Stirring conveying device for polystyrene granule foaming cement composite material

A polyphenylene particle and foamed cement technology, which is applied in the sales of raw material supply devices, mixing operation control devices, mixing plants, etc., can solve the problems that the integrated mechanical construction of polystyrene foamed cement composite materials cannot be realized, and achieve the effect of heat preservation Highlight, avoid solid phase and liquid phase separation, and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The foaming machine 11 and thick slurry pump 3 mentioned in this embodiment are commercial products, and the foaming machine is produced by Beijing Zhongke Zhucheng Building Materials Technology Co., Ltd., and the model is SDJ-60-25. The thick slurry pump is produced by Yatian Machinery Co., Ltd., Tianchang City, Anhui Province, and the model is: CHN65-50-125.

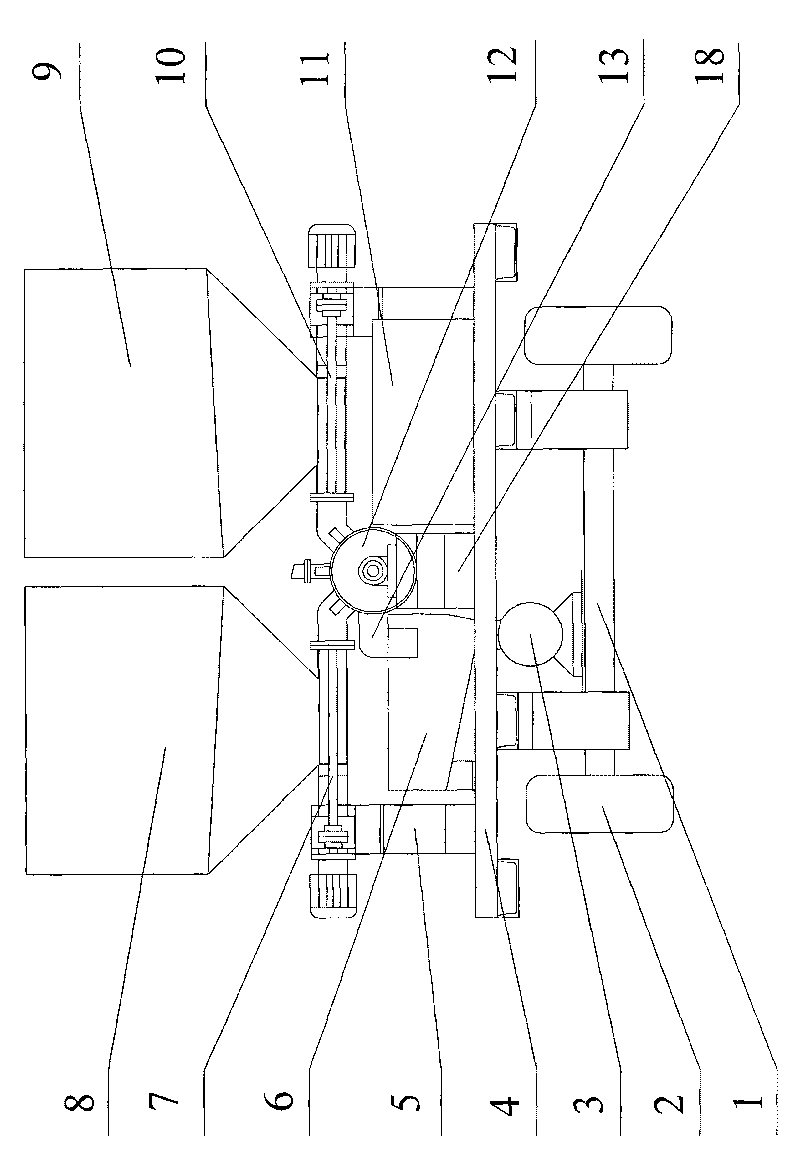

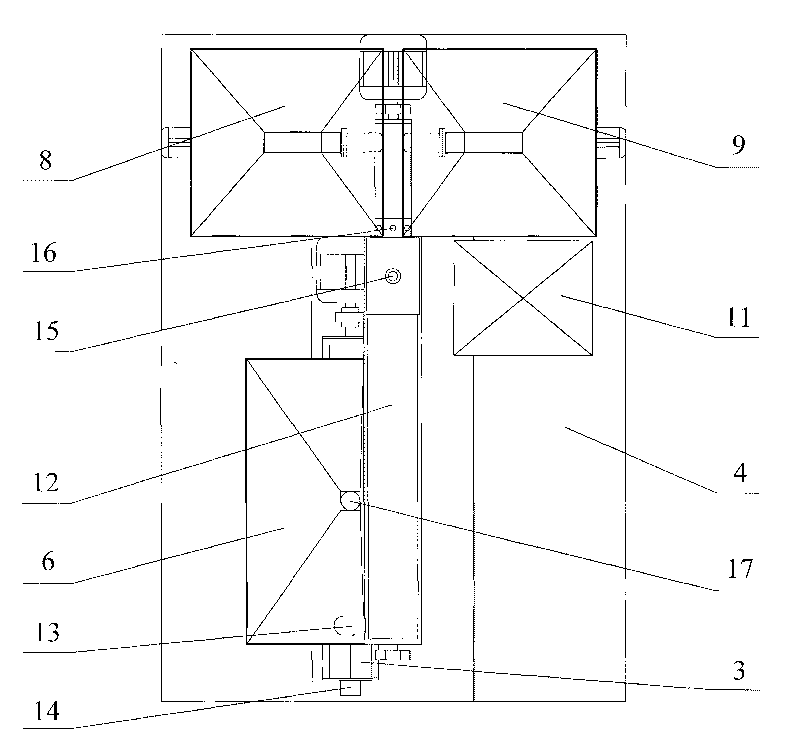

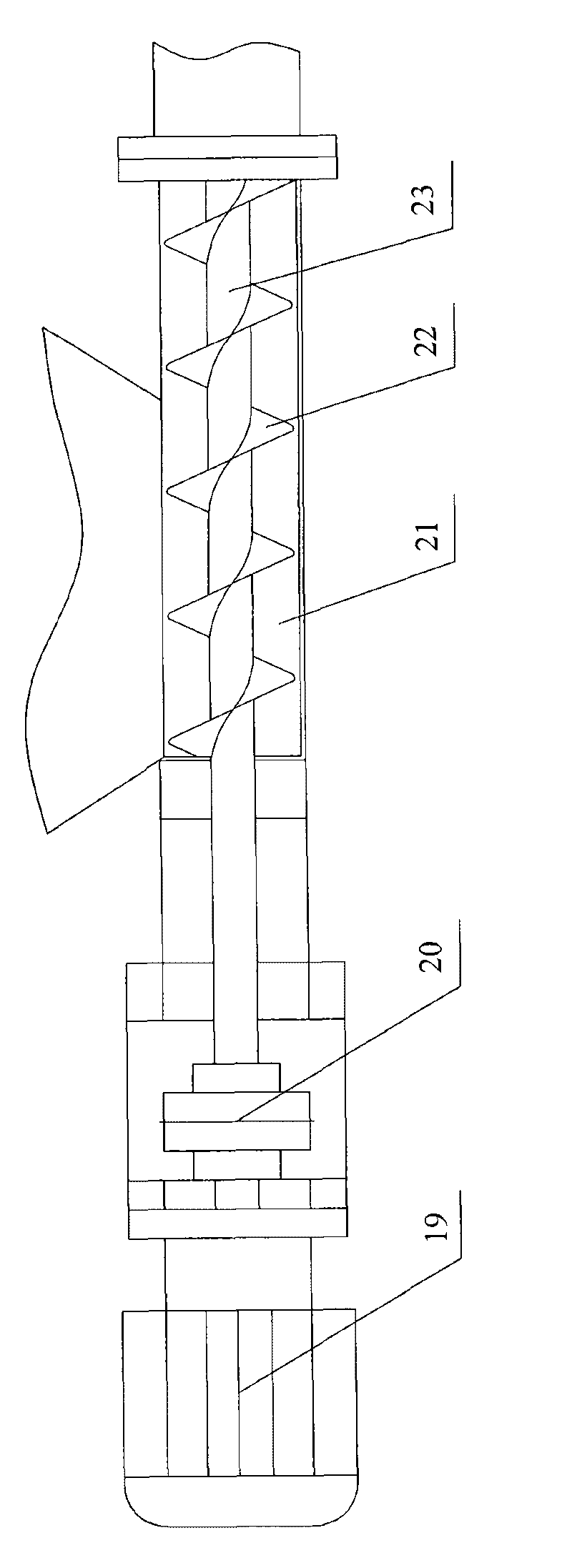

[0021] The mixing and conveying device for polystyrene particle firing cement composite material is mainly composed of a base 4, a cement silo 8, a polystyrene particle silo 9, a feeder, a foaming machine 11, a stirring conveyor 12, a slurry storage tank 6 and a thickener The slurry pump 3 is composed of a cement silo 8 and a polystyrene particle silo 9 installed on the base 4, a first feeder 7 is installed at the bottom of the cement silo 8, and a first feeder 7 is installed at the bottom of the polystyrene particle silo 9. Two feeders 10, foaming machine 11 and stirring feeder 12 are installed on the base, the...

Embodiment 2

[0026] The structure of this embodiment is the same as that of Embodiment 1, the difference is that a wheel shaft 1 is installed on the lower part of the base of the polystyrene particle foamed cement composite material mixing and conveying device, and a wheel 2 is installed on the wheel shaft.

[0027] Cement and polyphenylene particles are added into cement silo 8 and polyphenylene particle silo 9 respectively, and the mixing of cement and polyphenylene particles is dried by the first feeder 7 and the second feeder 10 below the two feeders. The material is transported to the mixing conveyor 12, and water is injected into the mixing conveyor 12 through the water injection port 16 of the mixing conveyor 12, and the foam machine 11 passes the prepared foam through the foam injection port 15 on the mixing conveyor 12. Inject into the agitating conveyor 12, and form the final mixed slurry through the agitation of the agitating conveyor 12. In order to avoid the suspension of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com