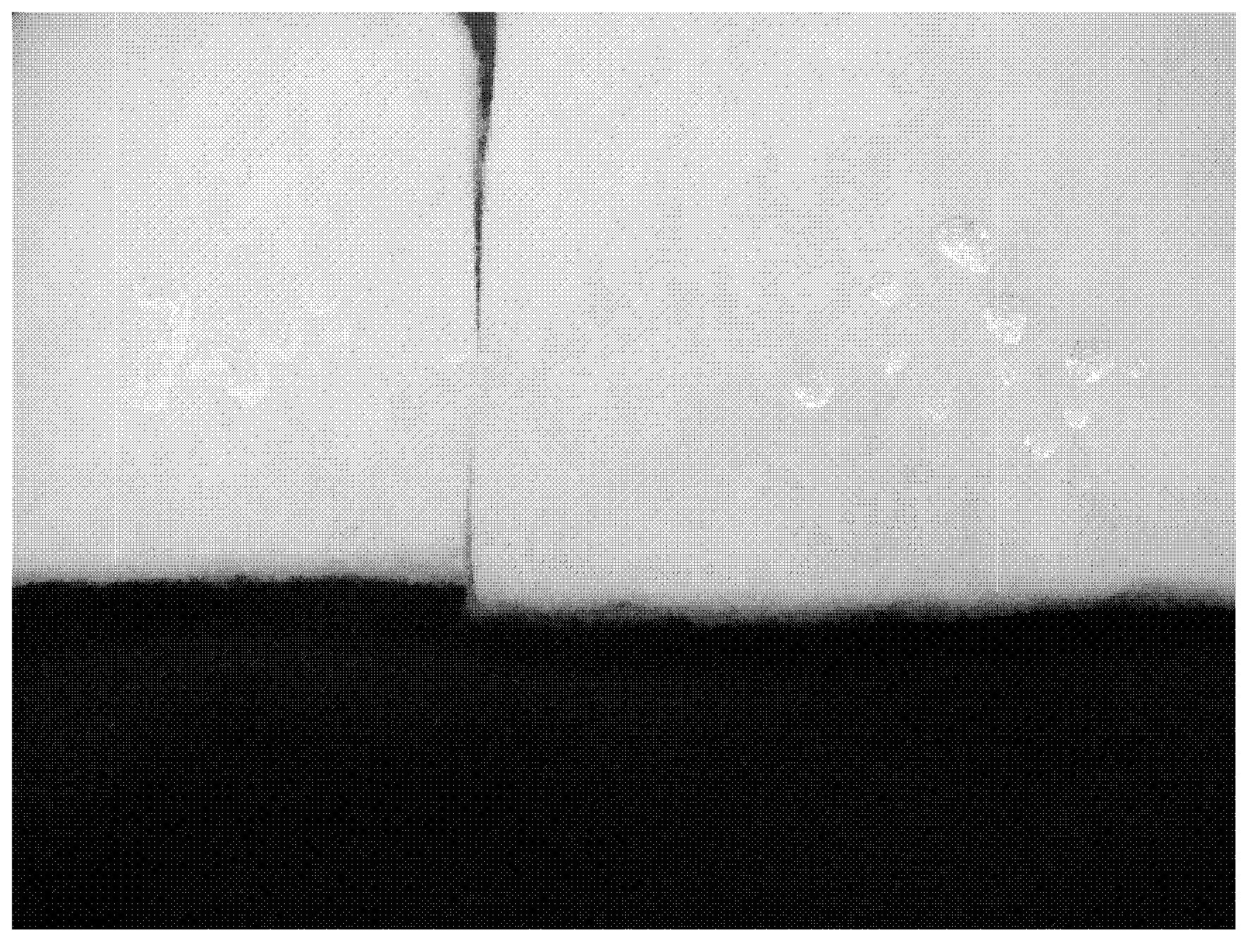

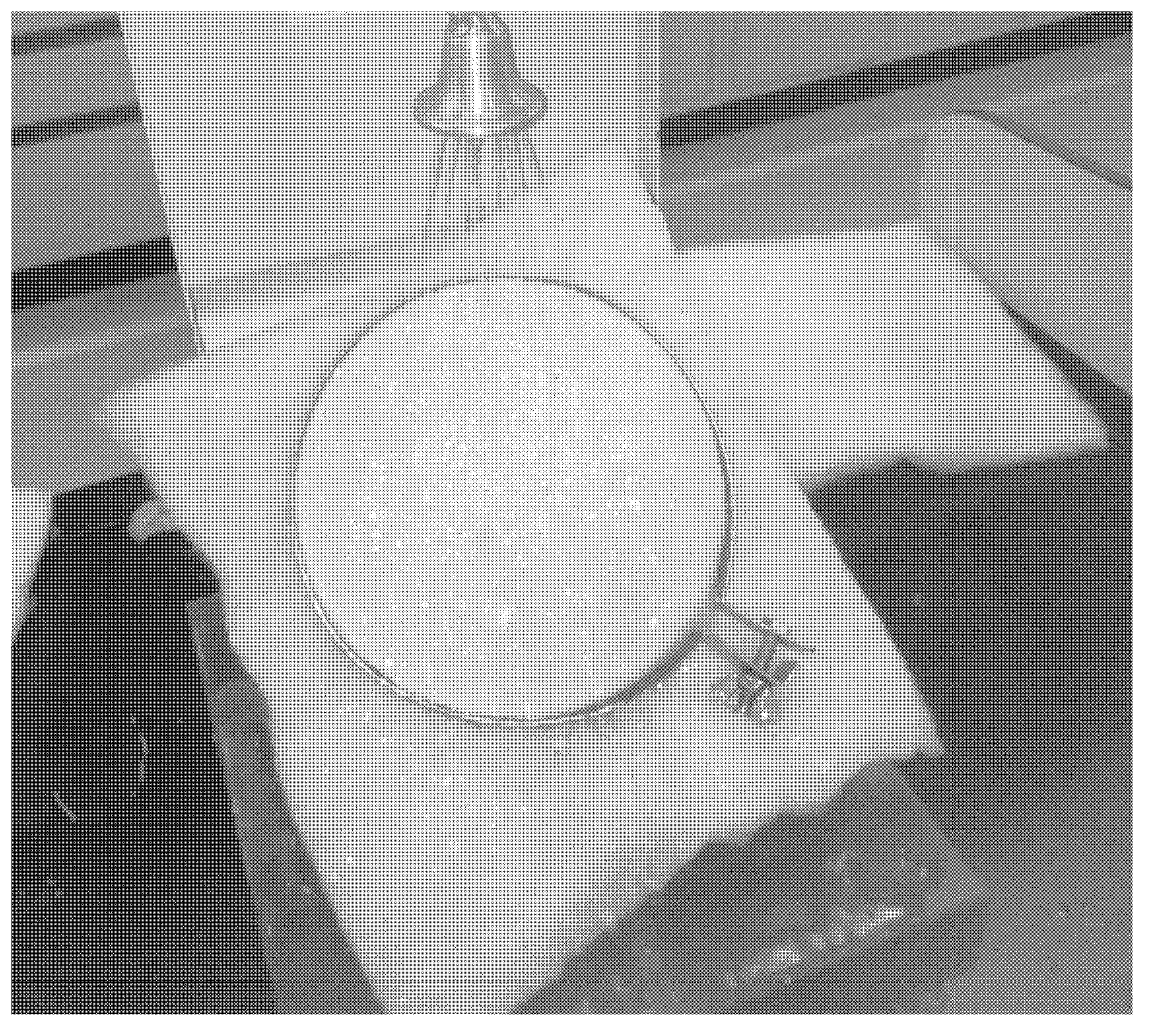

[0039] According to the AATCC22-2005 standard, the water-repellent effect of the water-repellent non-woven thermal insulation material sample of the embodiment and the common non-woven thermal insulation material (carded cross-lapped polyester thermal insulation material) was measured. Under the specified temperature and humidity conditions, use a sprinkler to fix the sample on the instrument, and then spray 250ml of red water. After the water is sprayed, remove the sample and shake it for 2 times. Observe the adhesion of water droplets on the surface of the sample. Figures 2 and 3 show the spray test results of the water-repellent non-woven thermal insulation material sample 1 and the common non-woven thermal insulation material not treated with the water-repellent agent, respectively.

[0040] Measure the weight of the sample before and after spraying water, and calculate the moisture content according to the following formula:

[0041] Moisture content % = (weight after sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com