Flexible and heterogeneous nylon-6 fiber and preparation method thereof

A nylon, light and soft technology, applied in the field of functional differential fiber production, can solve the problems of nylon 6 fiber not soft enough, poor spinnability and shape degree, poor elasticity, etc., achieve novel design method, improve spinnability properties, increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Preparation of soft polyisopolyamide 6 POY

[0053] Product specification: 90dtex / 24f POY, using fiber-grade nylon 6 slices with a relative viscosity of 2.2-2.6 as raw material, fiber-grade nylon 6 slices do not contain matting agent, adopts melt spinning method, the process is: feeding - melting, spinning - cooling forming - oiling - winding.

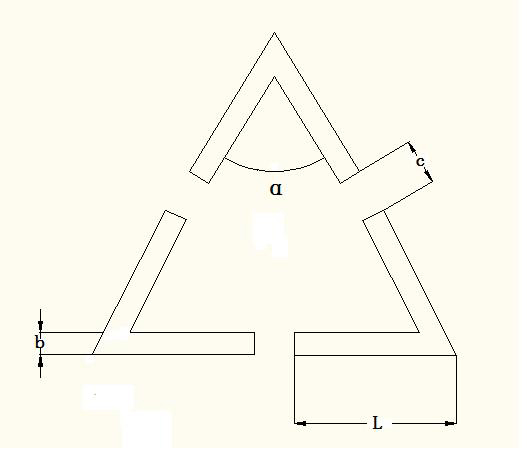

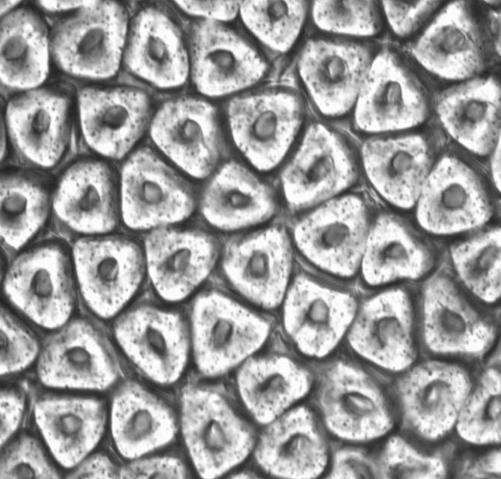

[0054] In this embodiment: V-shaped micro-hole combined spinneret, the size of the V-shaped spinneret micro-holes: the intersection angle α of the two sides of the V shape is 60??, the lengths of the two sides are equal, and the aspect ratio (L / b ) is 8, and L=0.70mm. The 3 V shapes are arranged in an equilateral triangle, the V-shaped cone angle faces outward, the V-shaped opening faces inward, and the gap between adjacent V-shaped spinneret microholes is 0.06mm, so they are combined into a structural unit (see attached figure 2 shown). The oil agent is Takemoto F5178, an aqueous solution with an oil concentration of 8%.

...

Embodiment 2

[0058] Preparation of soft polyisopolyamide 6 HOY

[0059] Fiber-grade nylon 6 slices with a relative viscosity of 2.42 are used as raw materials, and the fiber-grade nylon 6 slices contain 0.3% mass percentage of matting agent titanium dioxide. The melt spinning method is adopted, and the process is: feeding—melting, spinning—cooling Forming - oiling - winding.

[0060] In this embodiment: V-shaped micro-hole combined spinneret, the size of the V-shaped spinneret micro-hole: the intersection angle α of the two sides of the V shape is 75??, the lengths of the two sides are equal, and the aspect ratio (L / b ) is 5, and L=1.0mm. The three V shapes are arranged in an equilateral triangle, the V-shaped cone angle faces outward, the V-shaped opening faces inward, and the gap between adjacent V-shaped spinneret microholes is 0.055 mm, thus forming a structural unit. The oil agent is Dak L-1838, an aqueous solution with a mass concentration of oil agent of 10%. The specific process...

Embodiment 3

[0063] Preparation of soft polyisopolyamide 6 FDY

[0064] Fiber-grade nylon 6 chips with a relative viscosity of 2.45 are used as raw materials, and the mass percentage of titanium dioxide, a matting agent, is 0.3%. The melt spinning method is adopted. The process is: raw material pretreatment—melting, spinning—cooling and forming—— Oiling - stretching - heat setting - winding.

[0065] In this embodiment: V-shaped micro-hole combined spinneret, the size of the V-shaped spinneret micro-holes: the intersection angle α of the two sides of the V shape is 60??, the lengths of the two sides are equal, and the aspect ratio (L / b ) is 6, and L=0.8mm. The three V shapes are arranged in an equilateral triangle, the V-shaped cone angle faces outward, the V-shaped opening faces inward, and the gap between the adjacent V-shaped spinneret microholes is 0.04 mm, thus forming a structural unit. The oil agent is Takemoto F6468, an aqueous solution with a mass concentration of oil agent of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com