Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Less scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dispersion stabilizer for suspension polymerization of vinyl compound and method of producing the same

ActiveUS7070731B2Less polymer scale adhesionHigh bulk densityColloidal chemistry detailsAcetic acidPolymer science

The present invention provides a new dispersion stabilizer that satisfies, at a high level, the performances required for a dispersion stabilizer used for suspension polymerization. A method of producing a dispersion stabilizer that is useable for suspension polymerization of a vinyl compound and contains a vinyl alcohol polymer (A) includes producing the vinyl alcohol polymer (A) by heat-treating a vinyl alcohol polymer (B) at a temperature of 90 to 180° C. for 0.5 to 20 hours in an atmosphere in which an oxygen concentration is 8000 ppm or lower. The vinyl alcohol polymer (B) has a saponification degree of at least 60 mol % and contains a residual acetic acid group whose block character is in the range of 0.3 to 0.6.

Owner:KURARAY CO LTD

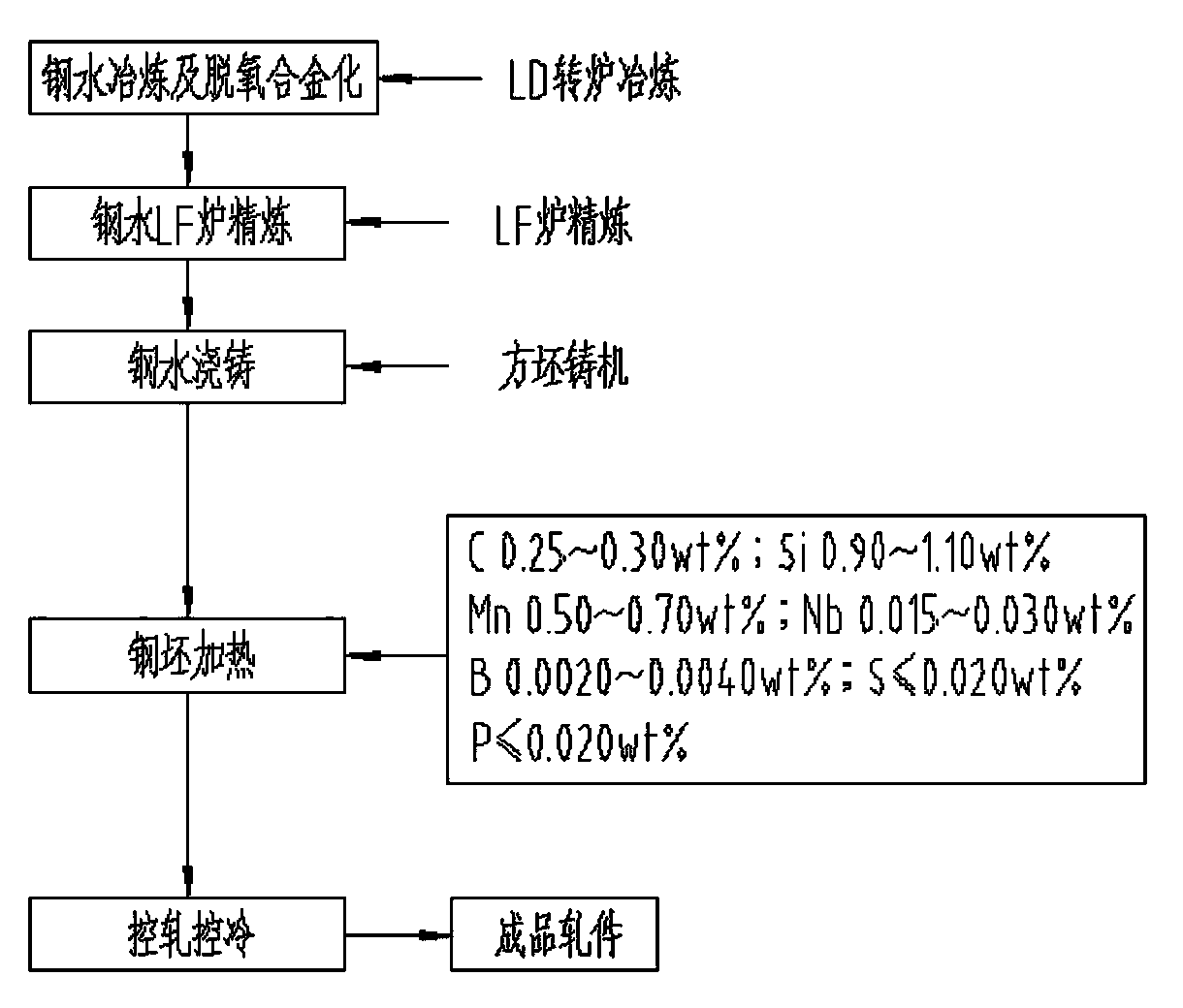

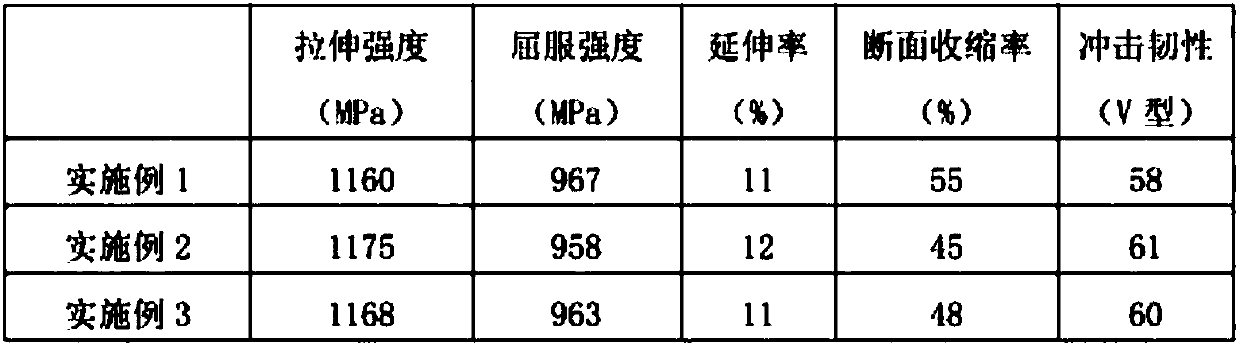

Optical round wire rod reinforcement bar for producing prestressed concrete steel rod and processing method

The invention discloses an optical round wire rod reinforcement bar for producing a prestressed concrete steel rod and a processing method. A steel blank comprises in percentage by weight: 0.25-0.30% of C, 0.90-1.10% of Si, 0.50-0.70% of Mn, 0.015-0.030% of Nb, 0.0020-0.0040% of B, no more than 0.020% of S, no more than 0.020% of P and the balance of Fe and inevitable impurities; the optical round wire rod reinforcement bar with the nominal diameter of 8.0-14.0mm is produced by heating and performing controlled rolling and controlled cooling to the steel blank, and has the following characteristics that the tensile strength (Rm) is 630-660MPa, the percentage reduction of area is more than or equal to 65%, and the ferrite grain size is 10.0-11.5 level. Through integration and creation of converter melting, LF melting, steel blank heading and multiple technology of standard and delay type controlled rolling and controlling cooling and the like, the invention provides a production method of the optical round wire rod reinforcement bar for producing the prestressed concrete steel rod, and the product is high in hardenability, and uniform in microscopic structure. The method has the advantages of excellent quality, low production cost, good processability, strong popularization and the like.

Owner:WUKUN STEEL

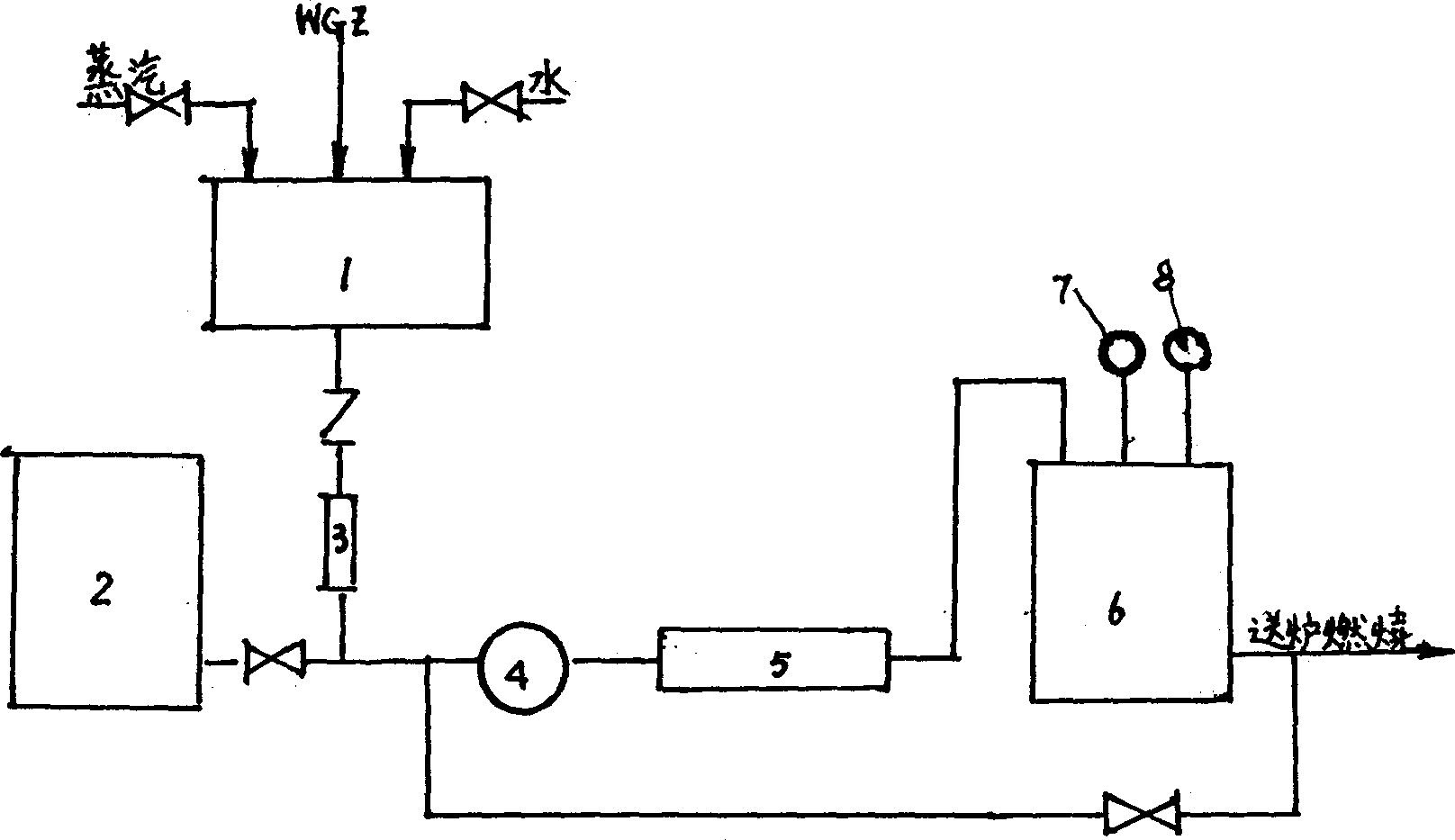

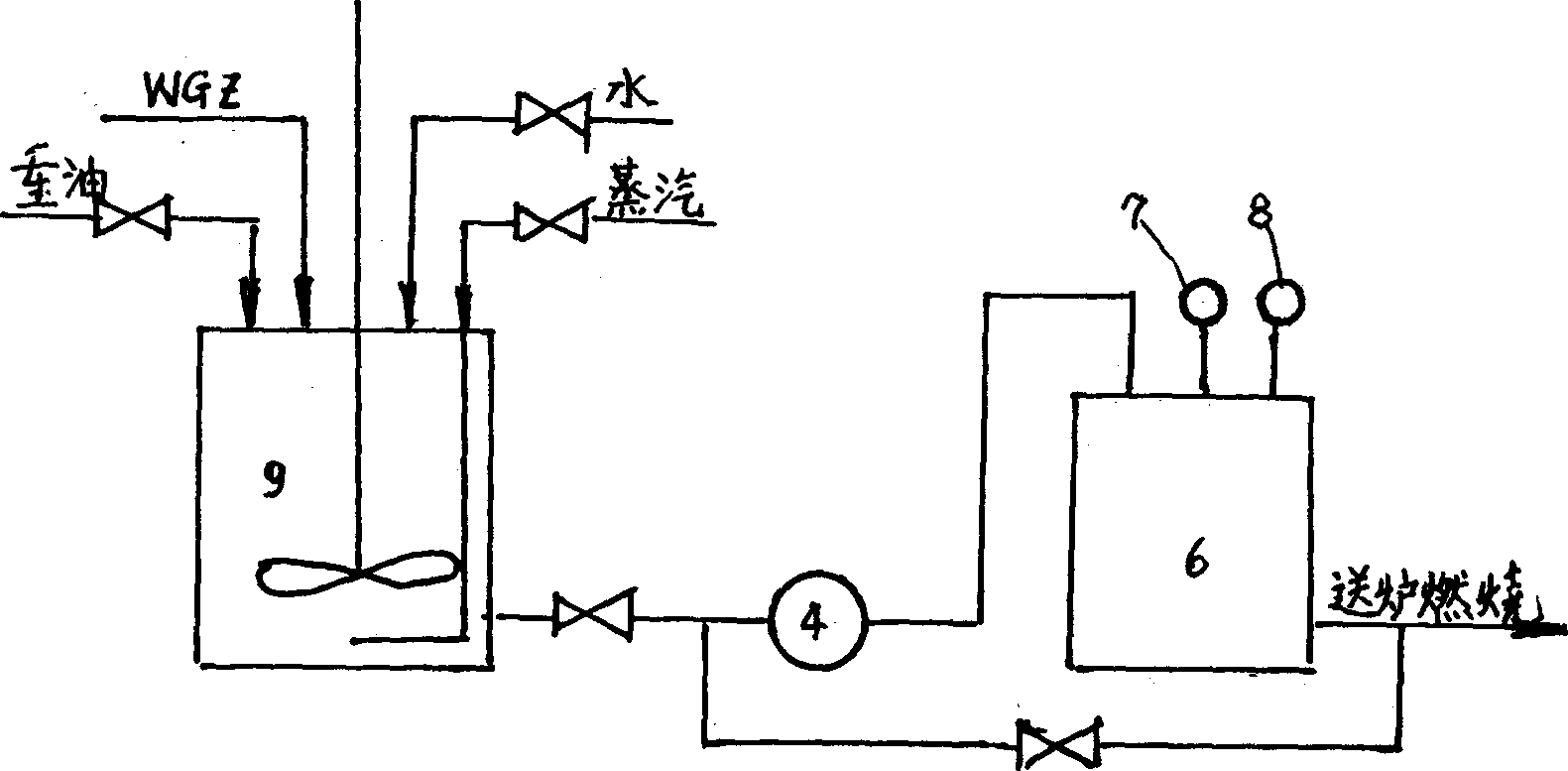

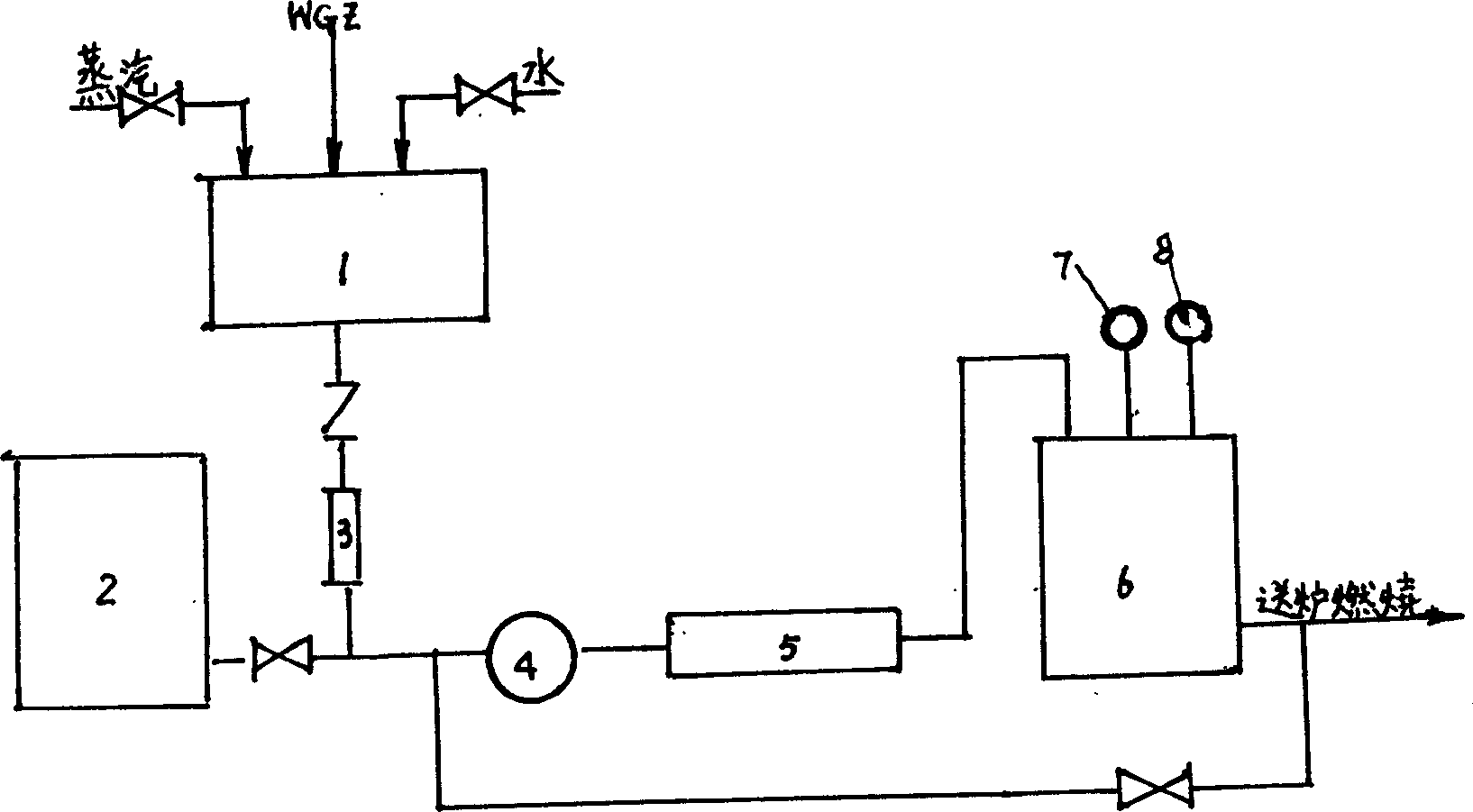

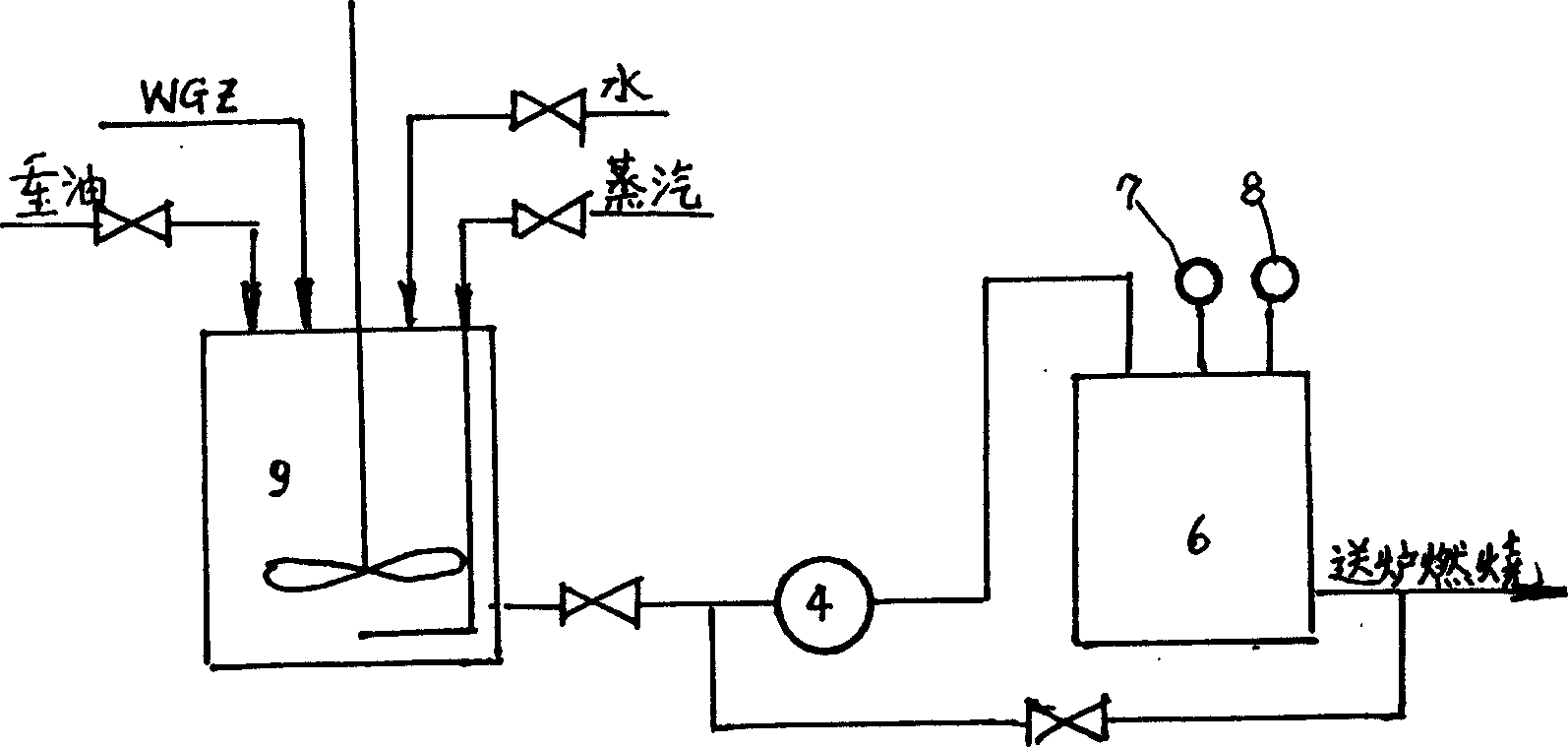

Multifunctional heavy oil and fuel oil additive, preparation and use thereof in preparing emulsified oil

InactiveCN1401745AWide emulsification rangeMix well and evenlyLiquid carbonaceous fuelsFuel oilDisperser

An oil-soluble multifunctional additive for heavy oil or fuel oil contains more surfactants, composite catalytic combustion adjuvant and detergent disperser, and is characterized by saving oil by 10-25%, increasing added water to 10-30% and eliminating black smoke. A process for preparing emulsified heavy oil or fuel oil is also disclosed.

Owner:WUHAN UNIV OF TECH

Rolling method of titanium steel composite board

ActiveCN102794299AQuality assuranceReduce harmTemperature control deviceWork treatment devicesForeign matterWater flow

The invention provides a rolling method of a titanium steel composite board. The rolling method comprises the following steps of: 1, selecting the titanium steel composite board provided with a titanium plate as an upper layer and a steel plate as a lower layer; 2, pre-treating a surface; 3, heating and soaking in a heating furnace; and 4, rolling on a hot mill, and removing scale and cooling by utilizing high-pressure water. According to different physical characteristics of the titanium plate and the steel plate under the high-temperature state, through setting the proper heating and soaking processes, and adopting the high pressure water to remove the scale and cool in the rolling process, an oxide skin on the surface of the titanium steel composite board is greatly reduced, and sundries on the surface of the titanium steel composite board are eliminated, meanwhile, the titanium plate and the steel plate are cooled at different water flows, so that the deformation degree of the titanium plate corresponds to the deformation degree of the steel plate, head buckle or unwarp phenomenon of the titanium steel composite board in the rolling process can be effectively prevented, and damage about a roller is greatly reduced; and the titanium steel composite board, rolled by the invention, has the advantages of clean and tidy surface, no foreign matters to press and good plate cut.

Owner:WESTERN TITANIUM TECH

Process for forging rear axle shaft flange of automobile

ActiveCN101947634AUniform deformationIncrease productivityRailway componentsVehicle componentsRound tableDiameter ratio

The invention discloses a process for forging a rear axle shaft flange of an automobile. The process comprises the following steps of: heating a round bar to the temperature of between 1,150 and 1,250 DEG C; upsetting and blanking the round bar on a horizontal forging machine by using a mold cone cavity so as to form a rear axle shaft middle blank of the automobile, wherein the rear axle shaft middle blank of the automobile is provided with a round table-shaped part which has a thicker front part and a thinner rear part, the length-to-diameter ratio of the round table-shaped part is 0.9 to 1.5, and the diameter is an average diameter of the round table-shaped part; controlling time for an upsetting and blanking process; keeping the temperature of the rear axle shaft middle blank of the automobile to be between 1,000 and 1,100 DEG C; and performing pendulum grinding and molding on the rear axle shaft middle blank of the automobile directly on a pendulum grinding machine so as to obtain the rear axle shaft flange of the automobile. The process has the advantages of improving the production efficiency of forging the rear axle shaft flange of the automobile, along with small required blanking and forging equipment, a small amount of scale produced by heating a forging piece, better surface quality of the forging piece, and the uniform deformation and high dimensional accuracy of the forged rear axle shaft of the automobile.

Owner:DONGFENG COMML VEHICLE CO LTD

Dispersion stabilizer for suspension polymerization of vinyl compound and method of producing the same

InactiveUS20060180956A1High bulk densitySuspension polymerization to be carried out more stablyColloidal chemistry detailsAcetic acidOxygen

The present invention provides a new dispersion stabilizer that satisfies, at a high level, the performances required for a dispersion stabilizer used for suspension polymerization. A method of producing a dispersion stabilizer that is useable for suspension polymerization of a vinyl compound and contains a vinyl alcohol polymer (A) includes producing the vinyl alcohol polymer (A) by heat-treating a vinyl alcohol polymer (B) at a temperature of 90 to 180° C. for 0.5 to 20 hours in an atmosphere in which an oxygen concentration is 8000 ppm or lower. The vinyl alcohol polymer (B) has a saponification degree of at least 60 mol % and contains a residual acetic acid group whose block character is in the range of 0.3 to 0.6.

Owner:KURARAY CO LTD

Method for producing a motor vehicle component and motor vehicle component

InactiveUS20130160906A1Less heatPrevents premature scalingFurnace typesHeat treatment furnacesDuctilityHigh intensity

A method for producing a motor vehicle component having two regions, with different strength is disclosed. A first one of the two regions has a high strength and a second one of the two regions has a higher ductility and lower strength relative to the first region. In a motor vehicle component produced with the method, the first region has a strength between 1400 and 1600 MPa at a breaking elongation A5>13% and the second region has a tensile strength between 950 and 1050 MPa at a breaking elongation A5>16%.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

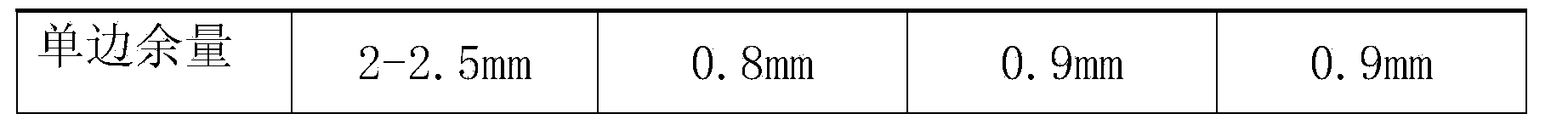

Continuous unidirectional solidification preparation method of high-purity oxygen-free copper rod

The invention discloses a continuous unidirectional solidification preparation method of a high-purity oxygen-free copper rod. The preparation method comprises the following steps of: firstly roasting cathode copper with the purity of 99.99% for 2-4 hours in a heat preserving furnace with the temperature of 200 degrees centigrade to be fully degassed, secondly placing the cathode copper into a smelting pot in a vacuum unidirectional solidification furnace, smelting at 1250-1350 degrees centigrade, performing heat preservation for 20-30min, and casting by the continuous unidirectional solidification furnace. The vacuum degree of the continuous unidirectional solidification furnace is in the range from 0.01 to 1Pa, the casting speed is in the range from 10 to 150mm / min, the cooling water consumption is in the range from 200 to 1000L / h, the cooling water temperature is in the range from 20 to 25 degrees centigrade, and the high-purity oxygen-free copper rod with the diameter of 6-18mm is prepared. The high-purity oxygen-free copper rod is characterized in that the oxygen content is less than 4ppm, the single crystal structure or the continuous column crystal structure along a length direction is present, the conductivity, mechanical property and processing performance is excellent, the finished product ratio is high and the production cost is low.

Owner:JIANGXI UNIV OF SCI & TECH

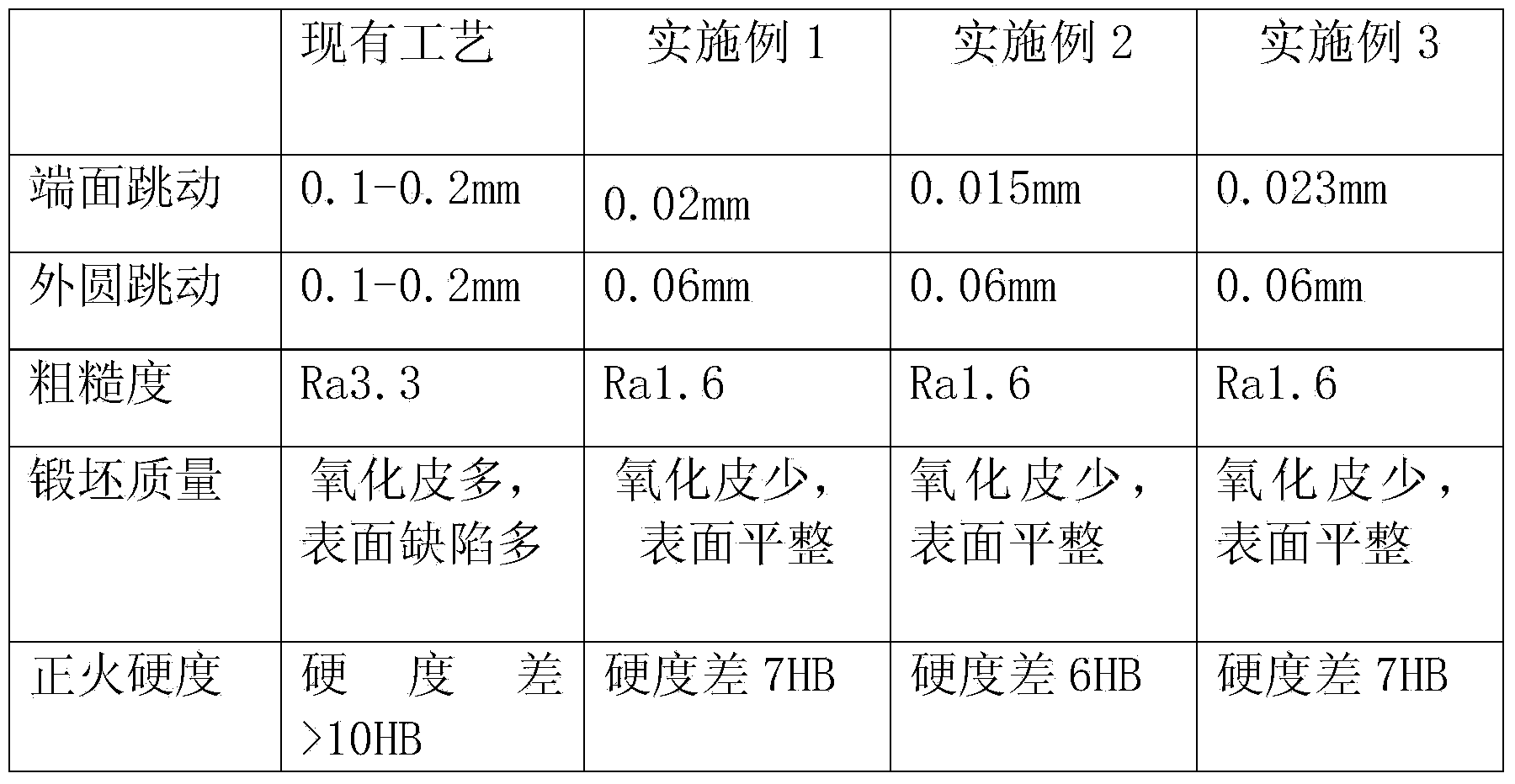

Processing process of internal spline gear blank used in agricultural machinery equipment transmission case

InactiveCN103707019AImprove processing efficiencyReduce processing costsGear wheelAgricultural engineering

The invention relates to a gear processing process. A processing process of an internal spline gear blank used in an agricultural machinery equipment transmission case comprises the steps of selecting material, blanking by a material shearer, forging blanks, isothermally normalizing, coarsely finish turning and pulling an internal spline in sequence. The processing process of the internal spline gear blank used in the agricultural machinery equipment transmission case has the advantages of being higher in processing efficiency, lower in processing cost and capable of comprehensively improving quality and precision of product of the internal spline gear blank.

Owner:平湖市海光机械有限公司

Heating and rolling method for wide thick titanium-steel composite plate

InactiveCN109351774AHeating evenlyEliminate head tearsWork heating devicesMetal rolling arrangementsForeign matterTitanium

The invention discloses a heating and rolling method for a wide thick titanium-steel composite plate. The heating and rolling method comprises the heating step and the rolling step. In the heating step, a titanium-steel composite plate blank is heated under the atmosphere of micro positive pressure and weak oxidability; heat preservation is conducted for 1.0-1.5 h at the temperature of 650 DEG C-700 DEG C in the preheating section; then, the temperature is rapidly increased to 880 DEG C-900 DEG C with 1.0-2.0 h in the heating section, and heat preservation is conducted for 1.0-2.0 h; and finally, heat preservation is conducted for 4.0-5.0 h at the temperature of 900 DEG C-930 DEG C in the soaking section. According to the method, in the heating step, heating of the titanium-steel compositeplate is uniform, the phenomena of head tearing, head buckling, upwarping and edge part folding in the titanium-steel composite plate rolling process are eliminated, the rolled plate shape is good, the surface is clean and tidy, edge part folding and foreign matter pressing-in are avoided, the performance is excellent, and the yield and the production efficiency are improved. The titanium-steel composite plate rolled through the method is free of the tearing phenomenon, the performance meets the GB / T8547 requirement, the surface is clean and tidy, edge part folding and foreign matter pressing-in are avoided, and the plate shape is good.

Owner:WUYANG IRON & STEEL

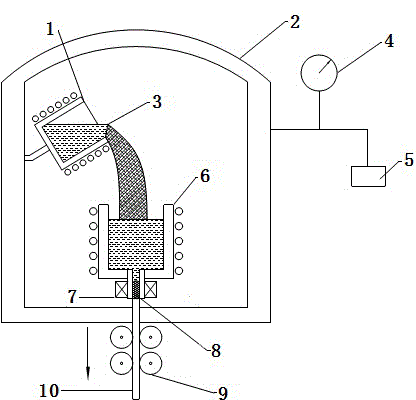

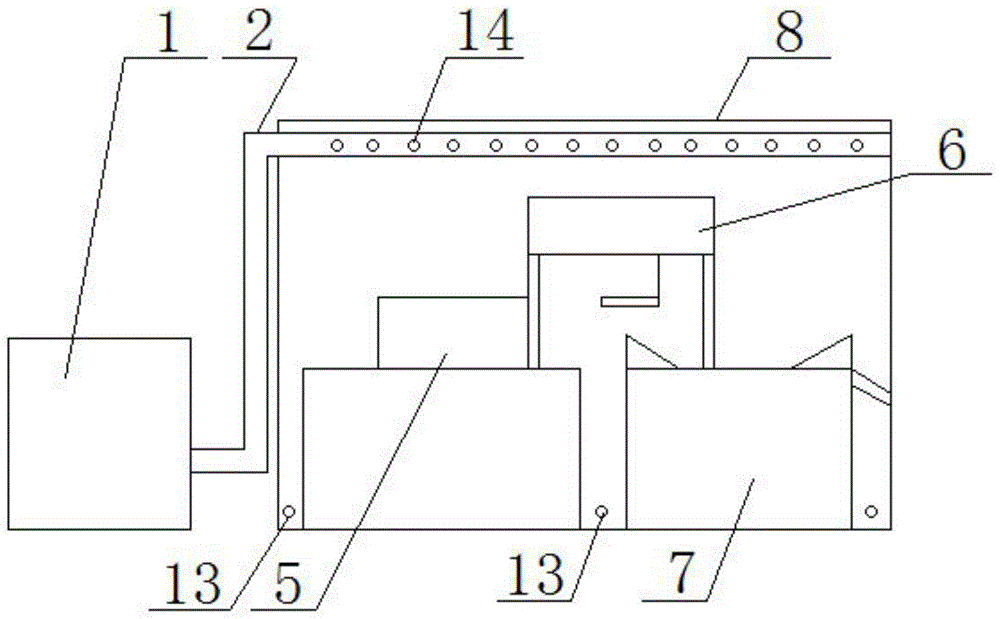

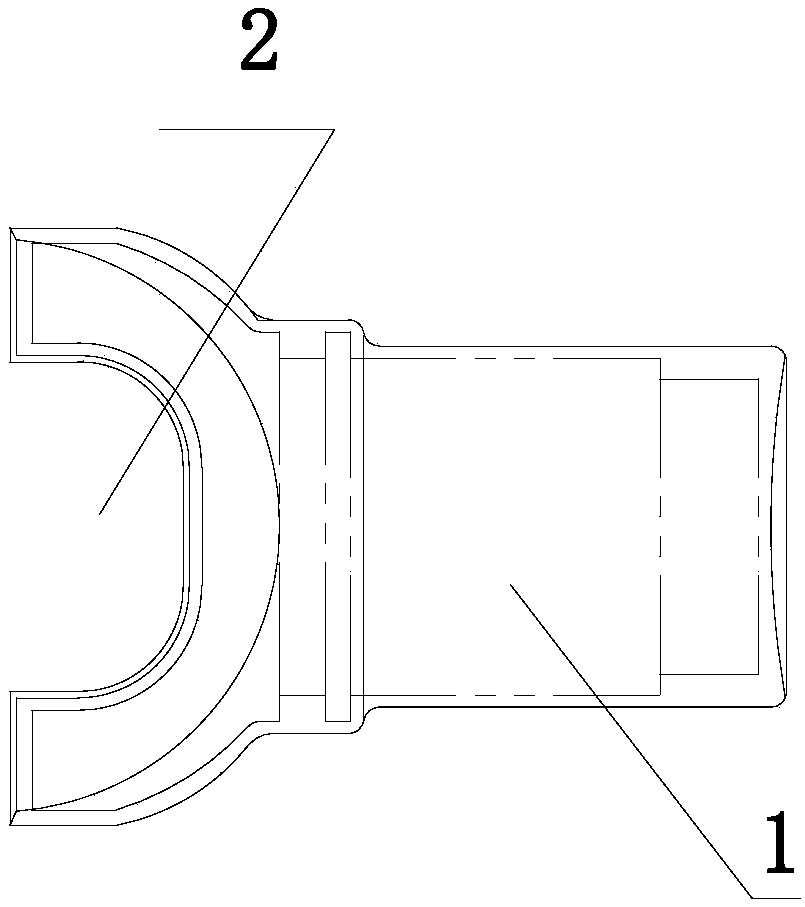

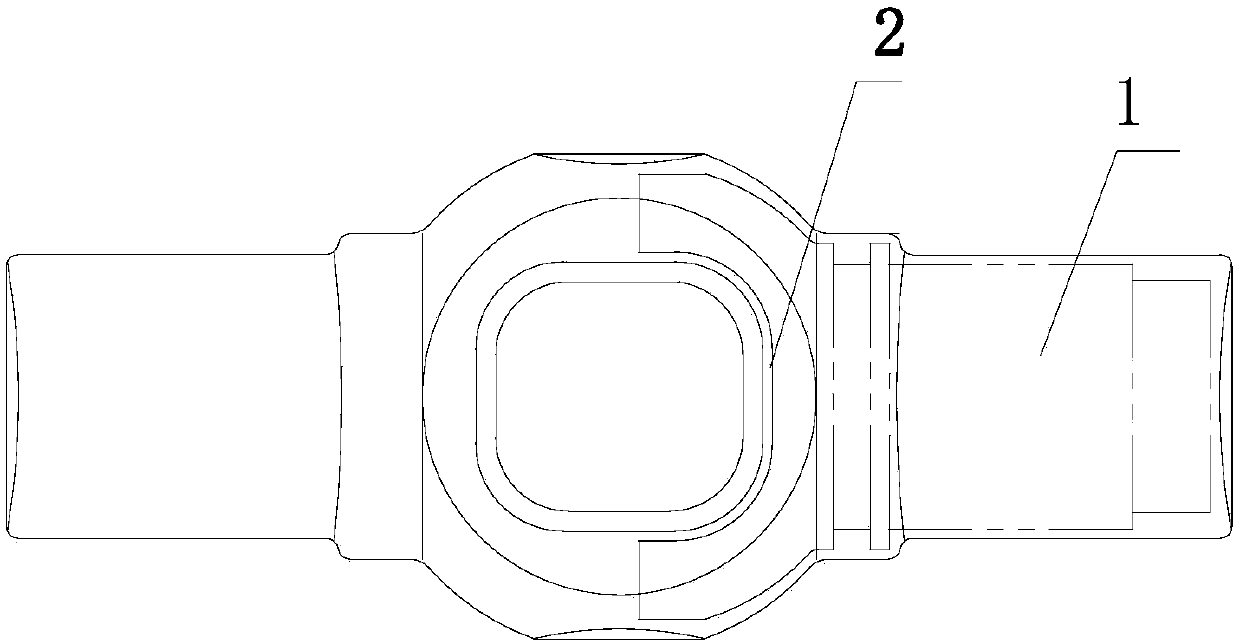

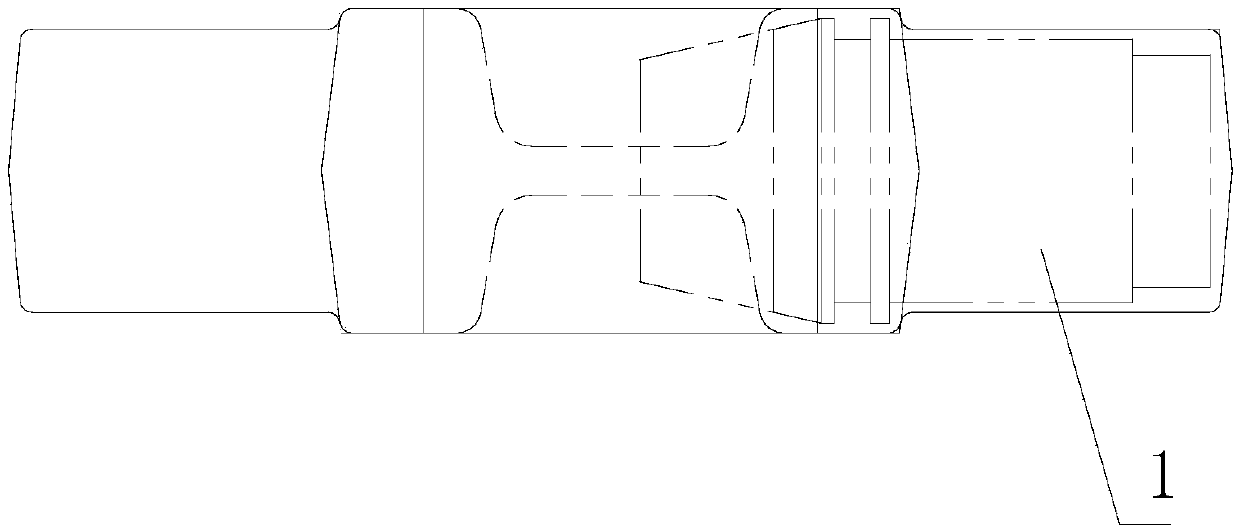

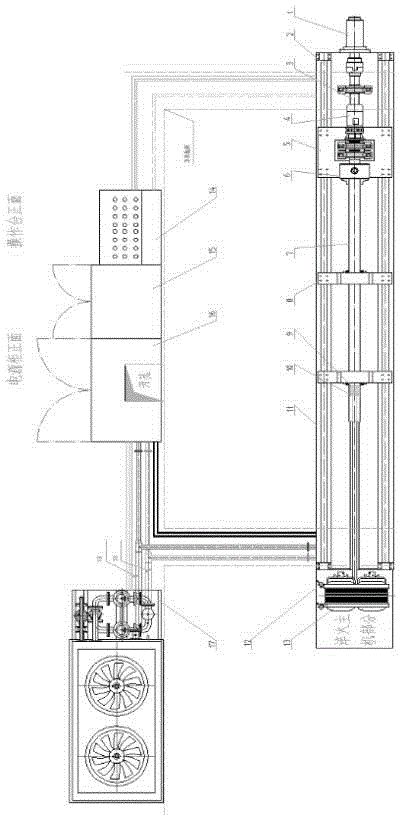

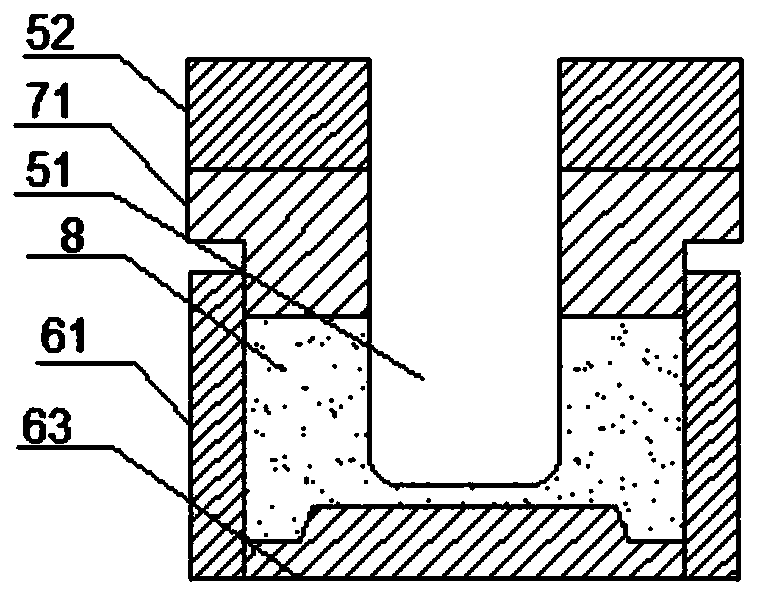

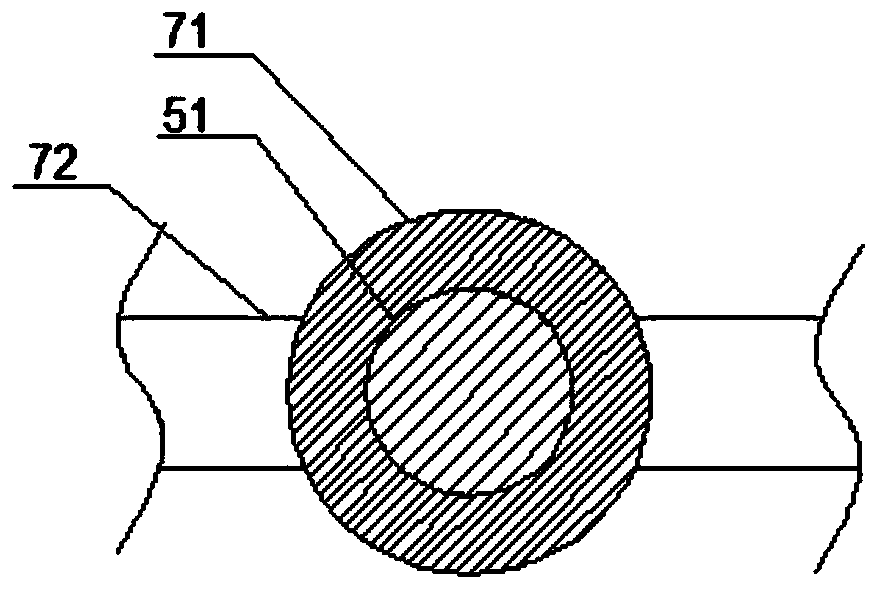

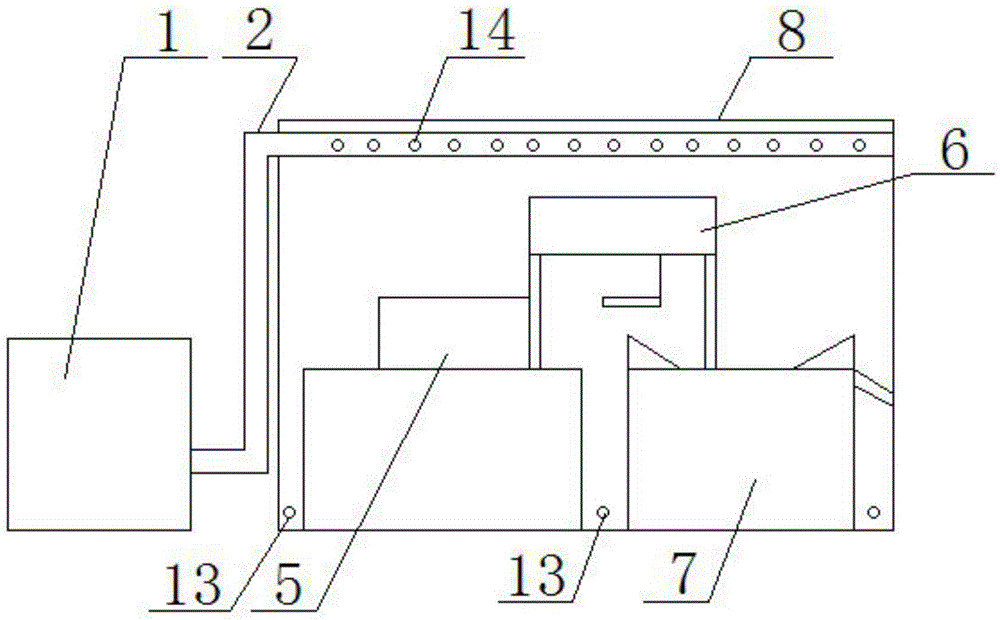

Non-oxidation brazing and thermal treatment device of hard alloy cutting teeth

ActiveCN104400172AAchieving brazing qualityExtend your lifeFurnace typesMetal working apparatusQuenchingManipulator

The invention provides a non-oxidation brazing and thermal treatment device of hard alloy cutting teeth, belongs to the technical field of cutting tools, and mainly solves the problems of the prior art of poor welding quality and thermal treatment effect. The non-oxidation brazing and thermal treatment device comprises a cryogenic box, a nitrogen transporting pipeline, a heating furnace, a quenching tank and a manipulator. The non-oxidation brazing and thermal treatment device is characterized in that the nitrogen transporting pipeline is arranged between the cryogenic box and a working bin, one part of the nitrogen transporting pipeline in the working bin is close to the top wall of the working bin, and oxidation discharge holes formed on the nitrogen transporting pipeline. The heating furnace, the quenching tank and the manipulator are located in the working bin of a sealed structure. A heating operation hole, a heating observation hole, a quenching operation hole and a quenching observation hole are formed at the top of the working bin. A waste gas discharge hole is formed on the lower portion of the working bin or on the side wall close to the bottom. A material inlet is formed on the side wall of one side of the working bin close to the heating furnace, a material outlet is arranged on the side wall of one side of the working bin close to the quenching tank, and a movable sealed device is arranged in the material outlet. The non-oxidation brazing and thermal treatment device reduces energy consumption and saves materials.

Owner:SHANXI LI PU LI TUO COAL PARTS MFG CO LTD

Forging process for locomotive sliding fork

InactiveCN107649639AAvoid artificial billeting processSimplify the operation processMetal-working apparatusEngine componentsMachine pressForging

The invention discloses a forging process of a sliding fork for a locomotive. A. According to the following steps: blanking: design the blanks of two sliding forks so that the two ends of the fork are opposite to form a group of blanks; B. Heating: The assembled rough blanks are heated and kept warm after heating; C. Pre-pressing: the pre-pressed blanks are put into the pre-pressing mold for pre-pressing and forming, and the scale is removed at the same time; D. Final forging: the pre-pressed blanks are put into Final forging in the final forging die; E. Trimming: Use a press to remove the flash from the final forged billet; F. Cutting: Cut the cooled billet from which the flash has been removed, and divide it into two parts to obtain two pieces. locomotive with sliding fork. The invention avoids the artificial billet making process, simplifies the operation process, reduces the working intensity, has a high degree of automation, improves the product quality and stability, and the force of the forging is more balanced during forming. The whole process only needs one heating, and the surface of the blank There is less scale and the surface quality of the product is improved.

Owner:CRRC DALIAN CO LTD

Copper belt production technology using upper continuous casting process

The invention relates to a production process for producing copper strips by an upward continuous casting method, which comprises the following steps: adopting copper with a purity of more than or equal to 99.95 percent as a raw material, throwing the raw material into a melting furnace for melting, and obtaining molten copper in the fused state; adding phosphor and rare earth into the molten copper in the fused state according to the proportion of addition of 0.008 to 0.04 kilogram of the phosphor and 0.005 to 0.01 kilogram of the rare earth into each 1,000 kilograms of the molten copper, and uniformly mixing the phosphor and the rare earth in the molten copper; and adopting the upward continuous casting method for casting, and guaranteeing that the temperature of the molten copper is controlled to be between 1,150 and 1,200 DEG C and the liquid level of the molten copper is 50 to 100 millimeters higher than that of a protective sleeve during casting. The production process casts the copper strips with low oxygen content, high resistivity, large density and good quality by adding the phosphor and the rare earth with proper proportion into the molten copper during upward casting.

Owner:江苏富威科技股份有限公司

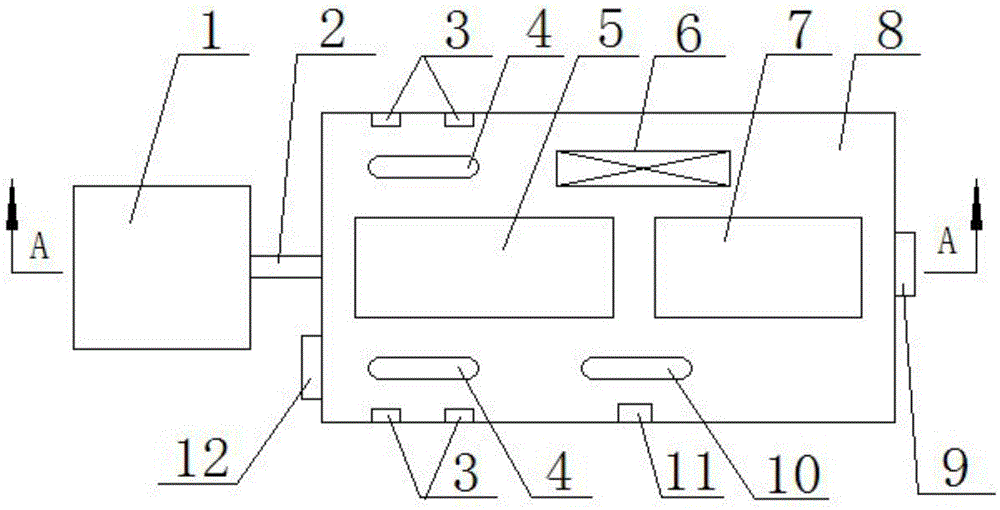

Intermediate-frequency quenching equipment for inner walls of steel tubes

InactiveCN104419806AImprove quenching qualityReduce heatingFurnace typesIncreasing energy efficiencyCooling towerMetallic materials

The invention relates to intermediate-frequency quenching equipment for the inner walls of steel tubes. The adopted technical scheme is as follows: the intermediate-frequency quenching equipment comprises a cooling tower and a quenching part, and is characterized in that the quenching part is installed on a non-workpiece side installed on the body of a quenching machining tool, a supporting plate at a workpiece side is installed on the body of the quenching machining tool through a linear guideway on the body of the quenching machining tool; the supporting plate is in threaded connection with a nut-screw pair, the nut-screw pair is connected with a supporting plate drive system, a chuck capable of fixing a pipeline workpiece is arranged on the supporting plate, and the chuck is connected with a workpiece rotation drive system; the quenching main machine of the quenching machining tool of the quenching part is connected with a quenching coil and a spray coil. The intermediate-frequency quenching equipment has the following beneficial effects that a quite high quenching quality can be easily obtained, the quenching quality is high, the production cost is low, the automation degree is high, the depth of a quenching layer, a quenching hardness and the like can be controlled, the oxidation burns of metal are less, the oxide skins are few, and the deformation amount is low, in this way, the waste of metal materials is reduced, the control is simple, and requirements on the labour skill levels of workers are low.

Owner:XI AN BANGHE ELECTRICAL EQUIP

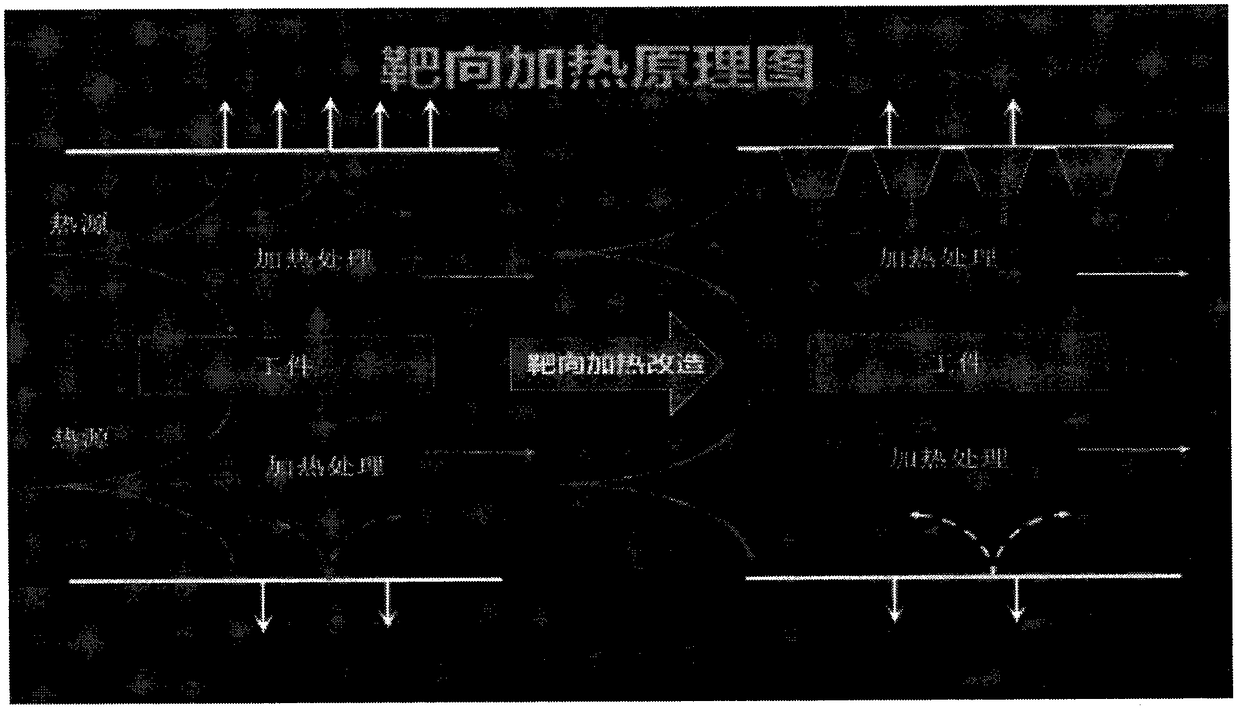

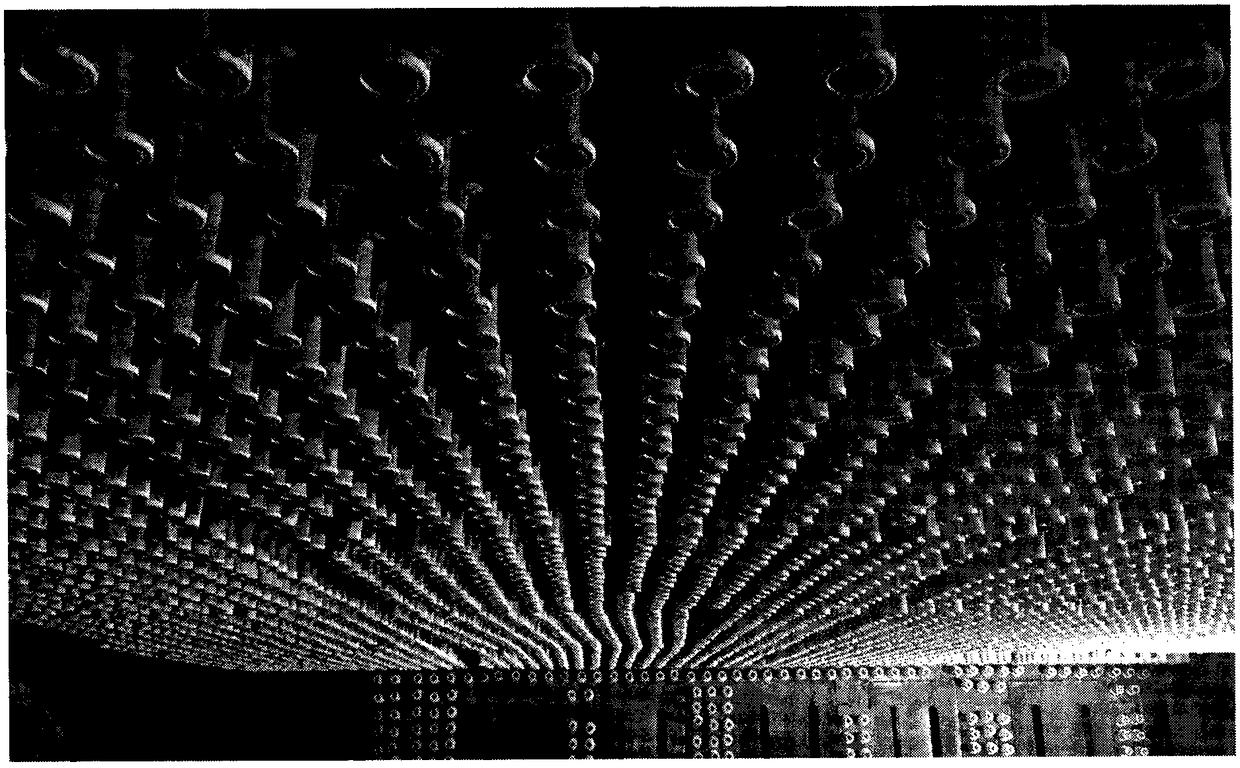

Method for reforming heating furnace with targeted heating elements

PendingCN108088256AGood energy saving effectImprove energy savingLinings repairThermal radiationHearth

The invention relates to a method for reforming a heating furnace with targeted heating elements. The method for reforming the heating furnace with the targeted heating elements comprises the steps that (1) the raw material texture of the targeted heating elements to be installed is determined; (2) the installation density and number of the targeted heating elements to be installed are calculatedand determined; (3) targeted heating element matrixes are made on the furnace top and the side wall of a hearth of the heating furnace; (4) the targeted heating elements are installed on the furnace top and the side wall of the hearth, the targeted heating elements are connected with a furnace lining through sintering materials, and mechanical fixation is conducted in the cold state; (5) coating treatment is conducted on the whole inner portion of the hearth with infrared thermal radiation nanometer materials; and (6) baking is conducted according to a heating curve, and after baking, the targeted heating elements and the furnace lining are sintered into a whole. By the adoption of the method for reforming the heating furnace with the targeted heating elements, radiation heat transfer in the hearth can be greatly enhanced, the service life of the furnace lining is prolonged, energy is saved, and the consumption is lowered.

Owner:HENAN SANSONG CERAMICS IND

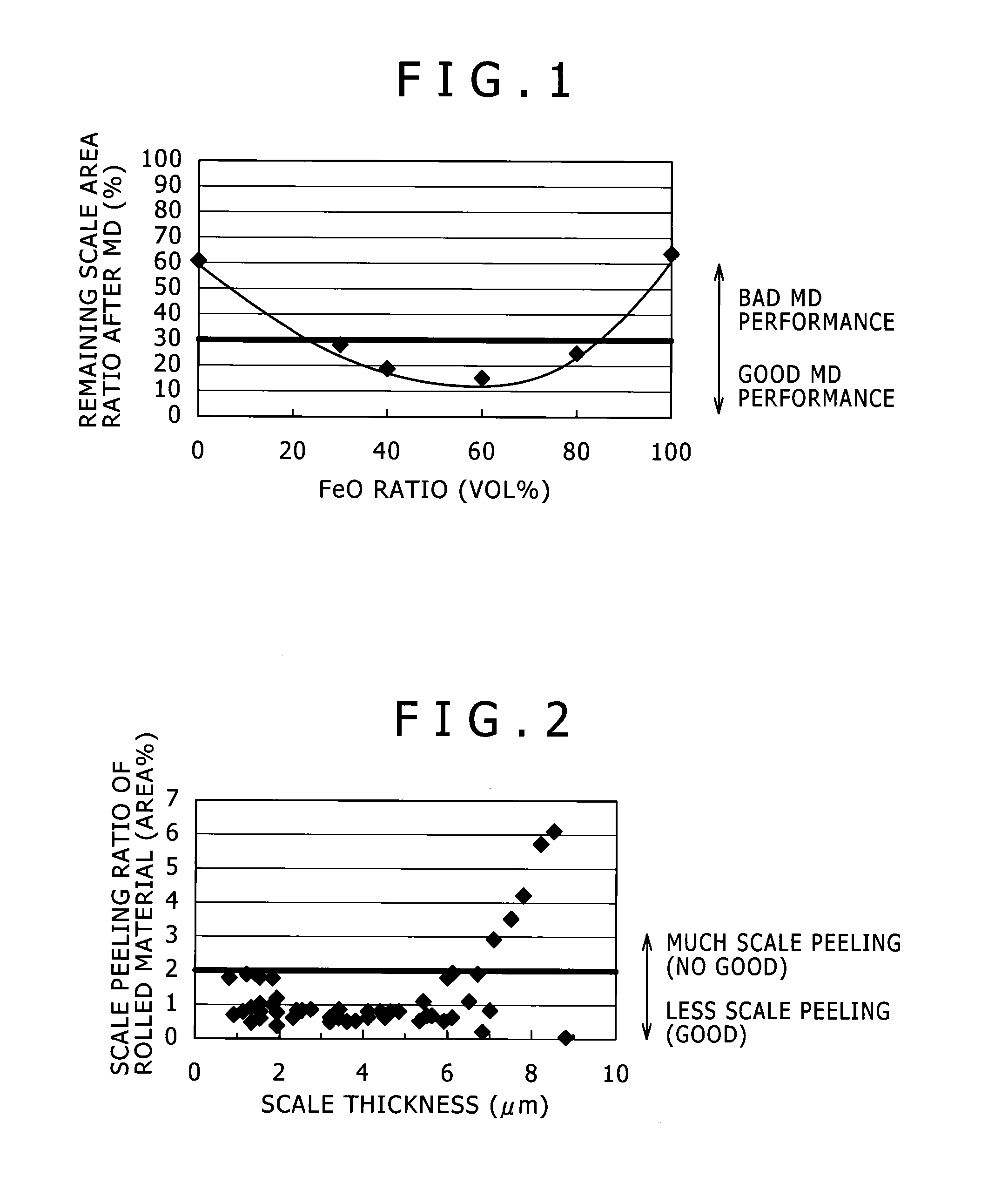

Steel wire material and method for manufacturing same

InactiveUS20130272913A1Quality improvementEasy to peelFurnace typesRollsChemical compositionMetallurgy

This steel wire material contains 0.05%-1.2% C (“%” means “% by mass,” same hereinafter for chemical components.), 0.01%-0.7% Si, 0.1%-1.5% Mn, 0.02% max. P (not including 0%), 0.02% max. S (not including 0%), and 0.005% max. N (not including 0%), with the remainder being iron and unavoidable impurities. The steel wire material has a scale 6.0-20 μm thick and holes of an equivalent circle diameter of 1 μm max. in said scale that occupy 10% by area max. Said scale does not detach in the cooling process after hot rolling or during storage or transportation but can readily detach during mechanical descaling.

Owner:KOBE STEEL LTD

High-precision closed-forging technology for forge piece

InactiveCN110238336AImprove yieldReliable workmanshipForging/hammering/pressing machinesHeating/cooling devicesPunchingProcess engineering

The invention provides a high-precision closed-forging technology for a forge piece. The technology comprises the technical steps of feeding, heating, heading, molding, punching and the like. By controlling the quality of raw materials and improving technical parameters in all steps, in cooperation with optimization of a formed mold, the finished product rate of the forging technology is greatly increased, the quality of the forge piece is obviously improved, the whole technology is stable and reliable, the control cost is lower, and the technology is suitable for industrial application and popularization.

Owner:泰州浙华机械精锻有限公司

Steel wire material and method for manufacturing same

InactiveUS20130272914A1Quality improvementPrevent rustFurnace typesRollsWire rodChemical composition

The steel wire material of the present invention contains 0.05 to 1.2% of C (mass %; same for the chemical components hereafter), 0.01 to 0.5% of Si, 0.1 to 1.5% of Mn, 0.02% or less (but not 0%) of P, 0.02% or less (but not 0%) of S, and 0.005% or less (but not 0%) of N, with the balance being iron and inevitable impurities. The wire material has a scale layer that is no thicker than 7.0 μm or less. The scale layer has an FeO percentage of 30 to 80 vol % and an Fe2SiO4 percentage of less than 0.1 vol %. The scale layer that is formed will not peel when cooled after hot rolling or during storage and transport, but will easily peel during mechanical descaling.

Owner:KOBE STEEL LTD

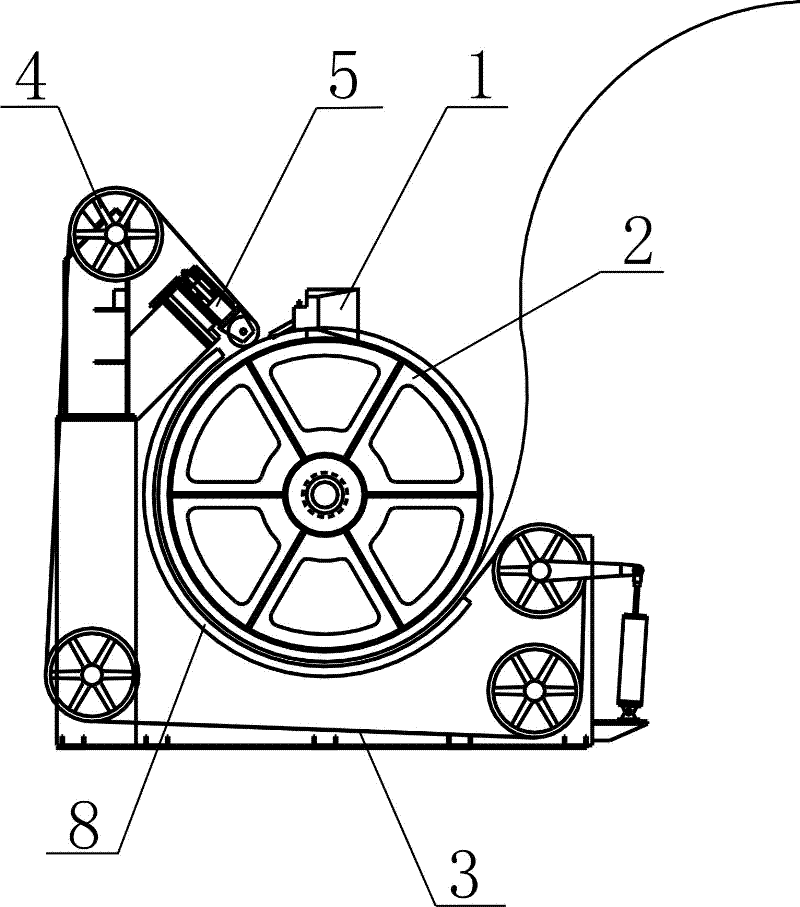

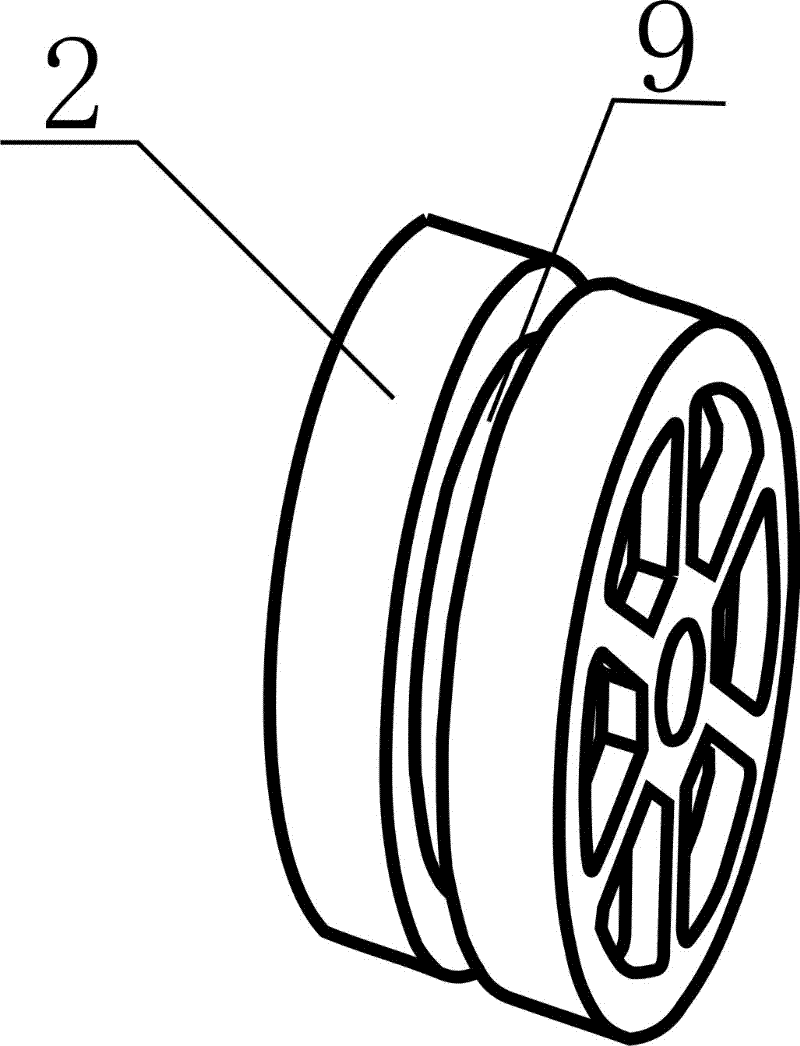

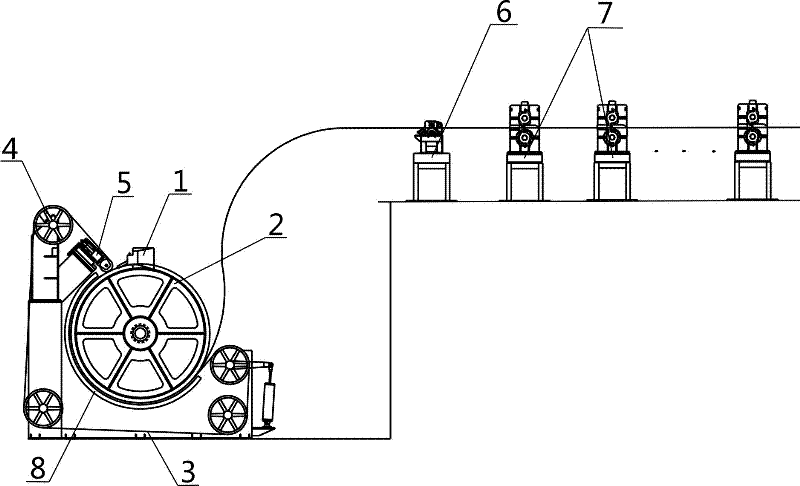

Tire type steel continuous-casting and continuous-rolling process and device thereof

InactiveCN102513354AIncrease production speedReduce lossesMetal rolling arrangementsEconomic benefitsSteel belt

The invention discloses a tire type steel continuous-casting and continuous-rolling process and a device thereof. The process comprises the following steps of: A, a melting pot; B, pouring and boiling; C, tire rotating for crystallization; D, straightening; and E, continuous rolling without torque. The tire type steel continuous-casting and continuous-rolling device comprises a pouring ladle, a casting wheel, a steel belt, tires, a steel belt pressure device, a straightening device and a hydraulic rolling device, wherein the pouring ladle is arranged above the casting wheel, and the steel belt packs the lower semicircle of the casting wheel; the steel belt is closed around the four tires and clings the lower part of the casting wheel through the steel belt pressure device; the steel belt can glue the casting wheel to rotate; and a spraying device is arranged around the steel belt and the casting wheel. According to the process and the device thereof, the continuous-casting and continuous-rolling procedures are greatly decreased, the production cost is reduced, the production efficiency is greatly increased, and the energy consumption is reduced by more than 30%. A mode of steel belt rotating and indirect cooling is adopted, so that the surface of steel has no crack and less oxide skin, and the quality and precision of finished products are increased. The device has a better economic benefit.

Owner:CHENGDU SHUHONG EQUIP MFG

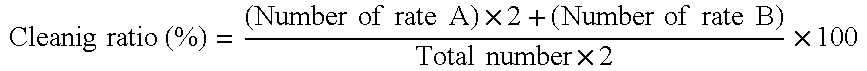

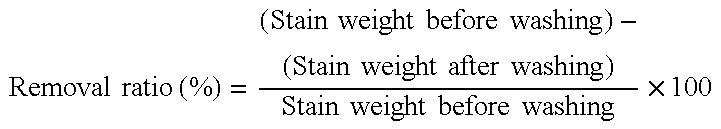

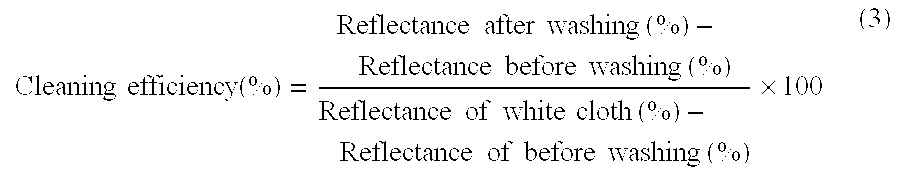

Cleaning fluid

InactiveUS20080058242A1Hard to attractLess scaleNon-ionic surface-active compoundsInorganic non-surface-active detergent compositionsSURFACTANT BLENDToilet

The cleaning fluid, which is easily mass-produced, low priced, and safe and is also free from chemical substances contains water from which polyvalent cations are removed and to which sodium ions are added. When the cleaning fluid is applied to an object to be cleaned, stain adhered onto the object can be removed by action of the water. The object washed with the cleaning fluid is free from remnant of chemical substances, as is often not the case when washed with a cleaning fluid using chemical-substances such as a surfactant, and is therefore safe. Furthermore, since water stain or scale hardly remains on the object washed, new stain is not easily attached. Accordingly, the cleaning fluid is particularly effective when it is used as a cleaning fluid for kitchen sinks, tableware, foods, washstands, bathrooms, toilets, vehicles and clothes.

Owner:MIURA COMPANY LIMITED

Equipment and method for internal high-pressure formation of high-plastic steel pipes

ActiveCN108842049AImprove structural strengthLess scaleFurnace typesHeat treatment furnacesInsulation layerSurface oxidation

The invention discloses equipment for internal high-pressure formation of high-plastic steel pipes, and belongs to the field of steel pipe quenching; and the equipment for internal high-pressure formation of the high-plastic steel pipes reduces scales on the surfaces of steel pipes. The equipment comprises a travelling bracket; a medium-frequency induction heater and a cooling device are arrangedon the travelling bracket in a steel pipe advancing direction in sequence; the travelling bracket is provided with a travelling device for driving the steel pipes to advance; an insulation device is arranged between the medium-frequency induction heater and the cooling device; the insulation device comprises an insulation bracket, and an insulation layer arranged on the insulation bracket; and through holes for enabling the steel pipes to pass through are formed in the insulation layer. As the insulation device is arranged between the medium-frequency induction heater and the cooling device, the scales on the surfaces of the produced steel pipes are few, and the structural strength of the steel pipes is higher.

Owner:江阴市一鸣管业科技有限公司

Multifunctional heavy oil and fuel oil additive, preparation and use thereof in preparing emulsified oil

InactiveCN1169927CIncrease surface areaMix well and evenlyLiquid carbonaceous fuelsActive agentOil additive

An oil-soluble multifunctional additive for heavy oil or fuel oil contains more surfactants, composite catalytic combustion adjuvant and detergent disperser, and is characterized by saving oil by 10-25%, increasing added water to 10-30% and eliminating black smoke. A process for preparing emulsified heavy oil or fuel oil is also disclosed.

Owner:WUHAN UNIV OF TECH

Process for preparing vinyl chloride copolymer resin

The present invention relates to a process for preparing a vinyl chloride copolymer resin by copolymerizing a vinyl chloride type monomer and a macromonomer having a polymer comprising an ethylenically unsaturated monomer containing a double bond in a main chain, which generates only a few scales and shows excellent polymerization stability. The present invention is achieved by the process for preparing a vinyl chloride copolymer resin by copolymerizing a vinyl chloride type monomer and a macromonomer having a polymer comprising an ethylenically unsaturated monomer containing a double bond in a main chain, wherein the vinyl chloride type monomer and the macromonomer having a polymer comprising an ethylenically unsaturated monomer containing a double bond in a main chain are dispersed and mixed at a temperature from 20° C. to 60° C. for at least 1 minute, and then copolymerization reaction thereof is initiated.

Owner:KANEKA CORP

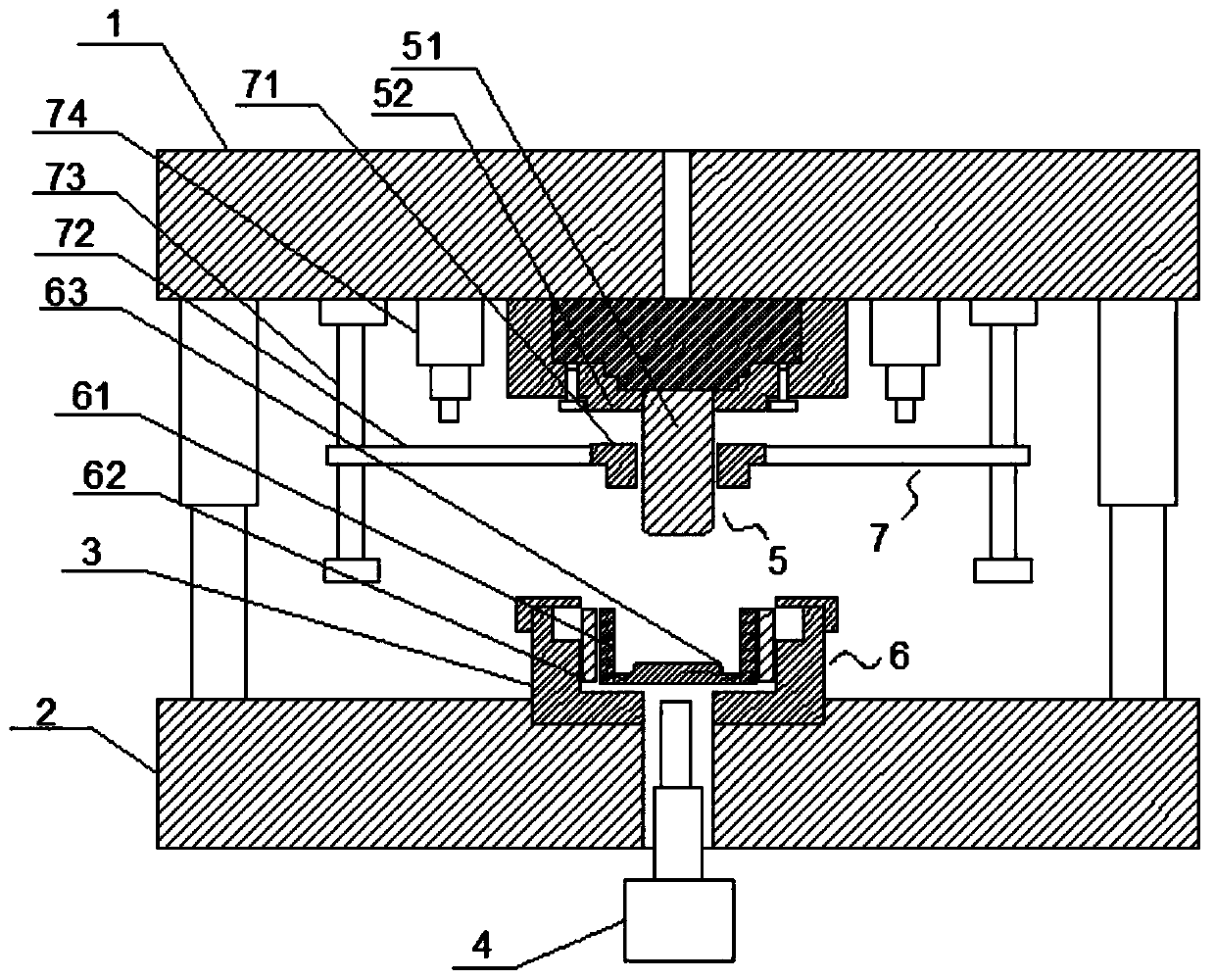

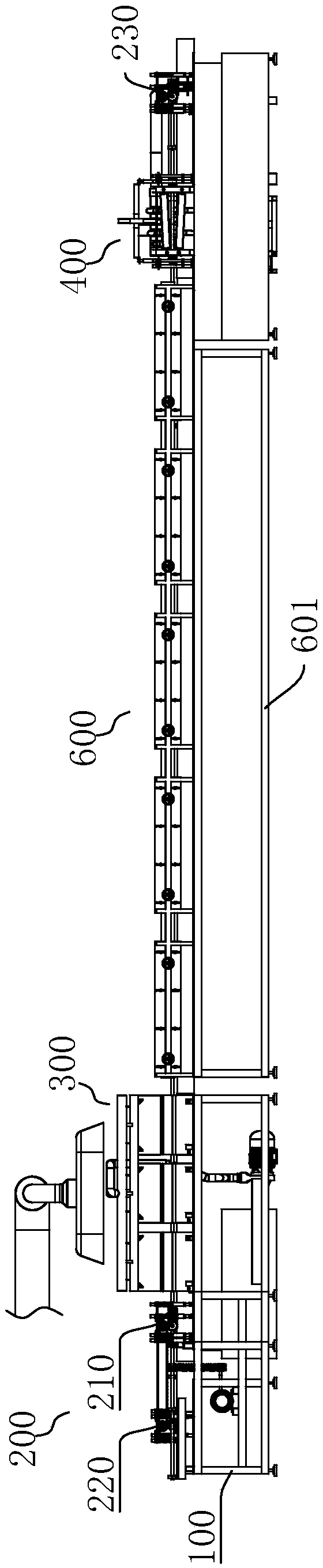

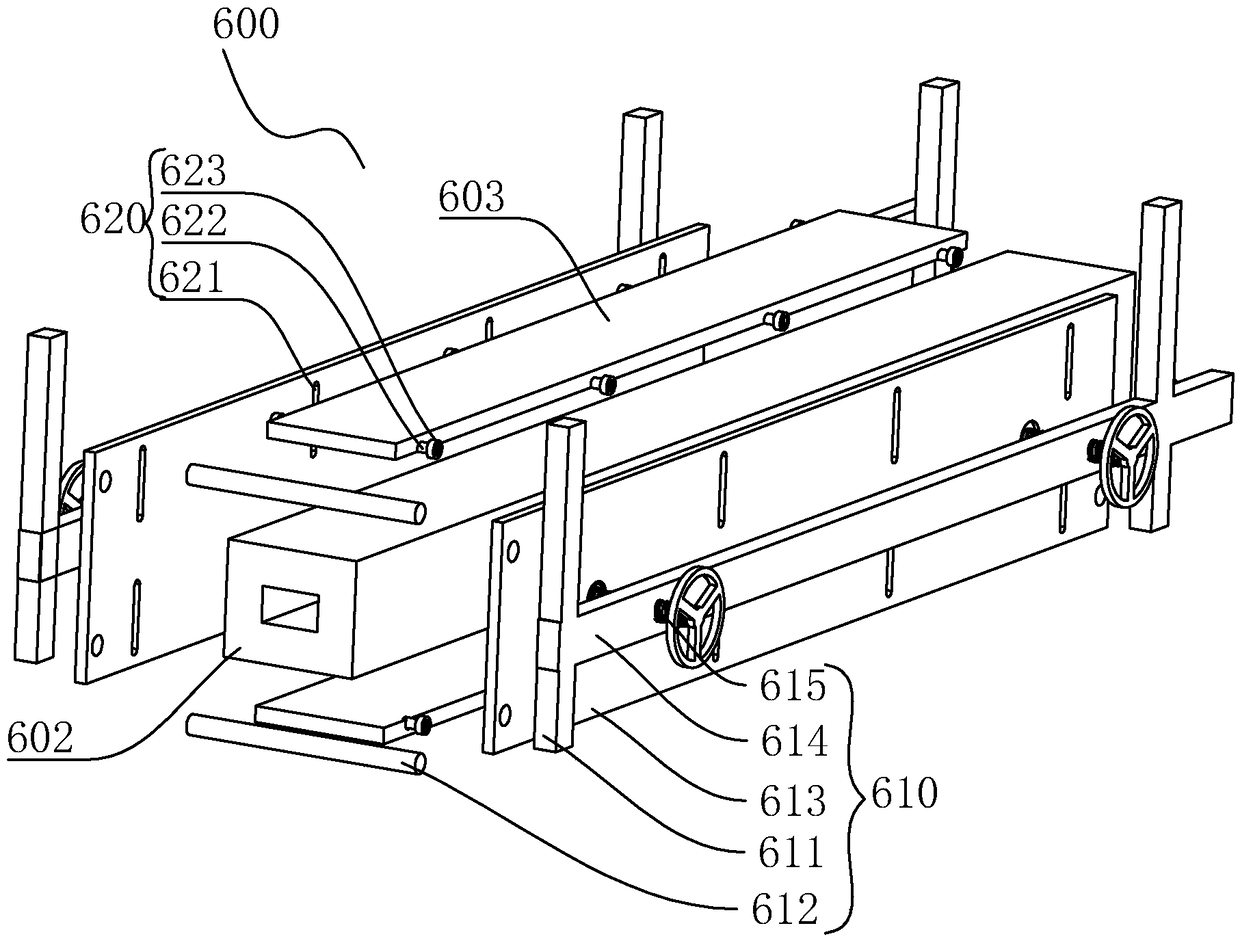

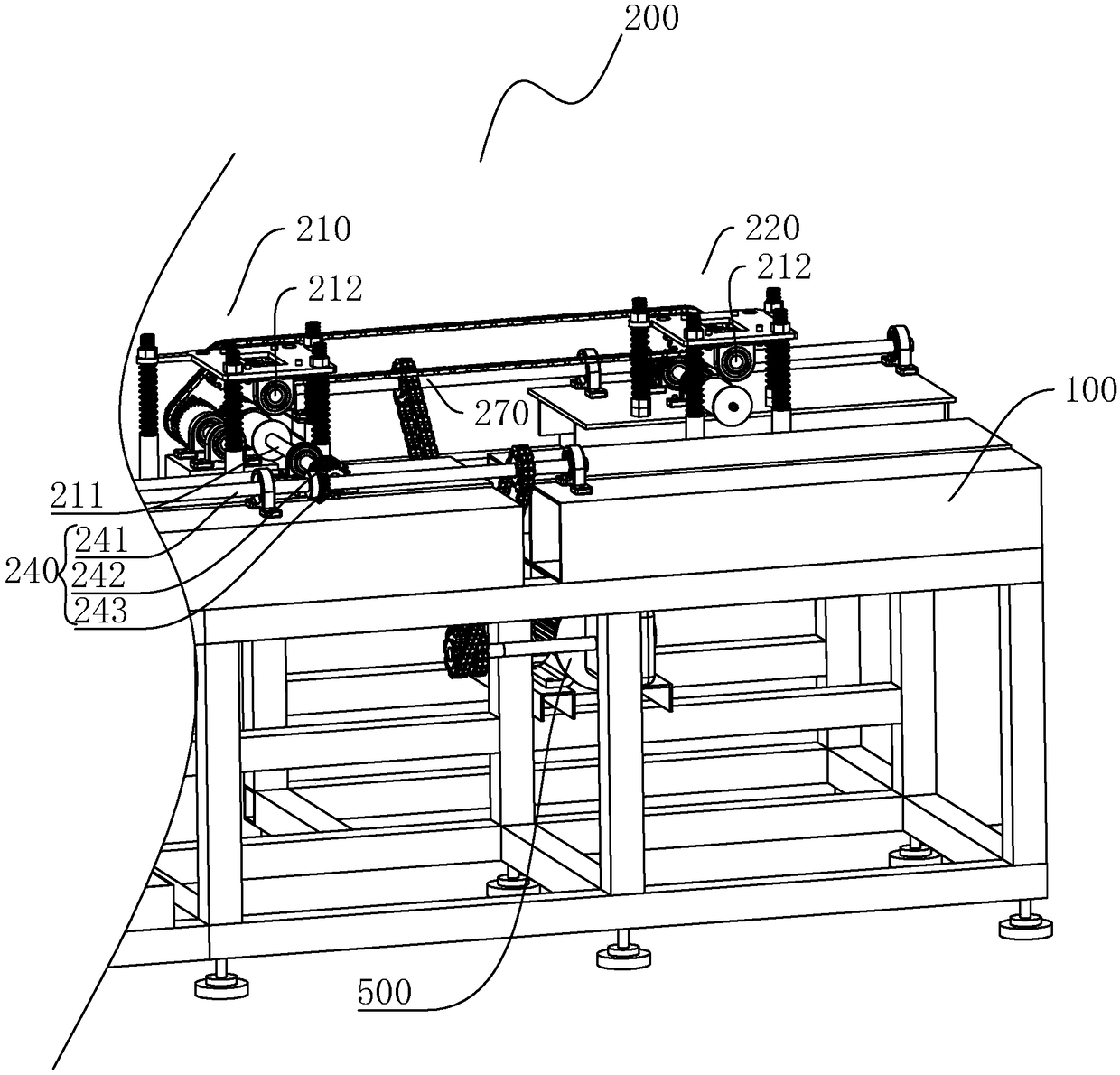

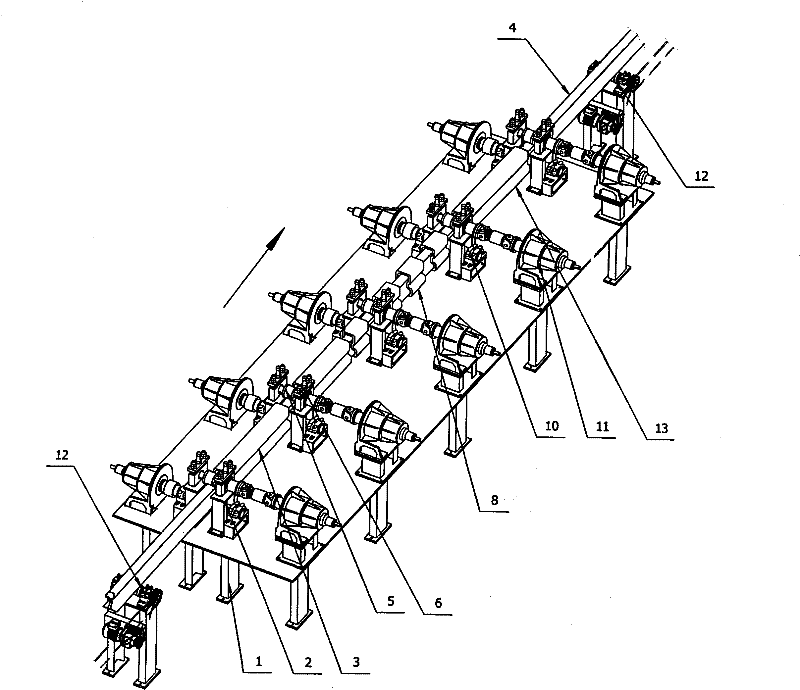

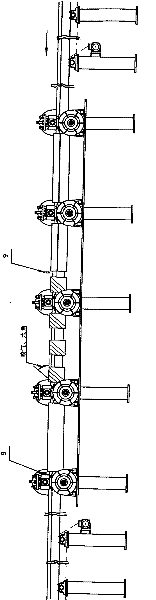

Offline or online integral quenching/tempering thermal treatment production line for standard steel rail and profiled steel rail

ActiveCN101942553BUniform heating powerFast heating powerFurnace typesHeat treatment furnacesProduction lineFrequency conversion

The invention relates to an offline or online integral quenching / tempering thermal treatment production line for a standard steel rail and a profiled steel rail, which is structurally characterized by comprising a chassis, an upper compression roller support, electromagnetic induction heaters, a steel rail, upper compression rollers, an upper compression roller adjusting device, lower pinch rollers, an air and water injection device, an infrared thermodetector, a bearing block, a frequency conversion and speed regulation speed reducer, a charging end and discharging end live-roll table 12 anda tempering induction heater. The invention has the advantage that the steel rail can not deflect when moving in the middle. Frequency conversion and speed regulation are adopted by a driving / driven roller set and the pinch roller. A plurality of pairs of pinch rolls are formed by using the upper compression rollers and the lower pinch rollers to forcibly pinch the steel rail to limit the deformation of the steel rail; the height of the upper compression rollers can be regulated; the shifting speed required by a heating and spray quenching process is satisfied by adopting the frequency conversion and the speed regulation speed, and two electromagnetic induction heaters are arranged to heat the steel rail to reach the process temperature. The infrared thermodetector can monitor the heatingfinal temperature of the steel rail, the temperature of the steel rail can be stabilized in the temperature range of the quenching process, and the heating temperature is even.

Owner:朱兴发

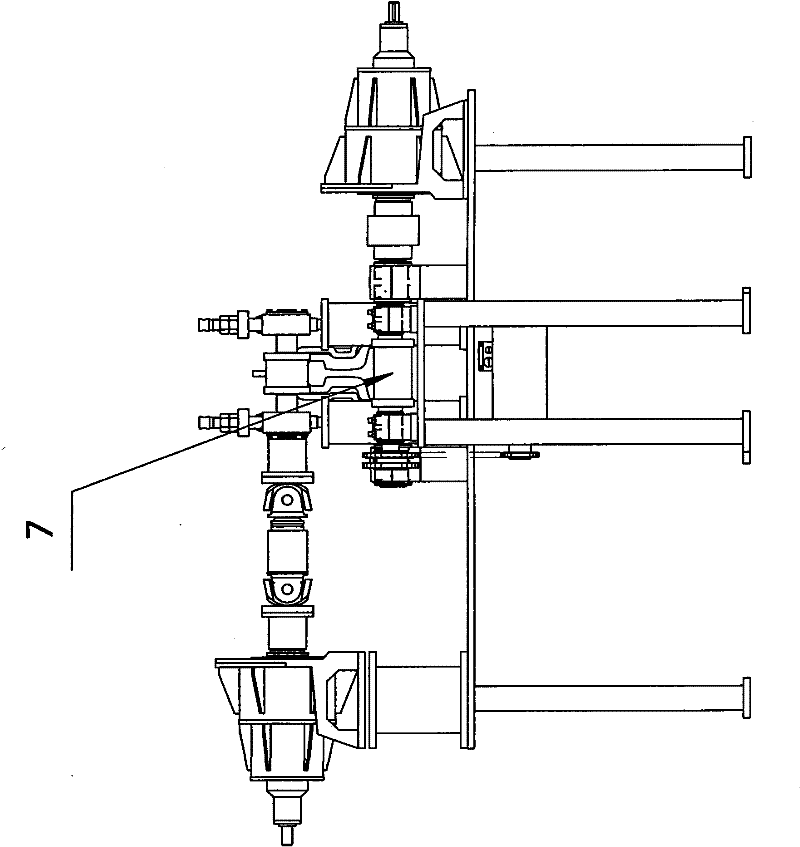

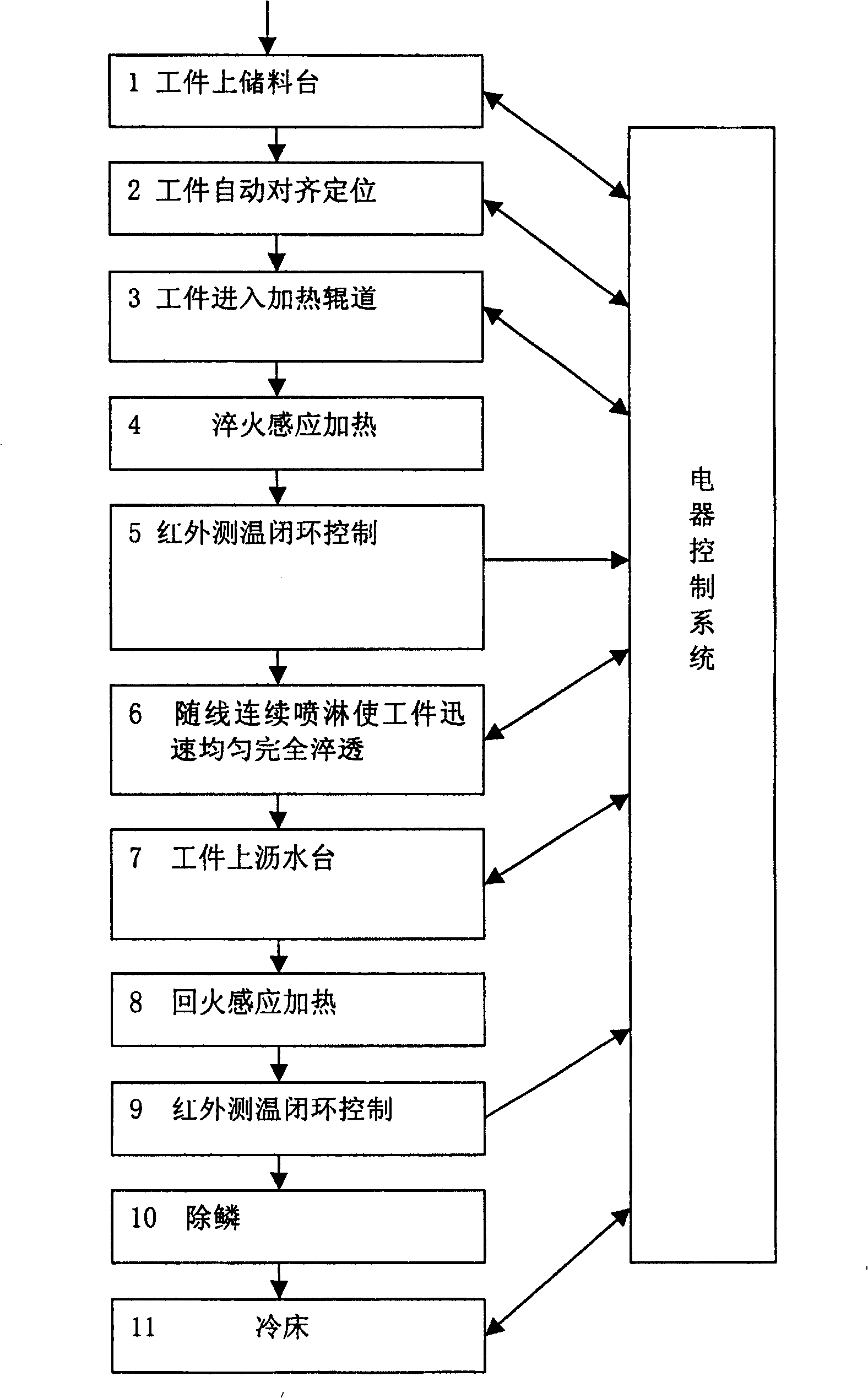

Medium frequency induction heating treatment method for steel pipe, petroleum well pipe and drill pipe

ActiveCN100422353CNo pollution in the processHeating evenlyFurnace typesIncreasing energy efficiencyClosed loopPetroleum

This invention provides a kind of main-frequency induction heating method using in the frequency treatment system of steel pipe and the tube and drill pipe of oil well. This method include put the work piece to the storage platform, the work piece automatic alignment and localization, the work piece enter the heating roller, quenching inducing heated, closed loop temperature control system, continuum spray ensure the work piece being uniformly quenched entire and quickly, the water stay in the work piece being ejected on the detearing platform, the work piece is heated by the temper inducing heater which controlled by the infrared thermometer controller, descaling device, and then enter the descaling device , the final is the cooling platform. The intermediate-frequency induction heater is using as the heating system, which is safe, no pollution and with little oxide scale. The heater roller ensure the work piece is heated uniformly and entirely, and after this process the work piece no need to be straightened which decrease the cost. The spray quenching equipment ensure the work piece could be uniformly quenched entire and quickly. The descaling device makes the surface of the work piece brightly. The detearing platform makes the work piece move automatically, which won' t influence the heating effect. And the water and steam could not enter the heating inducing loop either, which can increase the life of the loop..

Owner:朱兴发

Rolling method of titanium steel composite board

ActiveCN102794299BQuality assuranceReduce harmTemperature control deviceWork treatment devicesForeign matterHigh pressure water

The invention provides a rolling method of a titanium steel composite board. The rolling method comprises the following steps of: 1, selecting the titanium steel composite board provided with a titanium plate as an upper layer and a steel plate as a lower layer; 2, pre-treating a surface; 3, heating and soaking in a heating furnace; and 4, rolling on a hot mill, and removing scale and cooling by utilizing high-pressure water. According to different physical characteristics of the titanium plate and the steel plate under the high-temperature state, through setting the proper heating and soaking processes, and adopting the high pressure water to remove the scale and cool in the rolling process, an oxide skin on the surface of the titanium steel composite board is greatly reduced, and sundries on the surface of the titanium steel composite board are eliminated, meanwhile, the titanium plate and the steel plate are cooled at different water flows, so that the deformation degree of the titanium plate corresponds to the deformation degree of the steel plate, head buckle or unwarp phenomenon of the titanium steel composite board in the rolling process can be effectively prevented, and damage about a roller is greatly reduced; and the titanium steel composite board, rolled by the invention, has the advantages of clean and tidy surface, no foreign matters to press and good plate cut.

Owner:WESTERN TITANIUM TECH

Steel wire material and method for manufacturing same

InactiveUS9708696B2Quality improvementEasy to scaleFurnace typesMetal rolling arrangementsChemical compositionMetallurgy

A method of manufacturing a steel wire material that contains 0.05%-1.2% C (“%” means “% by mass,” same hereinafter for chemical components.), 0.01%-0.7% Si, 0.1%-1.5% Mn, 0.02% max. P (not including 0%), 0.02% max. S (not including 0%), and 0.005% max. N (not including 0%), with the remainder being iron and unavoidable impurities. The steel wire material has a scale 6.0-20 μm thick and holes of an equivalent circle diameter of 1 μm max. in said scale that occupy 10% by area max. Said scale does not detach in the cooling process after hot rolling or during storage or transportation but can readily detach during mechanical descaling.

Owner:KOBE STEEL LTD

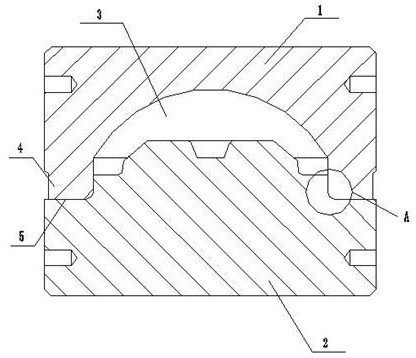

Butterfly-shaped cylinder bottom closed die forging structure

The invention provides a butterfly-shaped cylinder bottom closed die forging structure. A die assembly concave edge is arranged on the edge of a lower die, and a cavity in the lower die is higher than the die assembly concave edge; and the edge of an upper die is provided with a lock catch matched with the die assembly concave edge, after die assembly, the lock catch is clamped on the die assembly concave edge to seal a casting cavity, and in the vertical direction, the angle between the vertical edge of the lock catch and the vertical edge of the die assembly concave edge is 3.5-5 degrees. The butterfly-shaped cylinder bottom closed die forging structure has the advantages that under the condition that closed die forging is adopted, a forge piece is free of flash waste, materials are saved, and the material cost is reduced; no residual flash exists at the outer circle, the quality of the forge piece is improved, the machining allowance is reduced, and the production efficiency is improved; and when the forge piece is forged, the spherical surface faces upwards, and the oxide skin of a spherical part is reduced.

Owner:郑州煤机格林材料科技有限公司

Production method of cam plate

The invention relates to a production method of a cam piece. The production method of the cam piece comprises the following steps: 1, feeding, wherein the mass percentage of alloy components is as follows: 0.48 percent to 0.53 percent of carbon, 0.15 percent to 0.30 percent of silicon, 0.80 percent to 1.00 percent of manganese, 0.70 percent to 0.85 percent of chromium, 0.02 percent to 0.05 percent of aluminum, less than or equal to 0.03 percent of phosphorus, less than or equal to 0.02 percent of sulfur and the balance of iron and unavoidable impurities; 2, forging workblanks; 3, heating and punching; 4, annealing; 5, performing hole extrusion; 6, machining; 7, performing shot blasting treatment; and 8, performing hardening and tempering treatment. According to the production method of the cam piece, provided by the invention, the rate of finished products is high, and the produced cam piece has high precision and excellent comprehensive mechanical performance.

Owner:JIANGSU XINSHU FORGING CO LTD

Oxidation-free brazing and heat treatment device for cemented carbide picks

ActiveCN104400172BNo decarbonizationReduce oxidationFurnace typesMetal working apparatusNitrogen gasHeating furnace

The invention provides a non-oxidation brazing and thermal treatment device of hard alloy cutting teeth, belongs to the technical field of cutting tools, and mainly solves the problems of the prior art of poor welding quality and thermal treatment effect. The non-oxidation brazing and thermal treatment device comprises a cryogenic box, a nitrogen transporting pipeline, a heating furnace, a quenching tank and a manipulator. The non-oxidation brazing and thermal treatment device is characterized in that the nitrogen transporting pipeline is arranged between the cryogenic box and a working bin, one part of the nitrogen transporting pipeline in the working bin is close to the top wall of the working bin, and oxidation discharge holes formed on the nitrogen transporting pipeline. The heating furnace, the quenching tank and the manipulator are located in the working bin of a sealed structure. A heating operation hole, a heating observation hole, a quenching operation hole and a quenching observation hole are formed at the top of the working bin. A waste gas discharge hole is formed on the lower portion of the working bin or on the side wall close to the bottom. A material inlet is formed on the side wall of one side of the working bin close to the heating furnace, a material outlet is arranged on the side wall of one side of the working bin close to the quenching tank, and a movable sealed device is arranged in the material outlet. The non-oxidation brazing and thermal treatment device reduces energy consumption and saves materials.

Owner:SHANXI LI PU LI TUO COAL PARTS MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com