A bearing alloy surface high-frequency impact processing method

A high-frequency impact and bearing alloy technology, applied in the field of high-frequency impact processing, can solve problems such as difficult to guarantee accuracy, complicated processing methods, and troublesome problems, and achieve the effects of improving mechanical properties, saving equipment, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

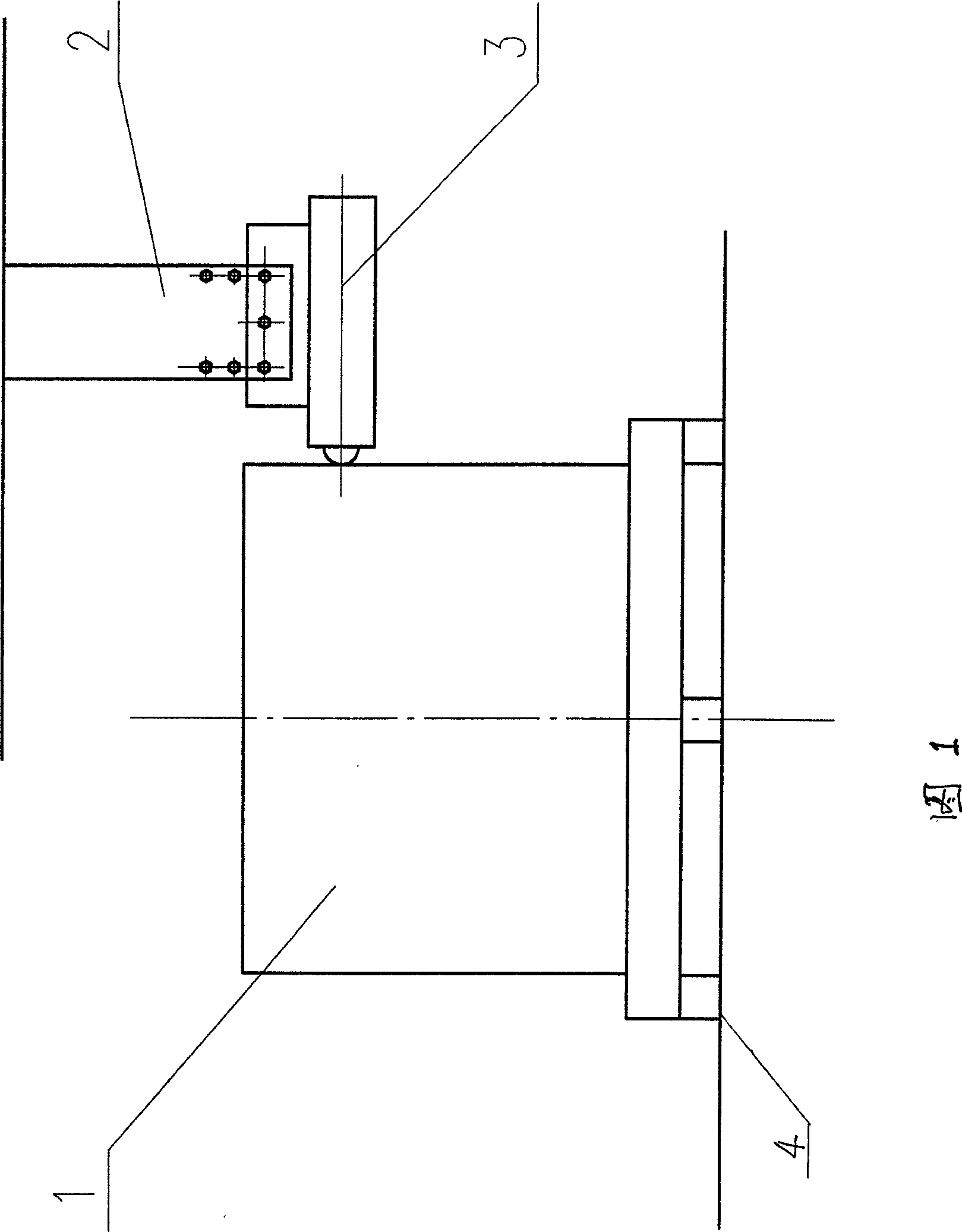

[0019] The method of high-frequency impact processing on the surface of bearing alloys is to fix the high-frequency impact processing head 3 on the tool bar 2 of the vertical lathe machine tool, and the bi-metal alloy to be processed uses tin-based Babbitt alloy as the friction-reducing layer (hardness HBa ≤0.1μm, surface microhardness increased by 20-40%.

[0020] The invention is a successful exploration for the inner and outer surfaces of the oil film bearing bushing of the bimetallic material with the bearing alloy with very low hardness (HB<24) as the anti-friction layer, and the superfinishing is carried out sequentially under one clamping. The brand-new processing method thus introduces a way of "cutting bends and straightening", which changes the traditional process route and process method, and has achieved remarkable results in reducing costs, improving efficiency, and improving performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com