Optical round wire rod reinforcement bar for producing prestressed concrete steel rod and processing method

A technology of concrete steel bars and processing methods, applied in the direction of improving process efficiency, etc., can solve the problems of delaying the promotion and application of steel bars for prestressed concrete, affecting the enthusiasm of new high-efficiency energy-saving materials, and the enthusiasm of steel bar production enterprises. Uniform microstructure, easy processing, no upsetting cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

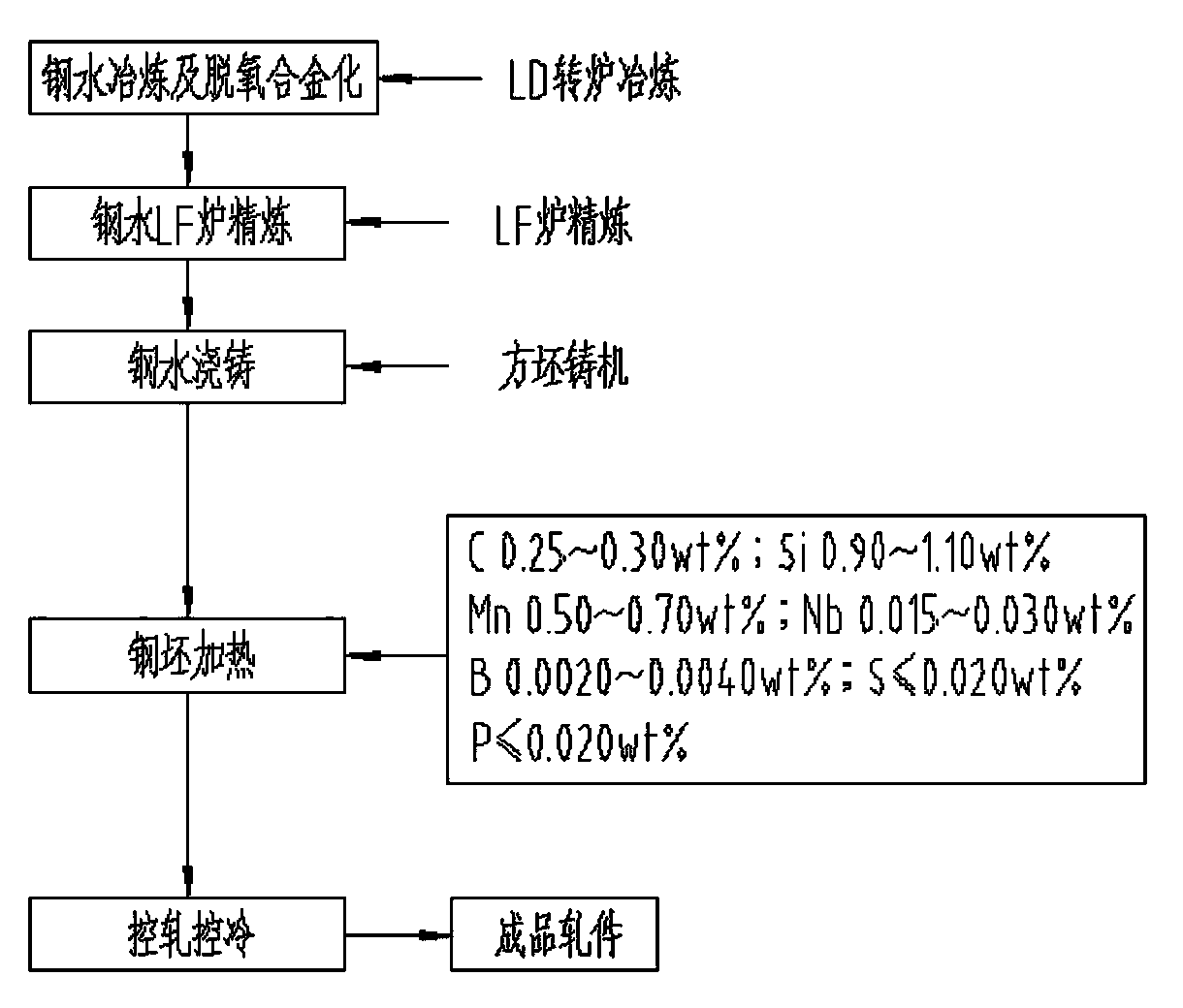

Method used

Image

Examples

Embodiment 1

[0031] The light circular wire rod steel bar used to make prestressed concrete steel rods has the following chemical composition in weight percentage: C 0.25wt%, Si 0.90wt%, Mn 0.50wt%, Nb 0.015wt%, B 0.0020wt%, P 0.020 wt%, S 0.020 wt%, the rest is Fe and unavoidable impurities. After processing through the following procedures, a smooth round steel bar with a diameter of 8.0mm is obtained:

[0032] Described molten steel smelting and deoxidation alloying are molten iron (chemical composition C 4.0wt%, Si 0.30wt%, Mn 0.25wt%, P 0.170wt%, S 0.015wt%, the rest is Fe and unavoidable impurity ), steel scrap (chemical composition C 0.20wt%, Si 0.25wt%, Mn 0.30wt%, P 0.055wt%, S 0.040wt%, the rest is Fe and unavoidable impurities) and pig iron (chemical composition C 3.2wt% %, Si 0.40 wt%, Mn 0.25 wt%, P 0.110wt%, S 0.020wt%, and the rest are Fe and unavoidable impurities) into the LD converter for conventional top-bottom compound blowing, adding in conventional amounts Lime, dol...

Embodiment 2

[0039] The light disc steel bar used to make prestressed concrete steel rods has the following chemical composition in weight percentage: C 0.28wt%, Si 1.00wt%, Mn 0.60wt%, Nb 0.023wt%, B 0.0030wt%, P 0.017 wt%, S 0.016 wt%, the rest is Fe and unavoidable impurities. After processing through the following procedures, a smooth round steel bar with a diameter of 12.0mm is obtained:

[0040]Described molten steel smelting and deoxidation alloying are molten iron (chemical composition C 5.0wt%, Si 0.60wt%, Mn 0.55wt%, P 0.145wt%, S 0.012wt%, the rest is Fe and unavoidable impurity ), steel scrap (chemical composition C 0.30wt%, Si 0.40wt%, Mn 0.65wt%, P 0.045wt%, S 0.030wt%, the rest is Fe and unavoidable impurities) and pig iron (chemical composition C 3.6wt% %, Si 0.55 wt%, Mn 0.45 wt%, P 0.090 wt%, S 0.016 wt%, and the rest are Fe and unavoidable impurities) into the LD converter for conventional top-bottom composite blowing, adding conventional amounts Lime, dolomite, magnes...

Embodiment 3

[0047] The light round wire rod steel bar used to make prestressed concrete steel rods has the following chemical composition in weight percentage: C 0.30wt%, Si 1.10wt%, Mn 0.70wt%, Nb 0.030wt%, B 0.0040wt%, P 0.012wt%, S 0.013wt%, the rest is Fe and unavoidable impurities. Processed through the following procedures to obtain smooth steel bars with a diameter of 14.0mm:

[0048] Described molten steel smelting and deoxidation alloying are molten iron (chemical composition C 5.5wt%, Si 0.80wt%, Mn 0.70wt%, P 0.110 wt%, S 0.010wt%, the rest is Fe and unavoidable impurity ), steel scrap (chemical composition C 0.35wt%, Si 0.55wt%, Mn 1.00wt%, P 0.030wt%, S 0.020wt%, the rest is Fe and unavoidable impurities) and pig iron (chemical composition C 3.6wt% %, Si 0.55 wt%, Mn 0.40 wt%, P 0.070 wt%, S 0.010wt%, the rest is Fe and unavoidable impurities) into the LD converter for conventional top-bottom composite blowing, adding conventional amounts Lime, dolomite, and magnesite balls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com