High-frequency induction heating and spray quenching device and method thereof

A high-frequency induction heating and induction heating technology, which is applied in the direction of quenching device, heat treatment equipment, energy efficiency improvement, etc., can solve the problems of low positioning accuracy, long loading and unloading and clamping cycle, and achieve efficiency reduction, shorten loading and unloading and Clamping cycle, effect of improving heating positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

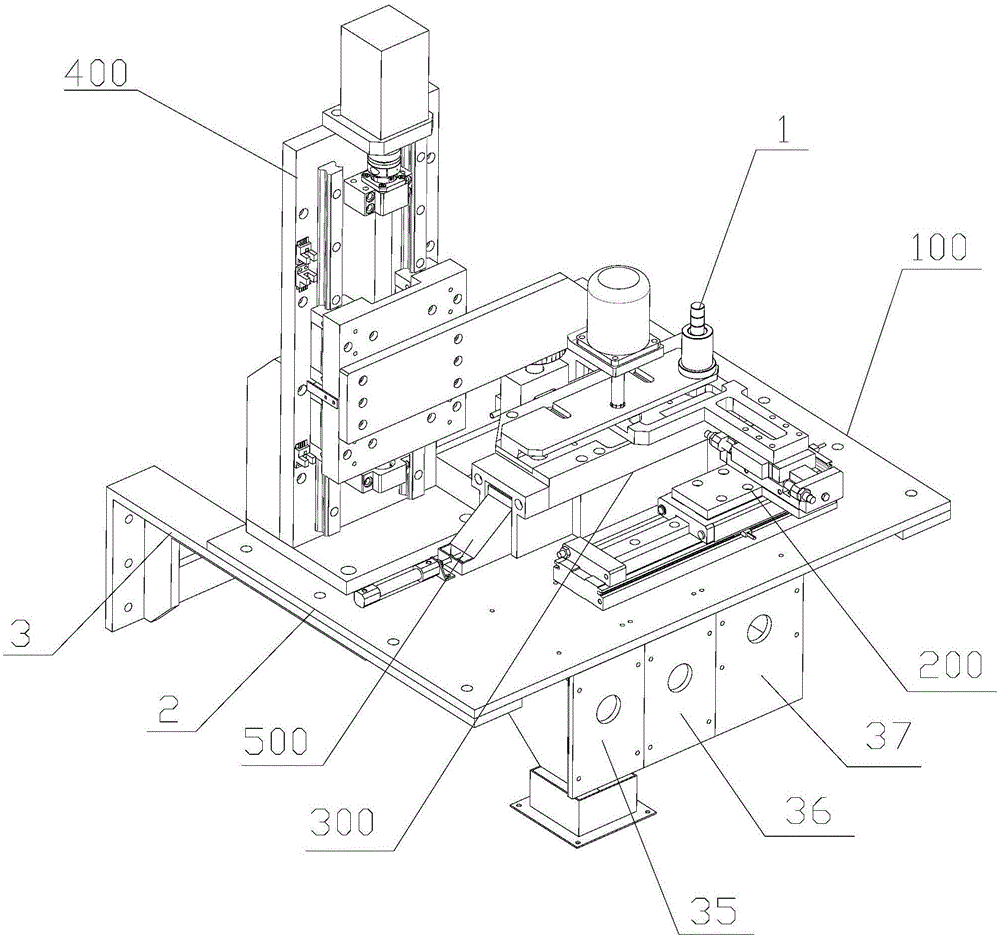

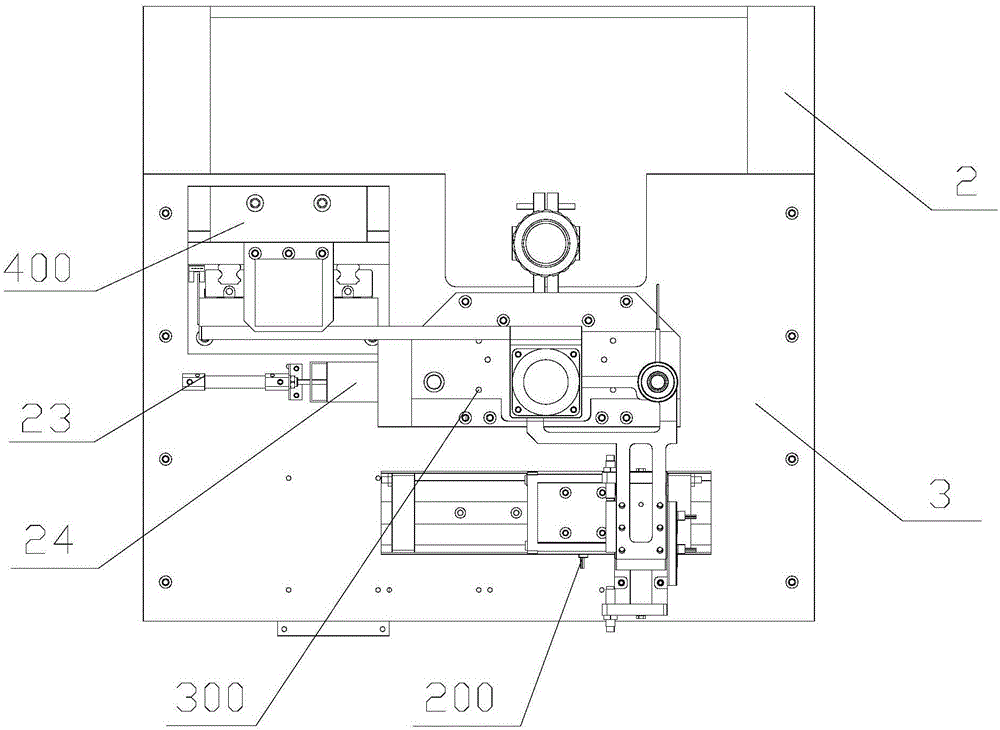

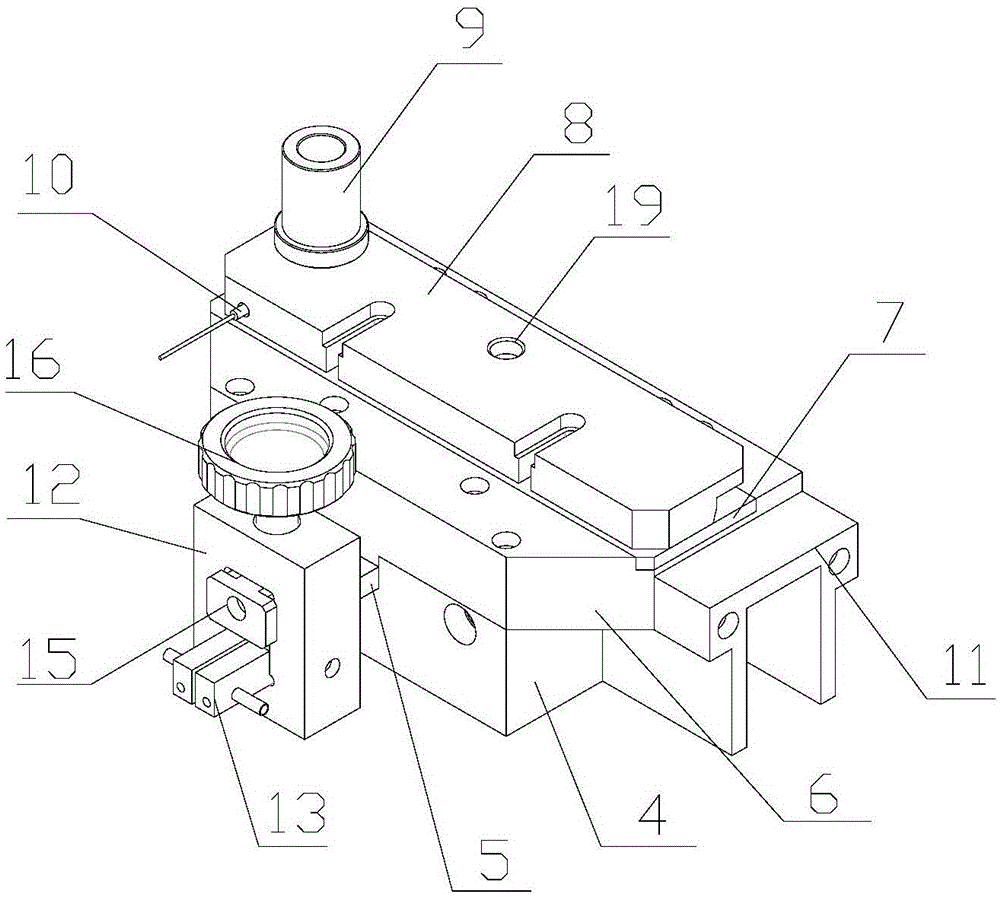

[0040] Such as Figure 1-2 As shown, a device for high-frequency induction heating and liquid spray quenching of the present invention includes a workbench 100 and a loading and unloading mechanism 200 for loading and unloading the workpiece 1 from the loading hopper, for the workpiece 1 The sensor assembly 300 for heating and quenching, the heat monitoring assembly for monitoring the heating energy of the workpiece 1, the servo slide 400 for driving the workpiece 1 into and out of the sensor assembly 300, the blanking and diverting mechanism 500, and the workbench 100 Including the platen 2 and the bracket 3, the loading and unloading mechanism 200, the sensor assembly 300 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com