Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about "Double pile fabrics splitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing coloured foreign fiber burnt-out fabric

InactiveCN101440551AClear patternStrong three-dimensional senseDouble pile fabrics splittingPattern makingEngineeringBurning out

The invention provides a method for processing color foreign fiber burnt-out fabric. The method comprises the following steps: material selection; first weaving; pile cutting; rinsing; pre-drying; burnt-out print; water washing, softening and dewatering; drying; scalding-shearing; and tailoring. The method is characterized in that: the material selection comprises the selection of covering weave material and the selection of ground weave material; and, the covering weave material is frame spinning purified cotton yarn or viscose glue cotton blended yarn, and the ground weave material is colored terylene filament, wherein the colored terylene filament is 23 to 40 mass percent, and the frame spinning purified cotton yarn or viscose glue cotton blended yarn is 60 to 77 mass percent. The method has the advantages that: because the colored terylene filament is selected as the ground weave, and the frame spinning purified cotton yarn or viscose glue cotton blended yarn is selected as the covering weave, after burnt-out print, the fabrics can achieve the effects of clear pattern, reasonable three dimensional appeal and dusky gentleness; moreover, the fabrics also have good softness and ideal heat insulating ability.

Owner:CHANGSHU SHENHUA KNITTING

Production method of double-layer Raschel super soft blanket

InactiveCN107587253ASmooth and reverse hair with good glossSoft and delicateDouble pile fabrics splittingWarp knittingYarnAfter treatment

The invention provides a production method of a double-layer Raschel super soft blanket. The production method comprises the following steps of 1, spinning, wherein velvet yarn and bottom yarn are warped through a warping machine and then spun on a braider, and after slitting and cloth inspecting, grey cloth is obtained; 2, before-finishing, wherein the obtained grey cloth is subjected to grey cloth shaping, grey fabric hot lighting and grey cloth brushing; 3, dyeing and finishing, wherein the grey cloth subjected to before-finishing is subjected to printing or ironing, primary drying, steaming color curing, water curing and secondary drying; 4, after-treatment, wherein cotton print after being dyed and finished is subjected to brushing, hot light ironing and shearing, embossing and cutting, and two blankets are oppositely sewed together to obtain the double-layer Raschel super soft blanket; 5, package warehousing, the obtained double-layer Raschel super soft blanket is packaged and warehoused. The produced blanket product is good in luster whether in smooth and straight hair or in retrorse hair, thick, plump, soft and fine in hand feeling and high in product stability.

Owner:无锡中天丝路云联纺织股份有限公司

Warp knitting and producing method for elastic double-side short plush fabric

InactiveCN103541144AEasy to operateLight weightDouble pile fabrics splittingWarp knittingEngineeringWarp knitting

The invention relates to a warp knitting and producing method for elastic double-side short plush fabric under the condition of containing spandex yarns as base yarns in base cloth. Plush is 50-75D Dacron FDY (fully drawn yarn), Dacron DTY (draw textured yarn) or Dacron-brocade composite yarns, the base yarns are 50D / 24F Dacron FDY or Dacron DTY and composite 40D spandex yarns, and the plush and the base yarns are knitted to obtain a single-side plush finished gray fabric with weight ranging from 210-320g / m2. The gray fabric is sequentially subjected to back fluffing, carding, finishing, shearing and inspecting after being inspected, and finally packaged to obtain finished products. By modifying the production method and equipment, the blank in the textile field is filled by the produced warp-knitted elastic double-side short plush fabric, and the problem that some after-finishing facilitates are not easy to operate due to the fact that the warp-knitted elastic fabric containing the spandex base cloth has high elasticity is solved. The produced fabric is light in gram weigh, has double-side short plush, good heat retention property and comfortability, and further meets the requirement that people pursue comfortability and perfect style.

Owner:SHANGHAI WEILE TEXTILES CO LTD

Polyimide weft-knitted double-faced velvet protective fabric and production process thereof

InactiveCN106192183AImprove flame retardant performanceGood warmth retentionDouble pile fabrics splittingWeft knittingFiberYarn

The invention discloses a polyimide weft-knitted double-faced velvet protective fabric and a production process thereof. 32S polyimide staple fiber yarns and 100D / 48 flame retardant polyester low elastic yarns are knitted on a terry-looping machine and treated by the steps of high-temperature water washing, lustering, dehydrating, drying, galling, combing and cutting, ironing, trimming, fleecing and shaping; and the 32S polyimide staple fiber yarns cover the 100D / 48 flame retardant polyester low elastic yarns. The polyimide weft-knitted double-faced velvet protective fabric has the advantages of good flame retardant property, good warm-keeping property, radiation resistance, acid and alkali resistance, corrosion resistance, bacterium resistance, good strong force, good firmness, soft hand feeling, bright luster, fluffiness and fleecing, good anti-galling and anti-balling-up properties and stable cloth surface the shrinkage rate is smaller than 5% and the weft bias is smaller than 3%; and the flame retardant damaged length of the cloth surface reaches 1.6 cm and the effect is good.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

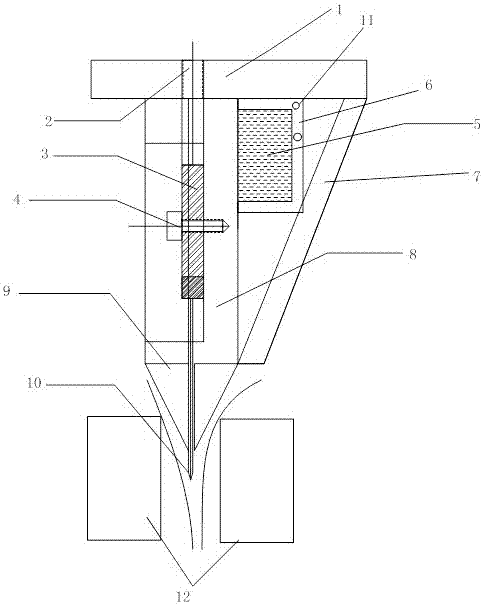

Cutter hook combining body of loop cutting machine

InactiveCN104328620AFast cutting speedAvoid instabilityDouble pile fabrics splittingWhole bodyInstability

The invention provides a cutter hook combining body of a loop cutting machine. The cutter hook combining body comprises a hook needle and a cutter, wherein a needle hammer is arranged in the middle of a needle body of the hook needle; a threading hole is formed in a needle head part of the hook needle; the needle body between the threading needle and the needle hammer is provided with a cutter groove parallel to the axis of the hook needle; the cutter groove is communicated with the threading hole; the cutter is arranged in the cutter groove; the tail end of the cutter is provided with the cutter hammer parallel and level to the needle hammer; and the front end of the cutter is provided with a cutter edge matched with the threading hole. According to the cutter hook combining body, the cutter groove is formed and the cutter hook combining body is arranged in the cutter groove of the hook needle, so that the cutter hook is of a movable integrated type and the instability caused by pin connection of the previous cutter hook combining body is avoided; the problem that burrs hooked by the pin connection are more so that a cutter disc cannot be inserted is solved and ultra-short fluff can be manufactured; the history of sueding the ultra-short fluff by using a double-faced fabric is finished; the needle hammer and the cutter hammer are arranged, and the needle hammer is parallel and level to the cutter hammer, so that the cutter can stably move in a cutter barrel along the cutter groove and the hook needle and the cutter can be combined to form a whole body; and the stability of the cutter hook combining body is improved.

Owner:LIANYUNGANG YUANFENG MACHINERY

Process method of blind embossing jacquard satin print of towel

ActiveCN101748619ARich in colorIncrease the level of detailDouble pile fabrics splittingPhotomechanical apparatusEngineeringVolumetric Mass Density

The invention relates to the technical field of jacquard weaving print of fabrics, in particular to an effective processing method of combining printing of blank towel pattern and print pattern, i.e. a process method of the blind embossing jacquard satin print of a towel. The process method of the blind embossing jacquard satin print of the towel of the invention comprises the following steps: manufacturing a blank towel, drying in a loose mode, cutting cloth with soft nap, carrying out pretreatment to the blank towel, drying in a loose mode, secondary cutting cloth with soft nap, printing, drying and tidying. The printed towel produced with the technical scheme has abundant colors, high fine degree, vivid pattern effect and environment protection, can satisfy requirements of consumers on towel color density and permeability, greatly improves printing speed and production efficiency and integrally lowers production cost.

Owner:LOFTEX INDS

Treatment process of double-sided thermal insulation knitted fluffy cloth

InactiveCN109554876AImprove textureImprove breathabilityDouble pile fabrics splittingRougheningThermal insulationPulp and paper industry

The invention relates to the technical field of post-finishing treatment of fabrics, in particular to a double-sided thermal insulation knitted fluffy cloth treatment process. The double-sided thermalinsulation knitted fluffy cloth treatment process comprises the following steps: fluffing at a front surface -> reverting the cloth, and fluffing the bottom surface -> inversely combing the fluffs onthe bottom surface -> inversely ironing the fluffs on the bottom surface -> smoothening and cutting the fluffs on the bottom surface -> reverting the cloth, and inversely combing the fluffs on the front surface -> inversely ironing the fluffs on the front surface -> smoothening and cutting the fluffs on the front surface -> inversely ironing the fluffs on the front surface -> smoothening and cutting the fluffs on the front surface. The treatment process of the double-sided thermal insulation knitted fluffy cloth has the advantages that the technological process is simplified, the processing and production cost is reduced, the processing efficiency is improved, and the double-sided fluffing process is adopted to increase the thickness of the cloth, so that an air layer is formed on two sides of a cloth body, and the thermal insulation effect of the cloth is improved; and by virtue of a fluff combing and cutting process, the fluff dropping rate of the fabric is reduced, the fabric is more neat, practical, beautiful and top-graded.

Owner:广东易通纺织科技有限公司

Process method of blind embossing jacquard satin reactive print of towel

ActiveCN101748621ARich in colorIncrease the level of detailDouble pile fabrics splittingPhotomechanical apparatusEngineeringVolumetric Mass Density

The invention relates to the technical field of jacquard weaving print of fabrics, in particular to an effective processing method of combining printing of blank towel pattern and print pattern, i.e. a process method of the blind embossing jacquard satin reactive print of a towel. The process method of the blind embossing jacquard satin reactive print of the towel of the invention comprises the following steps: manufacturing a blank towel, drying in a loose mode, cutting cloth with soft nap, carrying out pretreatment to the blank towel, drying in a loose mode, secondary cutting cloth with soft nap, printing reactive print, drying, steaming, flat washing and tidying. The printed towel produced with the technical scheme has abundant colors, high fine degree, vivid pattern effect and environment protection, can satisfy requirements of consumers on towel color density and permeability, greatly improves printing speed and production efficiency and integrally lowers production cost.

Owner:LOFTEX INDS

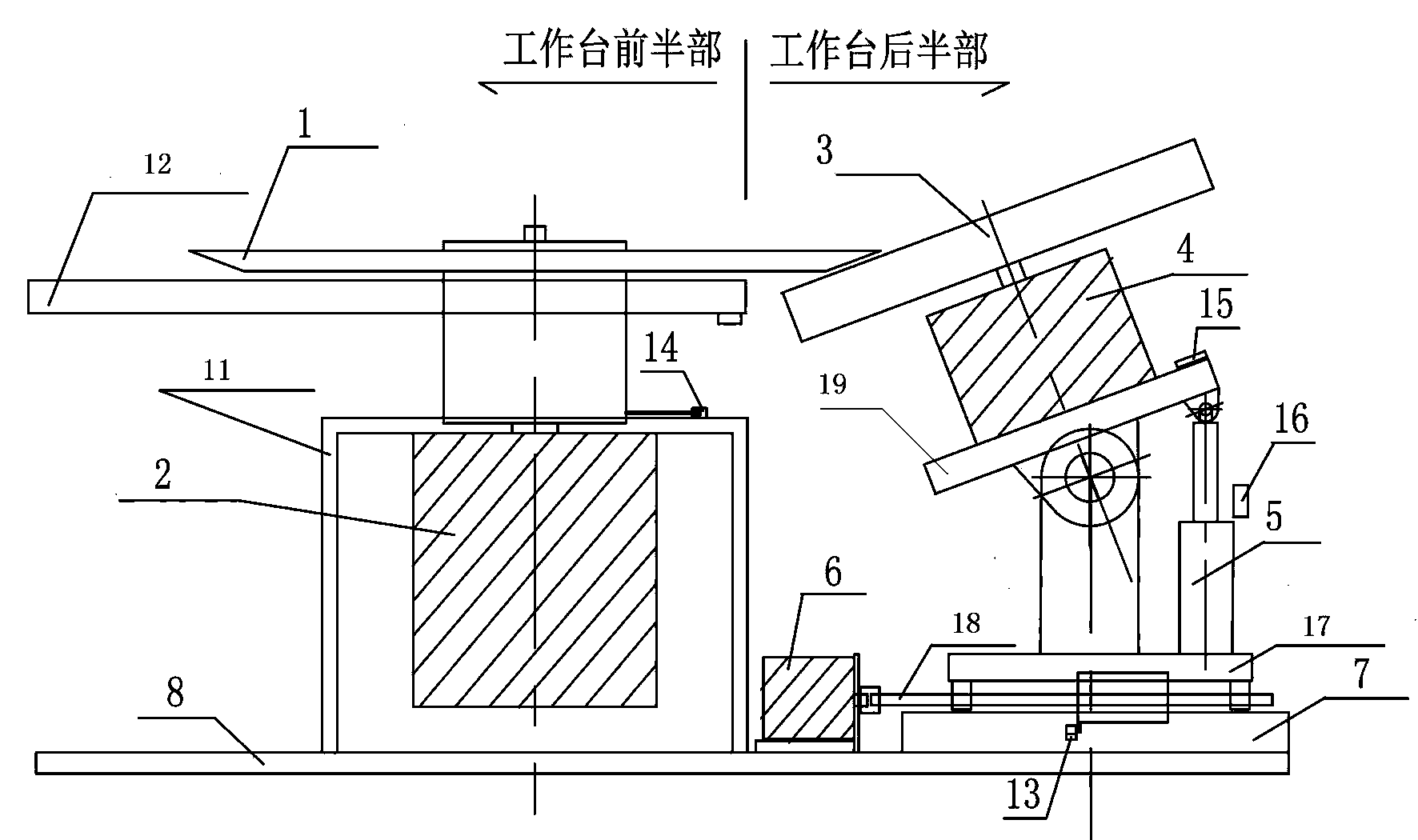

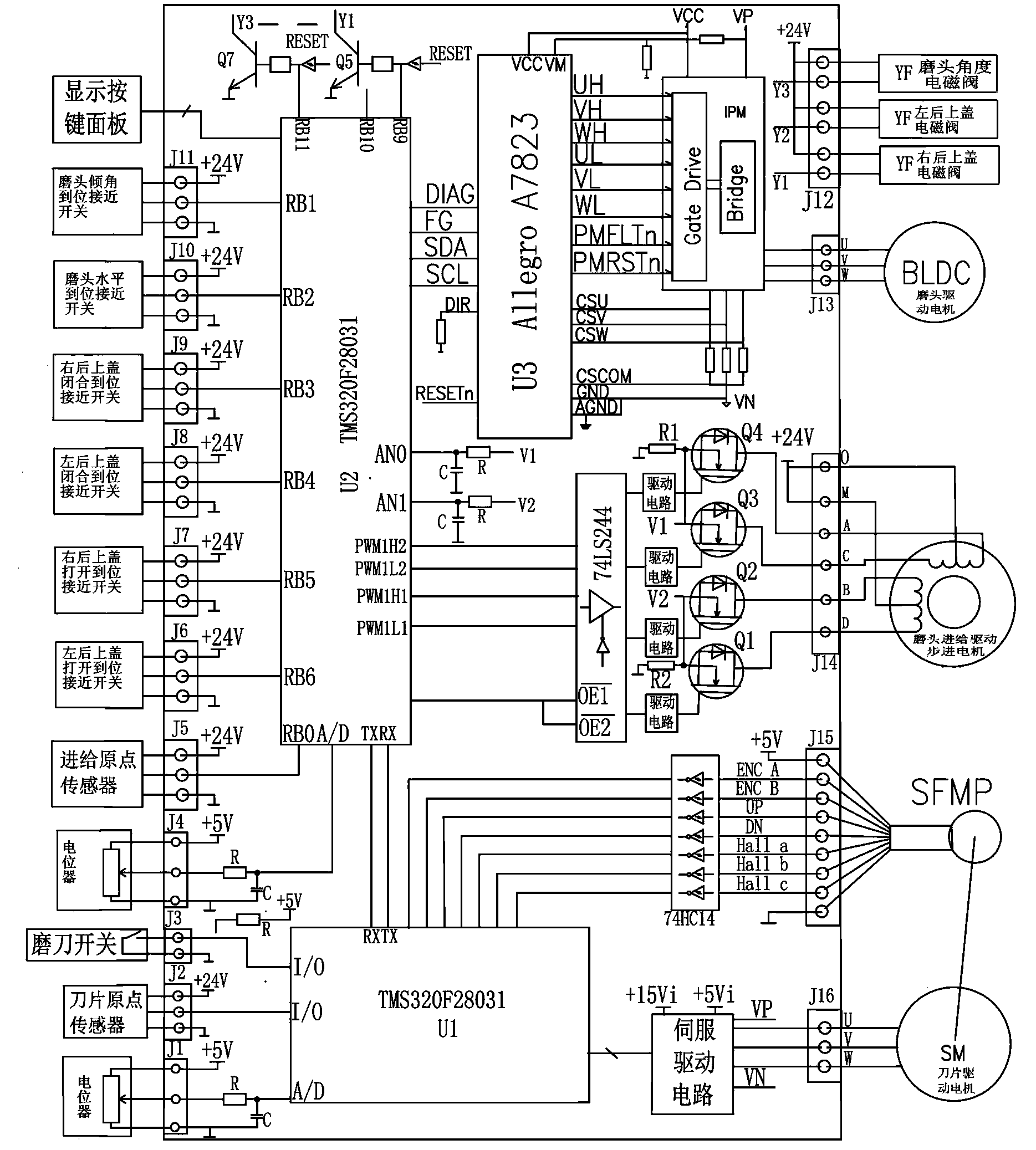

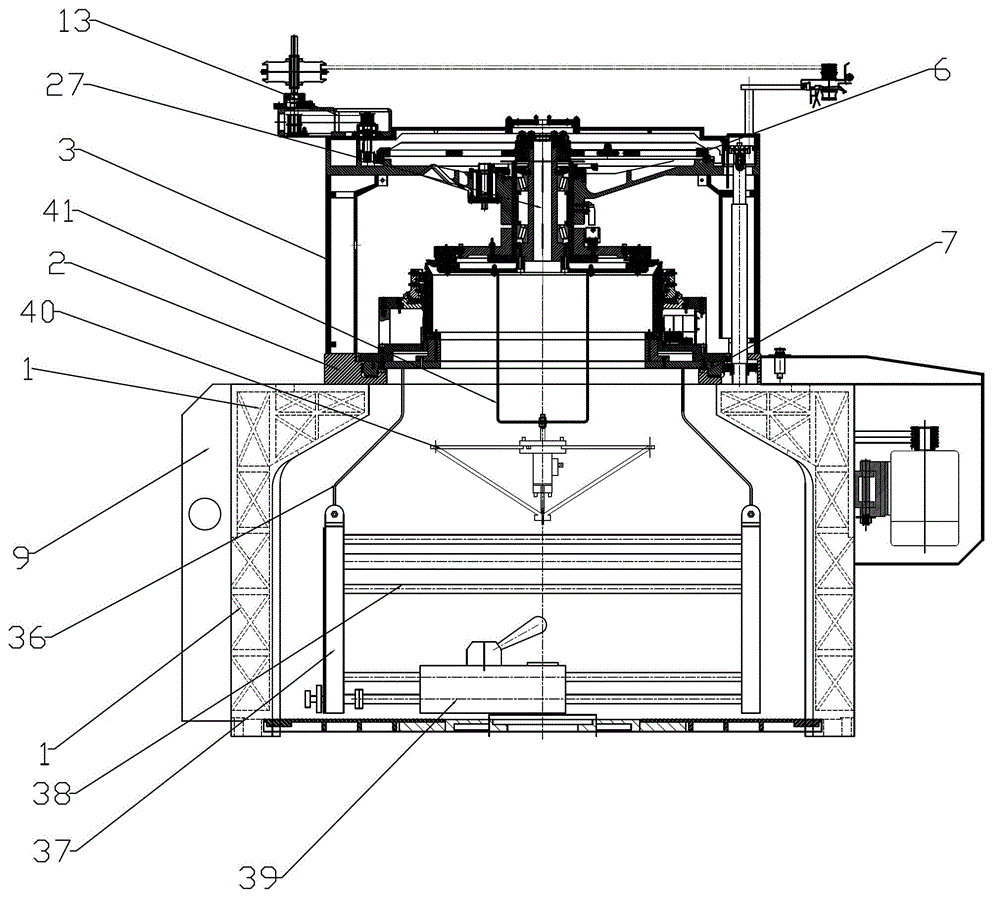

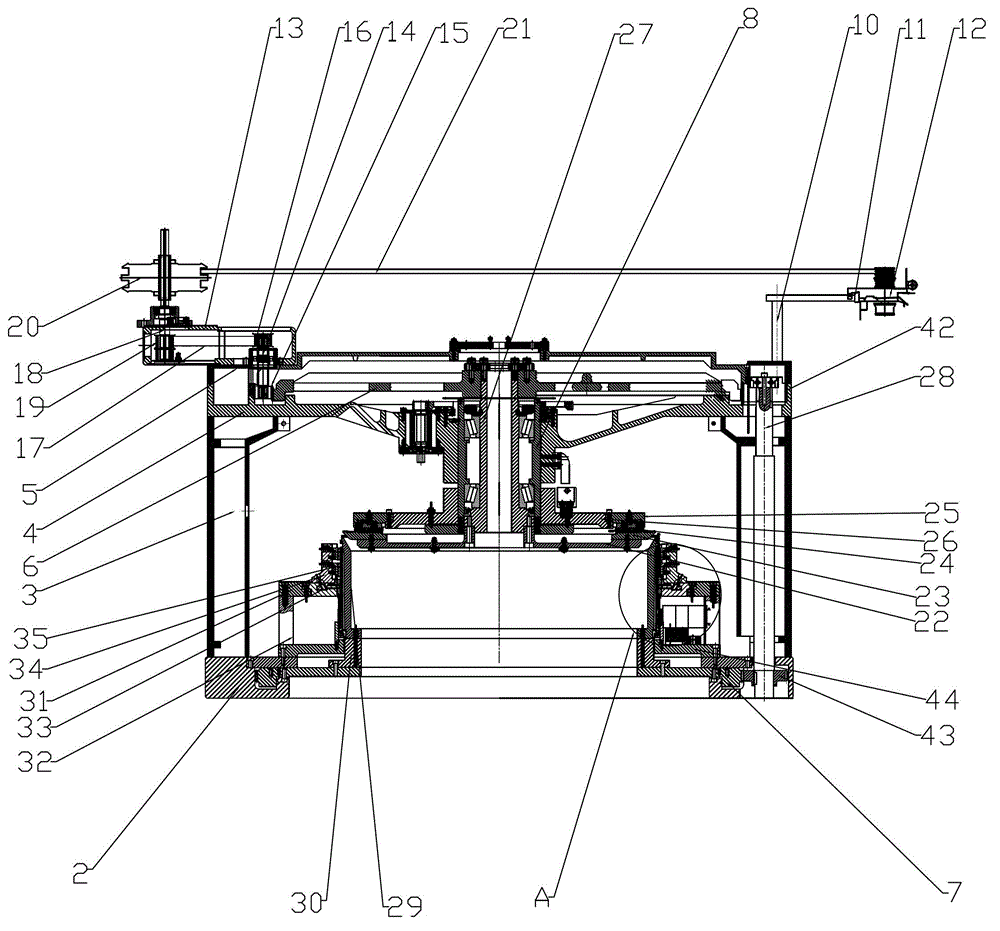

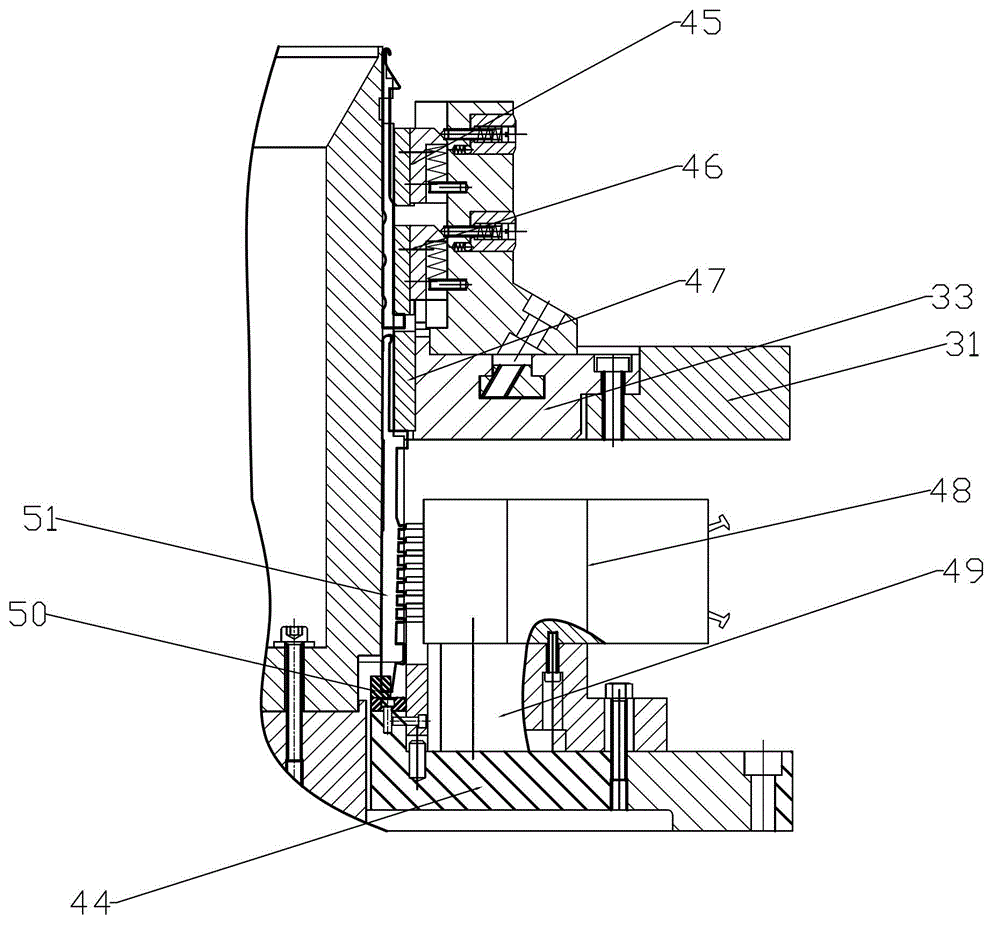

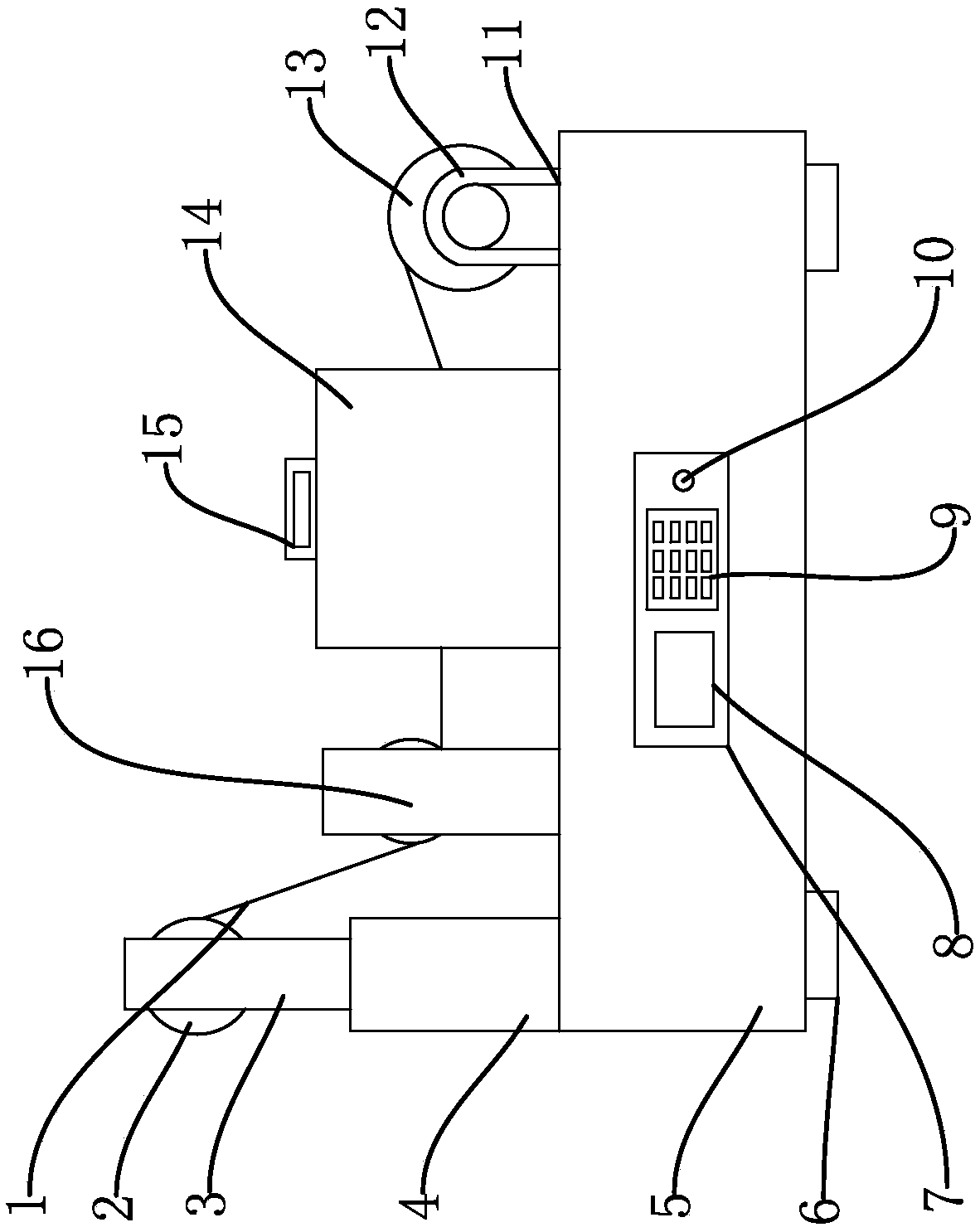

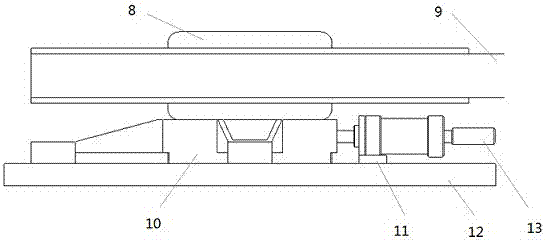

Double-sided wool fabric material slitting machine with full-automatic grinding knife and control method thereof

ActiveCN104131434AReduce vibrationSmall footprintDouble pile fabrics splittingMotor controlKnife blades

The invention relates to a double-sided wool fabric material slitting machine, and particularly relates to a double-sided wool fabric material slitting machine with a full-automatic grinding knife, which mainly solves the technical problem of overlong consumed time of a manual grinding knife of a slitting machine. The technical scheme is as follows: a grinding head mechanism is additionally arranged on the rear half part of the existing double-sided slitting machine, a rear upper cover is divided into two parts, automatically opened by an MCU (Microprogrammed Control Unit) through an air cylinder control mechanism and confirmed to be in place by being detected by a proximity switch, then the grinding head mechanism automatically rotates to a grinding angle under the action of an air cylinder and also confirmed to be in place by the proximity switch, and then the automatic feed of a grinding head is realized through a stepping motor control mechanism by utilizing an original point detection sensor; a knife blade automatically rotates to the correct grinding angle through MCU calculation during grinding, and then only a two-phase winding of a knife blade driving motor is electrified to lock the knife blade; the profile modeling of a special-shaped knife blade can be realized, and automatic storage and memory can be realized. The double-sided wool fabric material slitting machine disclosed by the invention is mainly used for the full-automatic grinding knife of the double-sided wool fabric material slitting machine.

Owner:上海德徽实业有限公司

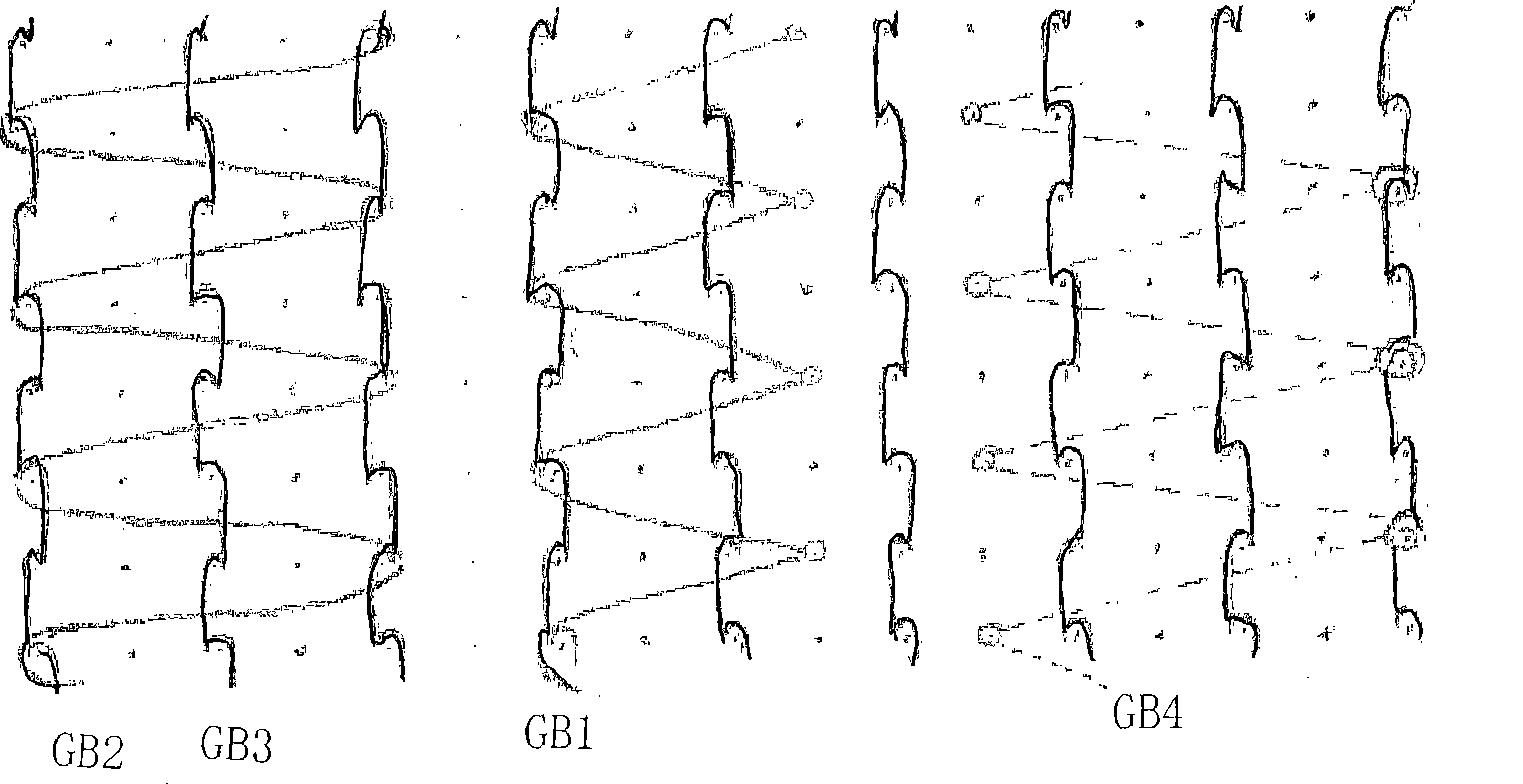

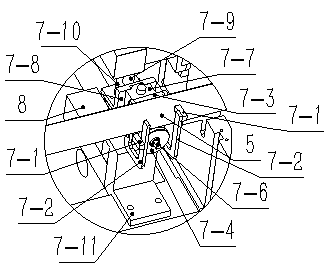

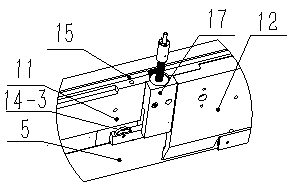

Computer jacquard and cut loop velvet machine

ActiveCN102912579ACompact structureReasonable structureDouble pile fabrics splittingPile loops cuttingJacquard loomEngineering

The invention relates to a computer jacquard and cut loop velvet machine, which belongs to the technical field of jacquard looms. The computer jacquard and cut loop velvet machine comprises a low velvet needle pressing triangle, a high velvet needle pressing triangle, a middle shell needle pressing triangle, a needle selector, a needle selector seat, a pulling triangle, a pattern bit, a low plate knife needle, a high plate knife needle, a low plate loop reversing needle, a high plate loop reversing needle, a cut velvet plain-knitting triangle, a cut velvet needle-raising triangle, a safety triangle and a jacquard needle-raising triangle, wherein the low velvet needle pressing triangle and the high velvet needle pressing triangle are connected above and below the internal side of a second Hough in sequence; and the internal side of a middle shell is connected with the middle shell needle pressing triangle. The velvet shearing flat needle triangle is connected to the low velvet needle pressing triangle; and the velvet shearing needle raising triangle is connected with the high velvet needle pressing triangle. The computer jacquard and cut loop velvet machine provided by the invention has the advantages as follows: compact and reasonable structure is obtained; any pattern with one to four colors, such as high and low cut velvet patterns, a high cut low loop pattern, a high and low loop pattern, a flat cut pattern, a flat loop pattern and a hollow-out pattern, can be woven; the product quality is improved; and the production cost is reduced.

Owner:WUXI JIALONG TEXTILE MACHINERY

Production process of anti-mosquito coral fleece composite fabric

InactiveCN108589010AHigh degree of automationIncrease productivityDouble pile fabrics splittingLamination ancillary operationsPolyesterPulp and paper industry

The invention provides a production process of anti-mosquito coral fleece composite fabric, belongs to the technical field of fabric and solves the problems about fabric in the prior art. The production process of the anti-mosquito coral fleece composite fabric comprises the steps as follows: S1, weaving: 150D / 288F superfine polyester drawn textured yarn used as base yarn and common polyester monofilament used as wool yarn are placed in a warp knitting machine to be woven; S2, slitting: slitting is performed by a fleece slitting device and gray cloth is prepared; S3, presetting: the prepared single-sided fleece gray cloth is preset by a setting machine, the presetting temperature of the setting machine is set, the running speed of the single-sided fleece gray cloth is controlled, and preset gray cloth is obtained; S4, preparation of an anti-mosquito layer; S5, compositing; S6, aftertreatment; S7, post-setting. The production process has the advantage that the production quality is improved.

Owner:海宁市华泰针织有限公司

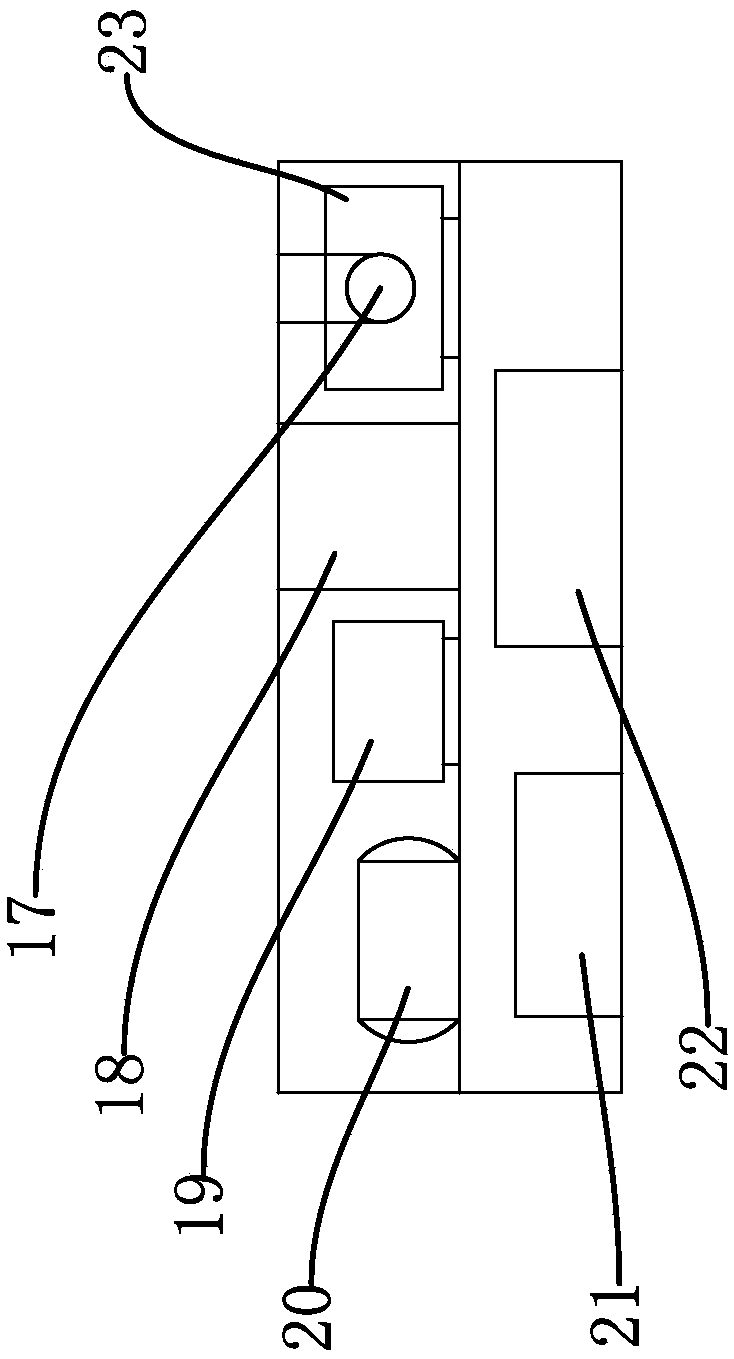

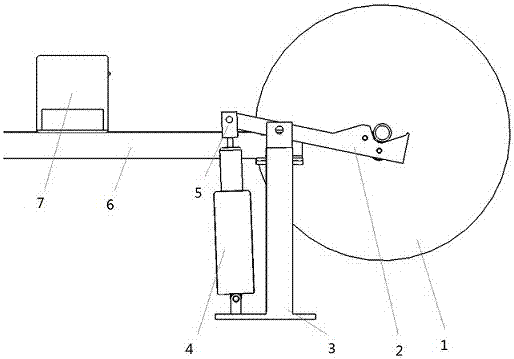

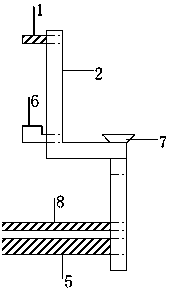

Velvet cutting machine system and using method thereof

ActiveCN107217437ASmooth and high-quality cuttingSolve the problem of overheatingDouble pile fabrics splittingFinal product manufactureMachining systemMachine tool

The invention discloses a velvet cutting machine system and a using method thereof. The velvet cutting machine system comprises a velvet cutting machine tool clamping part, a velvet cutting machine driving part and a velvet cutting machine roller part, wherein the velvet cutting machine tool clamping part is used for vertically and upwards sending sectioned stuffed blank, fixing a cutting knife edge in the middle part of the sectioned stuffed blank and enabling the sectioned stuffed black not to swing left and right; the velvet cutting machine driving part is used for driving a velvet cutting machine and enabling the velvet cutting machine to work normally; the velvet cutting machine roller part is used for conveying the stuffed blank to a tool clamping position or conveying cut stuffed blank to a storage place. According to the velvet cutting machine system disclosed by the invention, length uniformity and surface smoothness of sectioned finished fluff can be effectively controlled, the design structure is simple, and manufacturing and production are easy.

Owner:张福跃

Double-color double-brush double-shaking fabric and production method thereof

InactiveCN103397453AFast coloringWith warm functionDouble pile fabrics splittingWeft knittingPolyesterYarn

The invention discloses a double-color double-brush double-shaking fabric and a production method thereof. The double-color double-brush double-shaking fabric is formed by 75D / 36F plain stitches, looped pile stitches with stretched sinker loops of 100D / 144FSC positive ion silk, and 150D / 96F looped pile stitches with stretched sinker loops through weft knitting via sequential interlooping, wherein dacron of the looped pile stitches with the stretched sinker loops of the 100D / 144FSC positive ion silk is 50%modified positive ion dacron, spun polyester threads in each inch in the warp direction of the double-color double-brush double-shaking fabric are 36 in number, spun polyester threads in each inch in the weft direction of the double-color double-brush double-shaking fabric are 18 in number, the weft knitting via the sequential interloping is carried out on the layer of the plain stitches and the looped pile stitch layers with the stretched sinker loops at first, then postprocessing is carried out on the fabric after dyeing and drying are carried out on the fabric, and a heat preservation agent is attached to the fabric at last. According to the double-color double-brush double-shaking fabric, after-finishing is carried out, comfortableness and softness are achieved, chromaticity is high, meanwhile a heat preservation function is achieved, and the fabric is comfortable and appropriate to be worn by a person.

Owner:JIANGYIN CITY SHENCHENG GARMENT

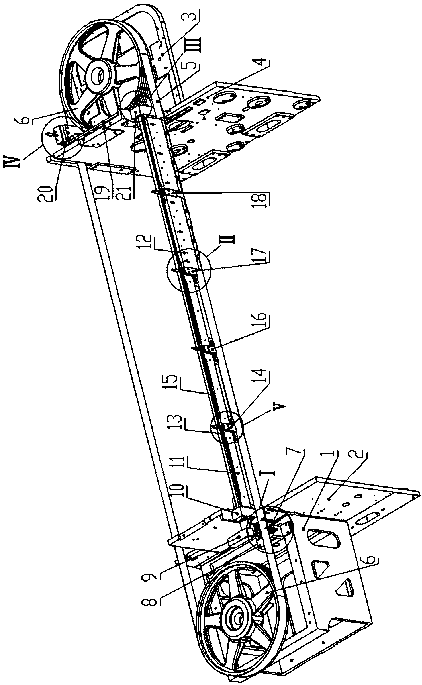

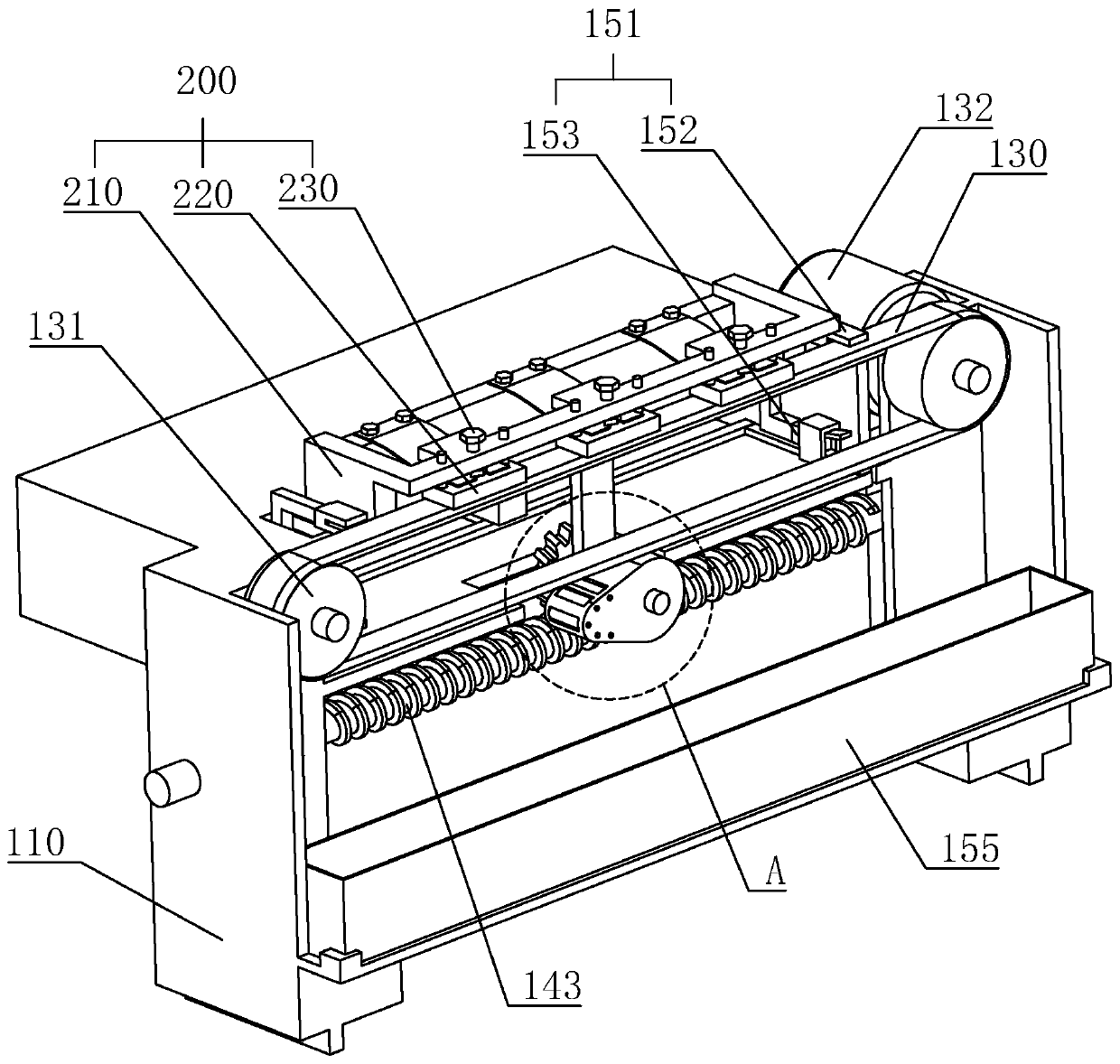

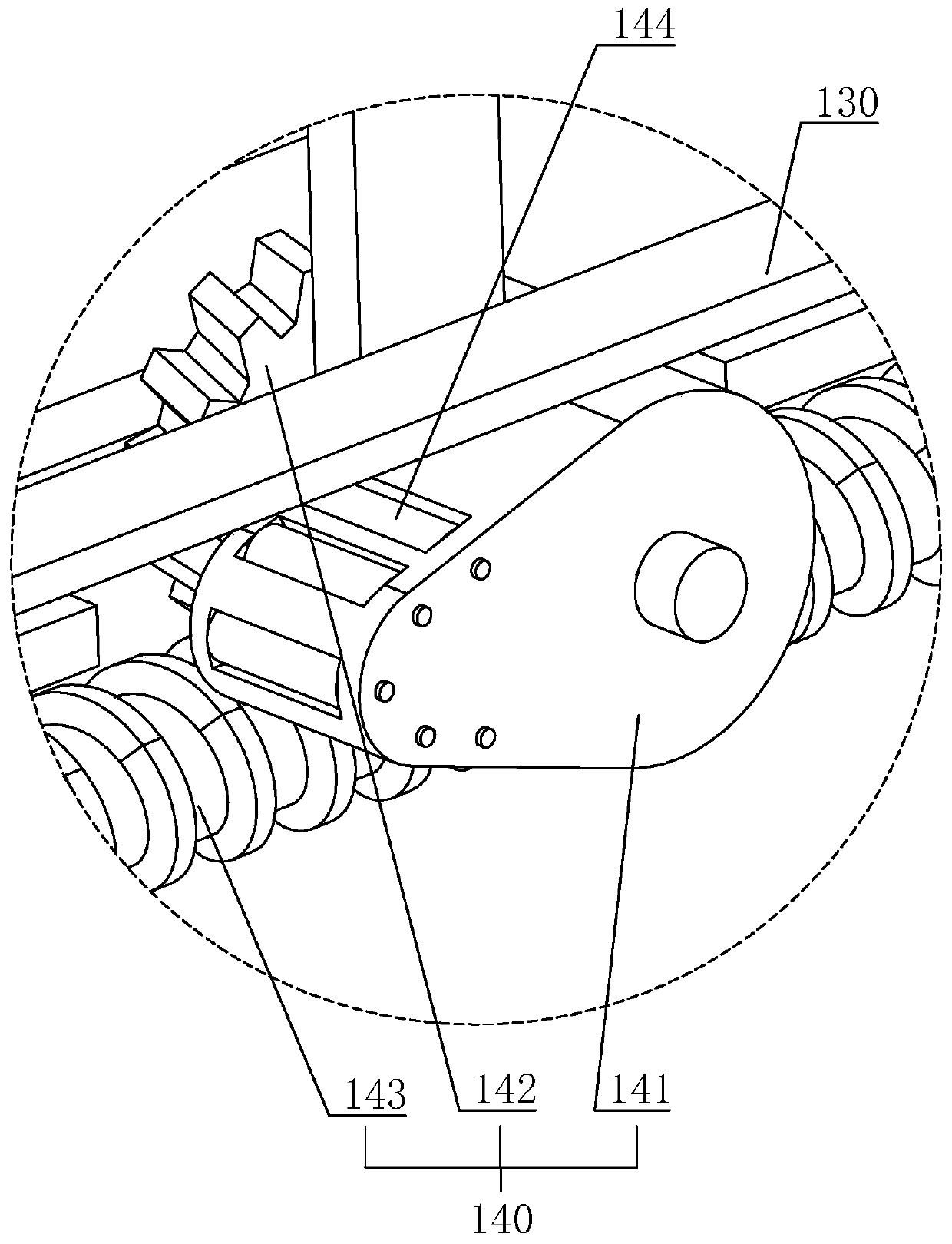

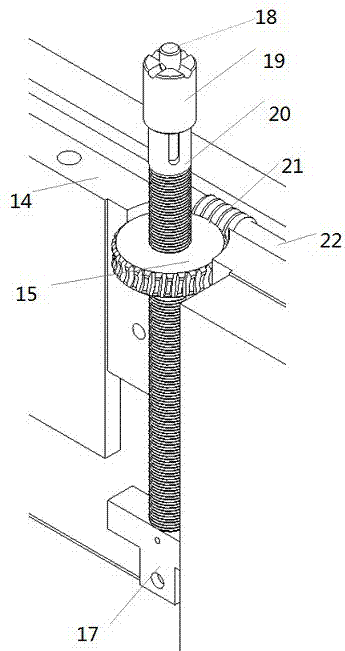

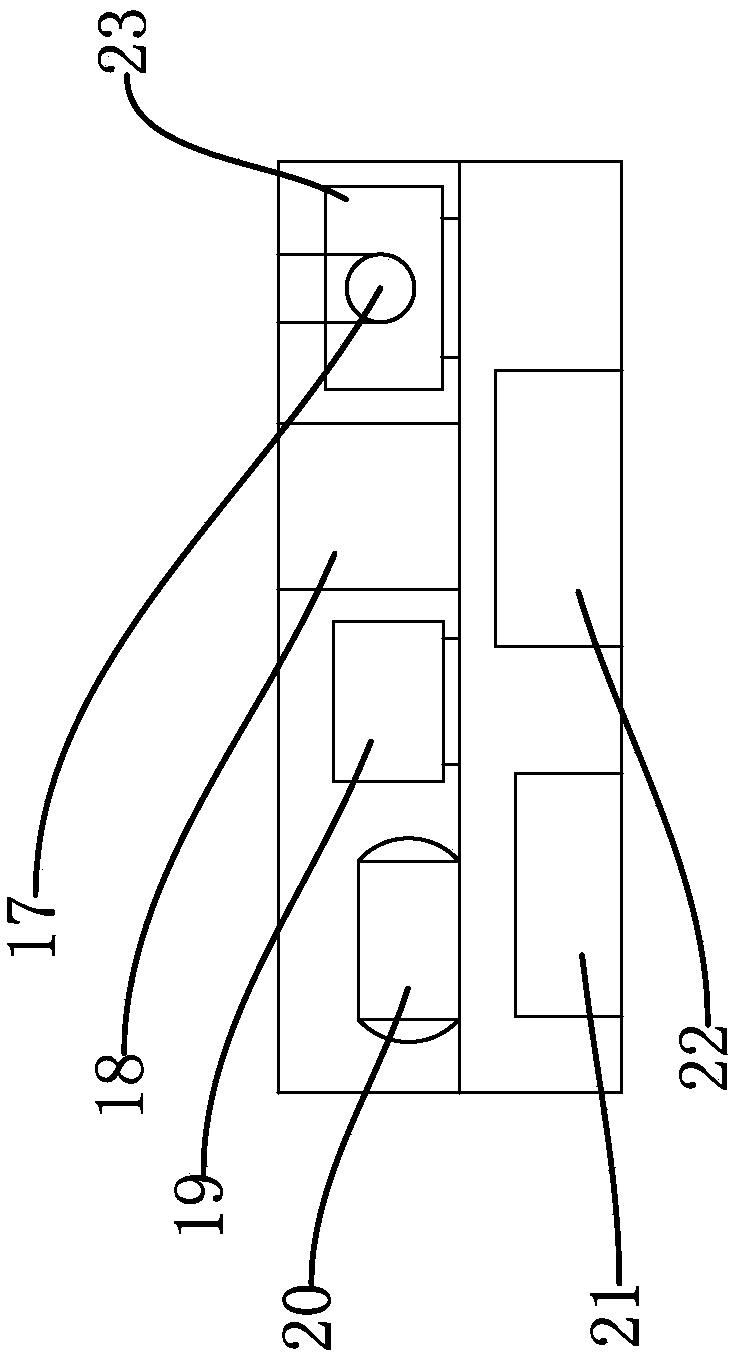

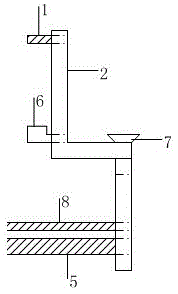

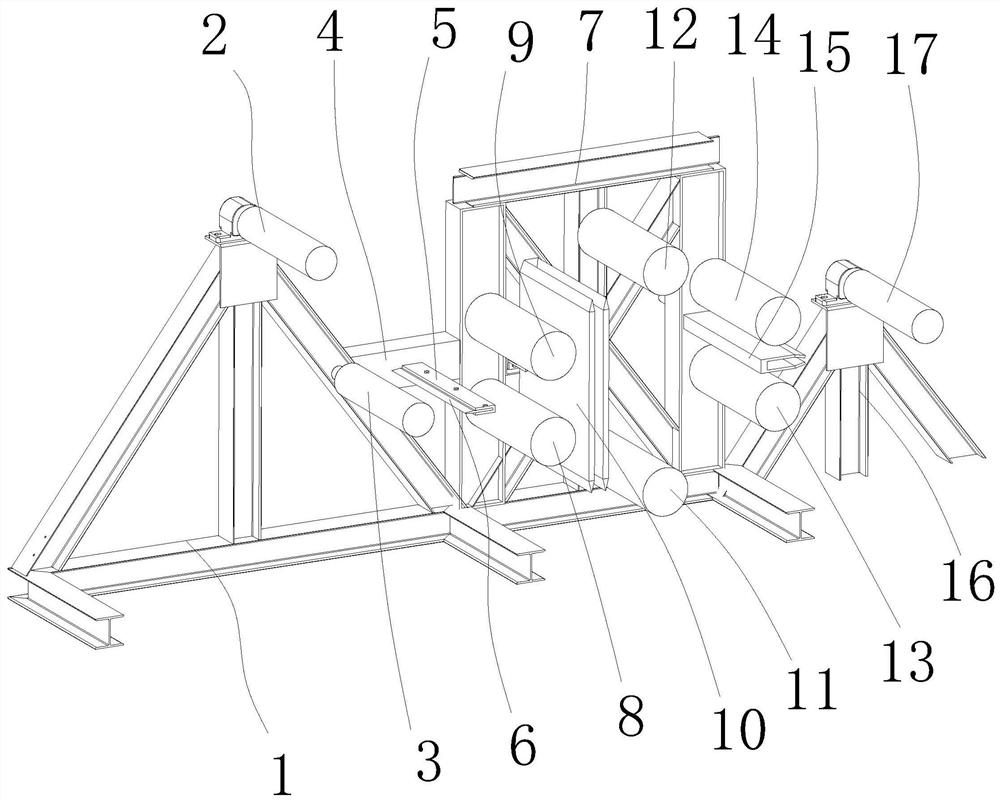

Cutter belt adjustment system of vertical-cutter-type high-speed digital-control fabric separator

PendingCN110409094AAvoid lostProtection securityDouble pile fabrics splittingFlywheelDigital control

The invention discloses a cutter belt adjustment system of a vertical-cutter-type high-speed digital-control fabric separator. The system comprises a flywheel box supporting plate, a left wallboard, aflywheel supporting plate, a right wallboard, a cutter belt, flywheels, an upward adjustment mechanism, two servo motors, a left supporting slide block, a cutter rack plate, a servo motor connectionrod, a first downward adjustment mechanism, four worm connection rods, a transmission mechanism, second, third, fourth and fifth downward adjustment mechanisms and a right supporting slide block; an output shaft of the first servo motor is connected with the upward adjustment mechanism and drives the upward adjustment mechanism to move up and down; an output shaft of the second servo motor is connected with the first downward adjustment mechanism through the servo motor connection rod; all the downward adjustment mechanisms are arranged at the upper side of the cutter belt and can drive the cutter belt to move downward. The cutter belt adjustment system is simple in structure, the position of the cutter belt is more conveniently, efficiently and accurately adjusted, and a spacer fabric ismore efficiently and stably separated. The aim of up-down adjustment for the cutter belt is to make a separated wool fabric flatter, and the separation process is more stable.

Owner:CHANGZHOU WUJIN WUYANG TEXTILE MACHINERY

Band knife structure of nap cutting machine

The invention relates to the technical field of nap cutting machines, in particular to a band knife structure of a nap cutting machine. The structure comprises a rack, wherein a sliding frame is glidingly connected to one side of the rack, a band knife is arranged on the sliding frame, an ejection device used for ejecting the band knife is arranged on the sliding frame and comprises a propping block glidingly connected to the sliding frame and propped against the band knife and a first driving assembly arranged on the sliding frame and used for driving the propping block to move, and a bearingframe is arranged on the lower side of the sliding frame and located below the band knife. The band knife structure has the effects as follows: the first driving assembly drives the propping block tomove toward one side of the band knife, after the propping block is contacted with the band knife, the band knife can be ejected out of the sliding frame and can be collected by the bearing frame after falling, and later, an operator takes down the bearing frame and then replaces the band knife for treatment. In the dismounting process, the operator almost does not need to make contact with the band knife and can take down the band knife, the probability of cut injury of the operator is reduced, and the potential safety hazard is reduced.

Owner:绍兴皂树纺织科技有限公司

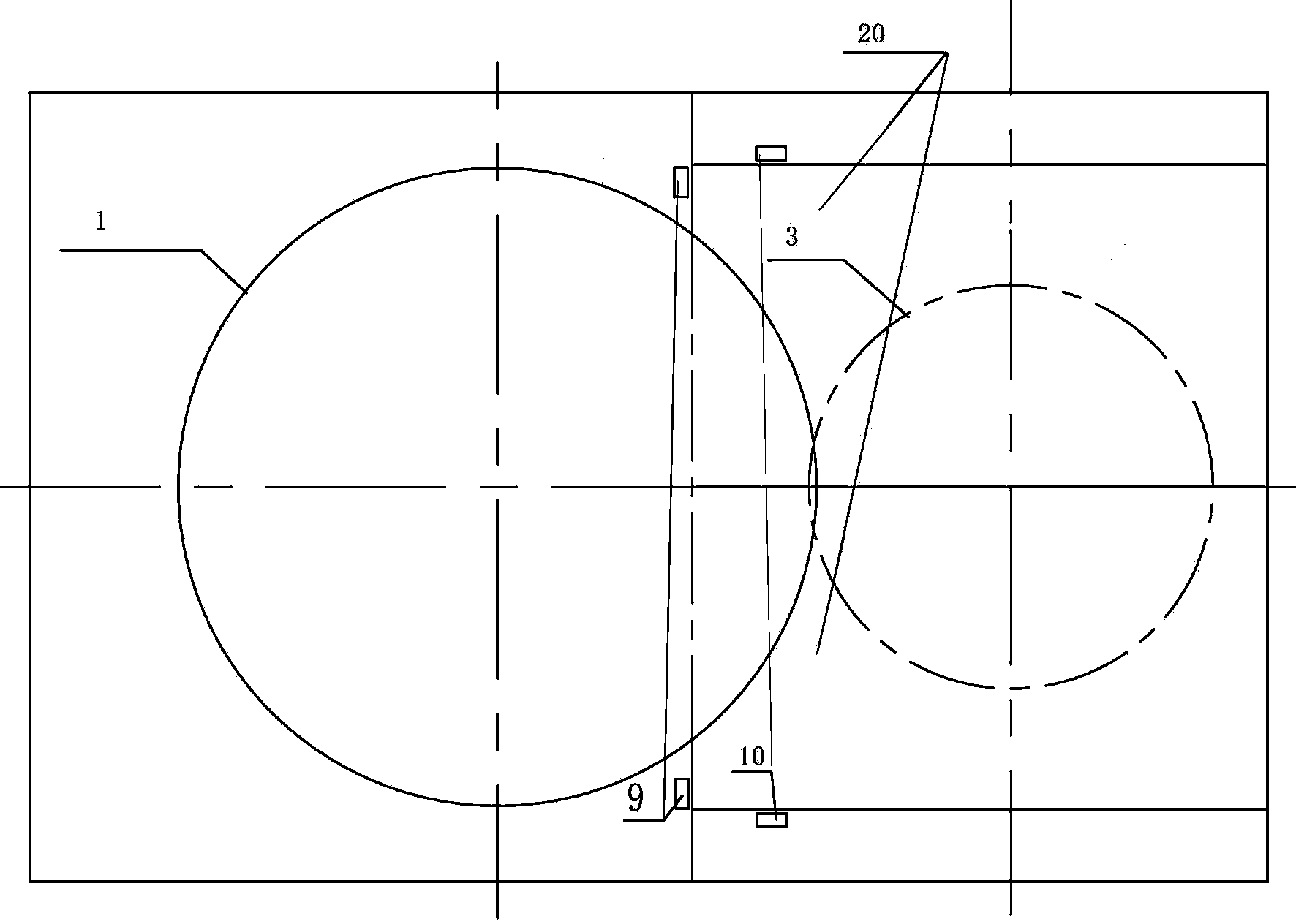

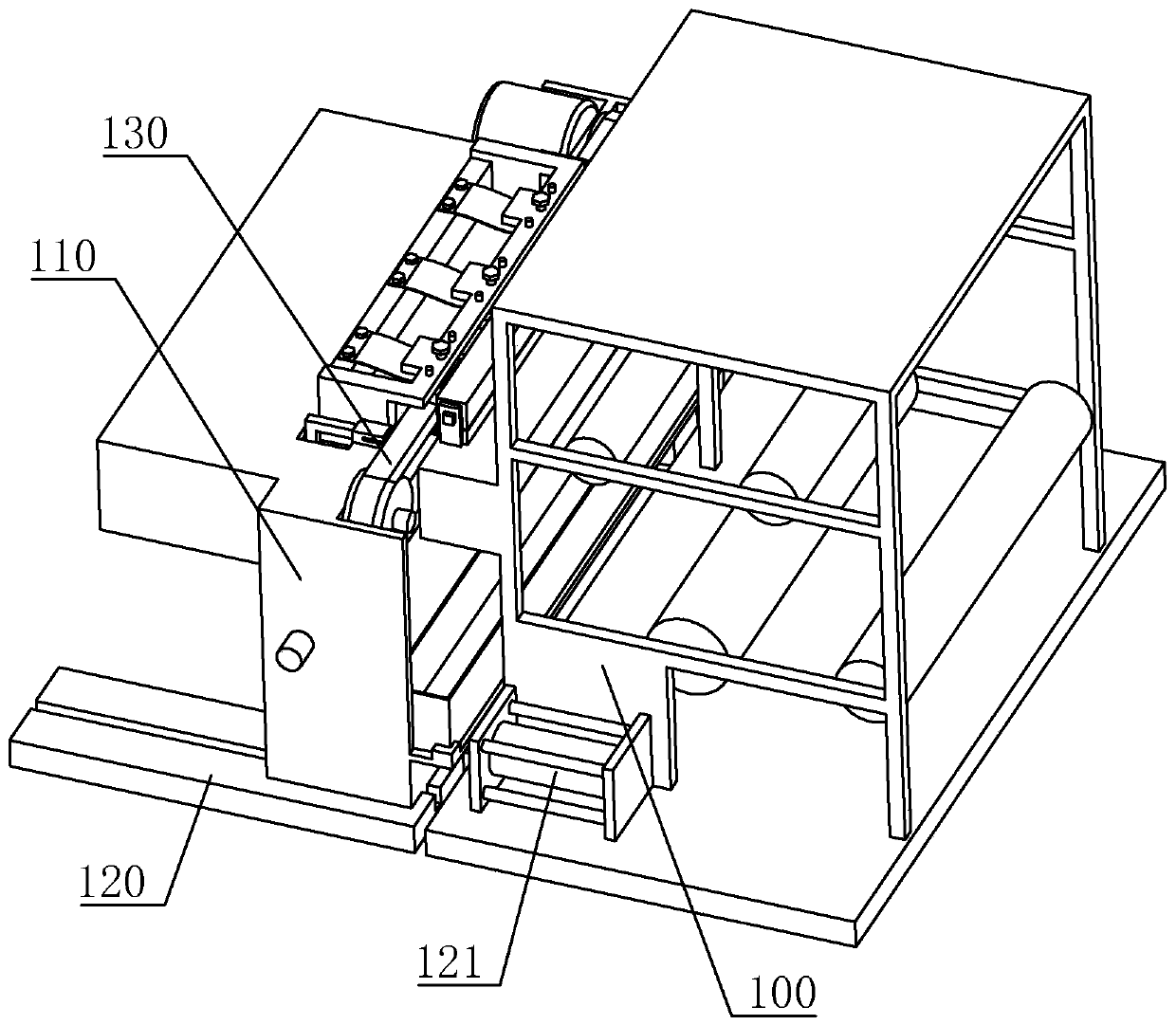

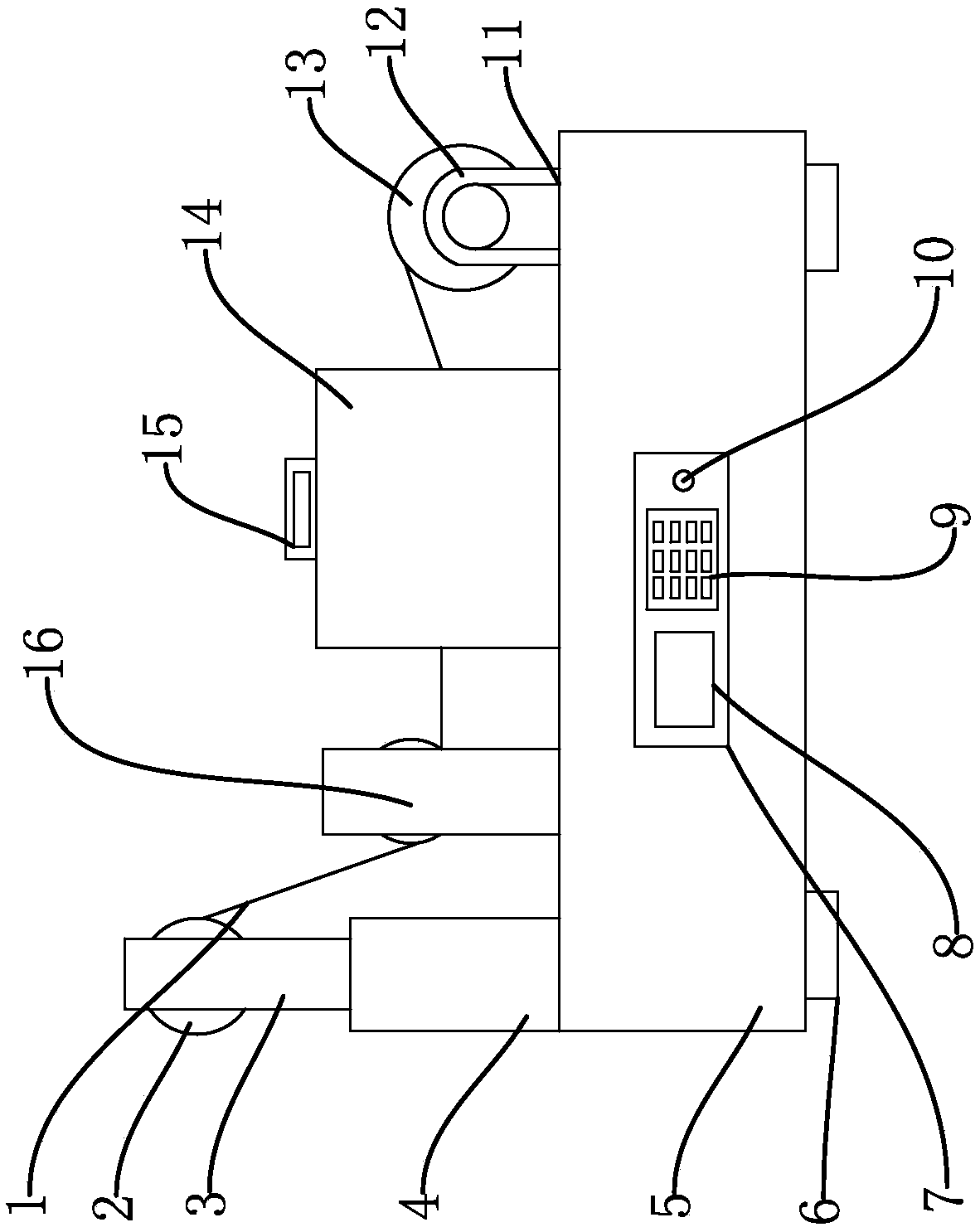

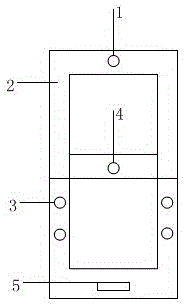

Smart multilayer fabric divider

PendingCN107201620AImprove cloth qualityQuality improvementDouble pile fabrics splittingEngineeringMechanical engineering

The invention discloses a smart multilayer fabric divider. The smart multilayer fabric divider comprises a cloth conveying transmission device and a pile cutting device, wherein the cloth conveying transmission device comprises a plurality of cloth conveying guide rollers and a metal detection device; the cloth conveying guide rollers are used for conveying grey cloth to the front of the metal detection device, detecting whether needle breakage occurs in the grey cloth or not, and conveying the grey cloth to a tape knife cutting position; the pile cutting device is used for cutting the grey cloth into two parts from the middle with a tape cutter, wherein the two parts serve as a side A and a side B respectively; on the side A and the side B, cloth is delivered along the same direction through a side A cloth delivery guide roller assembly and a side B cloth delivery guide roller assembly; a visual detection device for detecting the height of lint on the side A and the side B and a servo control device for controlling the height of the lint on the side A and side B are arranged in cloth delivery paths of the side A and the side B along the same direction. By adopting the smart multilayer fabric divider, the technical level of workers is lowered, the whole production flow is simplified, the machining time is shortened, and the production efficiency is increased; meanwhile, single-layer lint having higher cloth quality can be obtained.

Owner:CHANGZHOU WUJIN WUYANG TEXTILE MACHINERY

Two-tone two-side-brushed two-side-anti-pilling fabric and production method thereof

InactiveCN103409917AFast coloringWith warm functionDouble pile fabrics splittingWeft knittingPolyesterYarn

The invention discloses a two-tone two-side-brushed two-side-anti-pilling fabric and a production method thereof. The two-tone two-side-brushed two-side-anti-pilling fabric is formed by sequentially stringing 150D / 48F plain stitches, single-tone 150D / 144FCD cationic yarn pile loops with stretching sinker loops and single-tone 150D / 96F pile loops with stretching sinker loops through weft knitting. Polyester of the 150D / 144FCD cationic yarn pile loops with the stretching sinker loops is 70% modified cationic polyester. A plain stitch layer and a pile loop layer with the stretching sinker loops are subjected to weft knitting and sequential stringing to form the fabric, the number of polyester yarns within each inch in the warp direction of the two-tone two-side-brushed two-side-anti-pilling fabric is 36, the number of polyester yarns within each inch in the weft direction of the two-tone two-side-brushed two-side-anti-pilling fabric is 18, the fabric is dyed and dried and then subjected to after treatment, and finally a warm-keeping agent adheres to the fabric. By means of the after treatment, the two-tone two-side-brushed two-side-anti-pilling fabric is comfortable, soft and firm in chromaticity, has a warm-keeping function and is comfortable and fit when being worn on the body.

Owner:JIANGSU SHENGLI ENTERPRISE

Fleece composite fabric and preparation method thereof

InactiveCN111321503AReduce pasting processMeet secret requirementsDouble pile fabrics splittingSucessive textile treatmentsYarnFiber

The invention discloses a preparation method for a fleece composite fabric and the fleece composite fabric. The preparation method comprises the steps of warping, namely, warping a plurality of yarnsonto 2 to 3 warp beams, wherein each warp beam at least contains 4,000 yarns, the yarns are long chemical fibers, and the thickest yarn is 75D; weaving, namely, feeding all warped yarns onto a loon through loom beams of the loom after drifting and drawing are performed, wherein the loom beams of the loom correspond to the warp beams, and performing interweaving and beating-up on pile wefts and ground wefts in proportion, wherein the ground wefts and warp yarns form a ground fabric, and the pile wefts and the warp yarns are interwoven to form looped piles; cutting piles, namely, enabling a grayfabric to pass through a pile cutting device to cut the floats of the pile wefts to form short single piles; and performing after-treatment, namely, performing after-treatment on the gray fabric subjected to pile cutting to obtain the fleece composite fabric. The fleece composite fabric disclosed by the invention is woven integrally, so that a subsequent fleece pasting process is reduced; and therefore, the process is simpler and more environment-friendly.

Owner:上海安踏体育用品有限公司

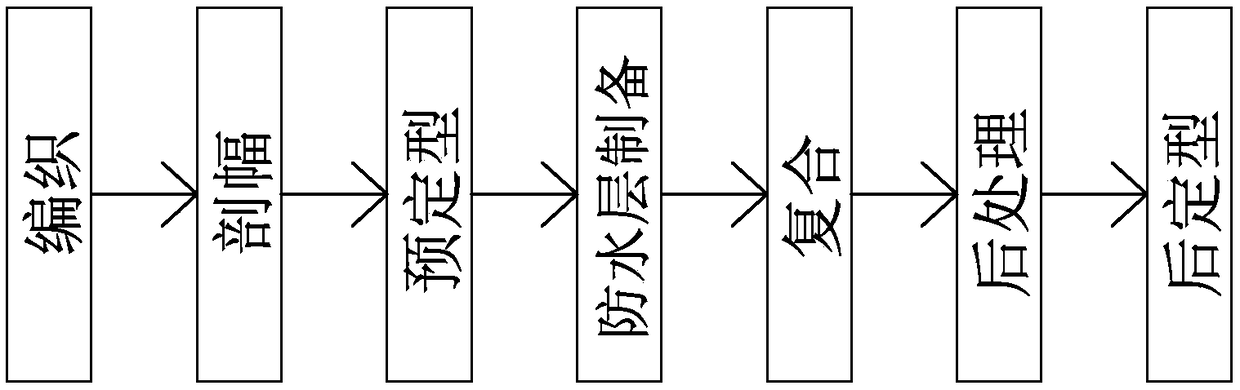

Production process for waterproof coral velvet composite fabric

InactiveCN108608712AHigh degree of automationIncrease productivityDouble pile fabrics splittingFibre treatmentPolyesterUltra fine

The invention provides a production process for a waterproof coral velvet composite fabric, belonging to the technical field of fabrics. The production process solves the problem of low production quality in the prior art. The production process for the waterproof coral velvet composite fabric comprises the following steps: S1: weaving: with polyester ultra-fine low-elasticity yarns with a specification of 150D / 288F as bottom yarns and ordinary polyester monofilaments as wool yarns, weaving the two yarns in a warp knitting machine; S2, slitting: carrying out slitting and cutting by using a velvet cutting device so as to obtain grey cloth; S3, pre-setting: subjecting the single-side-plush grey cloth obtained in the previous step to pre-setting with a setting machine, setting the pre-settingtemperature of the setting machine and controlling the running speed of the single-side-plush grey cloth so as to obtain pre-set grey cloth; S4, preparation of a waterproof layer; S5, laminating: laminating the waterproof layer with the grey fabric by using a laminating machine so as to obtain a semi-finished composite fabric; S6, post-treatment; and S7, post-setting. The production process provided by the invention has the advantage of improving production quality.

Owner:海宁市华泰针织有限公司

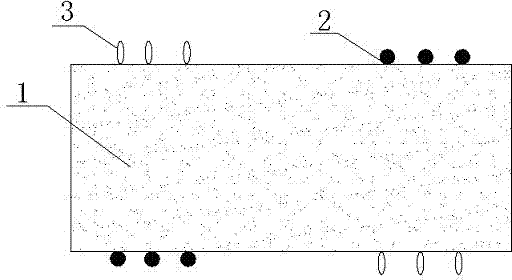

Double-layer fleece fabric cutting device

ActiveCN104233686AEasy to disassembleEasy to transportDouble pile fabrics splittingAgricultural engineeringCast iron

The invention discloses a double-layer fleece fabric cutting device. The double-layer fleece fabric cutting device structurally comprises two cast iron side walls, a support rod, a connecting cross bar, subpackaging rollers and a three-edge blade. When the double-layer fleece fabric cutting device is used, a coiled double-layer fleece fabric roller is required to be placed on the support rod on the cast iron side walls, the front end of the double-layer woven fleece fabric is cut open, the two cut ends of the fleece fabric wind the two subpackaging rollers, and the two subpackaging rollers are rotated simultaneously, so that the double-layer fleece fabric can be cut into two rolls of fabrics with one-side fleece. The double-layer fleece fabric cutting device has certain advancement in the textile field.

Owner:浙江志华家纺科技股份有限公司

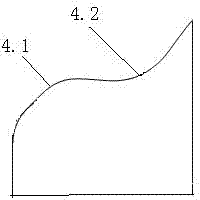

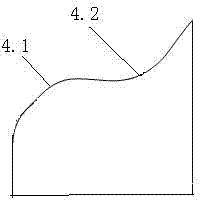

Triple-purpose shawl

ActiveCN102499603AUniform surfaceIncrease elasticityDouble pile fabrics splittingFibre treatmentFiberAcute angle

The invention relates to a triple-purpose shawl, which comprises a rectangular shawl body. A first long side of the shawl body is provided with a left connecting button set and a right connector set matched with the connecting button set, a second long side of the shawl body is provided with a left connector set matched with the connecting button set on the first long side and a right connecting button set matched with the connector set on the first long side, the shawl is made of ultrathin fibers, the surface of the pawl is subjected to cut pile treatment to form a cambered pile end face, the front cambered face of the cambered pile end face is convex, the rear cambered face of the cambered pile end face is concave, the front cambered face is smoothly connected with the rear cambered face, the rear cambered face and a generatrix of the rear side of each pile form an acute angle, and the front cambered face is smoothly connected with generatrices of the front sides of the piles. The triple-purpose shawl can be combined in different ways to wear, cannot slip when worn, and is high in water absorption and scratch resistance.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

Process method of blind embossing jacquard satin reactive print of towel

ActiveCN101748621BRich in colorIncrease the level of detailDouble pile fabrics splittingPhotomechanical apparatusMechanical engineeringEngineering

The invention relates to the technical field of jacquard weaving print of fabrics, in particular to an effective processing method of combining printing of blank towel pattern and print pattern, i.e. a process method of the blind embossing jacquard satin reactive print of a towel. The process method of the blind embossing jacquard satin reactive print of the towel of the invention comprises the following steps: manufacturing a blank towel, drying in a loose mode, cutting cloth with soft nap, carrying out pretreatment to the blank towel, drying in a loose mode, secondary cutting cloth with soft nap, printing reactive print, drying, steaming, flat washing and tidying. The printed towel produced with the technical scheme has abundant colors, high fine degree, vivid pattern effect and environment protection, can satisfy requirements of consumers on towel color density and permeability, greatly improves printing speed and production efficiency and integrally lowers production cost.

Owner:LOFTEX INDS

Production method of warp-knitted Raschel blanket

InactiveCN112359472AReduce labor costsReduce manufacturing costDouble pile fabrics splittingWarp knittingTextile printerFiber

The invention discloses a production method of a warp-knitted Raschel blanket. The production method of the warp-knitted Raschel blanket comprises the technological processes of raw material selection, weaving, sectioning, inspecting, high-temperature shaping, gray fabric brushing, grey cloth ironing and glossing, printing, permeating, drying and color fixing, washing, shaping and drying, brushing, ironing and glossing, ironing and shearing, after-finishing, cloth cutting, edge covering inspection, packaging, warehousing and the like, can achieve the effect of rapid brushing of the fiber twistof the front rough surface of grey cloth, and has the advantages of ironing gloss, exquisite hand feeling, smooth and flat rough surface, no wrinkles, rapid production and high efficiency, so that manual work is greatly reduced; air blowing cooling is conducted after the last time of ironing and glossing of the grey cloth is finished, so that the temperature reaches the normal temperature duringcropping, the consistency of the rough surface is guaranteed, and disordered wools and creases are avoided; and meanwhile, an oil fume purifier is additionally arranged to recover oil fume, so that oil fume emission is reduced, and environmental pollution is reduced.

Owner:连云港飞雁毛毯有限责任公司

Triple-purpose shawl

ActiveCN102499603BUniform surfaceIncrease elasticityDouble pile fabrics splittingFibre treatmentFiberAcute angle

The invention relates to a triple-purpose shawl, which comprises a rectangular shawl body. A first long side of the shawl body is provided with a left connecting button set and a right connector set matched with the connecting button set, a second long side of the shawl body is provided with a left connector set matched with the connecting button set on the first long side and a right connecting button set matched with the connector set on the first long side, the shawl is made of ultrathin fibers, the surface of the pawl is subjected to cut pile treatment to form a cambered pile end face, the front cambered face of the cambered pile end face is convex, the rear cambered face of the cambered pile end face is concave, the front cambered face is smoothly connected with the rear cambered face, the rear cambered face and a generatrix of the rear side of each pile form an acute angle, and the front cambered face is smoothly connected with generatrices of the front sides of the piles. The triple-purpose shawl can be combined in different ways to wear, cannot slip when worn, and is high in water absorption and scratch resistance.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

Double-layer flannelette splitting device

ActiveCN104233686BEasy to disassembleEasy to transportDouble pile fabrics splittingAgricultural engineeringCast iron

The invention discloses a double-layer fleece fabric cutting device. The double-layer fleece fabric cutting device structurally comprises two cast iron side walls, a support rod, a connecting cross bar, subpackaging rollers and a three-edge blade. When the double-layer fleece fabric cutting device is used, a coiled double-layer fleece fabric roller is required to be placed on the support rod on the cast iron side walls, the front end of the double-layer woven fleece fabric is cut open, the two cut ends of the fleece fabric wind the two subpackaging rollers, and the two subpackaging rollers are rotated simultaneously, so that the double-layer fleece fabric can be cut into two rolls of fabrics with one-side fleece. The double-layer fleece fabric cutting device has certain advancement in the textile field.

Owner:浙江志华家纺科技股份有限公司

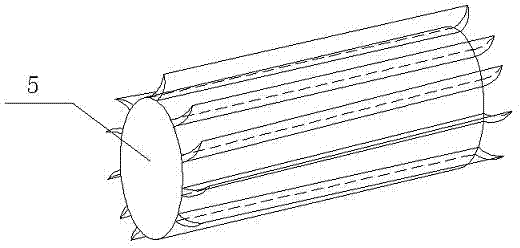

Cleaning flannelette with long-acting deodorization function and manufacturing method of cleaning flannelette

PendingCN114808243ASolve the problem of impactNo pollution effectDouble pile fabrics splittingHeating/cooling textile fabricsFiberProcess engineering

The invention discloses cleaning flannelette with a long-acting deodorization function and a manufacturing method thereof.The cleaning flannelette comprises flannelette, a flannelette face and a coating, the flannelette face is bonded to the top of the flannelette, the coating is arranged at the bottom of the flannelette, and the flannelette is composed of a plurality of flannelette warps; the flannelette is formed by selecting and processing raw materials, warping, weaving by a double-rapier loom, and sizing and finishing a coating. A double-layer cut pile process is adopted for production, no extra production procedure is added for fabric production deodorization, cost is low, operation is easy, sewage is not generated, pollution to the environment is avoided, nanoscale deodorization particles are distributed in a dotted mode through atomization and resin bonding, and washing resistance is achieved. The deodorization function is added, the hand feeling hardness of the fibers is not affected, it can be guaranteed that the cleaning flannelette is fresh and free of odor for a long time, a traditional deodorization finishing technology is changed, procedures are not increased, cost is low, and sewage and pollution are avoided.

Owner:山东艺成复合材料有限公司

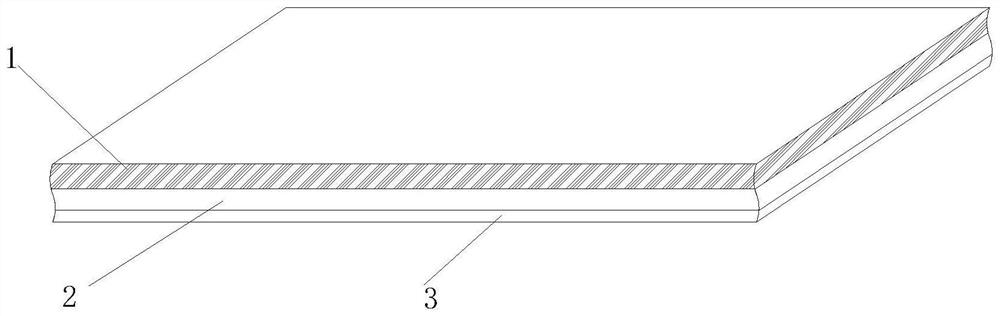

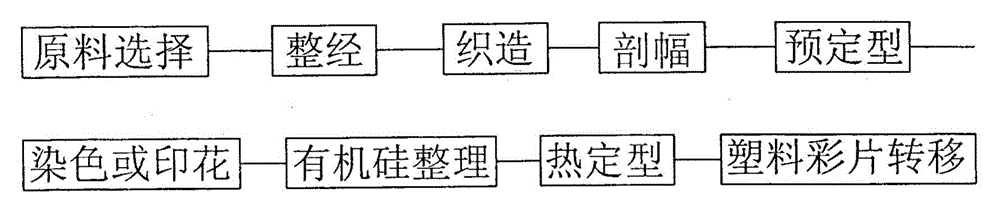

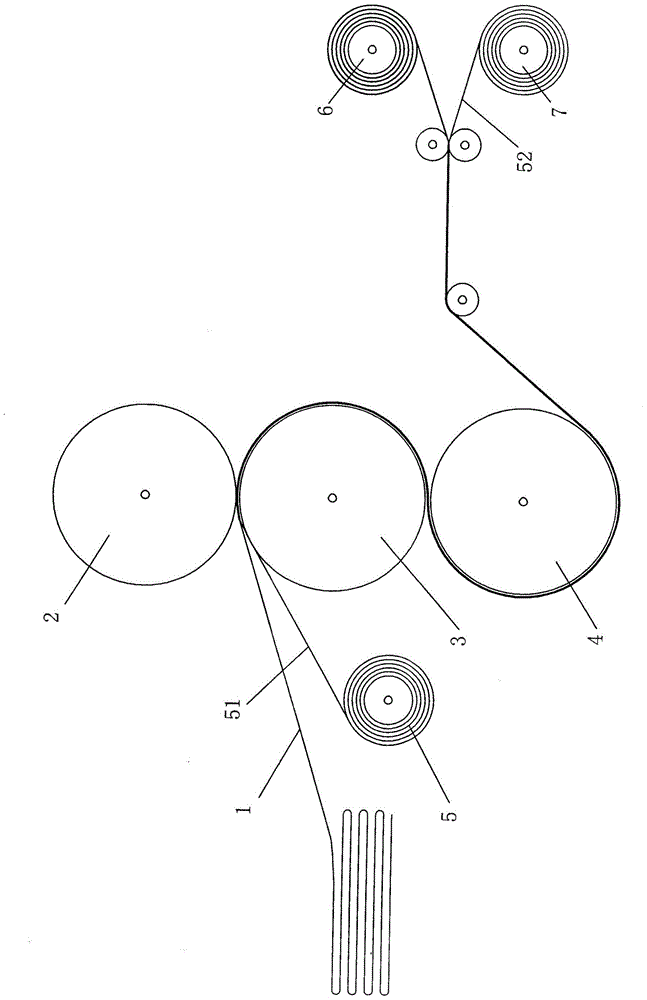

Preparation method of color piece fur fabric

ActiveCN104287247BAdd transfer stepsDouble pile fabrics splittingDuplicating/marking methodsColor filmEngineering

The invention discloses a production method of fur fabric with color piece and belongs to the technical field of clothing fabrics. The production method includes firstly, producing the fur fabric by the steps of raw material selection, warping, weaving, slitting, presetting, dyeing or printing, organic silicon finishing and heat setting; secondly, producing the fur fabric with the color piece by the step of transferring the plastic color piece, namely, feeding the fur fabric with the fur surface facing downwards between an upper pressure roll and a heating roll to enter the space between the heating roll and a lower pressure roll, and then feeding the fur fabric to a reeling station, while setting the plastic color piece with a release film in a reeling-off state, feeding the plastic color piece by facing the fur surface between the upper pressure roll and the heating roll along with the fur fabric to enter the space between the heating roll and the lower pressure roll, thereby completing transferring the plastic color piece to the fur surface of the fur fabric to obtain the fur fabric with the color piece. In addition, the release film is reeled by a release film reeling roll when the plastic color piece is discharged from the lower pressure roll; the running speed of the fur fabric to the reeling roll is equal to the reeling-off speed of the plastic color piece. The fur fabric with the color piece has both textures of fur and scales of animals.

Owner:CHANGSHU CITY QUNYING KNITTING MFG

Process method of blind embossing jacquard satin print of towel

ActiveCN101748619BRich in colorIncrease the level of detailDouble pile fabrics splittingPhotomechanical apparatusVolumetric Mass DensityEngineering

The invention relates to the technical field of jacquard weaving print of fabrics, in particular to an effective processing method of combining printing of blank towel pattern and print pattern, i.e. a process method of the blind embossing jacquard satin print of a towel. The process method of the blind embossing jacquard satin print of the towel of the invention comprises the following steps: manufacturing a blank towel, drying in a loose mode, cutting cloth with soft nap, carrying out pretreatment to the blank towel, drying in a loose mode, secondary cutting cloth with soft nap, printing, drying and tidying. The printed towel produced with the technical scheme has abundant colors, high fine degree, vivid pattern effect and environment protection, can satisfy requirements of consumers ontowel color density and permeability, greatly improves printing speed and production efficiency and integrally lowers production cost.

Owner:LOFTEX INDS

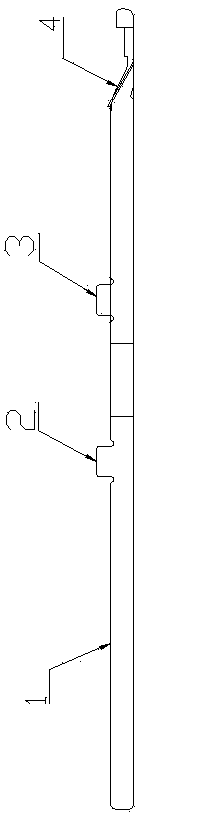

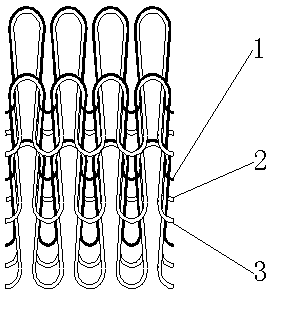

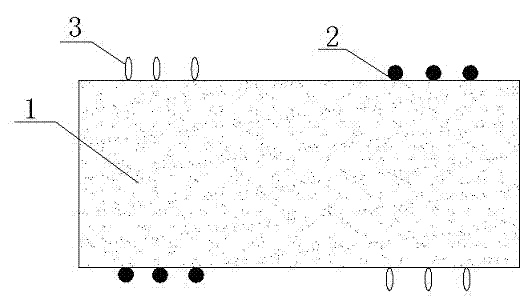

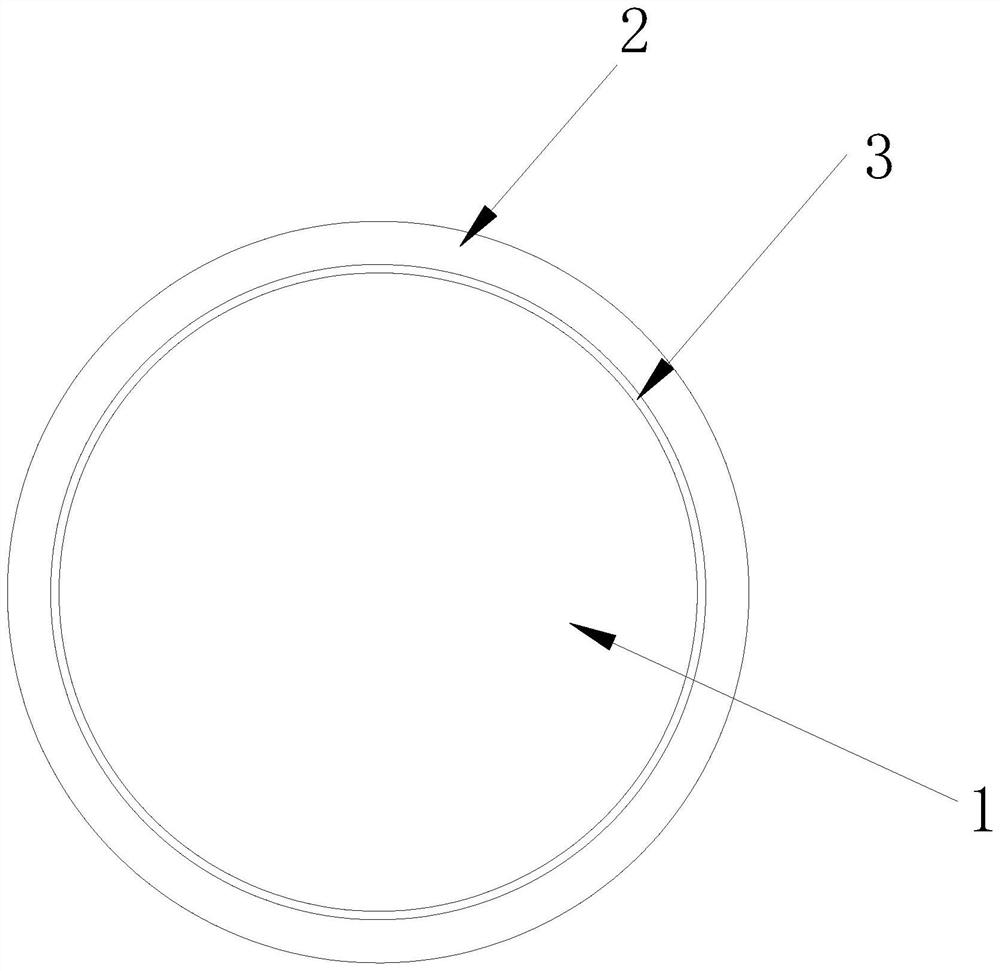

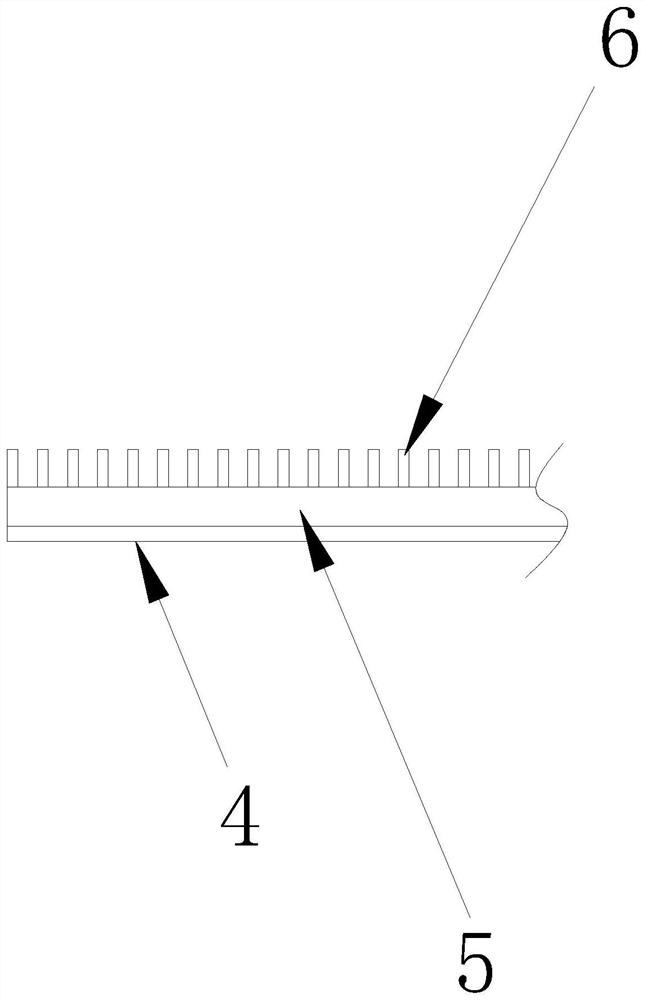

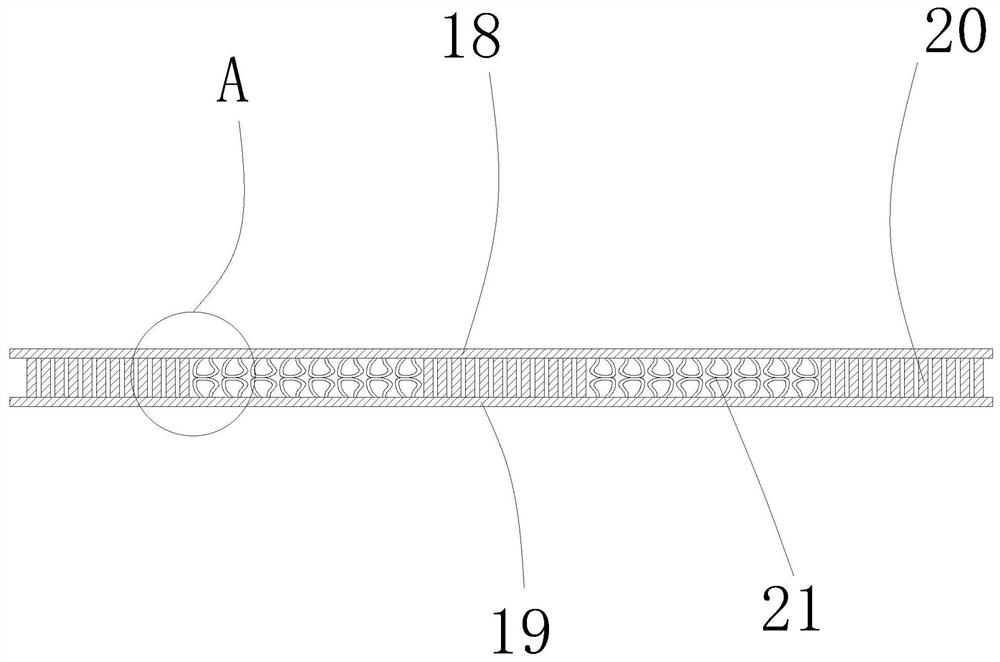

Super-strong cleaning decontamination cut pile electric appliance rolling brush cleaning cloth and manufacturing method thereof

PendingCN114795025AMeet functional requirementsReduce energy consumptionDouble pile fabrics splittingCarpet cleanersYarnEngineering

The invention discloses ultra-strong cleaning and decontamination cut pile electric appliance rolling brush cleaning cloth and a manufacturing method thereof.The cleaning cloth comprises a brush roller 1, a cleaning cloth layer 2 and a bonding layer 3, the bonding layer 3 is fixedly arranged on the outer surface of the brush roller 1 in a composite mode through the bonding layer 3, the bonding layer 3 comprises a bottom yarn layer 4, a pile layer 5 and hard filaments 6, and the bottom yarn layer 4 and the pile layer 5 are fixed in an interwoven mode; hard filaments 6 are uniformly fixed on the fluff layer 5. The manufacturing method comprises the following steps: 1, processing and warping raw materials, and weaving by a double-rapier loom to form a semi-finished product A; 2, ironing the semi-finished product A to form a semi-finished product B; 3, coating the semi-finished product B; 4, shaping the coated semi-finished product B to form a semi-finished product C; and 5, shearing and finishing the coated semi-finished product C to form a finished product. According to the invention, a double-layer pile cutting process is adopted for production, and pile is compounded with stiff hard filaments.

Owner:山东艺成复合材料有限公司

Preparation process of heat-preservation adjustable fabric

ActiveCN114855337AEfficient productionIncrease elasticityDouble pile fabrics splittingMechanical cleaningYarnProcess engineering

The invention discloses a preparation process of a heat-preservation adjustable fabric, relates to a textile production technology, and aims to solve the problem that the fabric cannot achieve the effect wanted by people even if various pattern textures are disorderly combined due to the fact that various pattern textures are combined together rarely existing in the prior art, and the key point of the technical scheme is that the preparation process comprises the following steps: step 1, preparing materials; yarn is prepared for warping, surface warp and ground warp denting is carried out, and surface weft and ground weft looming is carried out; step 2, performing jet weaving through a water jet loom, alternately performing jet weaving of a double weave and a towel weave to form an initial fabric, and rolling the initial fabric. According to the production method, the heat-preservation adjustable fabric with two kinds of pattern weaves combined together can be produced, meanwhile, the thickness of the fabric can be adjusted according to the requirement of people for cold and warm, the situation that a human body is too hot or cold is avoided, the yarn is made of acrylic fibers, and therefore the fabric is not prone to breakage. The heat preservation adjustable fabric has a further heat preservation effect.

Owner:吴江市富成芳针纺有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com