Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Process is directional" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

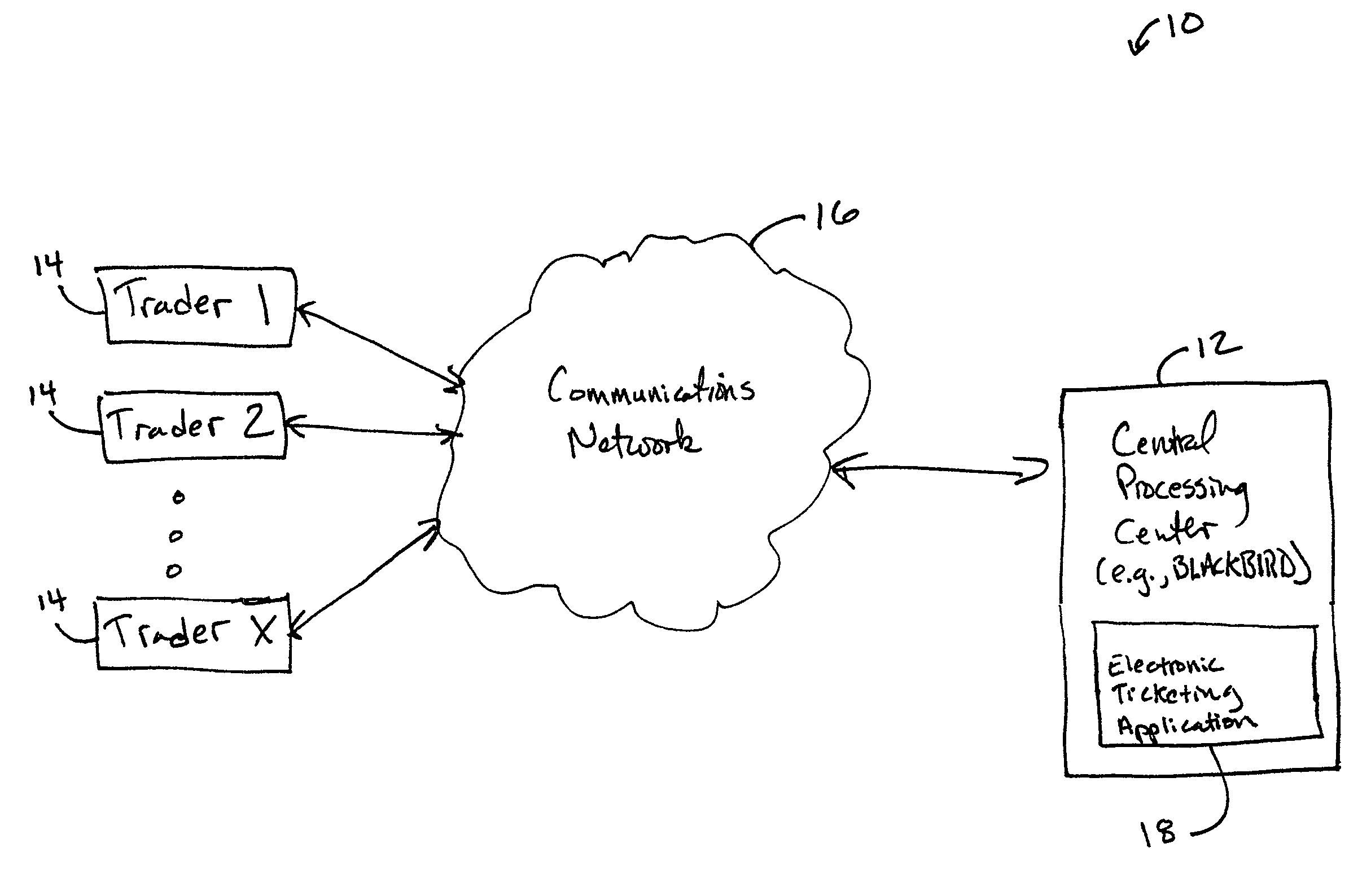

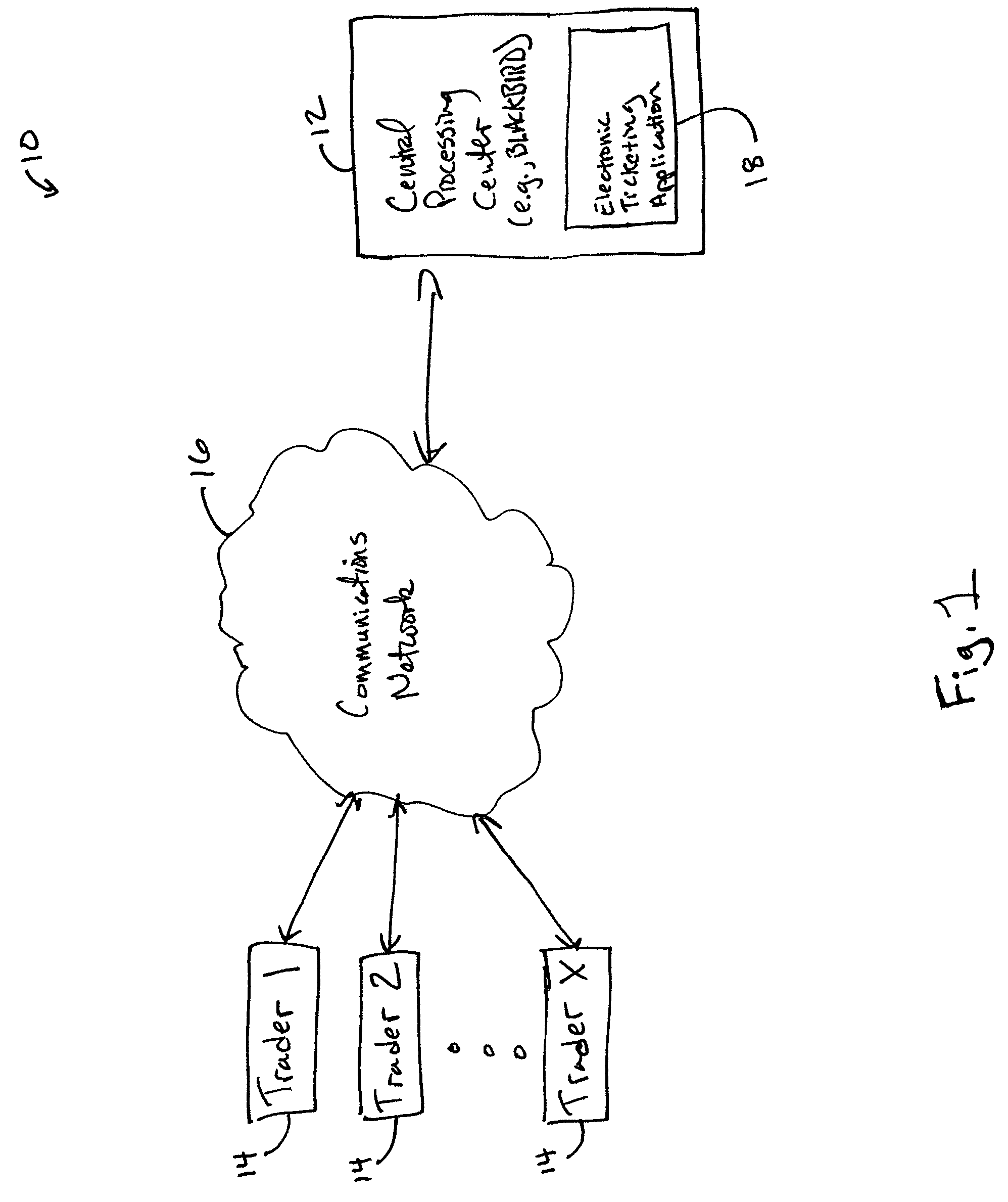

Systems and methods for conducting derivative trades electronically

InactiveUS20070282733A1Quickly and easily identifyProcess is directionalFinanceFacsimileComputer science

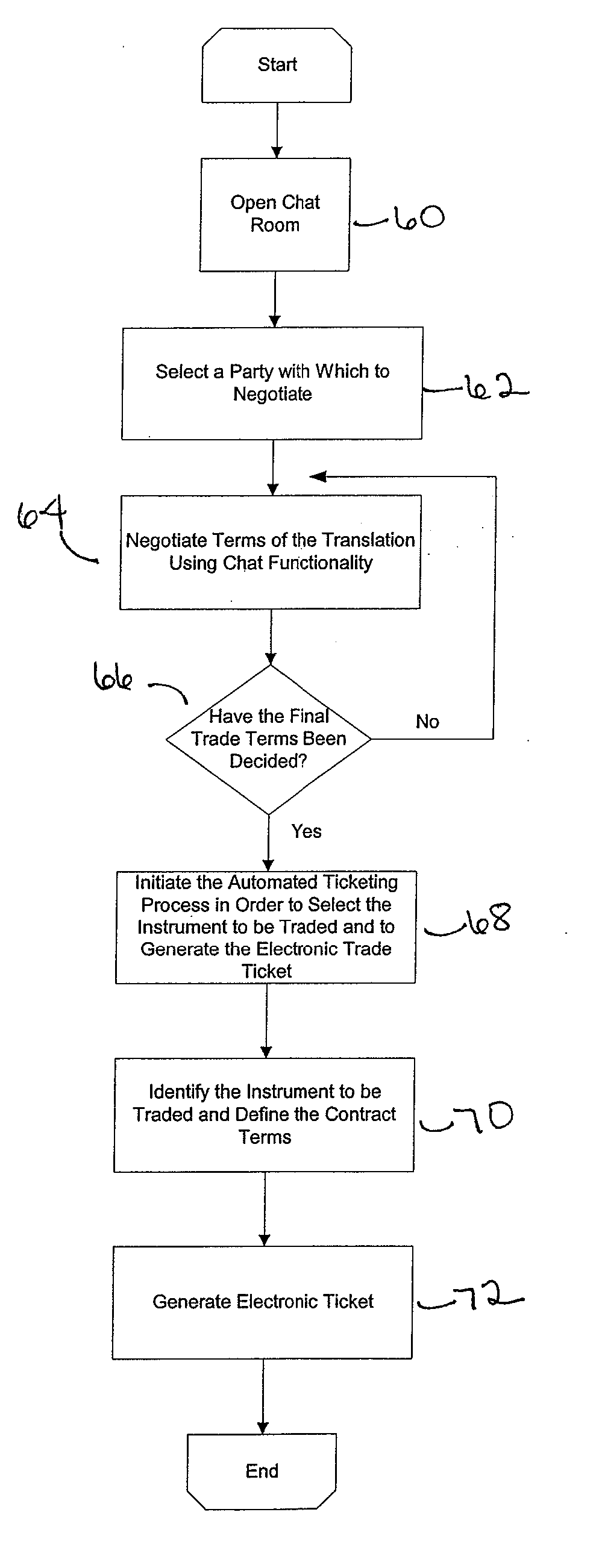

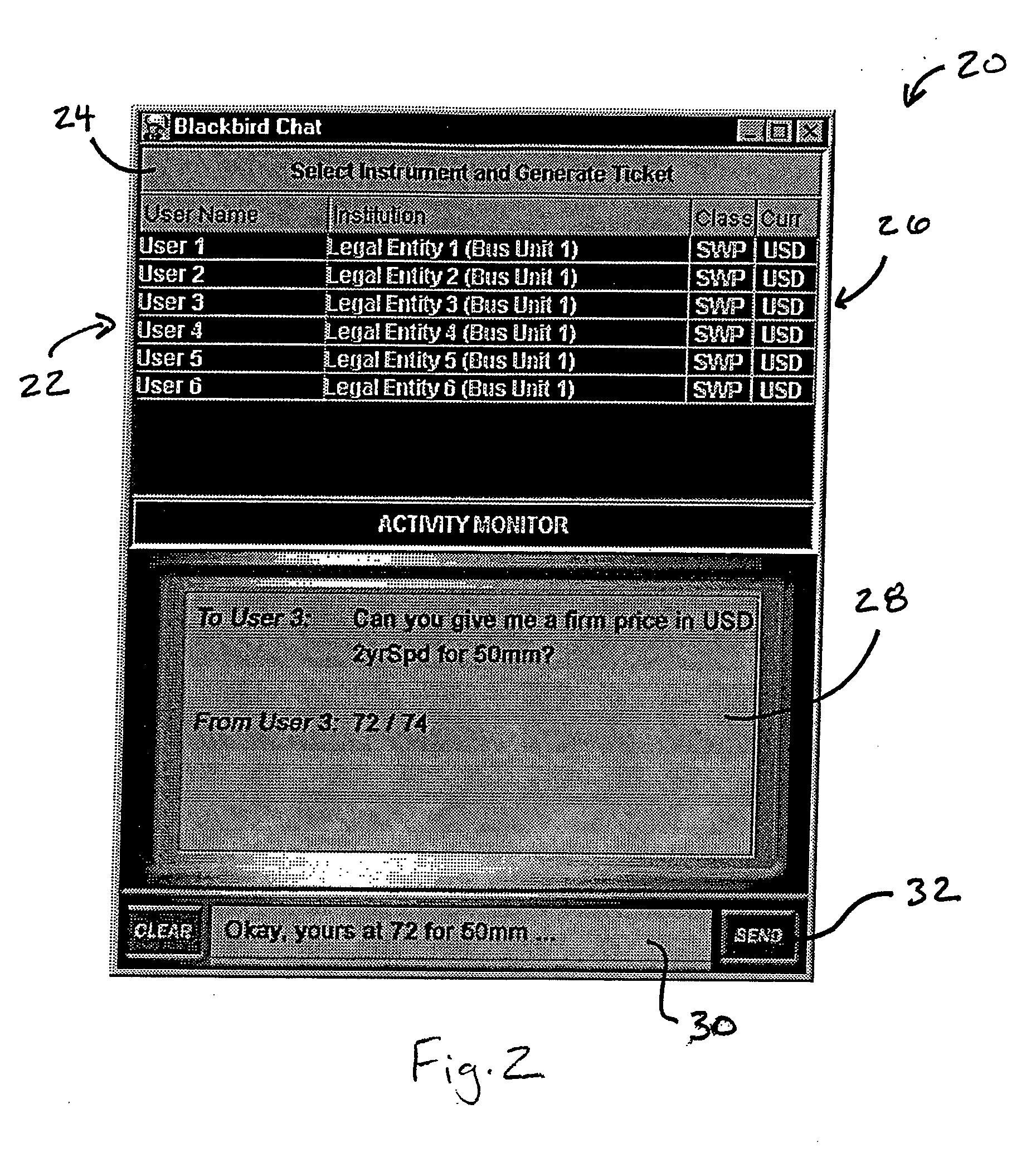

The present invention facilitates efficient negotiations of trade terms and the generation of an electronic trade ticket in the trading of financial instruments. The negotiation process is preferably conducted through a secure online chat program using point-to-point messaging, though the negotiations can take place using the tradition exchanges of phone calls and faxes outside of the confines of an electronic trading system. Once the trade terms have been agreed upon by both parties, then the parties enter an electronic trading system in accordance with the present invention to select the traded financial instrument and generate an electronic trade ticket with can be stored by the trading system and / or the each of the trading parties.

Owner:GFINET INC

Ready-to-use whole blood collection vessel

ActiveUS20090246866A1Easy to transportReduce riskBioreactor/fermenter combinationsBiological substance pretreatmentsBlood collectionHemolysis

The present invention relates to a sampling tube for collecting and processing a whole blood sample. The sampling tube contains a reagent for differential hemolysis of whole blood, wherein said reagent for differential hemolysis comprises a chemical for differential hemolysis and an anti-coagulant, and wherein said sampling tube is a ready-to-use and single-use sampling tube. It also relates to the use of said sampling tube in the processing of a whole blood sample for liquid chromatography and also to the use of a blood sample processed in such sampling tube in a liquid chromatography-based analysis.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

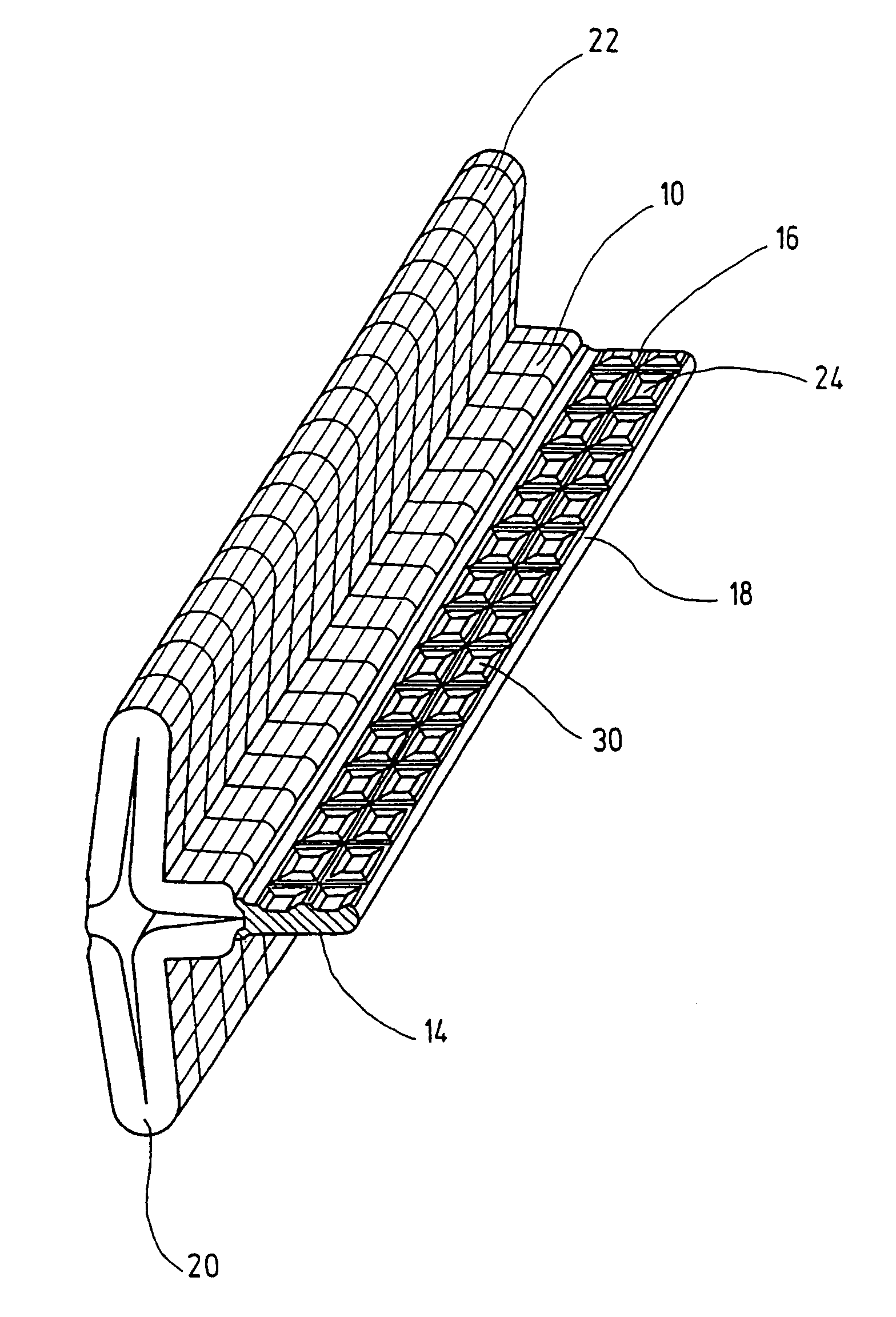

Filter element comprising an embossed weld connection clip and device for producing the same

InactiveUS6949155B1Reduce manufacturing costReduce usageMechanical working/deformationDispersed particle filtrationFilter matingBiomedical engineering

A tubular filter element and a device for producing the same for filtering fluids includes a filter mate. The facing ends of the filter mat are fixed in position by a connecting device which at least partially overlaps the filter mat.

Owner:HYDAC FILTERTECHNIK GMBH

Amorphous submicron particles

ActiveUS20080173739A1Increased space-time yieldProcess is directionalNatural mineral layered productsThin material handlingProcess engineeringAmorphous solid

A process for milling amorphous solids using a milling apparatus can result in particles having a median particle diameter d50 of <1.5 μm. The process includes: operating a mill in a milling phase with an operating medium selected from the group consisting of gas, vapor, steam, a gas containing steam and mixtures thereof, and heating a milling chamber in a heat-up phase before the actual operation with the operating medium in such a way that a temperature in the milling chamber, the mill exit or both, is higher than a dew point of the operating medium.

Owner:EVONIK OPERATIONS GMBH

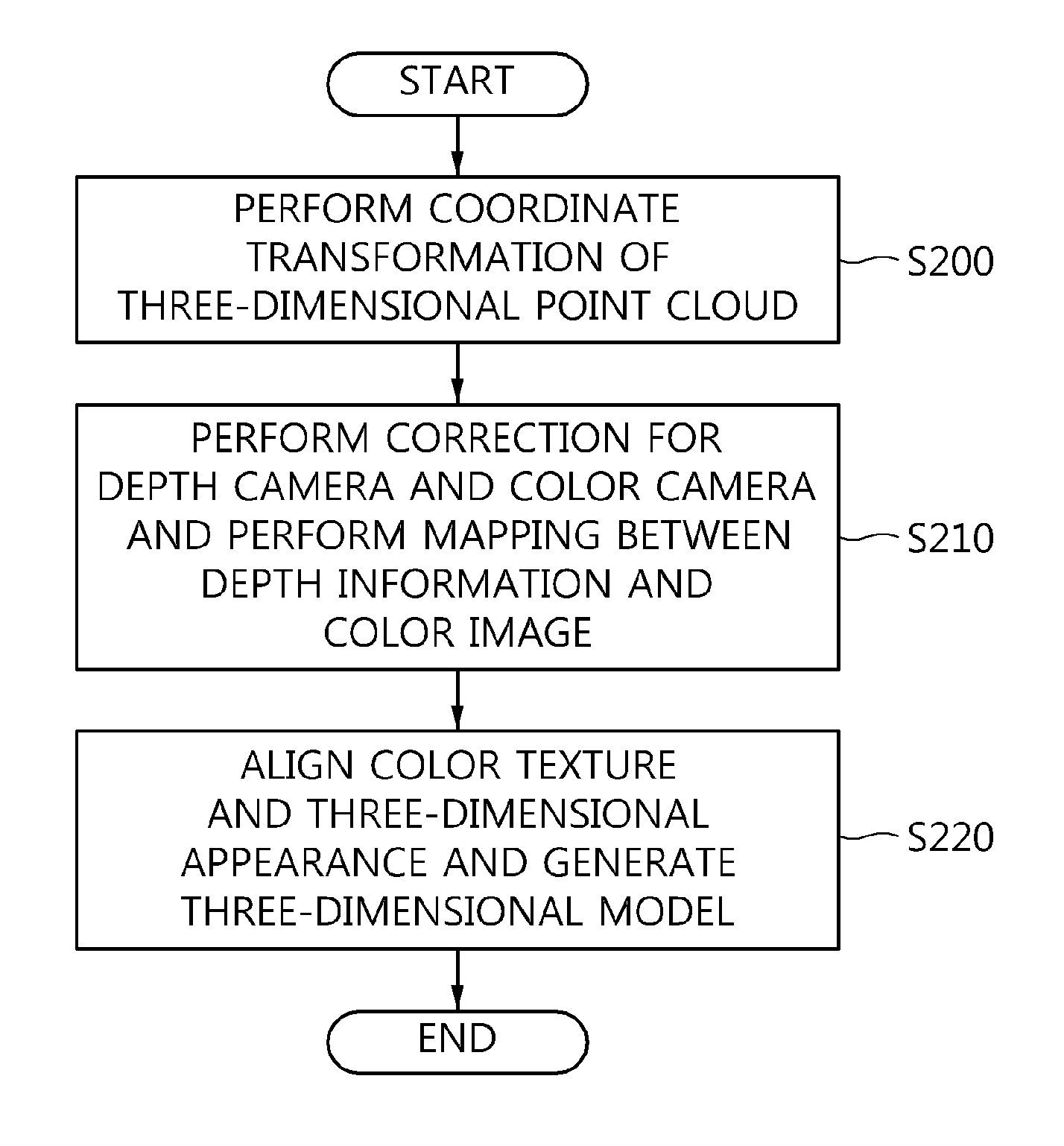

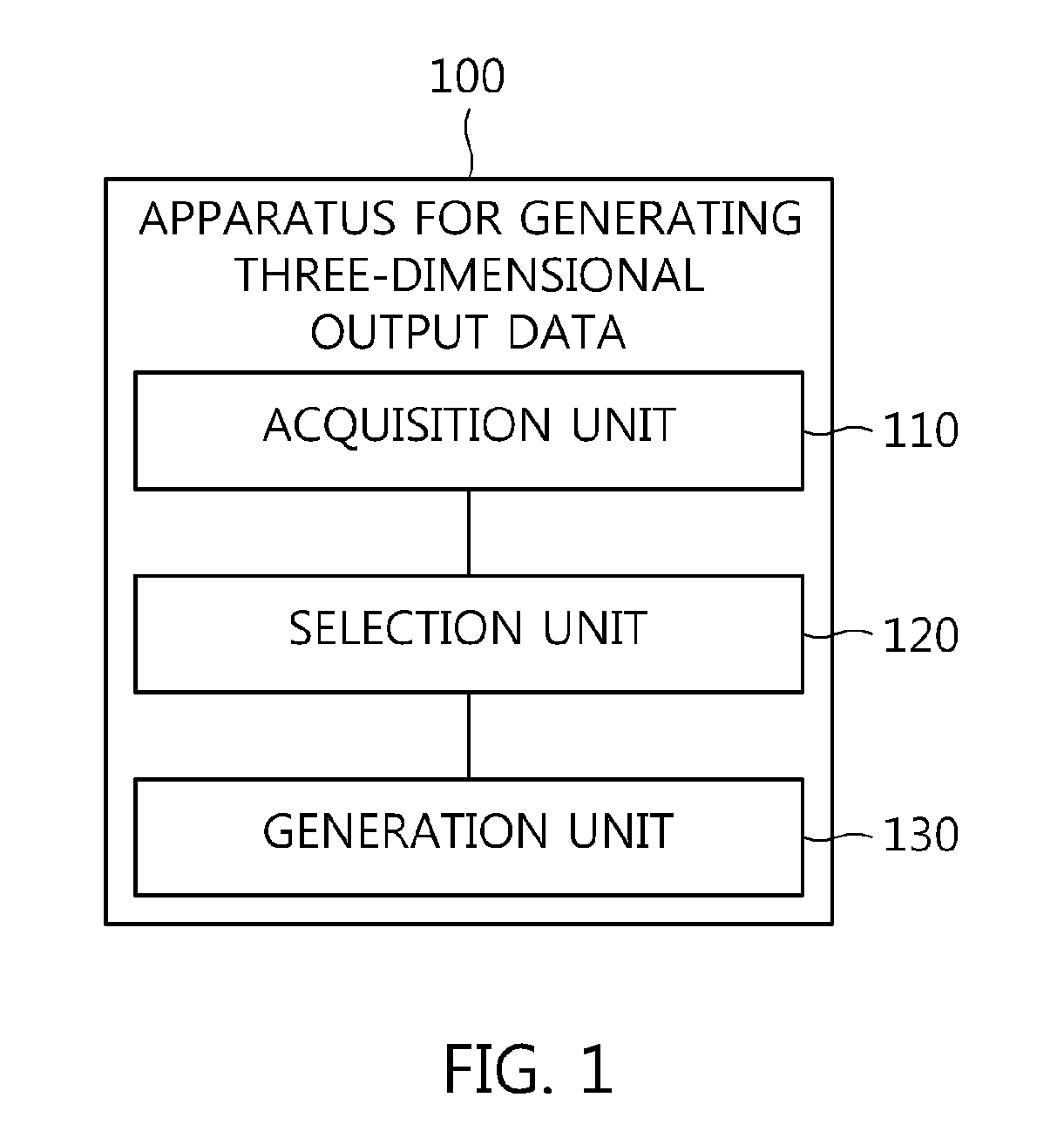

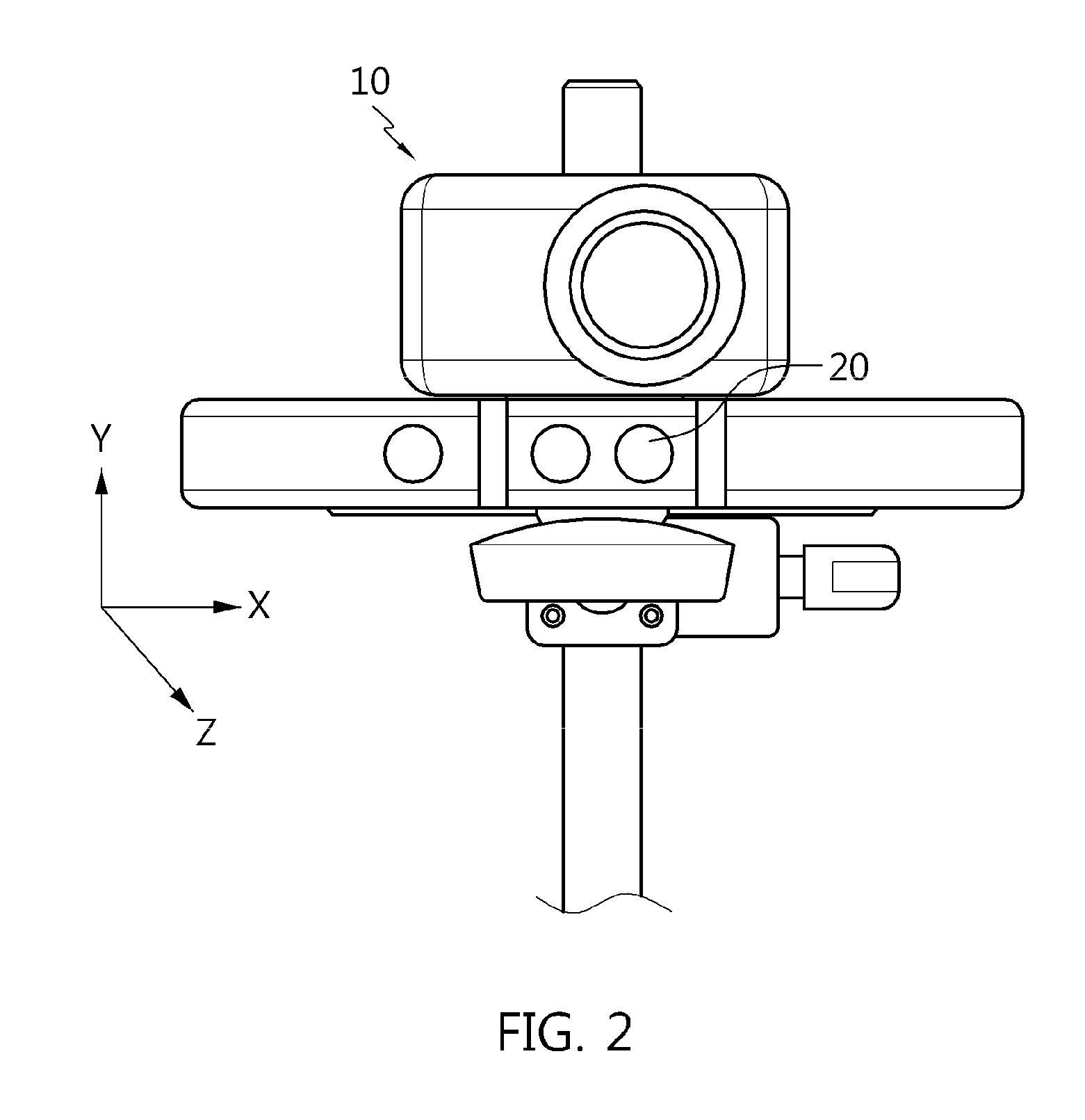

Apparatus and method for generating three-dimensional output data

InactiveUS20150172637A1Process is directionalImage enhancementImage analysisThree dimensional modelColor image

Disclosed are an apparatus and a method for generating three-dimensional output data, in which the appearance or face of a user is easily restored in a three-dimensional manner by using one or a plurality of cameras including a depth sensor, a three-dimensional avatar for an individual, which is produced through three-dimensional model transition, and data capable of being three-dimensionally output, which is generated based on the three-dimensional avatar for an individual. The apparatus includes an acquisition unit that acquires a three-dimensional model based on depth information and a color image from at least one point of view, a selection unit that selects at least one of three-dimensional template models, and a generation unit that modifies at least one of a plurality of three-dimensional template models selected by the selection unit and generates three-dimensional output data based on the three-dimensional model acquired by the acquisition unit.

Owner:ELECTRONICS & TELECOMM RES INST

Amorphous submicron particles

ActiveUS7850102B2Increased space-time yieldProcess is directionalThin material handlingGrain millingEngineeringMaterials science

Owner:EVONIK OPERATIONS GMBH

Method for producing a motor vehicle component and motor vehicle component

InactiveUS20130160906A1Less heatPrevents premature scalingFurnace typesHeat treatment furnacesDuctilityHigh intensity

A method for producing a motor vehicle component having two regions, with different strength is disclosed. A first one of the two regions has a high strength and a second one of the two regions has a higher ductility and lower strength relative to the first region. In a motor vehicle component produced with the method, the first region has a strength between 1400 and 1600 MPa at a breaking elongation A5>13% and the second region has a tensile strength between 950 and 1050 MPa at a breaking elongation A5>16%.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

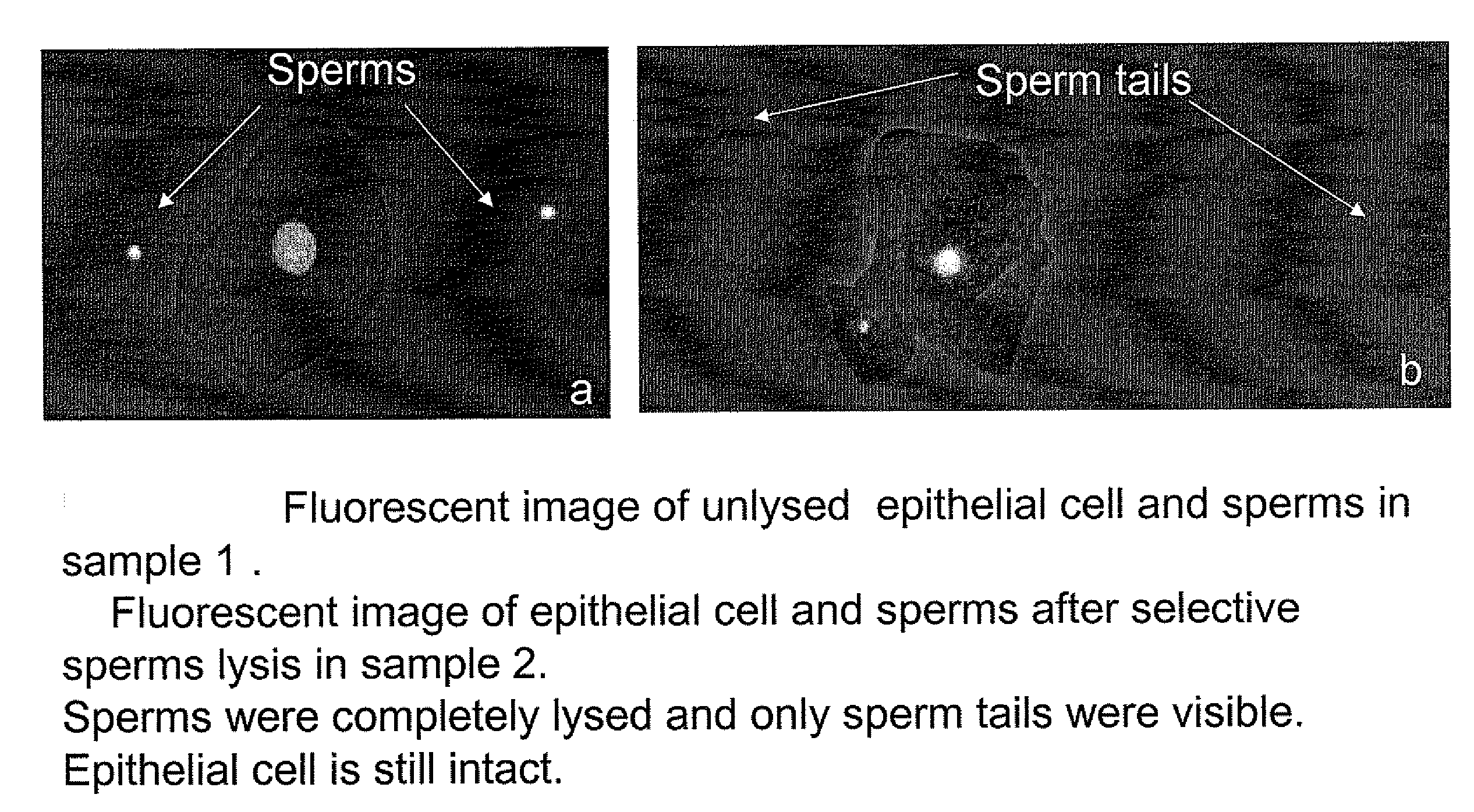

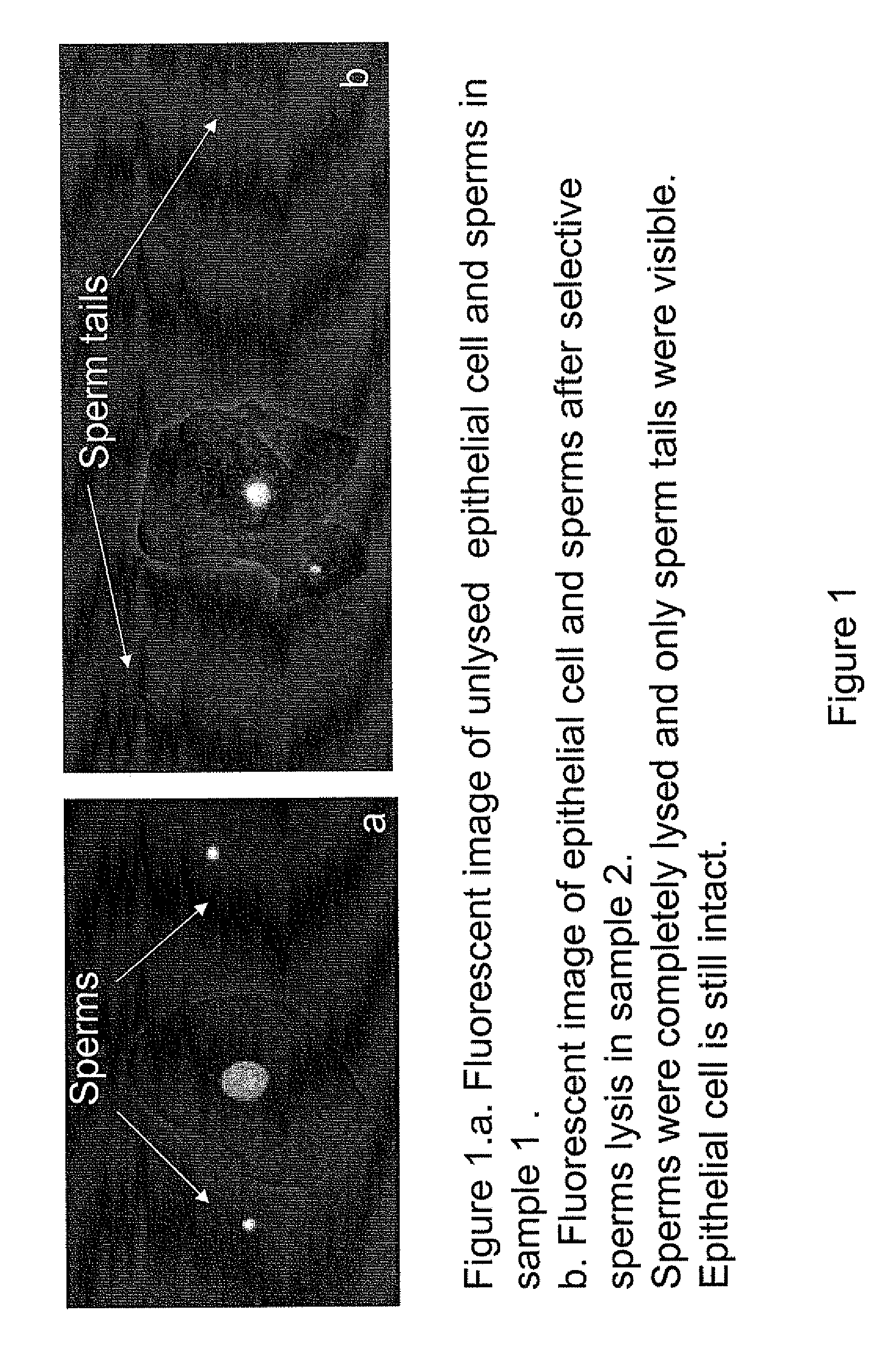

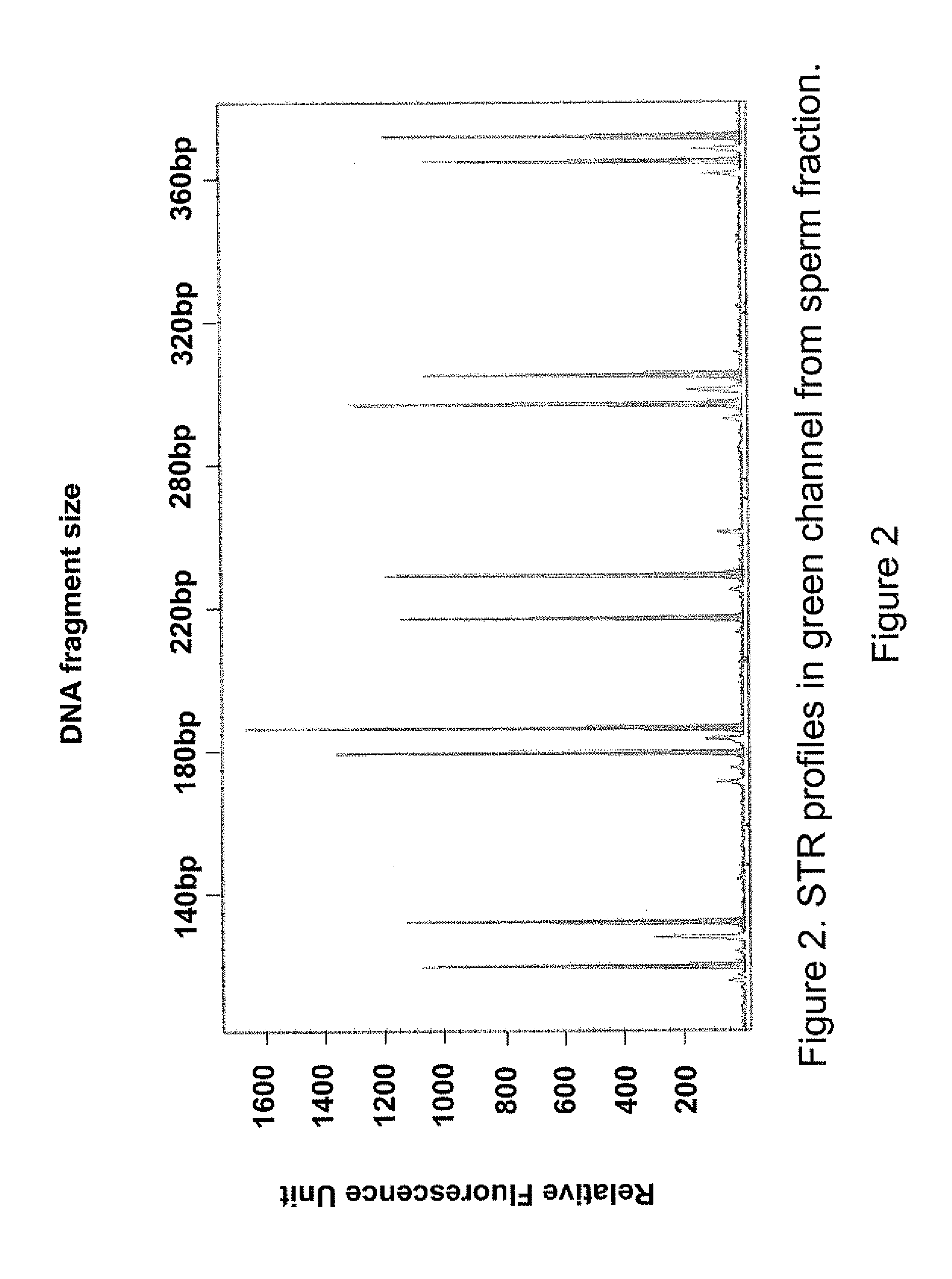

Selective Lysis of Sperm Cells

InactiveUS20080176320A1Reduce processing timeSimple working processSamplingMicrobiological testing/measurementMixed cellLysis

The teaching provides a method for selectively lysing sperm cells in a mixed cell sample, particularly in the field of forensic sciences. Reagents and kits for carrying out the methods are also provided.

Owner:APPL BIOSYSTEMS INC

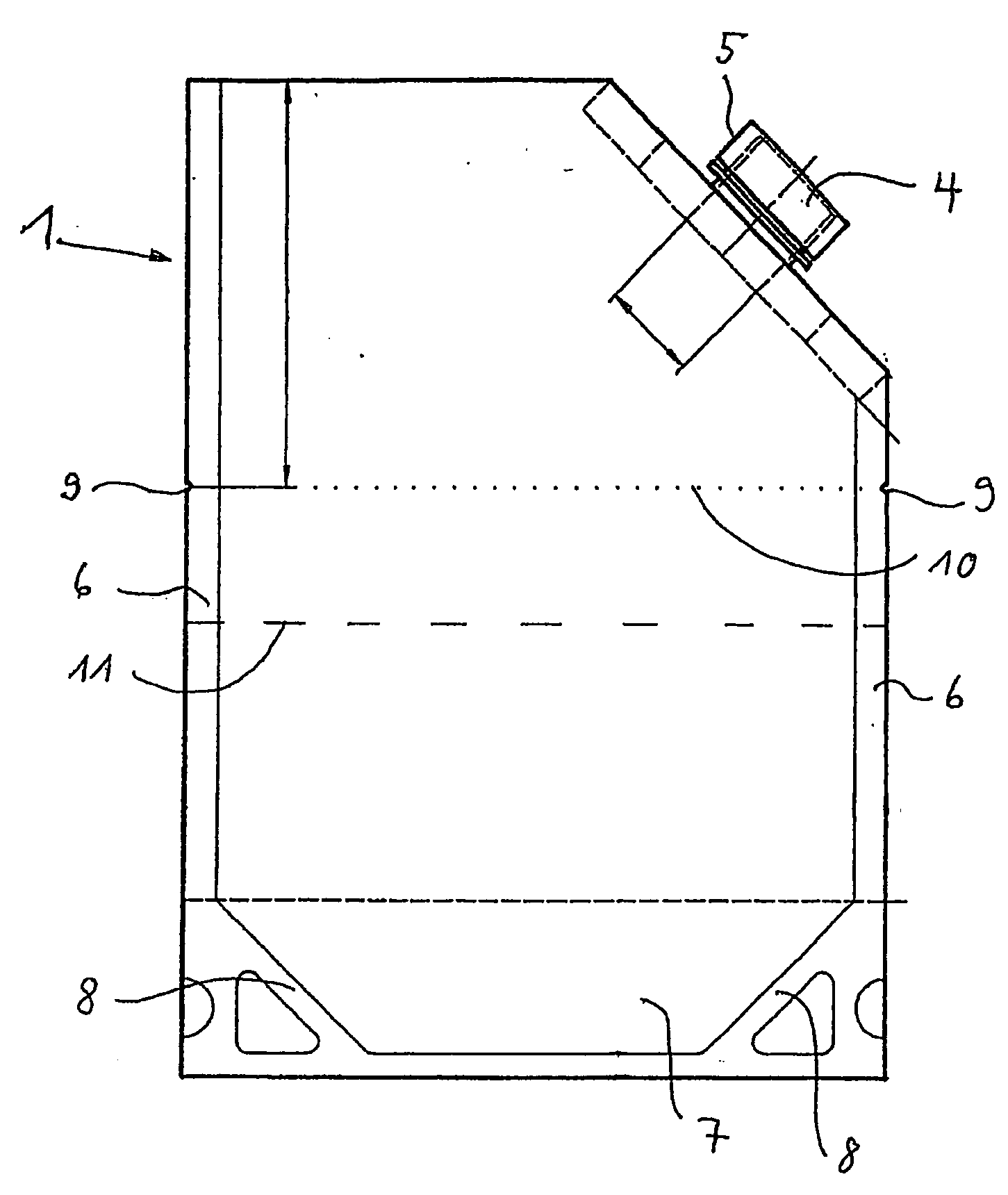

Method for processing a material and packing container for carrying out this method

ActiveUS8251568B2Simple processAvoid disadvantagesMixing methodsMixer accessoriesEngineeringMechanical engineering

Owner:SIKA TECH AG

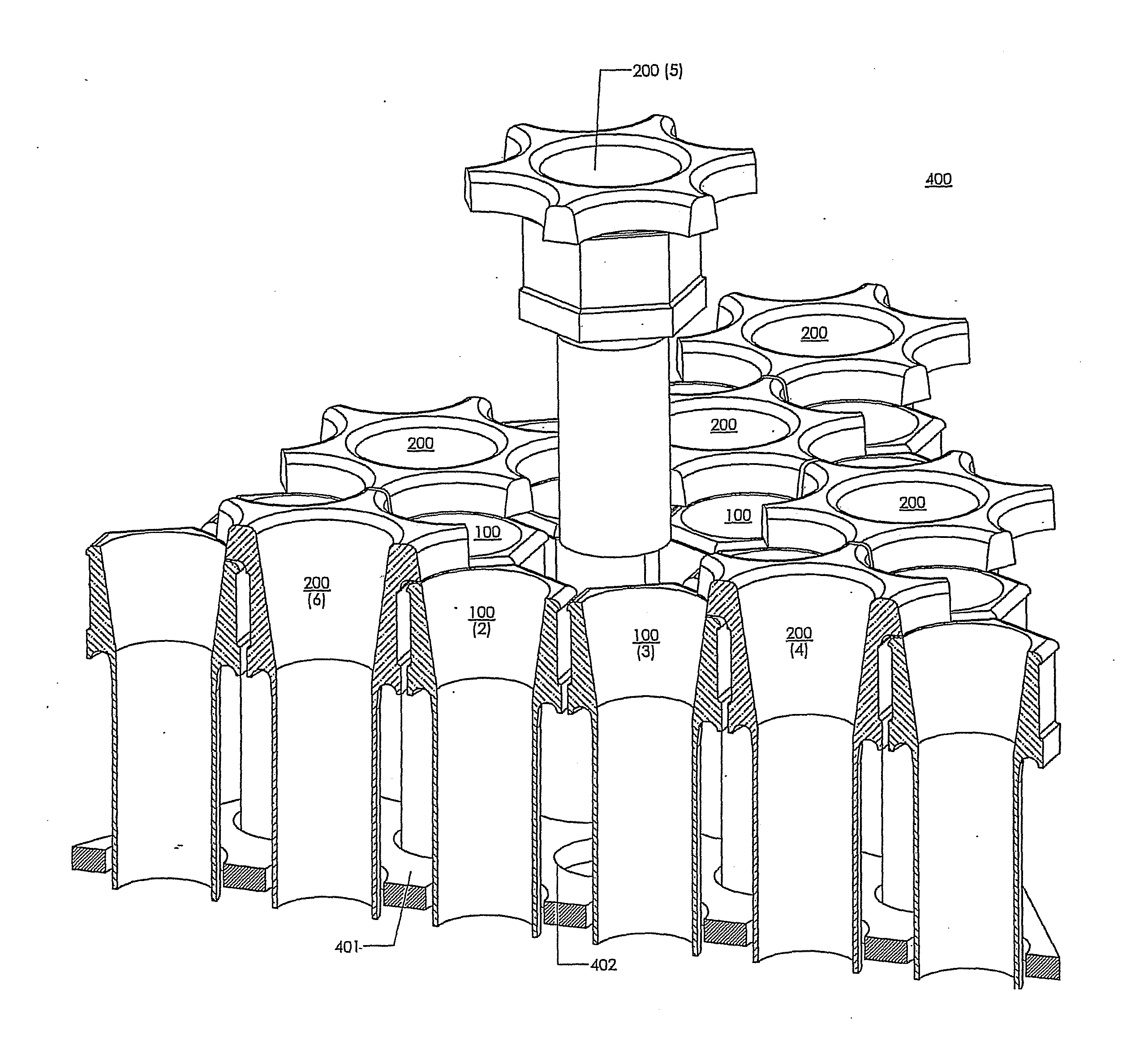

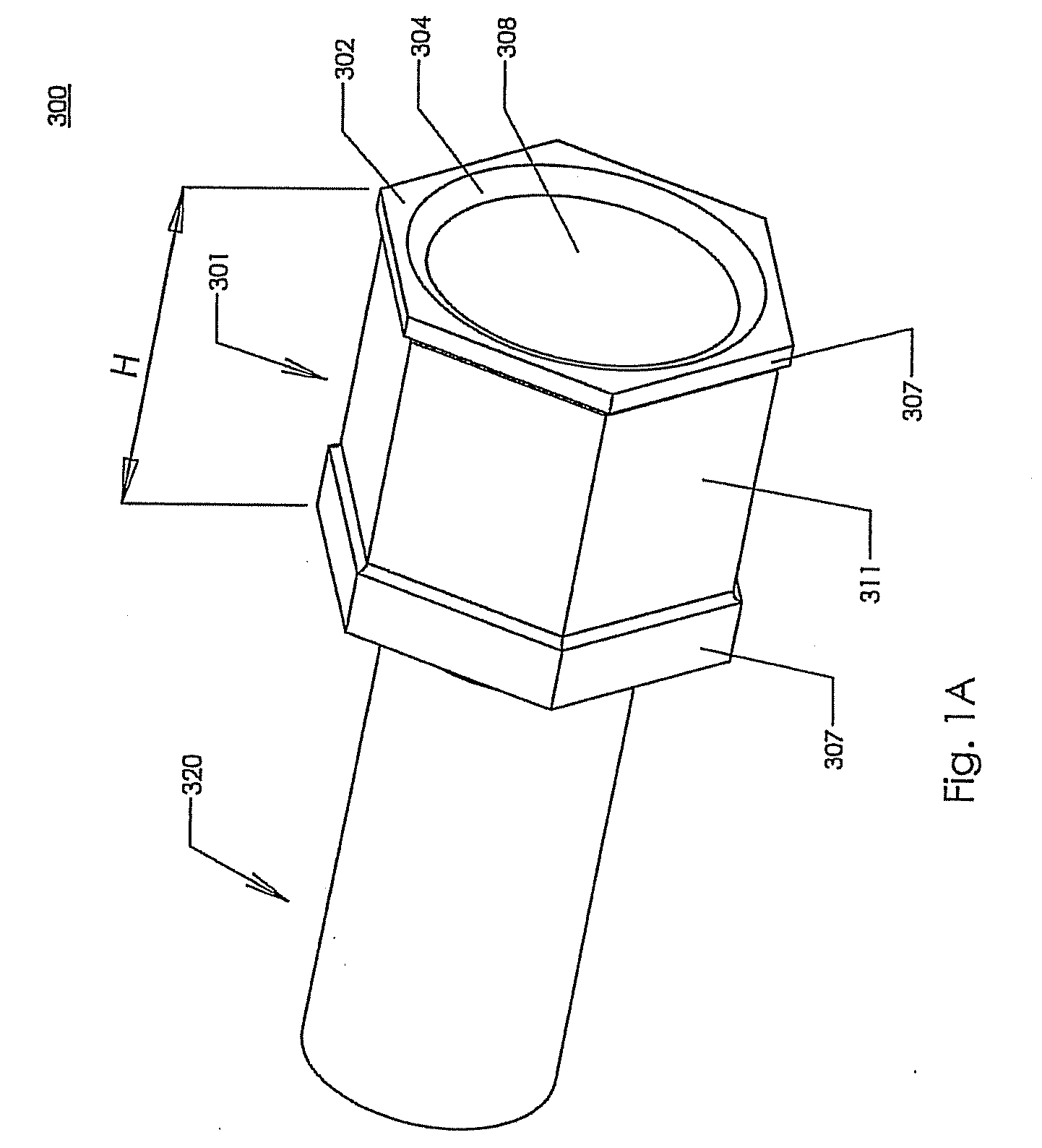

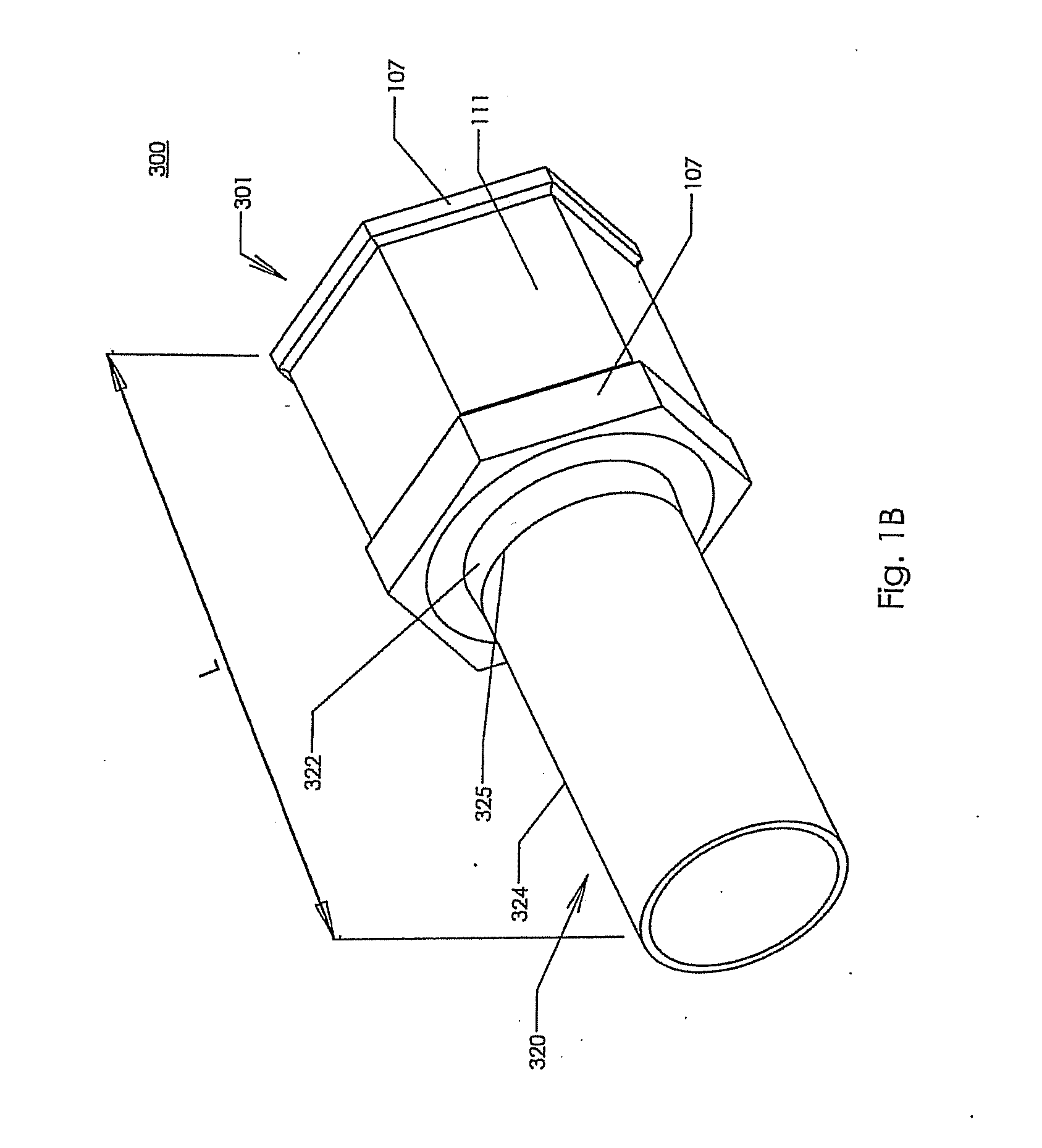

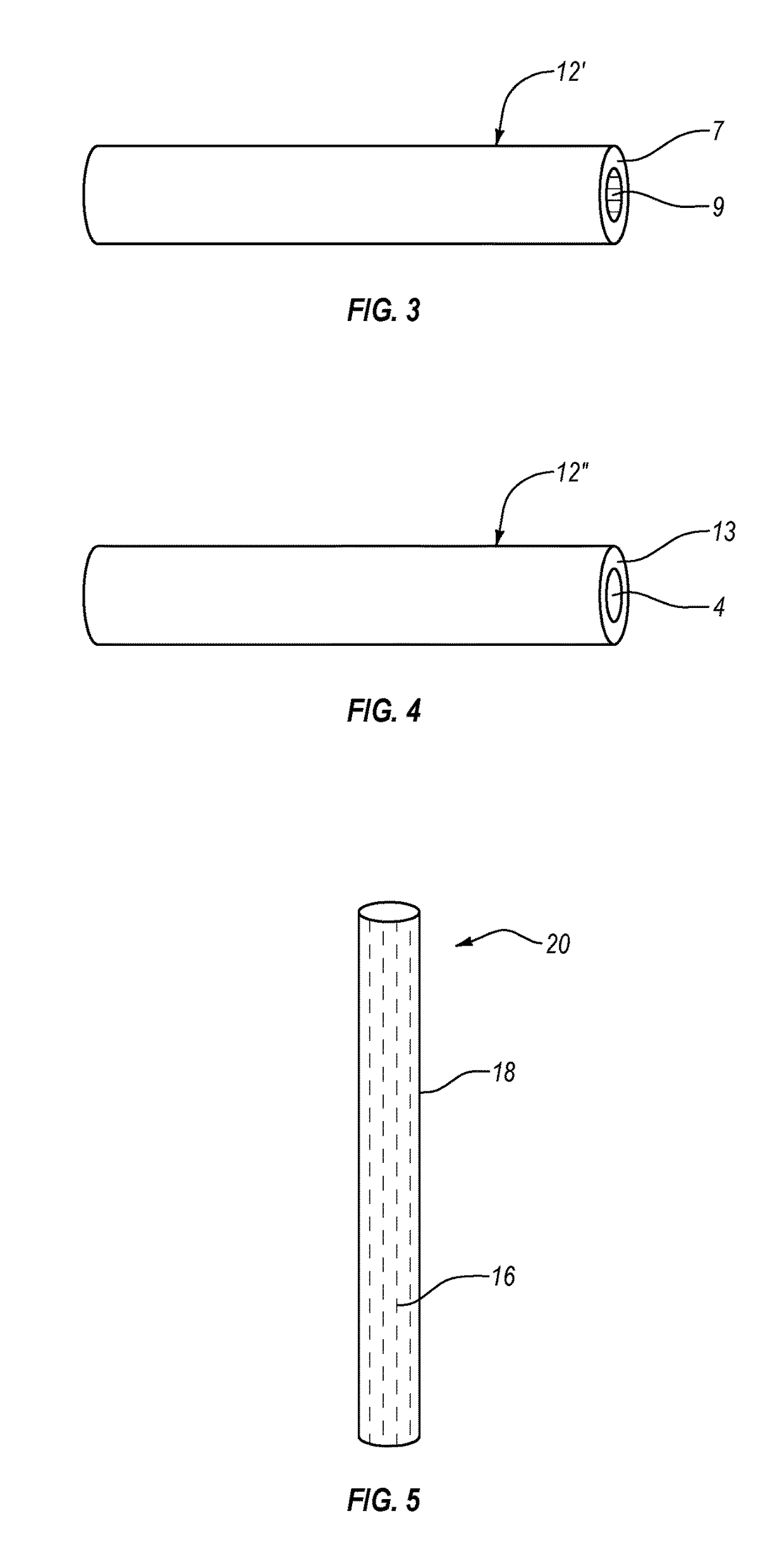

Ceramic ferrules and ceramic ferrule array including same for tube pitch variability tolerant process heat boiler system

InactiveUS20110024094A1Preserving functionProcess is directionalCorrosion preventionStationary tubular conduit assembliesEngineeringMechanical engineering

A cover ferrule is provided, including a hexagonally shaped head portion, a joint shield portion provided at an upper surface of the head portion, and a stein portion extending downwardly from a first end proximate a lower surface of the head portion to an opposed second end thereof. The joint shield portion includes a central opening, coaxially aligned with respect to central openings of the head and stem portions and with a central axis of the cover ferrule, and a plurality of extension members extending radially outwardly with respect to the central axis of the cover ferrule and defining arc portions connecting respectively adjacent extension members of the joint shield portion.

Owner:BLASCH PRECISION CERAMICS

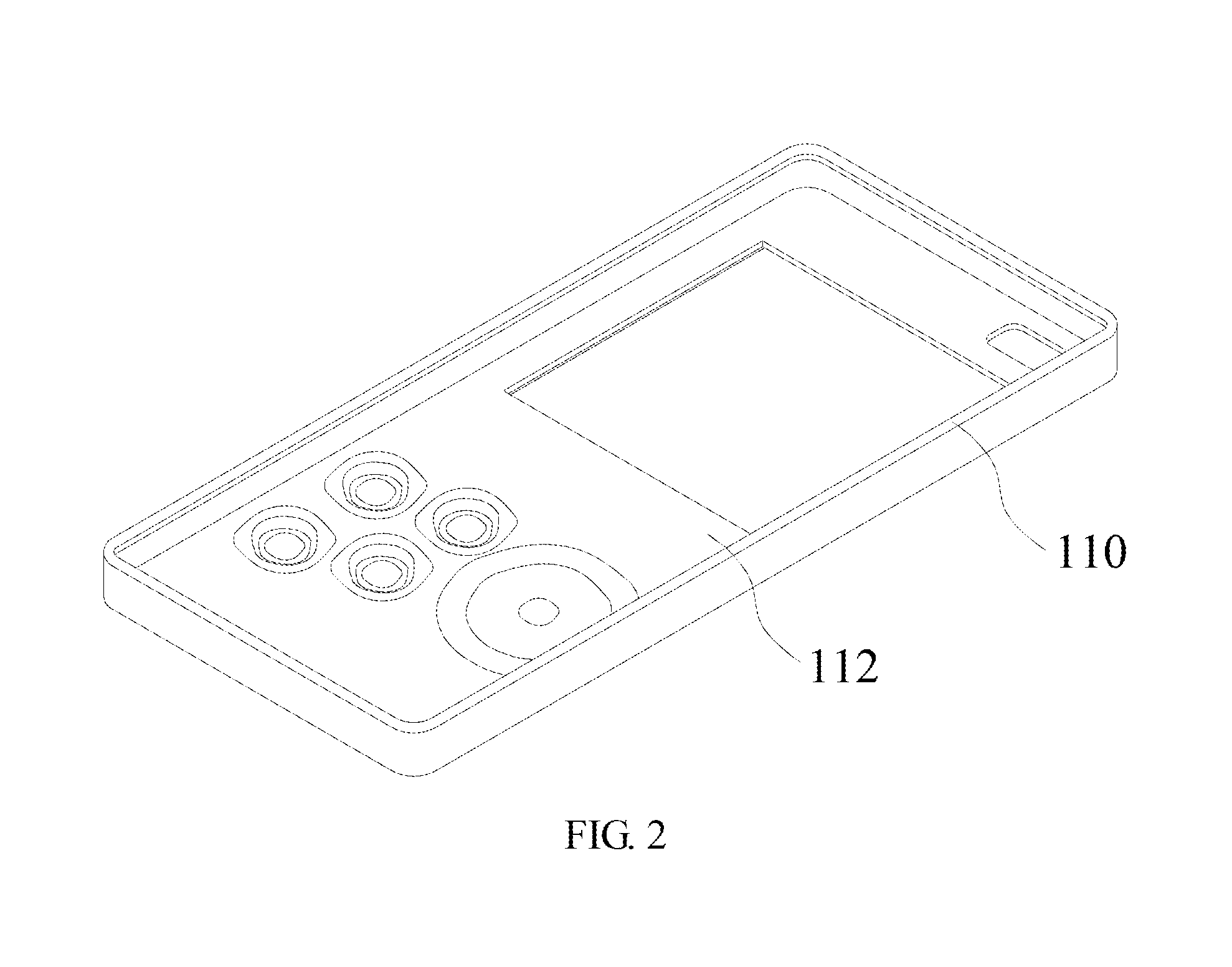

Smartphone cover module with embedded game controller

ActiveUS9281859B1Easy to carryImprove the sense of operationSubstation equipmentVideo gamesEngineeringElectrical and Electronics engineering

Disclosed herein is a smartphone cover module with an embedded game controller. The smartphone cover module includes a smartphone cover provided to protect a surface of a smartphone, with a through hole formed to expose the surface of the smartphone. A direction button is formed on the through hole of the smartphone cover and made of a conductive material. A direction-change support is formed into a shape of a pole that extends downwards from a central portion of a lower surface of the direction button, and spaces the direction button apart from the surface of the smartphone. A button restoring pad connects the direction button or the direction-change support to the smartphone cover, and is formed into a shape of a pad made of an elastic material, thus restoring the direction button from an inclined state to an original state.

Owner:LEE EUN ML

Planar composite material

A planar composite material comprises an UD fiber layer A made of discrete reinforcing fiber rovings and a fiber nonwoven layer B made of a thermoplastic nonwoven which may contain reinforcing fibers, wherein the layers A and B are needled to each other.

Owner:QUADRANT PLASTIC COMPOSITES

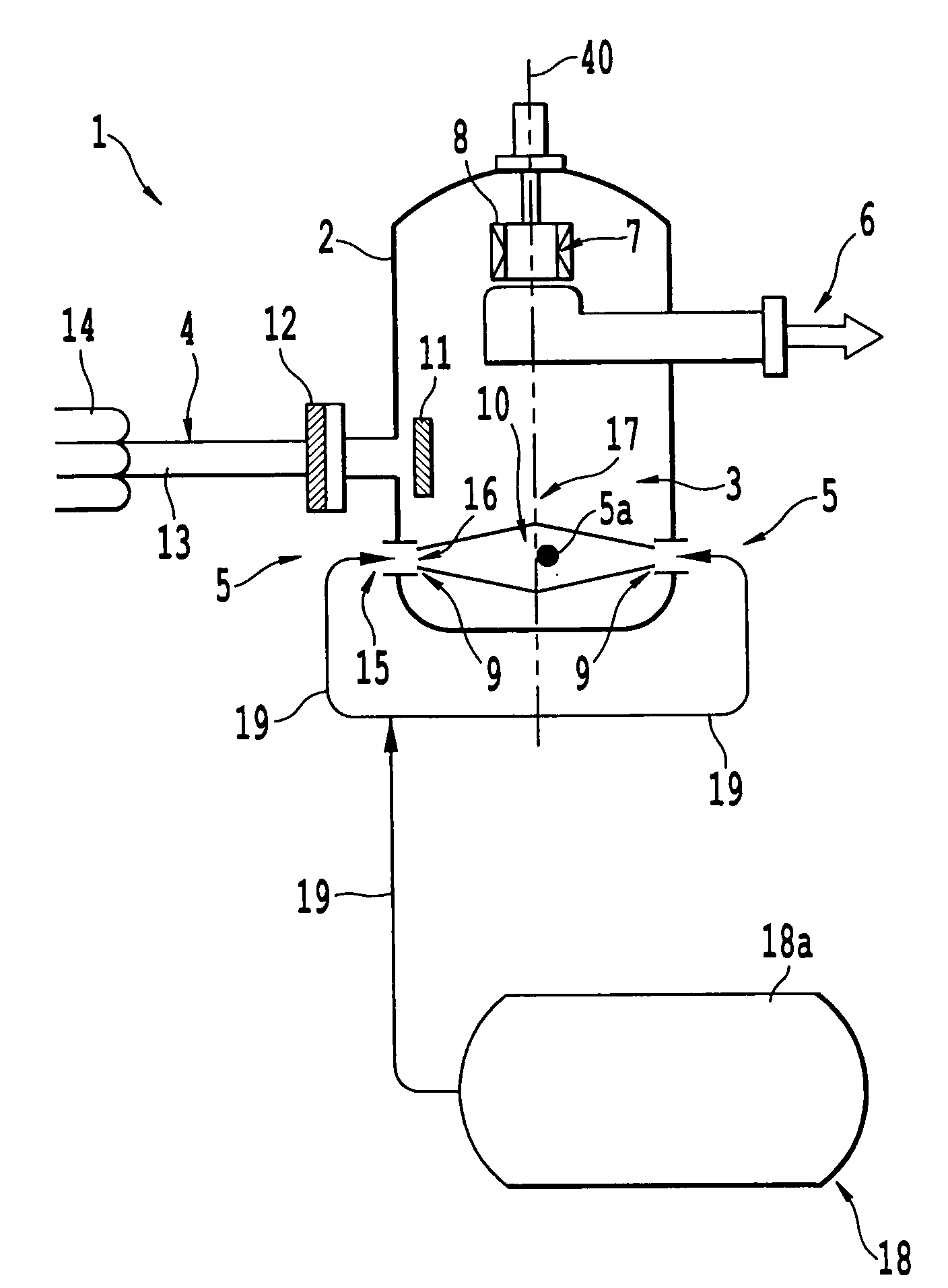

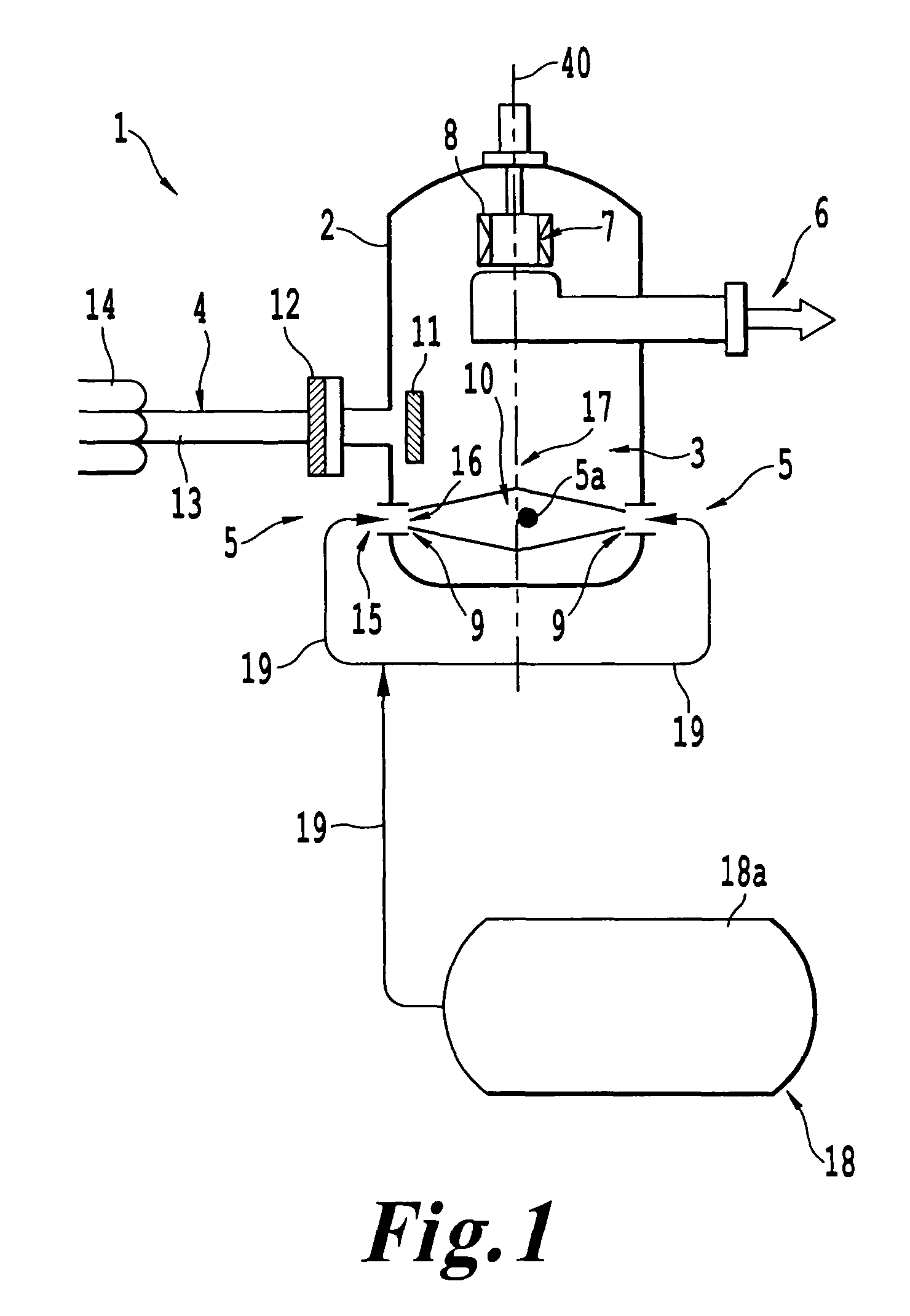

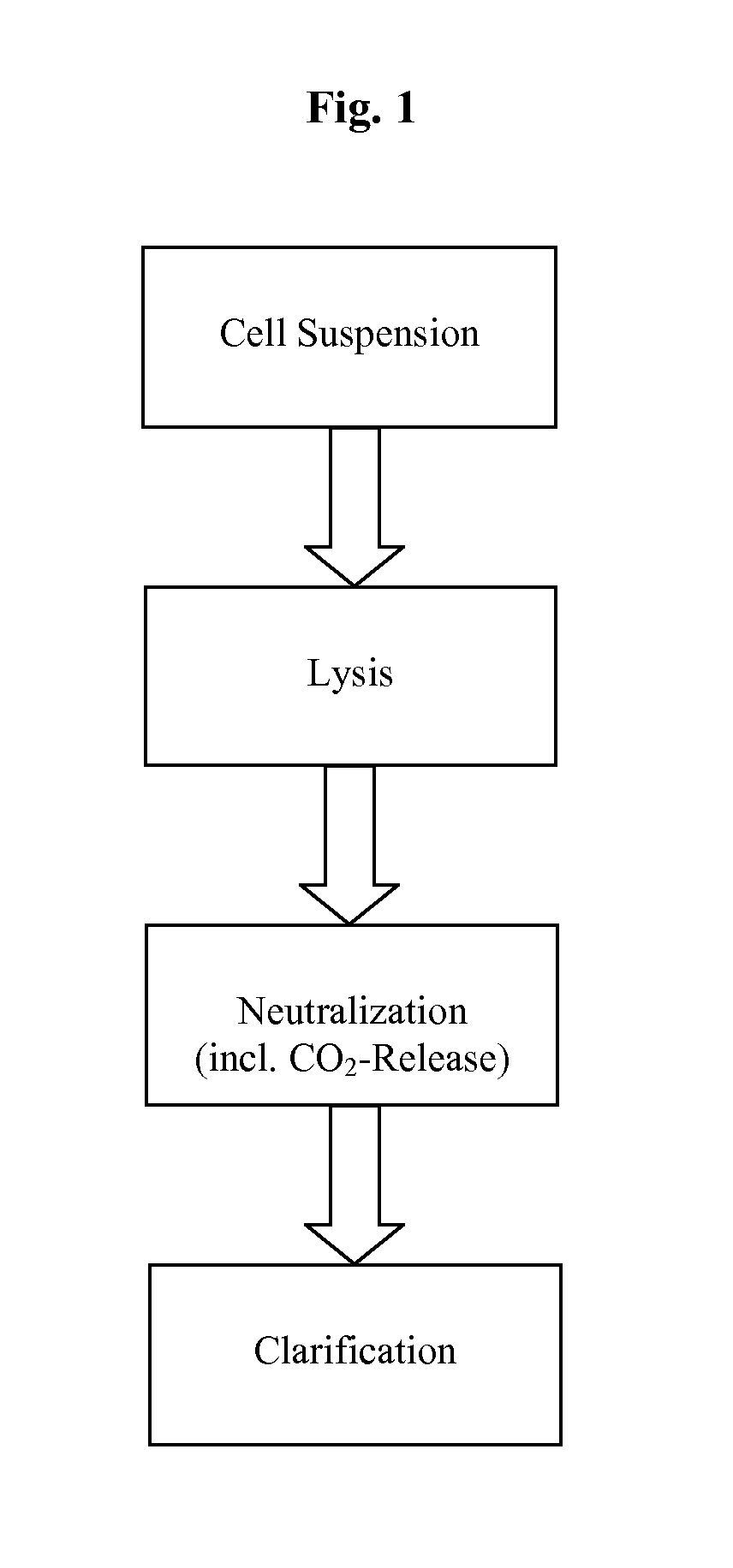

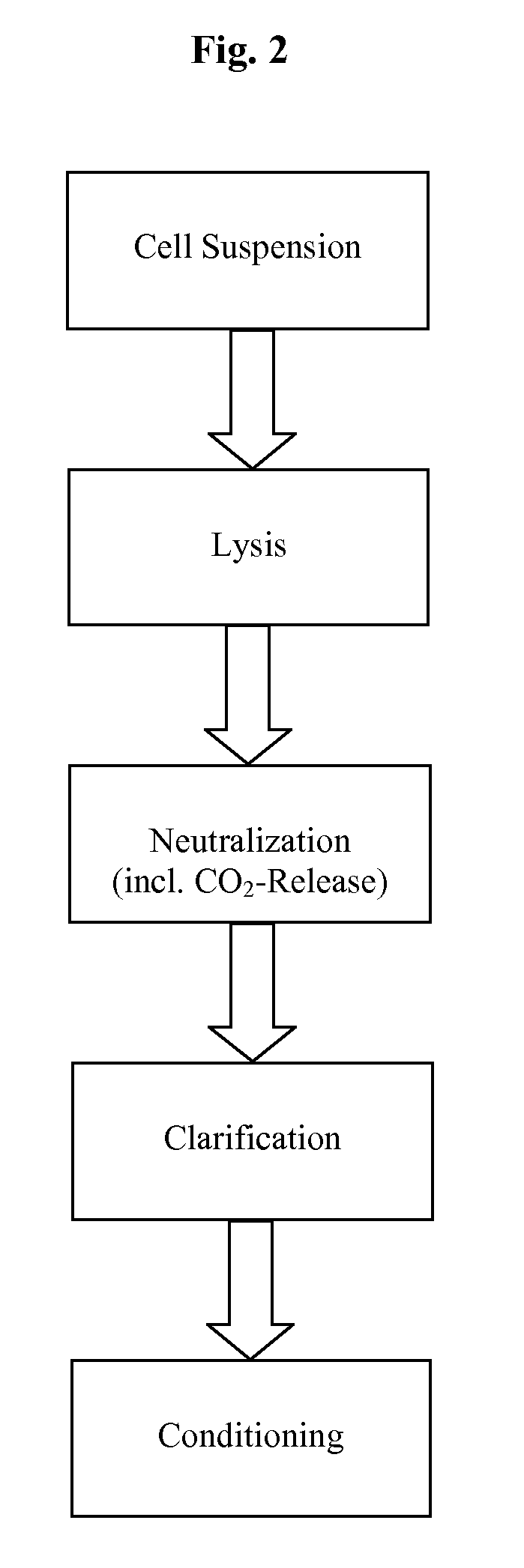

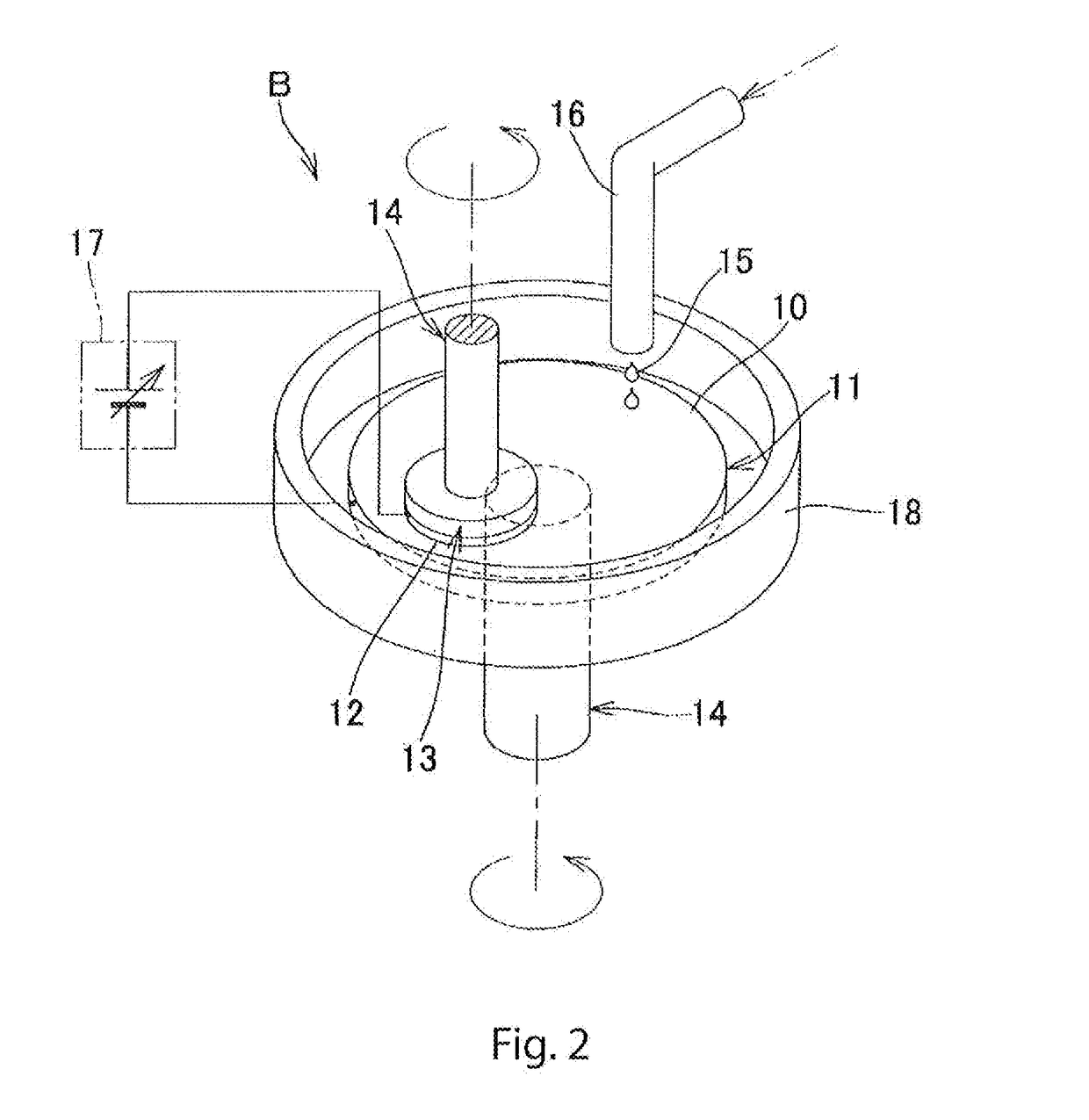

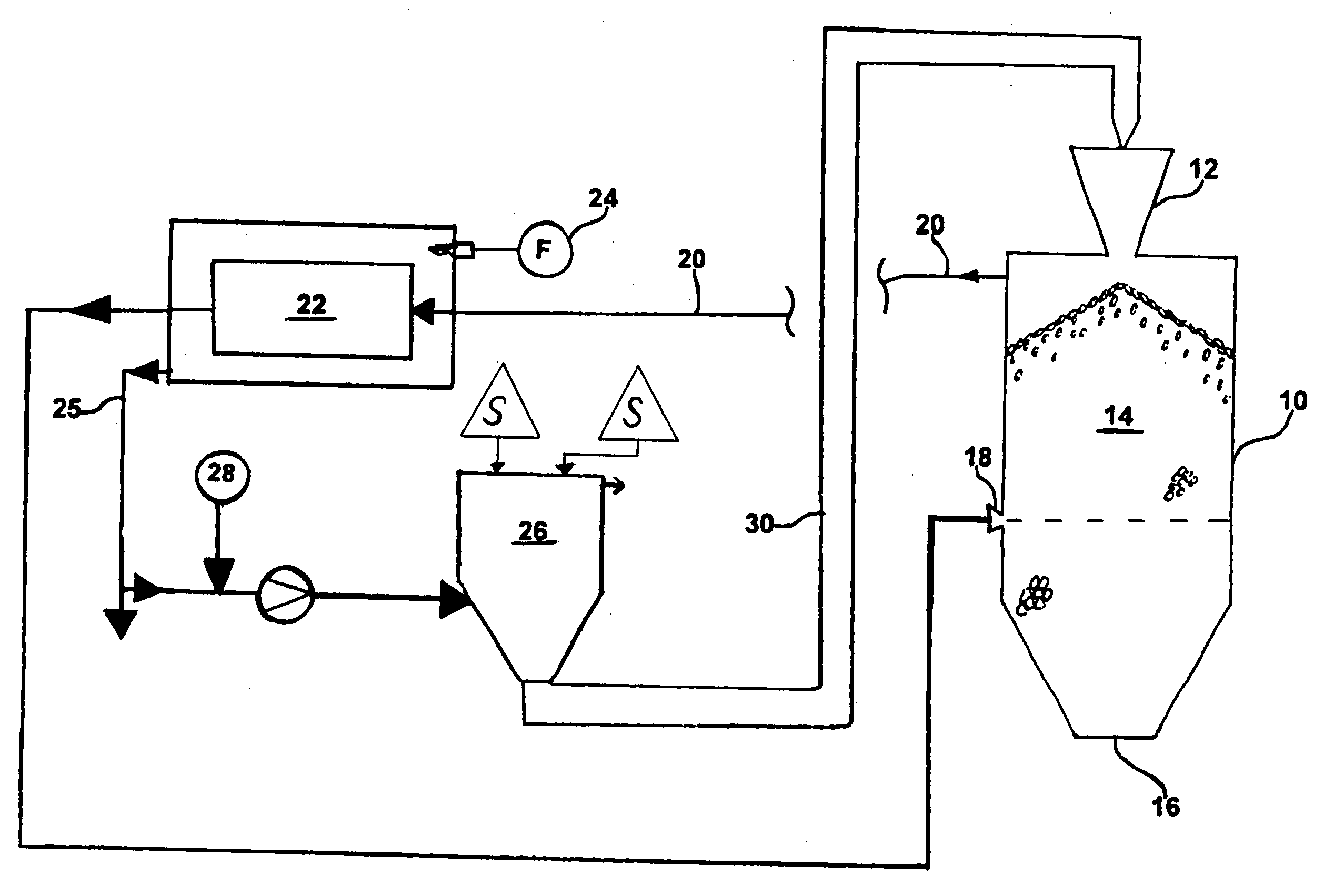

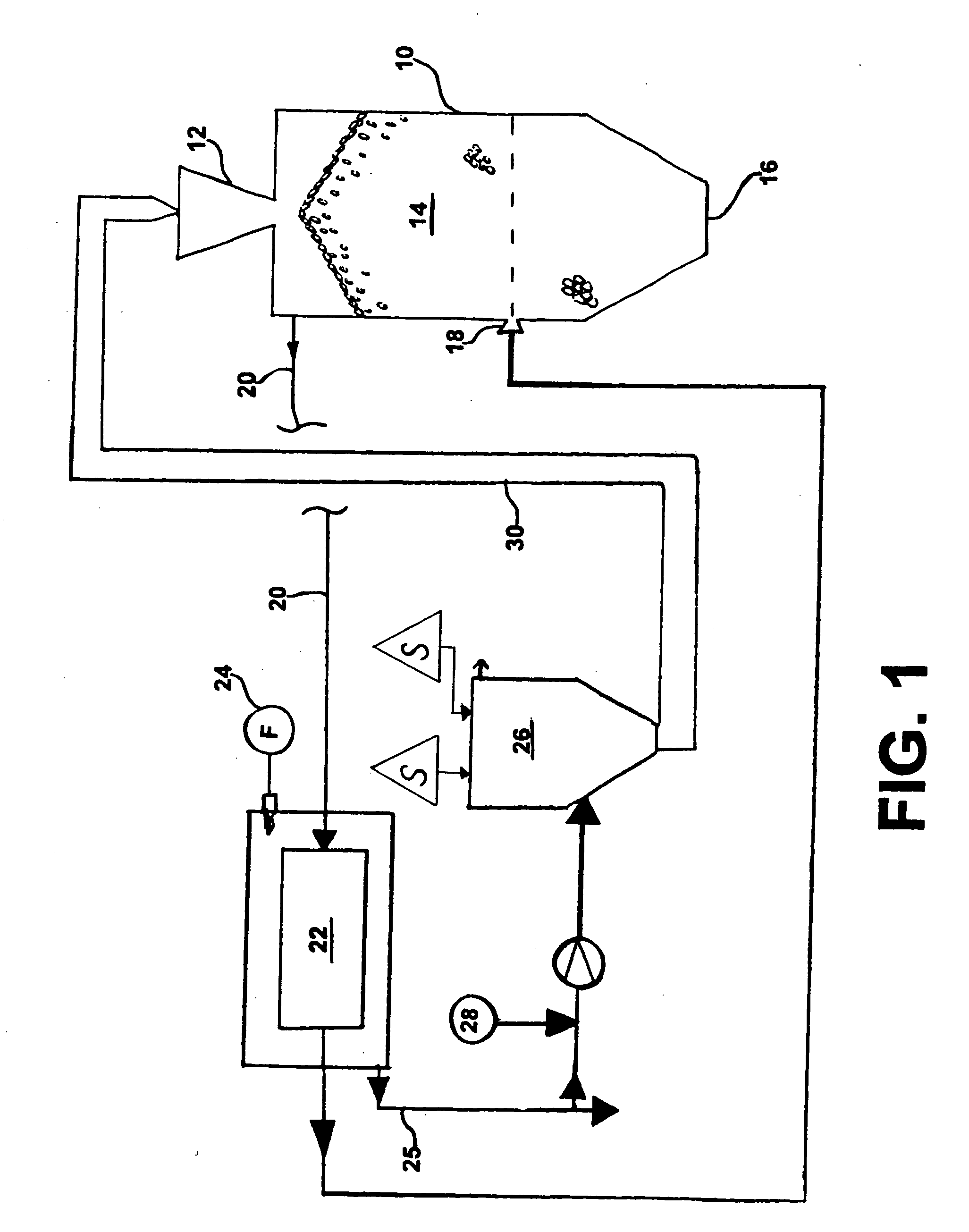

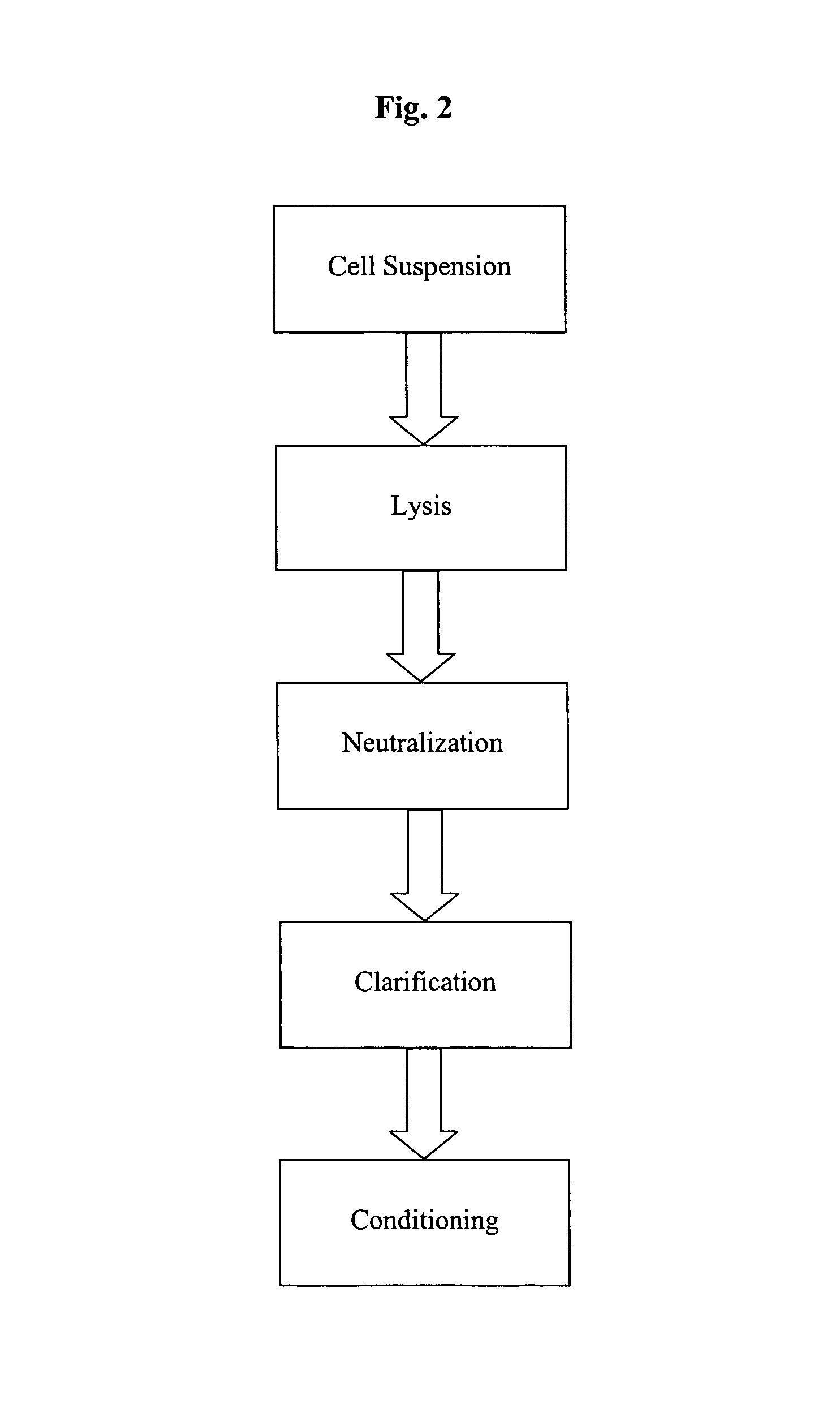

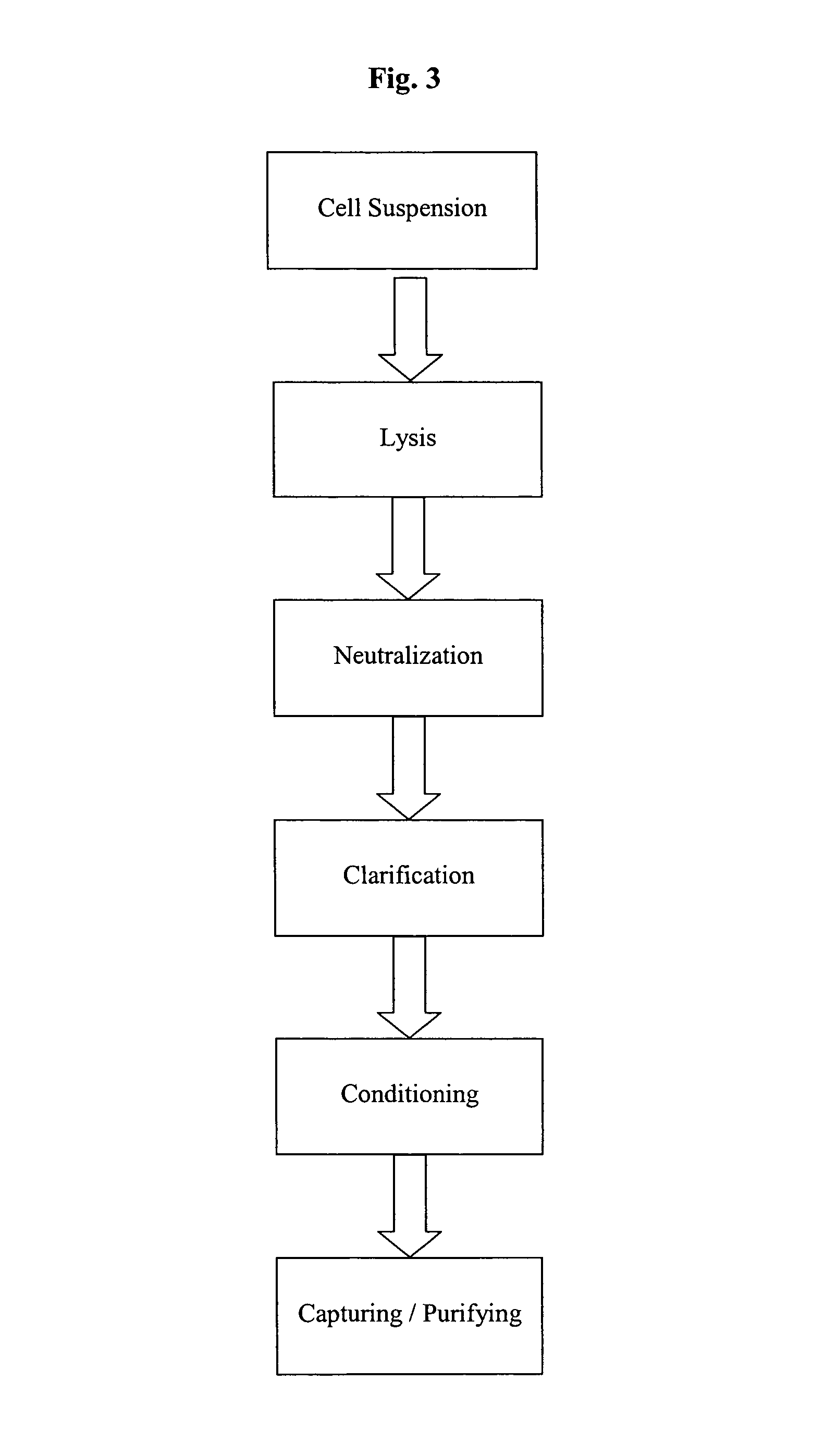

Methods and devices for producing biomolecules

InactiveUS20110124101A1Process is directionalSugar derivativesLoose filtering material filtersLysisPharmaceutical drug

A scalable process and device for producing a bio molecule, in particular pharmaceutical grade plasmid DNA is described. The process includes the steps of alkaline lysis, neutralization and clarification and can be further extended. For separating the lysate and the precipitate an improved floatation method is disclosed. This method is based on attachment of CO2 bubbles on the precipitate floe. The CO2 is released from a carbonate salt during or after neutralization (acidification). The method of the invention is preferably carried out in an automated continuous mode applying devices for lysis and neutralization and a novel device for completely continuous clarification (separation of floes and clarified lysate).

Owner:BOEHRINGER INGELHEIM RCV GMBH & CO KG

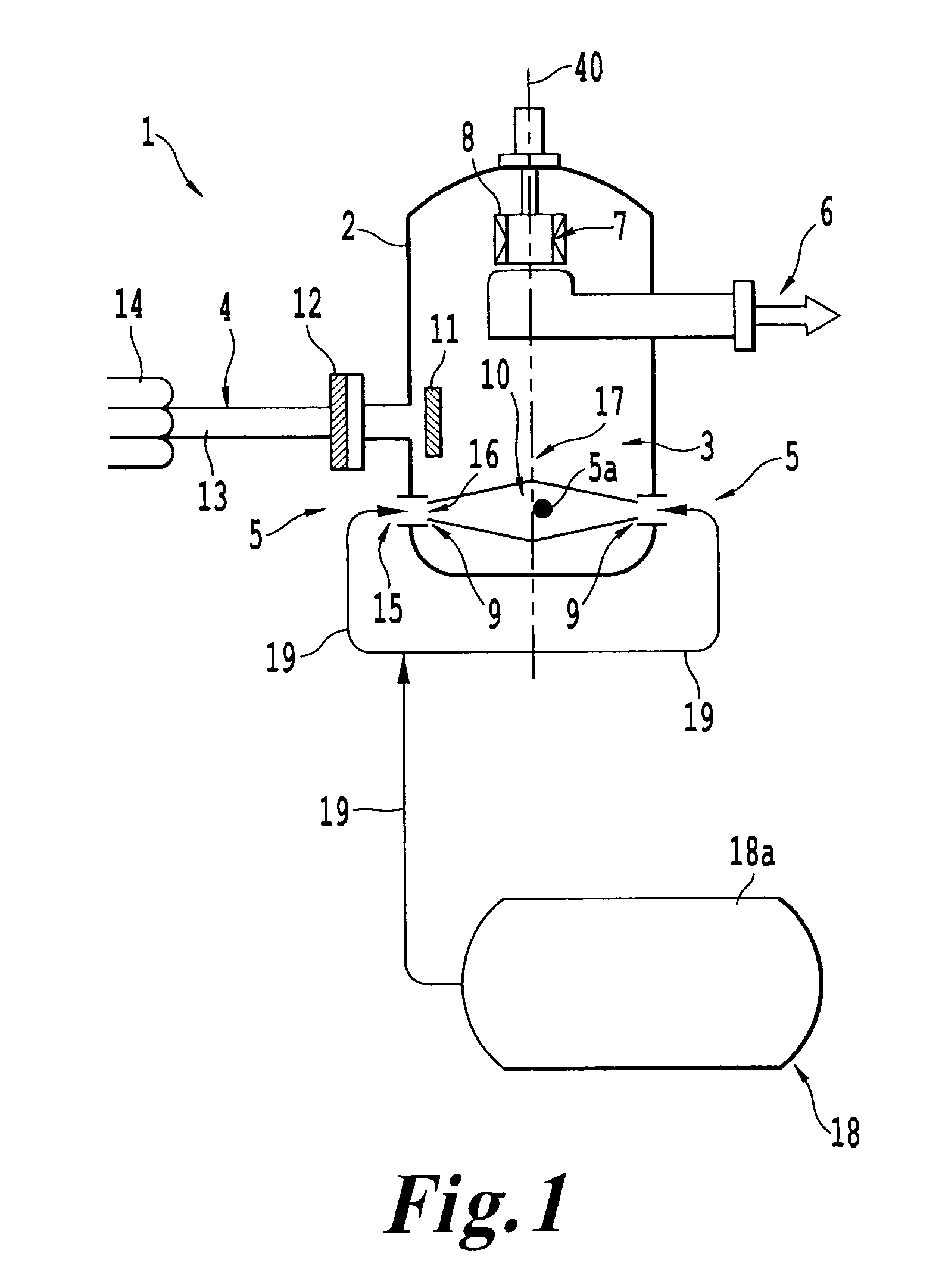

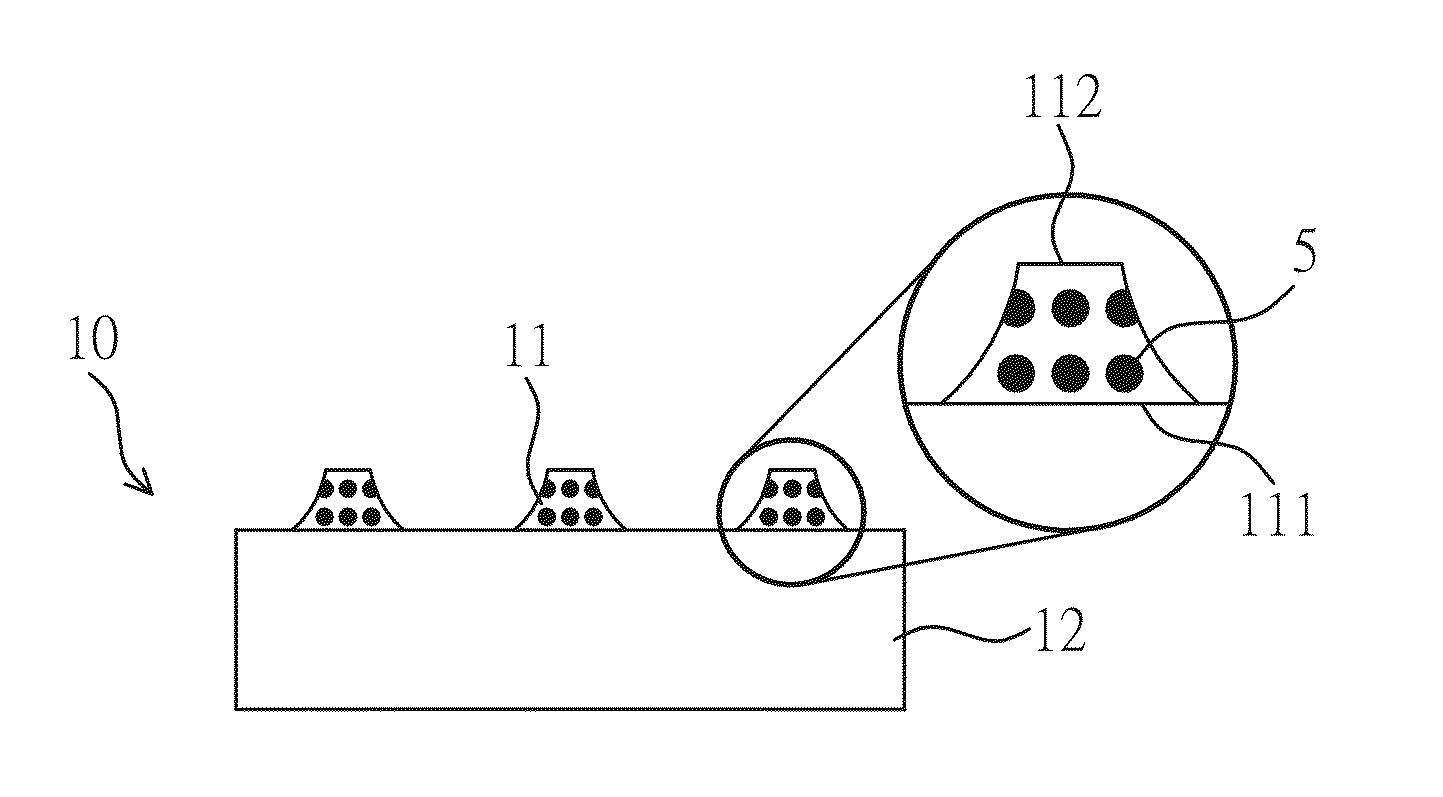

Method for processing wide-bandgap semiconductor substrate and apparatus therefor

ActiveUS20170069506A1Promote hydrolysisGood roomSemiconductor/solid-state device manufacturingSemiconductor devicesSurface finishEngineering

There are provided a processing method for a wide-bandgap semiconductor substrate and an apparatus therefor that use no abrasives or no abrasive grains, or no solution having a large environmental burden at all, can process a single crystal, which is SiC, GaN, AlGaN, or AlN, at a variety of processing speed, can obtain a surface of higher quality than the quality of a surface finished by CMP, and also have an excellent compatibility with a clean room. A catalytic substance having a function of promoting the direct hydrolysis of a work piece (5) or promoting the hydrolysis of an oxide film on the surface of the work piece is used as a processing reference plane (3). In the presence of water (1), the work piece is brought into contact with or extremely close to the processing reference plane at a predetermined pressure.

Owner:OSAKA UNIV +1

Method for processing a material and packing container for carrying out this method

InactiveUS20080142085A1Simple processAvoid disadvantagesMixing methodsPipeline systemsMechanical engineering

A method for processing a material, which is stored in a flexible packing container, comprises the following steps: At least one material or material mixture is fed to a first material or material mixture already located inside the packing container via a filling opening situated on the packing container; the filling opening is closed; the materials inside the packing container are mixed; a portion of the packing container is detached, and; the material mixture is processed via the resulting opening in the package container.

Owner:SIKA TECH AG

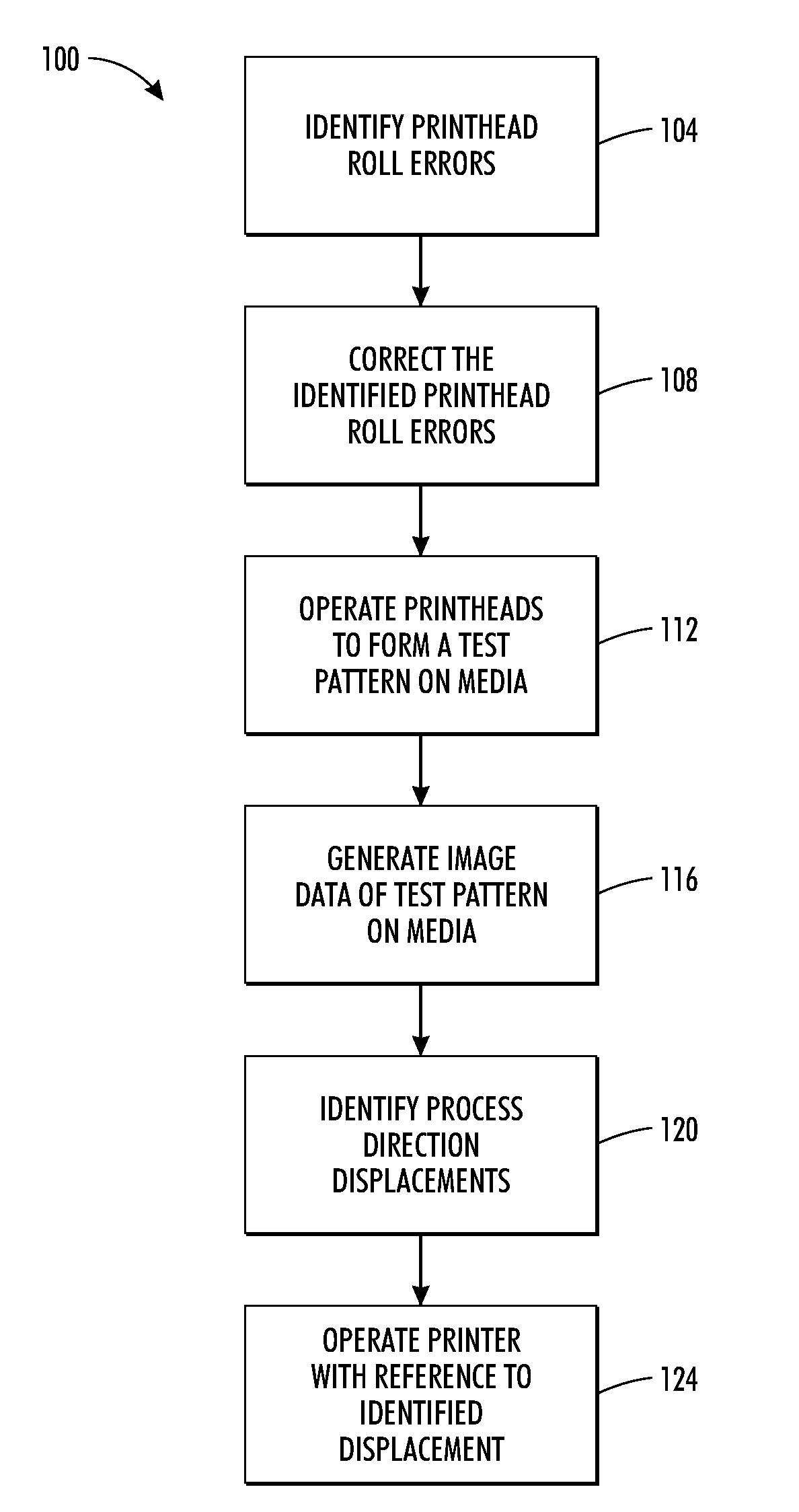

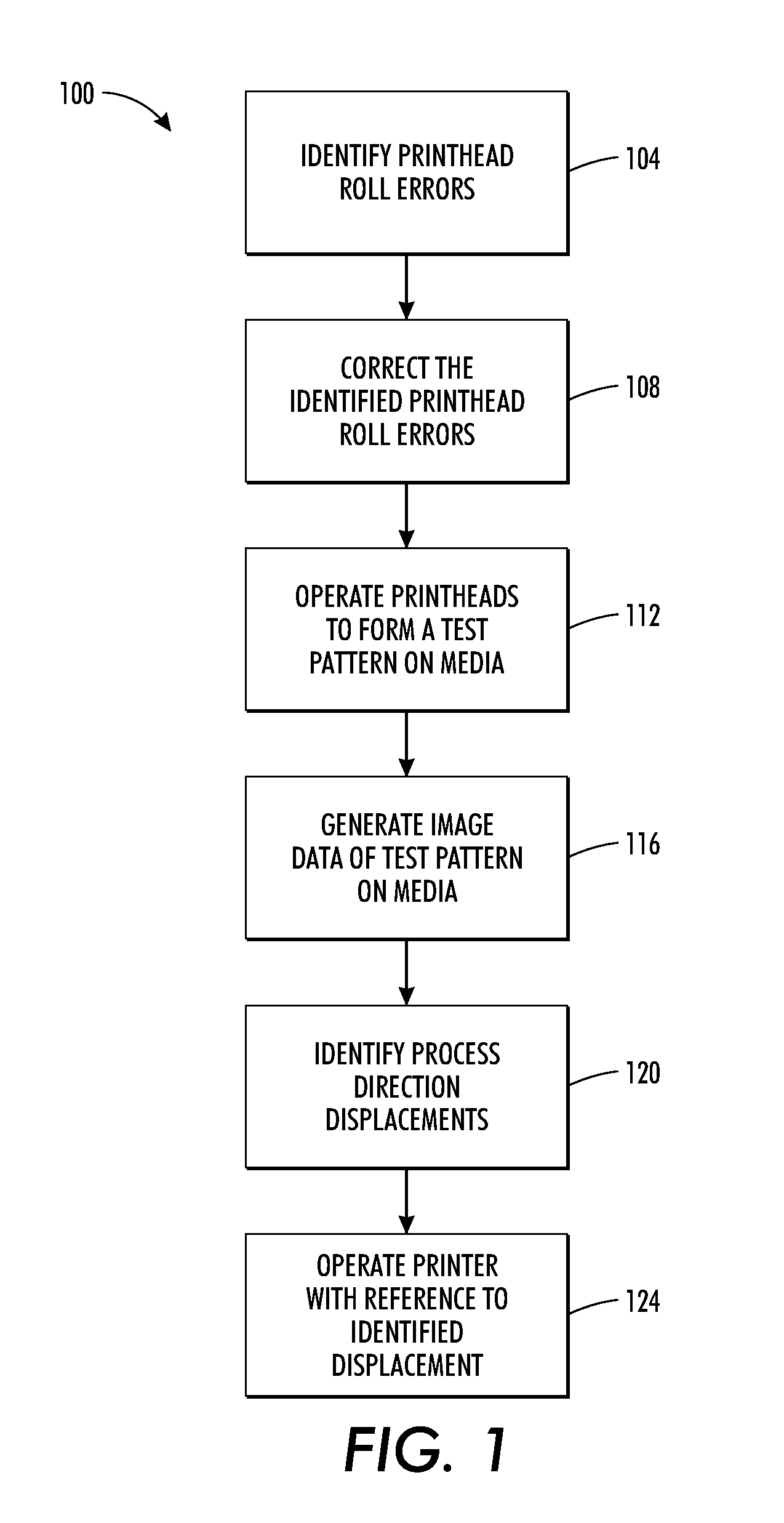

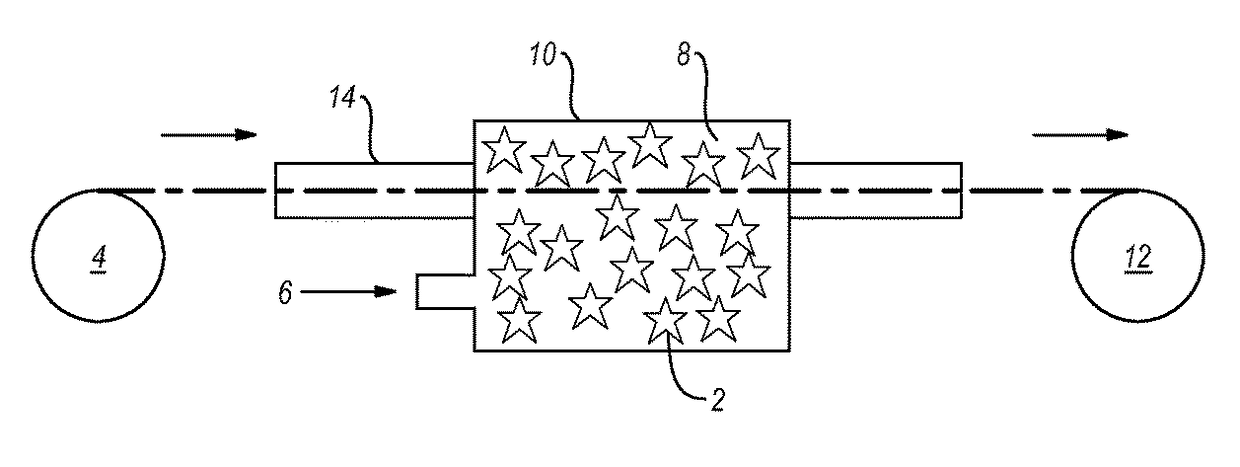

Method And System For Measuring And Compensating For Process Direction Artifacts In An Optical Imaging System In An Inkjet Printer

ActiveUS20110279503A1Compensation displacementProcess is directionalTypewritersOther printing apparatusEngineeringImaging data

A printer operating method enables a controller to identify process direction errors in an optical imaging system. The method includes identifying a printhead roll error for each printhead in a plurality of printheads in a printer, moving each printhead by an amount that corrects the printhead roll error for the corresponding printhead, generating a plurality of dashes on media with the plurality of printheads as the media moves past the plurality of printheads, identifying a position for each dash in the process direction from image data of the plurality of dashes on the media, identifying a displacement in the process direction for each optical detector in a linear array of optical detectors used to generated the image data of the plurality of dashes, the displacement being identified with reference to the identified positions for the dashes, and operating the printer to compensate for the identified displacements of the optical detectors.

Owner:XEROX CORP

Metal carbide fibers and methods for their manufacture

ActiveUS9803296B2High temperature resistanceIncrease temperatureInorganic material artificial filamentsConjugated artificial filamentsFiberCarbon fibers

A method of producing, from a continuous or discontinuous (e.g., chopped) carbon fiber, partially to fully converted metal carbide fibers. The method comprises reacting a carbon fiber material with at least one of a metal or metal oxide source material at a temperature greater than a melting temperature of the metal or metal oxide source material (e.g., where practical, at a temperature greater than the vaporization temperature of the metal or metal oxide source material). Additional methods, various forms of carbon fiber, metal carbide fibers, and articles including the metal carbide fibers are also disclosed.

Owner:ADVANCED CERAMIC FIBERS

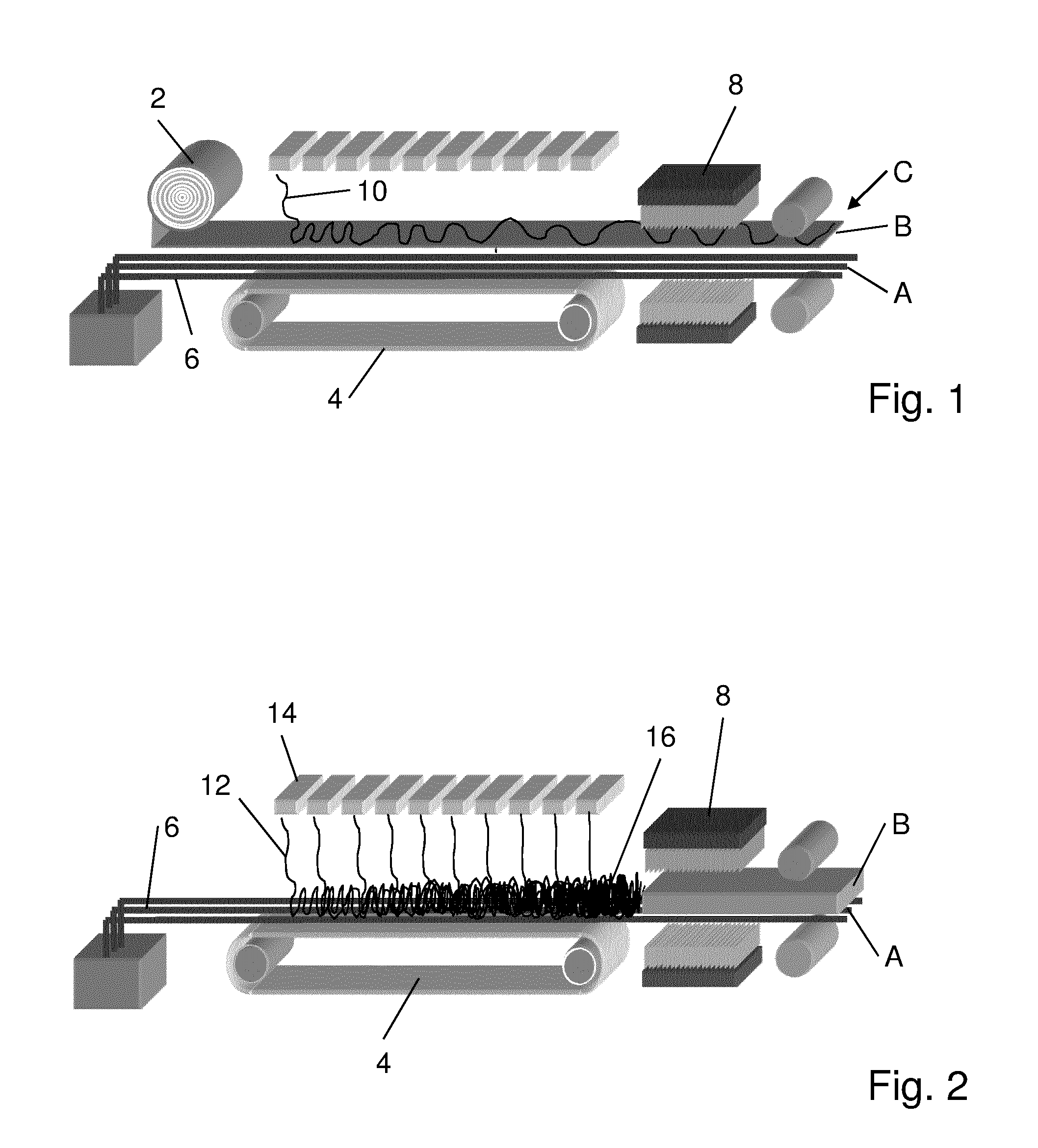

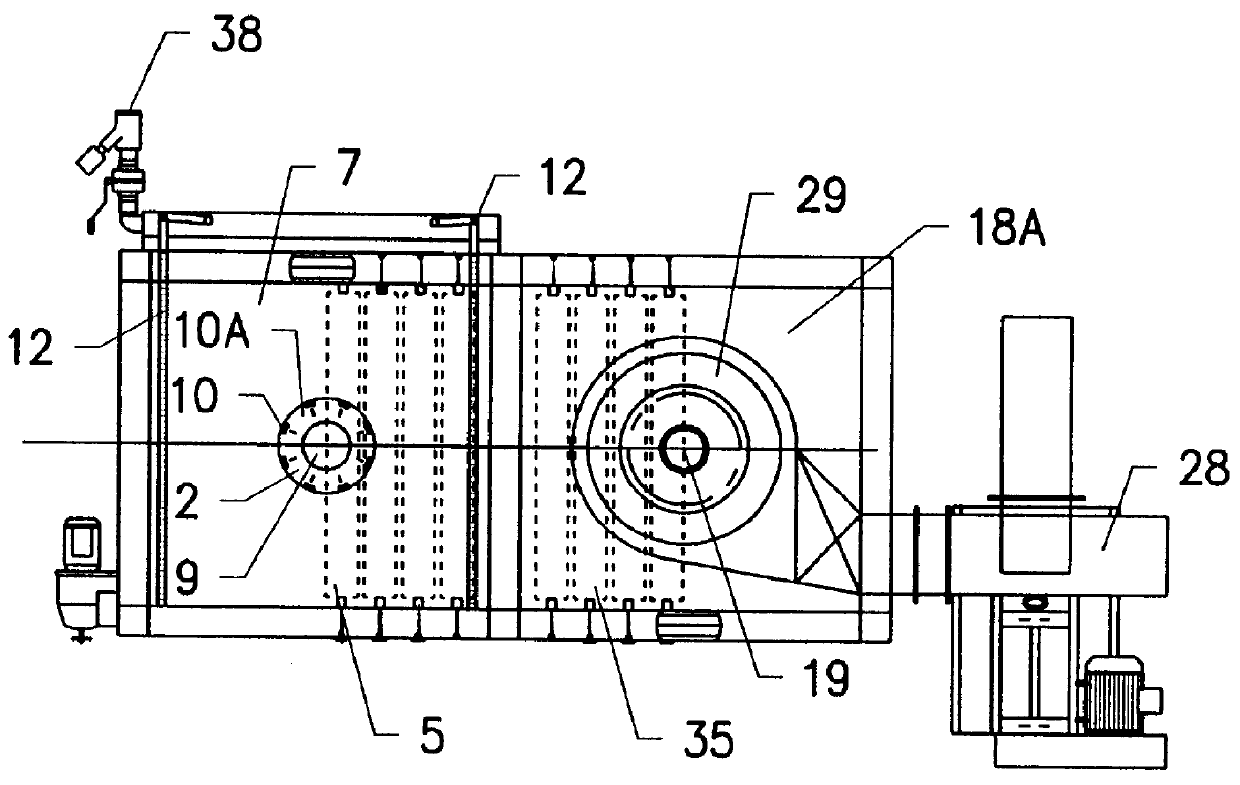

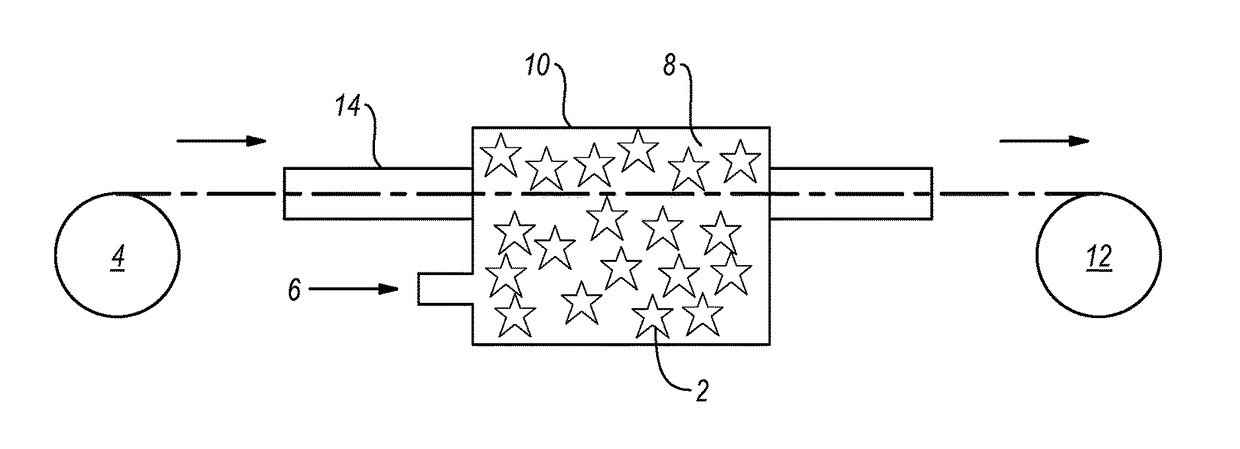

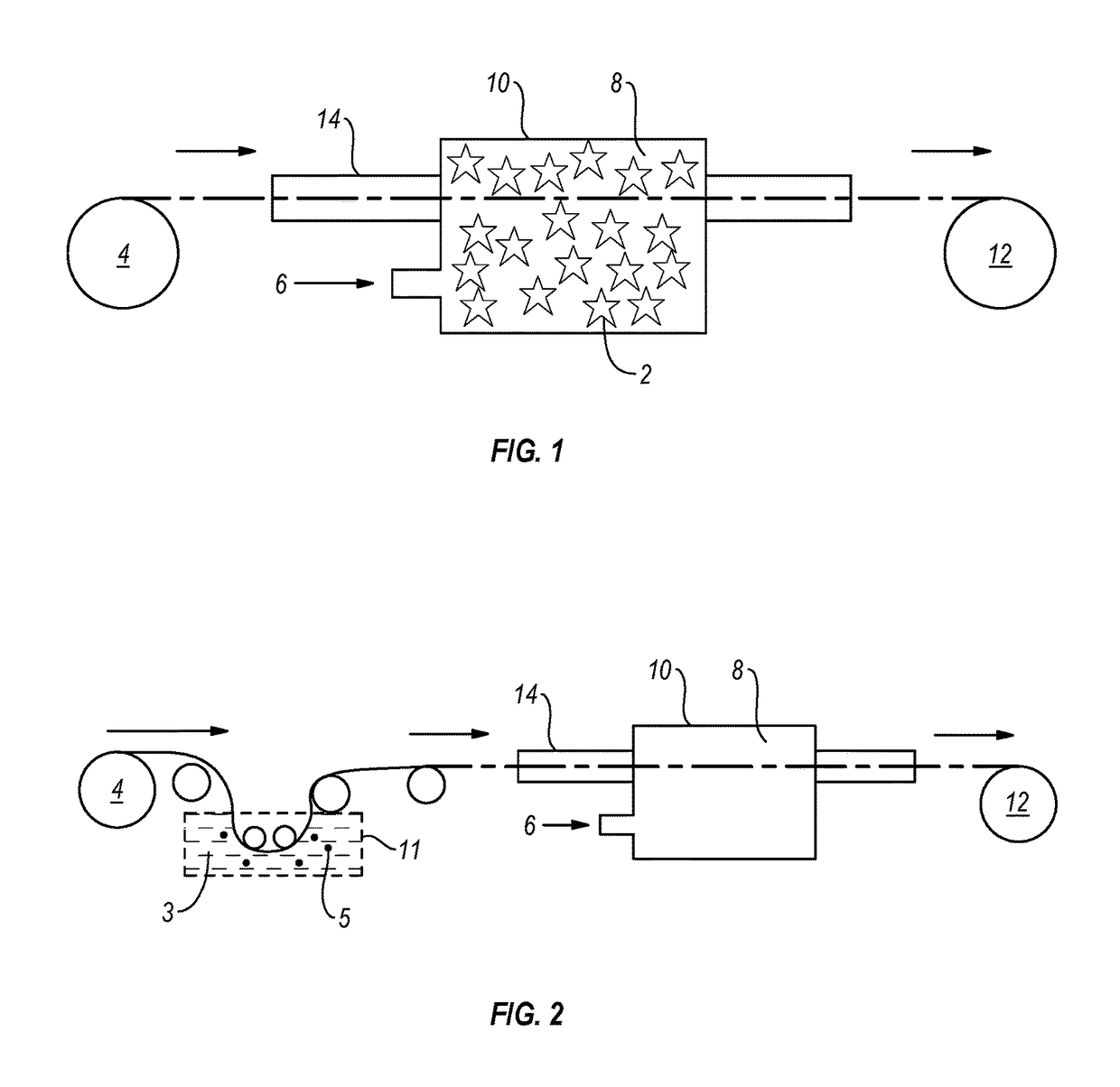

Method and apparatus for treating tubular knitted goods

InactiveUS6016591AAvoid processing stepsAvoid wastingHeating/cooling textile fabricsDrying machines with progressive movementsFiberEngineering

In a method and an apparatus for treating tubular knitted goods containing elastomeric fibers, the goods are effectively relaxed, expanded, and heat fixed or set in the desired expanded condition, while maintaining the tubular configuration of the goods and without cutting open and re-sewing the tubular configuration of the goods. The tubular knitted goods are continuously transported through a relaxing process followed by a heat fixing process and then a cooling process, while constantly maintaining the tubular structure of the goods. The goods are expanded in the radial or width direction by a tubular expander, and in the lengthwise direction by being transported between a feed roller arrangement and a draw-off roller arrangement operating at different transport velocities respectively. The temperature in the heat fixing chamber is preferably over 200 DEG C. and the transport velocity of the tubular knitted goods can be greater than 18 m / min.

Owner:LINDAUER DORNIER GMBH

Amorphous submicron particles

InactiveUS8039105B2Increased space-time yieldProcess is directionalSilicaSynthetic resin layered productsProcess engineeringAmorphous solid

A process for milling amorphous solids using a milling apparatus can result in particles having a median particle diameter d50 of <1.5 μm. The process includes: operating a mill in a milling phase with an operating medium selected from the group consisting of gas, vapor, steam, a gas containing steam and mixtures thereof, and heating a milling chamber in a heat-up phase before the actual operation with the operating medium in such a way that a temperature in the milling chamber, the mill exit or both, is higher than a dew point of the operating medium.

Owner:EVONIK OPERATIONS GMBH

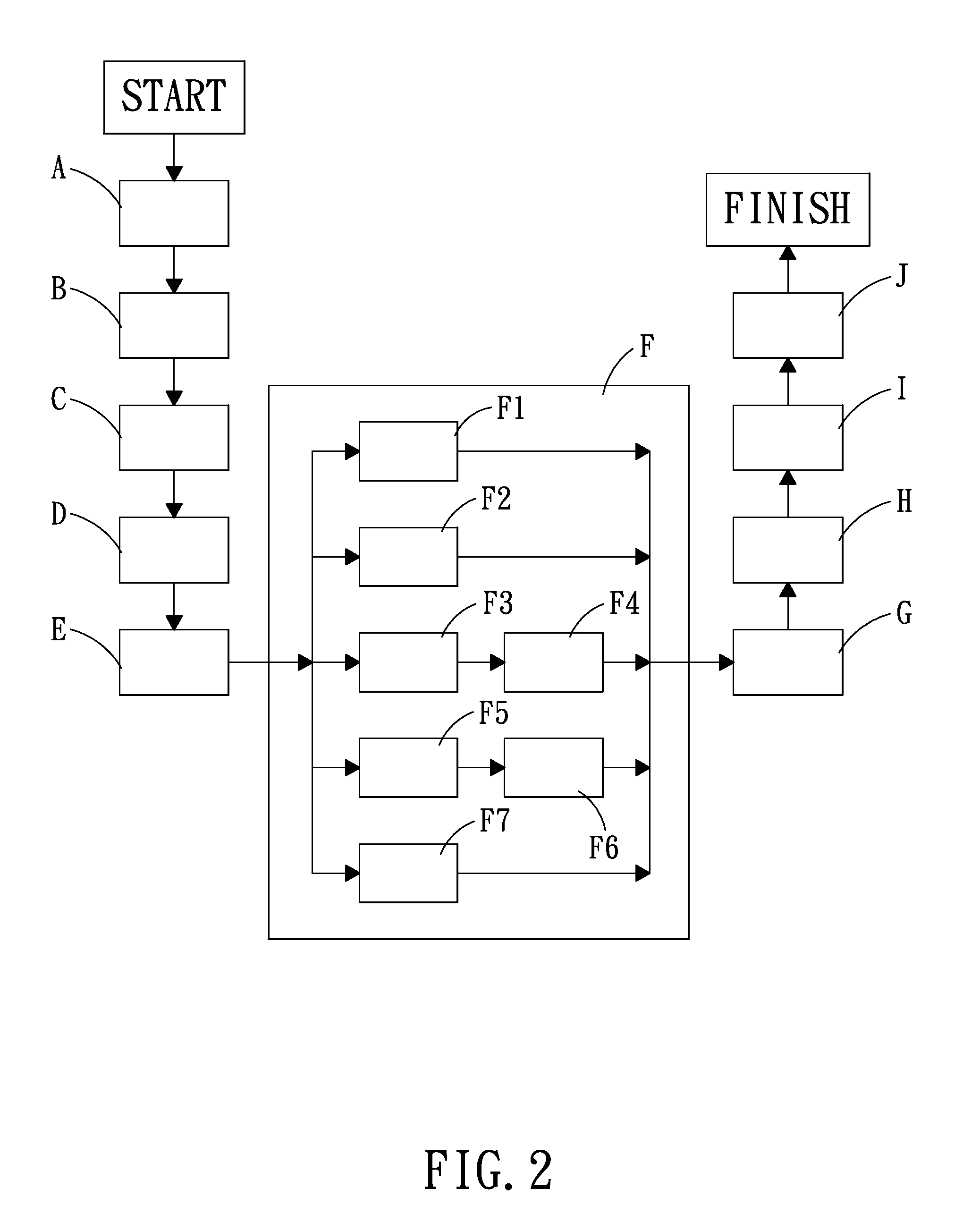

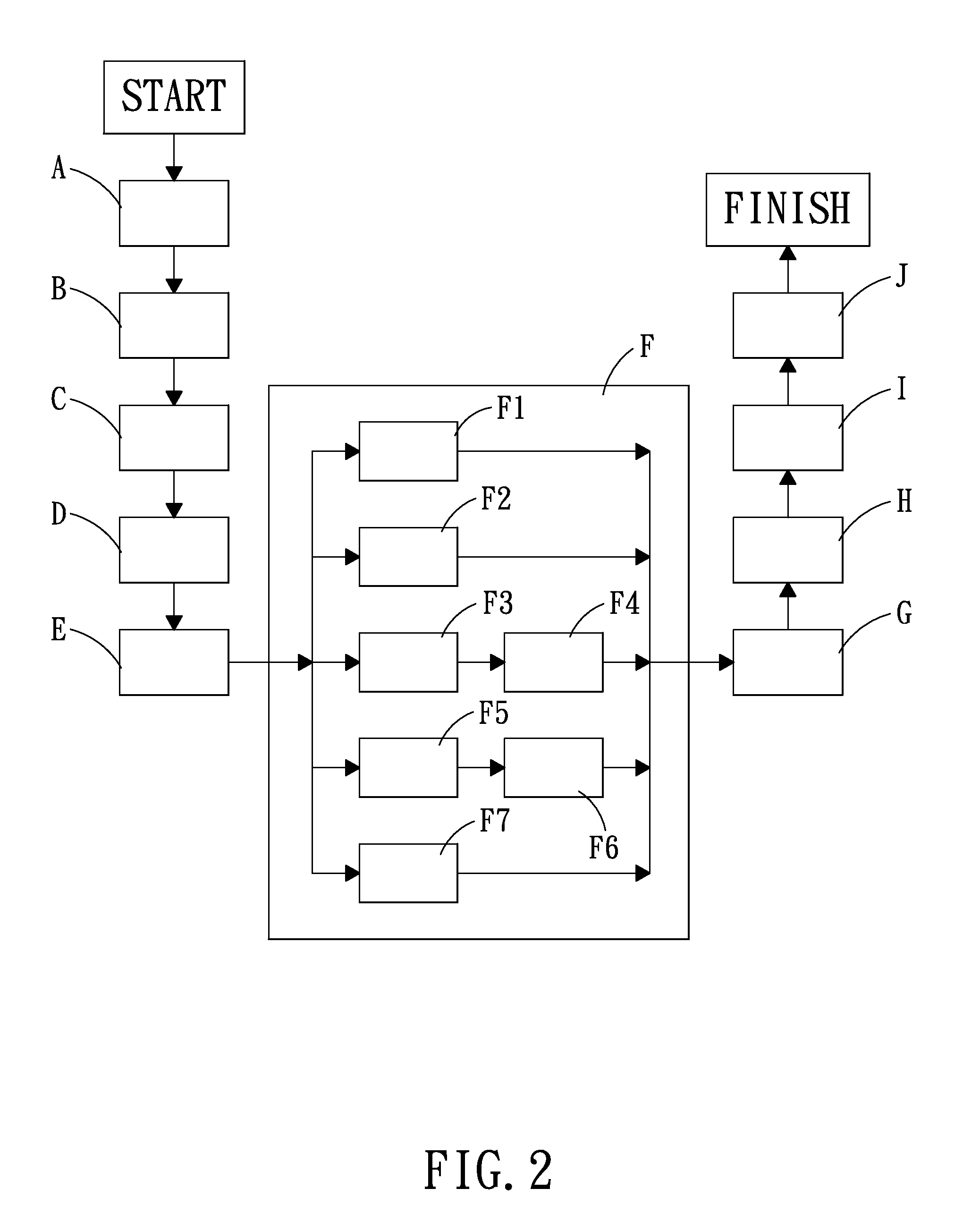

Processing method for in-mold coating integrative system

InactiveUS20120043702A1Reduce processing costsSave human effortCoatingsElectric/magnetic/electromagnetic heatingEngineeringInjection molding machine

A processing method for in-mold coating integrative system is used in cooperation with an injection molding machine. The injection molding machine comprises a rotatable work platform and a combination of at least one male mold and at least two female molds. The rotatable work platform is divided averagely into several work areas, and the processing proceeds sequentially in each work area by the rotation of the rotatable work platform. The processing method comprises following steps: injection molding a solid workpiece firstly, and leaving the solid work-piece on the male mold; rotating the rotatable work platform; performing surface coloring; rotating the rotatable work platform; injecting UV top-coat, the top-coat female mold is made of light-directing material and has a die cavity and a UV paint cavity on the surface of the solid workpiece, and a UV top-coat layer is injected into the UV paint cavity through a paint channel; irradiating the UV top-coat layer by a UV top-coat hardening lamp; and demolding to achieve a finished product. The method is of benefit to mass production, and can reduce labor cost and processing cost.

Owner:JIN YU SYUAN

Systems and methods for conducting derivative trades electronically

InactiveUS7761368B2Quickly and easily identifyProcess is directionalFinanceFacsimileComputer science

The present invention facilitates efficient negotiations of trade terms and the generation of an electronic trade ticket in the trading of financial instruments. The negotiation process is preferably conducted through a secure online chat program using point-to-point messaging, though the negotiations can take place using the tradition exchanges of phone calls and faxes outside of the confines of an electronic trading system. Once the trade terms have been agreed upon by both parties, then the parties enter an electronic trading system in accordance with the present invention to select the traded financial instrument and generate an electronic trade ticket with can be stored by the trading system and / or the each of the trading parties.

Owner:GFINET INC

Adjustable width steam box for fabric processing and method of using the same

InactiveUS9365965B2Process is directionalHighly effectiveDrying gas arrangementsHeating/cooling textile fabricsEngineeringPiston

A high efficiency steam box, particularly for the processing of fabrics. The box housing is subdivided into a plurality of steam chambers isolated from each other but communicating with a perforated steam tube which extends throughout the housing. Steam is delivered to the center portions of the steam tube and flows toward the ends. Valve pistons are movably positioned in the opposite end portions of the steam tube to confine the steam. The valve pistons are axially adjustable by a screw shaft extending through the steam tube and can be positioned to isolate outer chambers when processing narrow fabrics to prevent or minimize the discharge of steam from steam discharge slots extending beyond the edges of the fabric. Steam flow control can be integrated with positioning of the valve pistons to provide uniform steam flow per unit length of the discharge slots for optimum efficiency in processing and steam utilization.

Owner:TUBULAR TEXTILE LLC

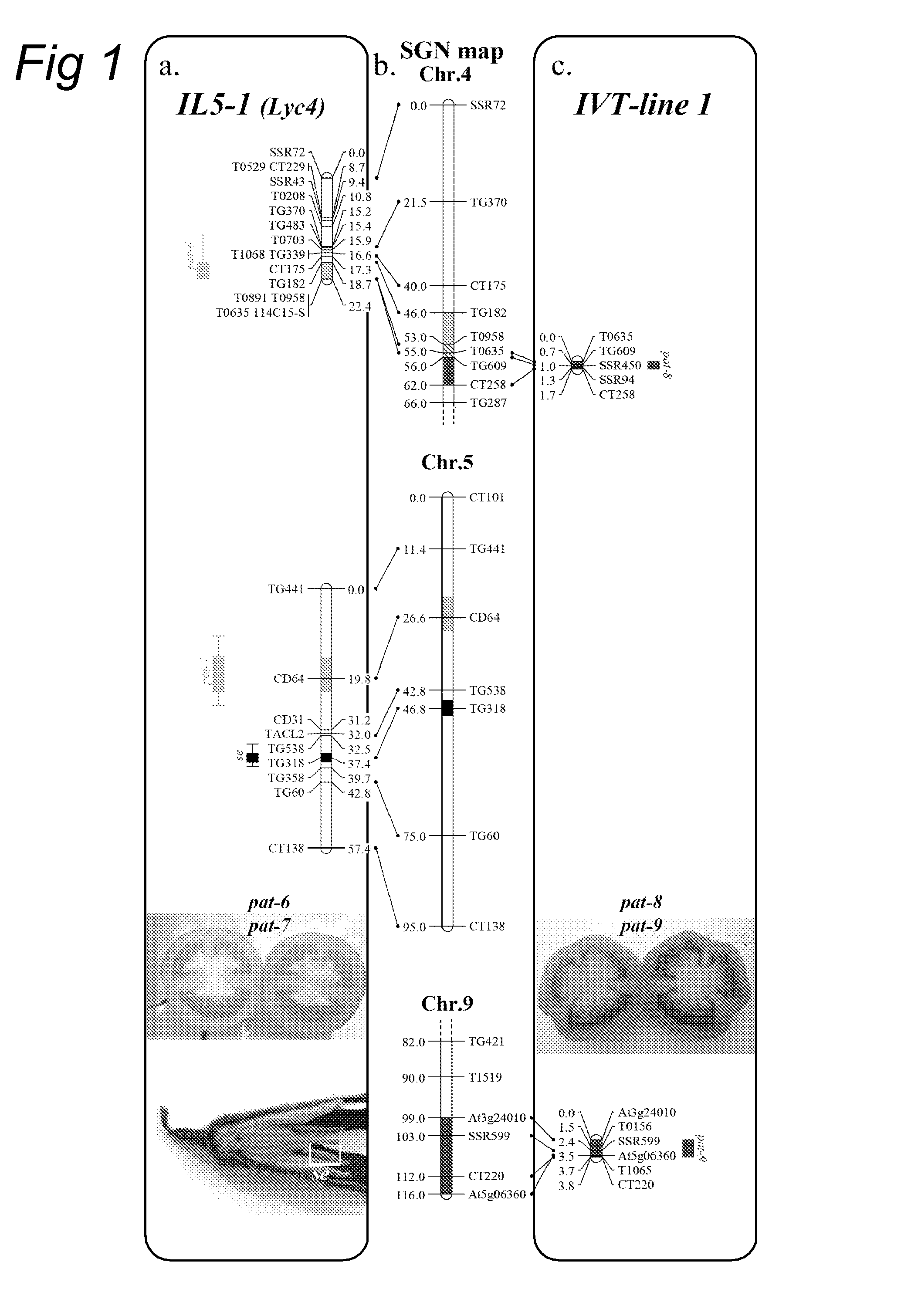

Parthenocarpy genes in tomato

InactiveUS9474222B2Excellent for hybridisationEasily cross-bredPlant genotype modificationAngiosperms/flowering plantsGeneSolanum

The present invention relates to Solanum lycopersicum plants carrying one or more of the pat-6, pat-7, pat-8 and pat-9 parthenocarpy genes. Preferred plants comprise a pair of pat-6 and pat-7 genes or a pair of pat-8 and pat-9 genes, whereby preferably the plant is homozygous for at least one of the two genes in the pair, more preferably the plant is homozygous for both genes in the pair. Such plants are capable of producing seedless tomatoes. The invention further relates to methods for producing plants carrying one or more of the pat-6, pat-7, pat-8 and pat-9 parthenocarpy genes using marker-assisted breeding.

Owner:MONSANTO HOLLAND

Composite Articles Comprising Metal Carbide Fibers

ActiveUS20180051396A1High temperature resistanceIncrease temperatureInorganic material artificial filamentsConjugated artificial filamentsFiberCarbon fibers

A method of producing, from a continuous or discontinuous (e.g., chopped) carbon fiber, partially to fully converted metal carbide fibers. The method comprises reacting a carbon fiber material with at least one of a metal or metal oxide source material at a temperature greater than a melting temperature of the metal or metal oxide source material (e.g., where practical, at a temperature greater than the vaporization temperature of the metal or metal oxide source material). Additional methods, various forms of carbon fiber, metal carbide fibers, and articles including the metal carbide fibers are also disclosed.

Owner:ADVANCED CERAMIC FIBERS

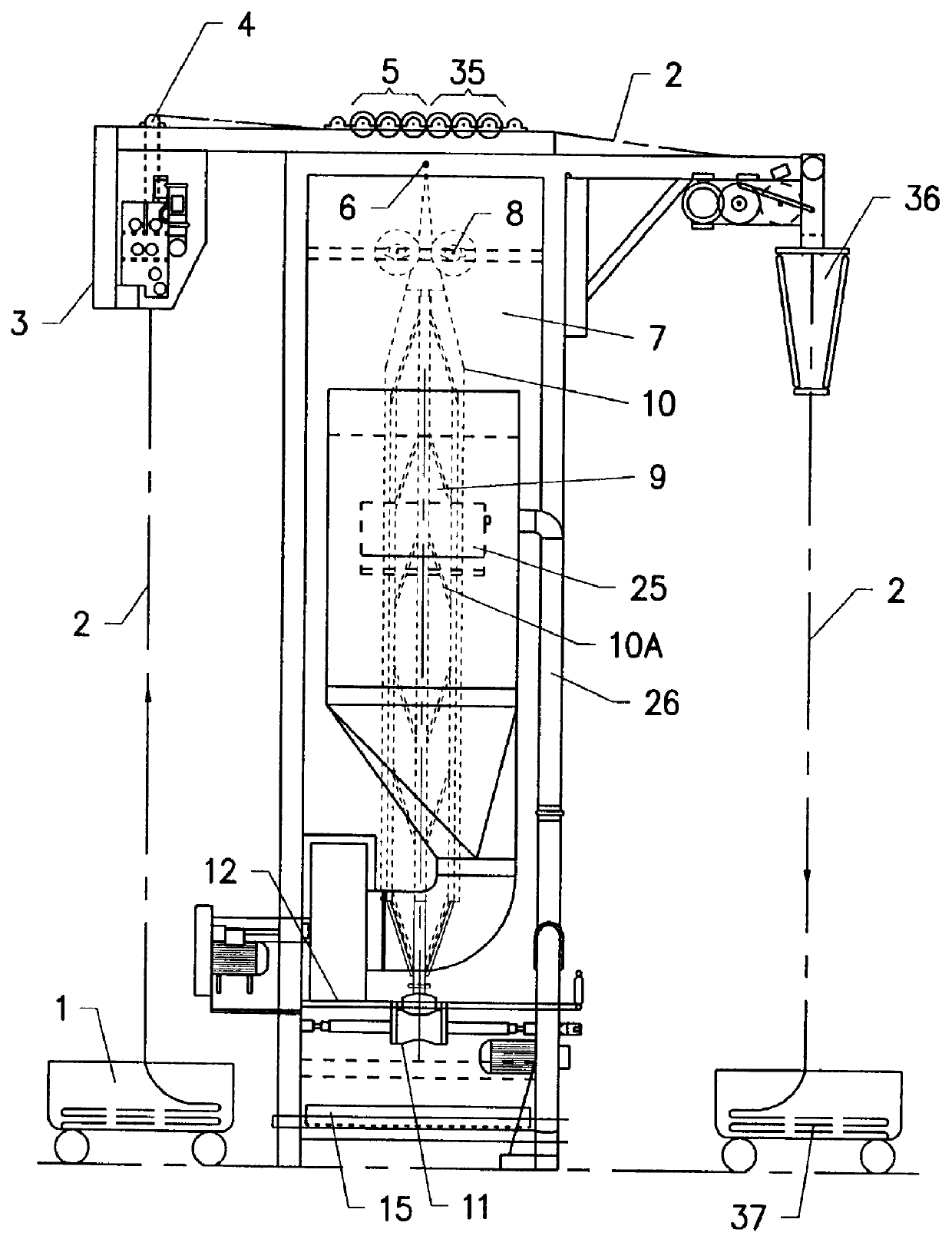

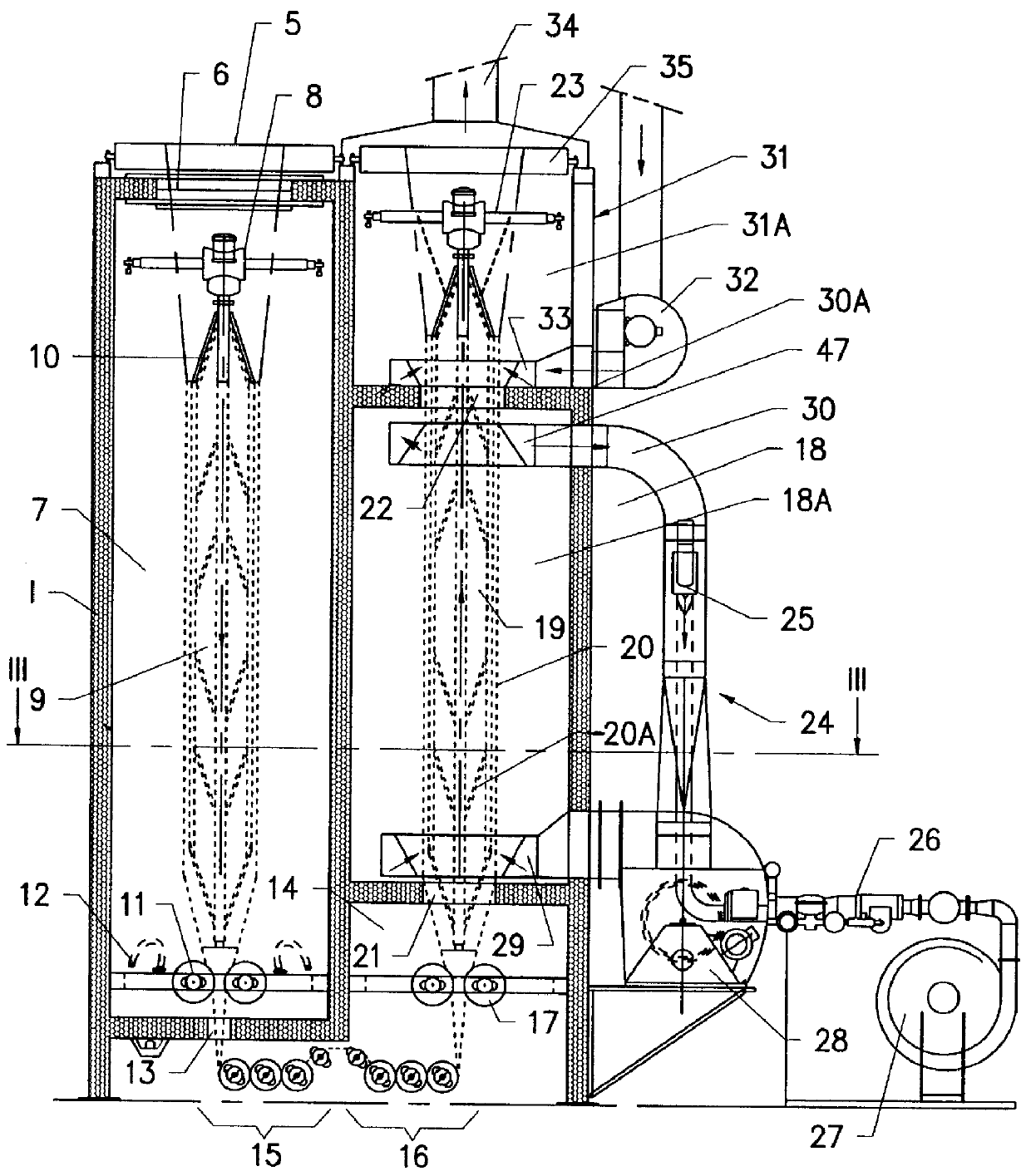

Combined pre-treatment process for enabling feed material to be charged in direct reduction processes

ActiveUS20050000320A1Promote productionEnhanced thermal profileExhaust gas handlingIncreasing energy efficiencyMetallurgyImproved method

An improved method and apparatus for pretreatment of solid lump feed material for gas and pellet / lump-based direct reduction processes, by initially storing the lump feed in stockpiles for stress release, followed by pre-drying the feed material prior to charging into the reduction furnace and finally increasing the average temperature of the reduction furnace, in order to reduce the amount of reduction at low temperatures, thereby minimizing the formation of fines within the furnace.

Owner:VALE LIMITED

Methods and devices for producing biomolecules

ActiveUS8501402B2Process is directionalMicrobiological testing/measurementNucleic acid reductionLysisPartial filling

A scalable process and device for producing a biomolecule, in particular pharmaceutical grade plasmid DNA. The process includes the steps of alkaline lysis and a neutralization. For separating the lysate and the precipitate, the mixture is allowed to gently flow downward through a clarification reactor that is partially filled, in its lower part, with retention material like glass beads, whereby the precipitate is retained on top of and within the retention. In a preferred embodiment of the lysis step, cell suspension and alkaline lysis solution flow through a lysis reactor that is filled with particulate material like glass beads. The process can be run continuously and fully automated.

Owner:BOEHRINGER INGELHEIM RCV GMBH & CO KG

Animation System

ActiveUS20220044466A1Improve the level ofProcess is directionalAnimationDetails involving graphical user interfaceAlgorithmAnimation

A system for creating an animation may include a template adapted for receiving animation content from a user and configured to guide the user in providing animation content. The system may also include a computing system configured to receive an image of a completed version of the template and generate an animation based on the completed template. The system may allow for generating an animation from a single image by identifying and extracting particular regions of the image and using their spatial relationship to sequence the regions in time rather than space.

Owner:NORDBERG TRYGVE AUSTIN

Processing method for in-mold coating integrative system

InactiveUS8647555B2Process is directionalReduce processing costsMouldsCoatingsEngineeringInjection molding machine

A processing method for in-mold coating integrative system is used in cooperation with an injection molding machine. The injection molding machine comprises a rotatable work platform and a combination of at least one male mold and at least two female molds. The rotatable work platform is divided averagely into several work areas, and the processing proceeds sequentially in each work area by the rotation of the rotatable work platform. The processing method comprises following steps: injection molding a solid workpiece firstly, and leaving the solid work-piece on the male mold; rotating the rotatable work platform; performing surface coloring; rotating the rotatable work platform; injecting UV top-coat, the top-coat female mold is made of light-directing material and has a die cavity and a UV paint cavity on the surface of the solid workpiece, and a UV top-coat layer is injected into the UV paint cavity through a paint channel; irradiating the UV top-coat layer by a UV top-coat hardening lamp; and demolding to achieve a finished product. The method is of benefit to mass production, and can reduce labor cost and processing cost.

Owner:JIN YU SYUAN

Biomimetic adhesive layer and method of manufacturing the same

InactiveUS20160144538A1Improve structural strengthSimple molding processNon-macromolecular adhesive additivesLayered productsPolymer sciencePolymer substrate

A biomimetic adhesive layer is provided, and has a plurality of protrusions with a bottom surface and an upper surface of each of the protrusions; and a support portion connecting with the bottom surface. The protrusions are formed by a polymeric material mixed with permeance particles. Moreover, a method of manufacturing a biomimetic adhesive layer is provided, and has the steps of: providing a metallic mold having a plurality of filling apertures; compressing a polymer substrate with the metallic mold to fill the polymer substrate within the apertures; curing the polymer substrate; and separating the metallic mold from the polymer substrate to obtain the biomimetic adhesive layer.

Owner:NATIONAL TSING HUA UNIVERSITY

Planar composite material

A planar composite material comprises an UD fiber layer A made of discrete reinforcing fiber rovings and a fiber nonwoven layer B made of a thermoplastic nonwoven which may contain reinforcing fibers, wherein the layers A and B are needled to each other.

Owner:QUADRANT PLASTIC COMPOSITES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com