Continuous unidirectional solidification preparation method of high-purity oxygen-free copper rod

A technology of directional solidification and oxygen-free copper rod, which is applied in the field of preparation of new non-ferrous metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

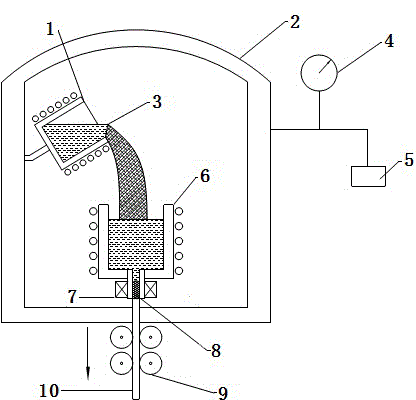

Image

Examples

Embodiment 1

[0028] Bake cathode copper with a purity of 99.99% and an oxygen content of 10ppm in a holding furnace at 200°C for 2 hours to fully degas, then put it into a melting crucible in a vacuum directional solidification furnace, close the furnace door, and lock the safety lock of the furnace door. After passing through the cooling water, turn on the mechanical pump switch to evacuate to 10Pa, then start the molecular pump to further evacuate to 10Pa -2 Pa, turn on the heating power of the induction coil for heating the outer layer of the melting crucible, and melt the charge at 1280°C. At the same time, heat the graphite heater on the outer layer of the continuous directional solidification crucible to ensure that the temperature in the continuous directional solidification crucible is above the melting point of copper liquid 1083.4°C before pouring; press down the control lever and pour the refined copper liquid 2 into the continuous In the directional solidification crucible, kee...

Embodiment 2

[0031] Bake cathode copper with a purity of 99.99% and an oxygen content of 20ppm in a holding furnace at 200°C for 4 hours to fully degas, put it into a melting crucible in a vacuum directional solidification furnace, close the furnace door, lock the safety lock of the furnace door, and After entering the cooling water, turn on the mechanical pump switch to evacuate to 10Pa, then start the molecular pump to further evacuate to 10Pa -2 Pa, turn on the heating power supply of the induction coil for heating the outer layer of the melting crucible, and melt the charge at 1300°C. At the same time, heat the graphite heater on the outer layer of the continuous directional solidification crucible to ensure that the temperature in the continuous directional solidification crucible is above the melting point of copper liquid: 1083.4°C before pouring; press down the control lever and pour the refined copper liquid into the continuous In the directional solidification crucible, keep warm...

Embodiment 3

[0034] Bake cathode copper with a purity of 99.99% and an oxygen content of 15ppm in a holding furnace at 200°C for 3 hours to fully degas, put it into a melting crucible in a vacuum directional solidification furnace, close the furnace door, lock the safety lock of the furnace door, and After entering the cooling water, turn on the mechanical pump switch to evacuate to 10Pa, then start the molecular pump to further evacuate to 10Pa -2 Pa, turn on the heating power supply of the induction coil for heating the outer layer of the melting crucible, and melt the charge at 1300°C. At the same time, heat the graphite heater on the outer layer of the continuous directional solidification crucible to ensure that the temperature in the continuous directional solidification crucible is above the melting point of copper liquid: 1083.4°C before pouring; press down the control lever and pour the refined copper liquid into the continuous In the directional solidification crucible, keep warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com