Equipment and method for internal high-pressure formation of high-plastic steel pipes

A technology of internal high-pressure forming and steel pipes, which is applied in the field of steel pipe quenching, can solve problems such as multiple scales and the influence of steel pipe structural strength, and achieve the effect of good structural strength of steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

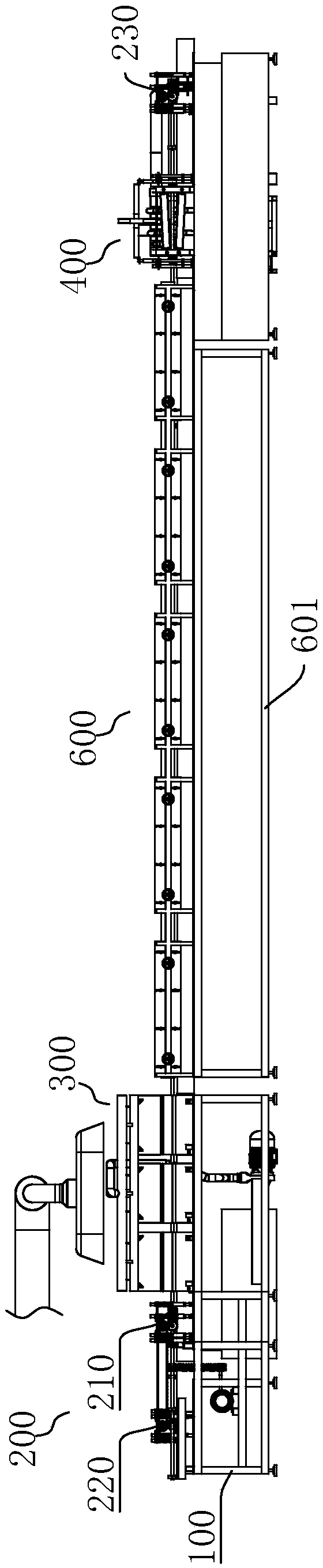

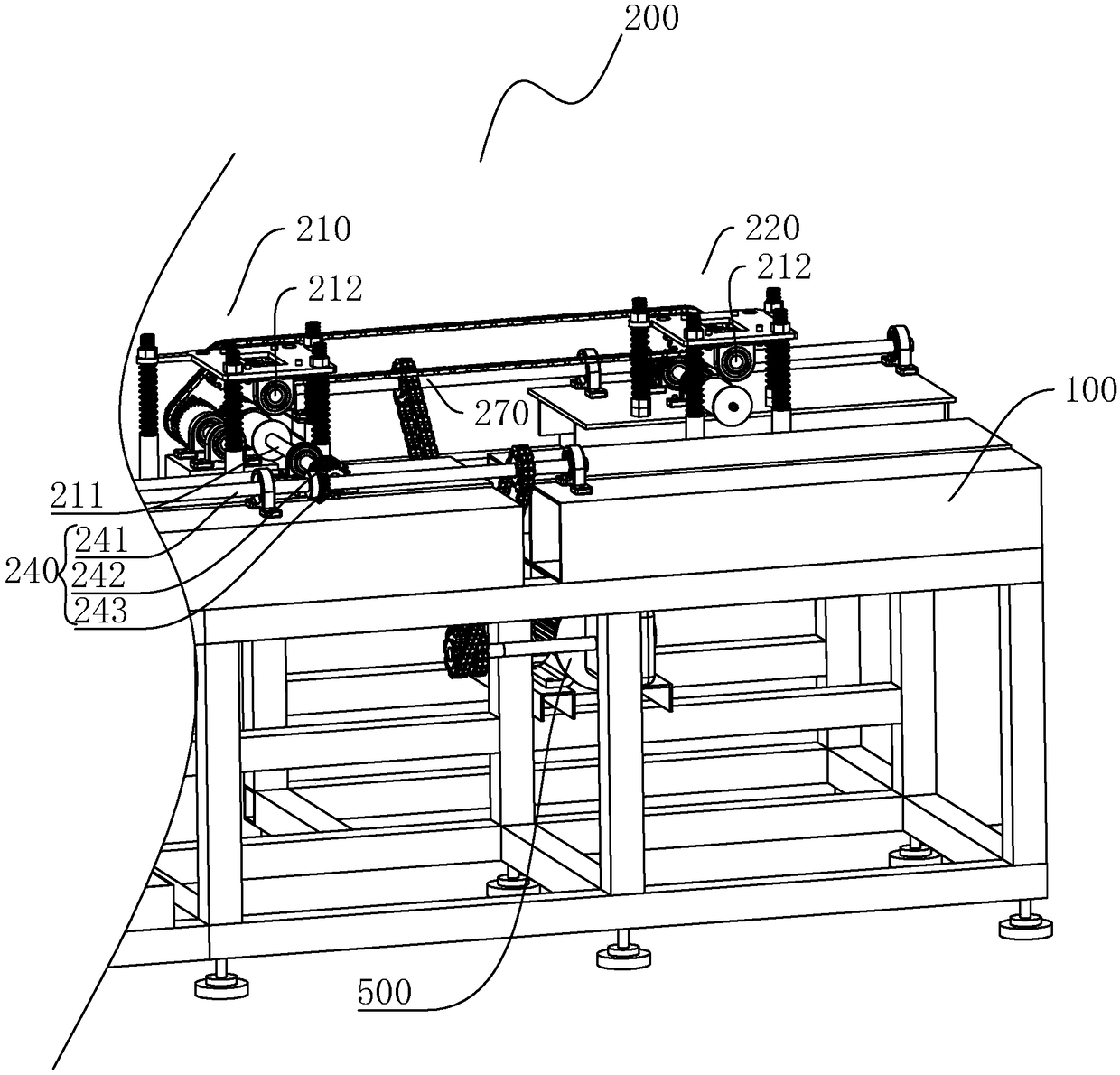

[0045] Embodiment 1: A kind of equipment for internal high pressure forming high plastic steel pipe, such as figure 1 As shown, the walking frame 100 is included, and the walking frame 100 is provided with an intermediate frequency induction heater 300, a heat preservation device 600, and a cooling device 400 in sequence along the advancing direction of the steel pipe.

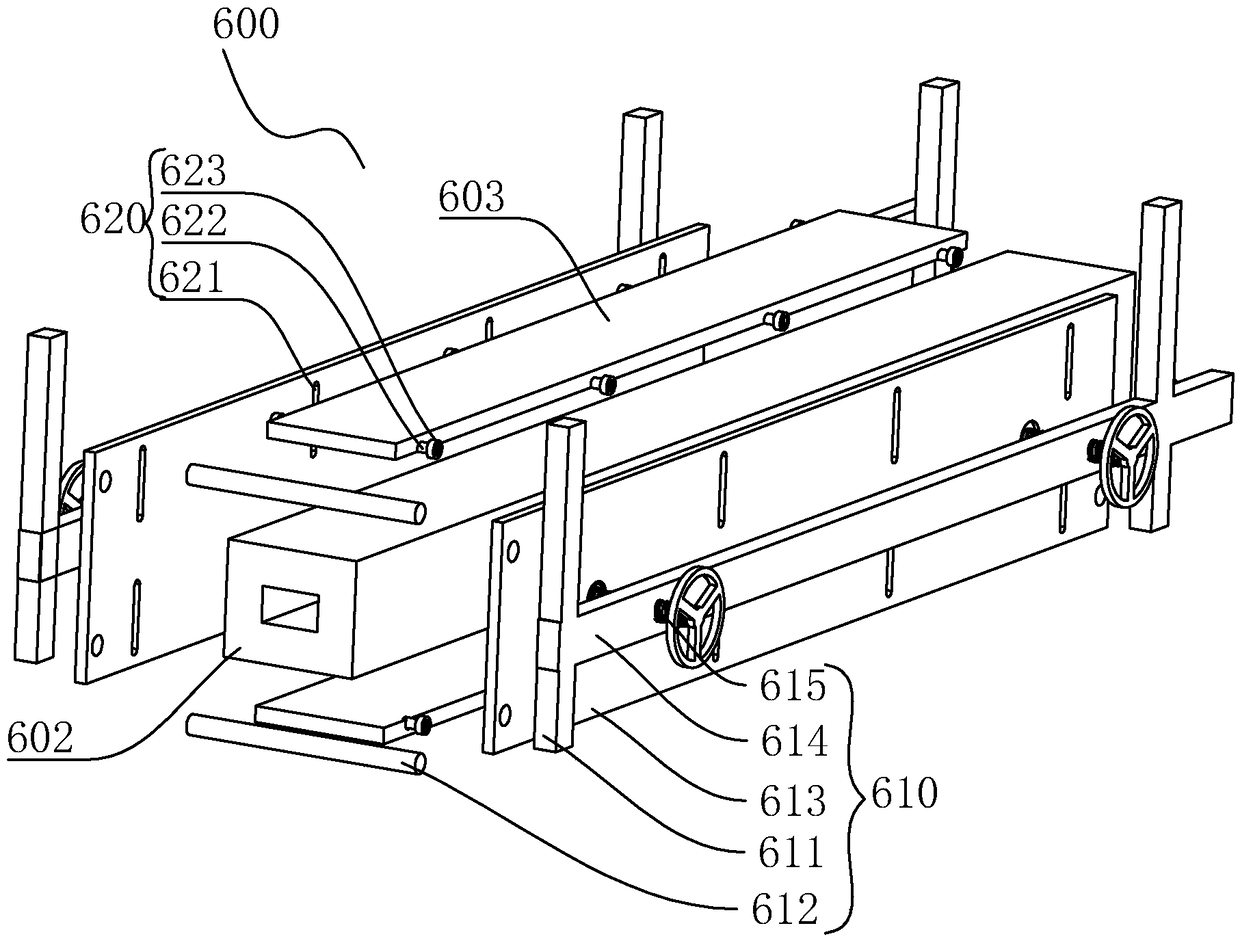

[0046] Such as figure 1 and 2As shown, the heat preservation device 600 includes a heat preservation support 601 and a heat preservation layer 602 arranged on the heat preservation support 601 , and a square through hole for passing through a square steel pipe is opened in the heat preservation layer 602 . The thermal insulation layer 602 is made of thermal insulation cotton, and the thermal insulation bracket 601 is provided with a first adjusting component 610 for adjusting the size of the through hole. After the steel pipe is heated by the medium frequency induction heater 300, it enters the square throug...

Embodiment 2

[0067] Embodiment 2: A kind of equipment for internal high pressure forming high plastic steel pipe, such as figure 1 and 6 As shown, the thermal insulation layer 602 is made of thermal insulation cotton, and the cross-section of the through hole is arranged in a circle. The thermal insulation bracket 601 is provided with a third adjustment component 630 for adjusting the diameter of the through hole. In this embodiment, the through hole is set in a circular shape, which is mainly suitable for circular steel pipes. When processing steel pipes of different sizes, the thermal insulation cotton is more suitable for the circular steel pipes during adjustment.

[0068] Such as Figure 6 As shown, the third adjustment assembly 630 includes two semicircular hoops 631 arranged up and down, the insulation layer 602 is located between the two hoops 631, the two sides of the heat preservation bracket 601 are respectively provided with adjustment plates 632, and the adjustment plates 632...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com