Woollen sweater and production thereof

A production process and technology for wool sweaters, applied in the textile industry, can solve the problems of added value of textile products, low technology content, low market competitiveness, functional monotonous heat preservation, etc., and achieve good shape and dimensional stability. , good heat retention and water absorption, smooth effect of milk fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Select the raw material of white gray yarn: select the yarn count of 32S / 2 as the raw material when the yarn count formed by blending 55% spun silk, 25% modal fiber, 10% milk fiber and 10% cashmere;

[0024] (2) Dyeing: according to the color of clothing design, the white gray yarn is dyed at room temperature;

[0025] (3) Rewinding: Eliminate yarn defects and lubricate the colored yarn, and package it into a package of about 1.6 kg;

[0026] (4) Weaving pieces: knitting the various parts of the sweater on the flat knitting machine;

[0027] (5) Sleeves: Sew up the various tissue parts of the sweater, and the stitches are even, straight and firm;

[0028] (6) Flat car: Sew anti-stretch webbing on the shoulder seam to shape the shoulder width and resist deformation;

[0029] (7) Hand sewing: Reinforce back stitching at the hem, cuff rib and intersection of hem seam and sleeve bottom seam, wrap thread ends and other auxiliary staples;

[0030] (8) Washing: Carry ou...

Embodiment 2~6

[0034] Except changing the consumption of spun silk, modal fiber, milk fiber and cashmere, other implementation conditions are identical with embodiment 1. The consumption of spun silk, modal fiber, milk fiber and cashmere among embodiment 2 to embodiment 6 is listed in following table 1.

[0035] Table 1

[0036] Example

Embodiment 7

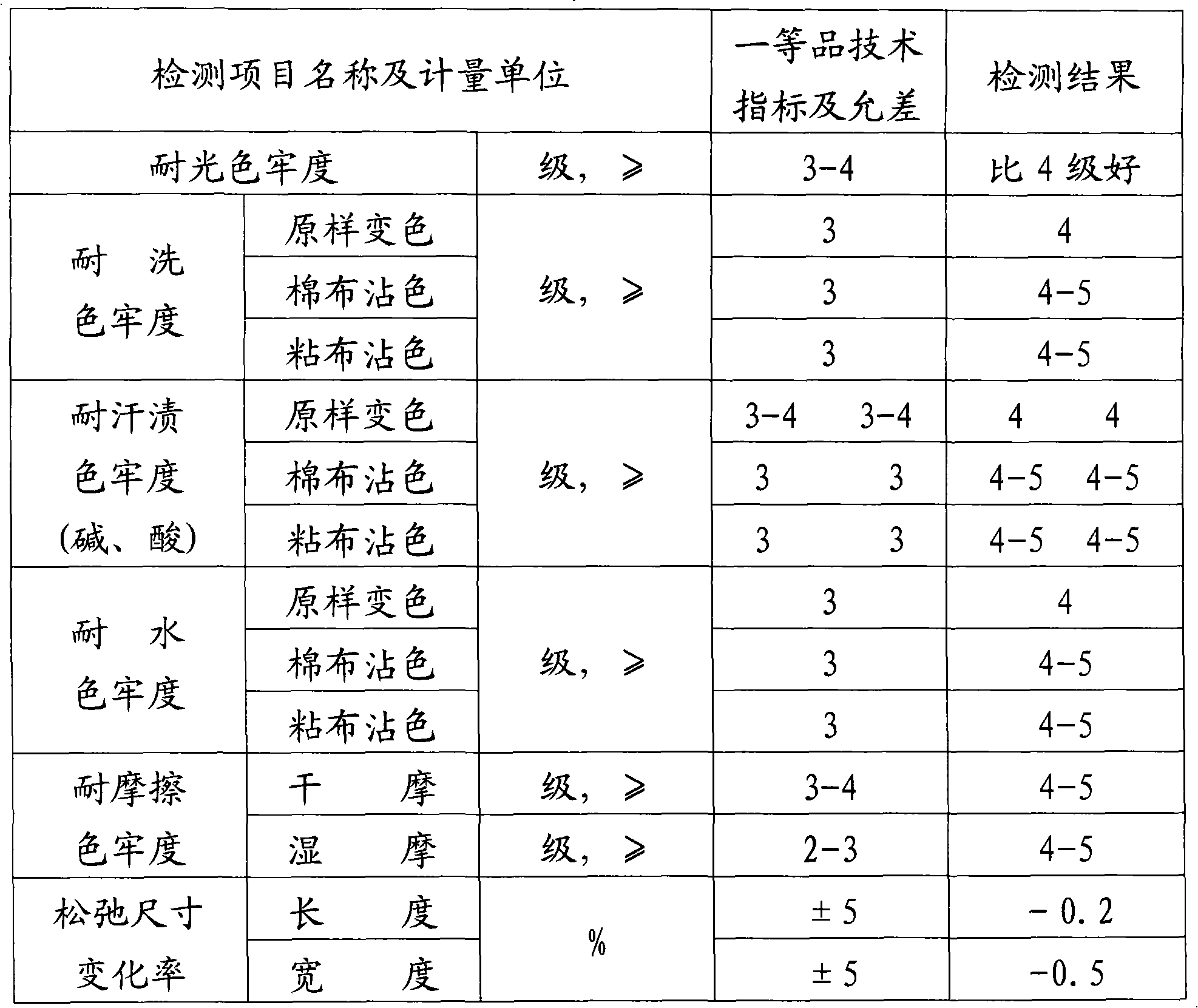

[0038] The various quality indexes that product of the present invention (embodiment 1) obtains after the laboratory detection of Jiangsu Provincial Textile Research Physical and Chemical Center are shown in Table 2 (wherein, the test results do not include the estimated value of uncertainty).

[0039] Table 2

[0040]

[0041] It can be known from Table 2 that all the indicators of the product of the present invention have reached the technical requirements of the textile industry standard FZ / T73005-2002 "Low Wool Blended and Wool-Like Knitted Fabrics" within the quality. At the same time, the woolen sweater of the present invention is made of a variety of fiber blends. By rationally arranging the weight ratio of each fiber to highlight the characteristics of each fiber, it integrates the advantages of various fibers and maintains the smooth feel of real silk fiber. It has the characteristics of cool, warm and water-absorbing properties, showing a soft and tough, bright an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com