Intermediate-frequency quenching equipment for inner walls of steel tubes

A technology for quenching equipment and the inner wall of steel pipes, applied in the direction of quenching equipment, heat treatment equipment, furnace types, etc., can solve the problems of difficulty in ensuring the uniformity of flame heating, waste of metal materials, burns of metal materials, etc., achieve low scrap rate, reduce scrap, The effect of reducing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

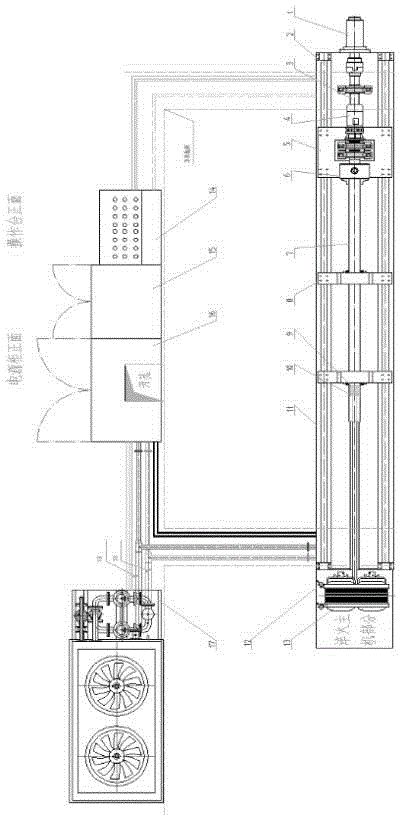

Image

Examples

specific Embodiment approach

[0026] detailed description: under Combined with the accompanying drawings Embodiments of the present invention are described, This embodiment does not constitute limitation of the present invention:

[0027] The present invention adopts the following technical scheme: including a cooling tower and a quenching part, characterized in that the quenching part is installed on the non-workpiece side of the quenching machine bed 11, and the workpiece side has a supporting plate 5 passing through the linear guide rail 2 on the quenching machine bed 11 Installed on it, the supporting plate 5 is threadedly connected with the nut screw pair 3, the nut screw pair 3 is connected with the supporting plate drive system 1, and the chuck 6 which can fix the pipeline workpiece is arranged on the supporting plate 5, and the chuck 6 and the The workpiece rotation drive system 4 is connected; the quenching machine tool quenching host 12 of the quenching part is connected with a quenching coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com