Pressure device for locking mould

A pressure device and mold clamping technology, applied in the field of mold clamping mechanism, can solve problems such as damaged oil leakage, high pressure bladder manufacturing requirements, etc., and achieve the effects of good sealing, good mold clamping and pressure keeping effect, and reduced manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

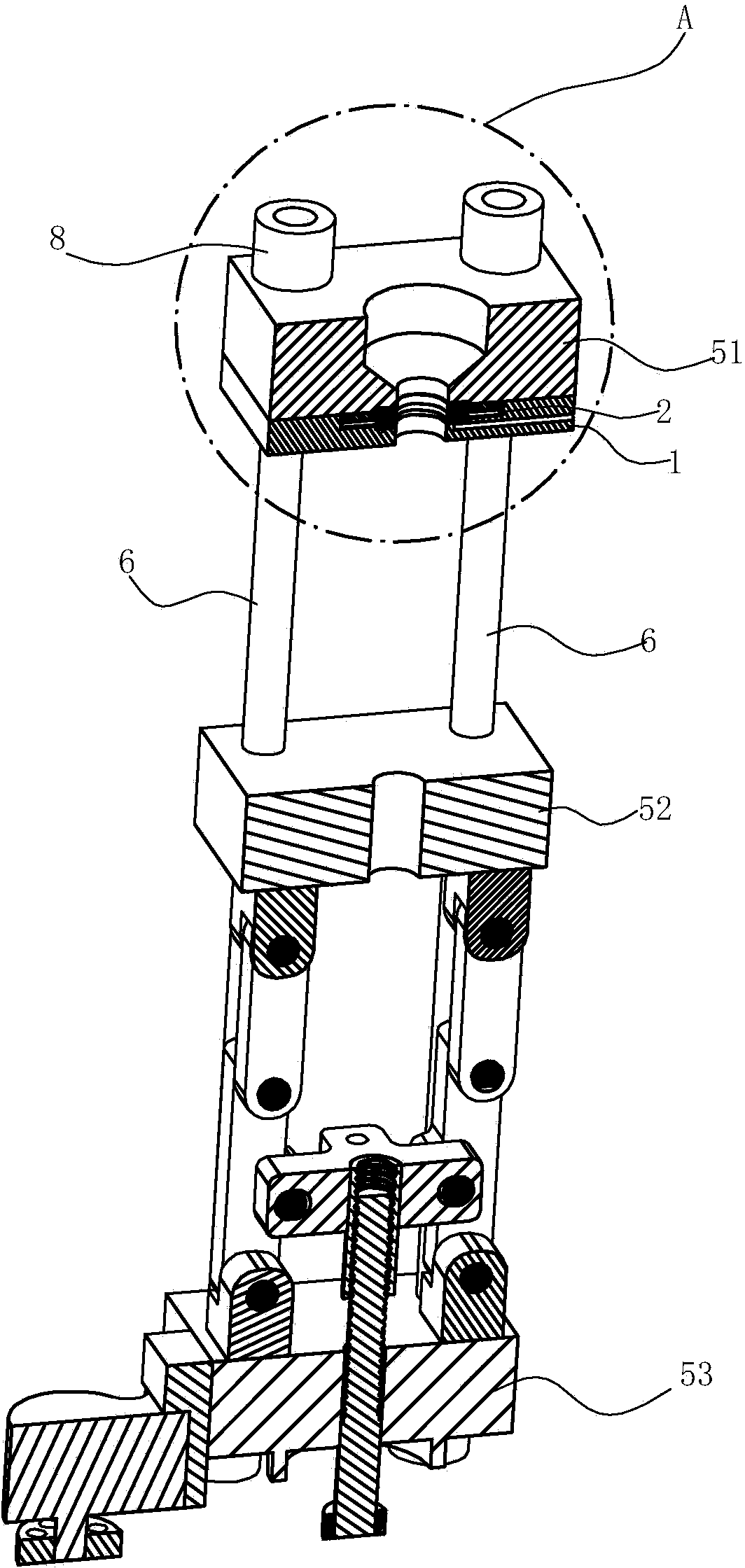

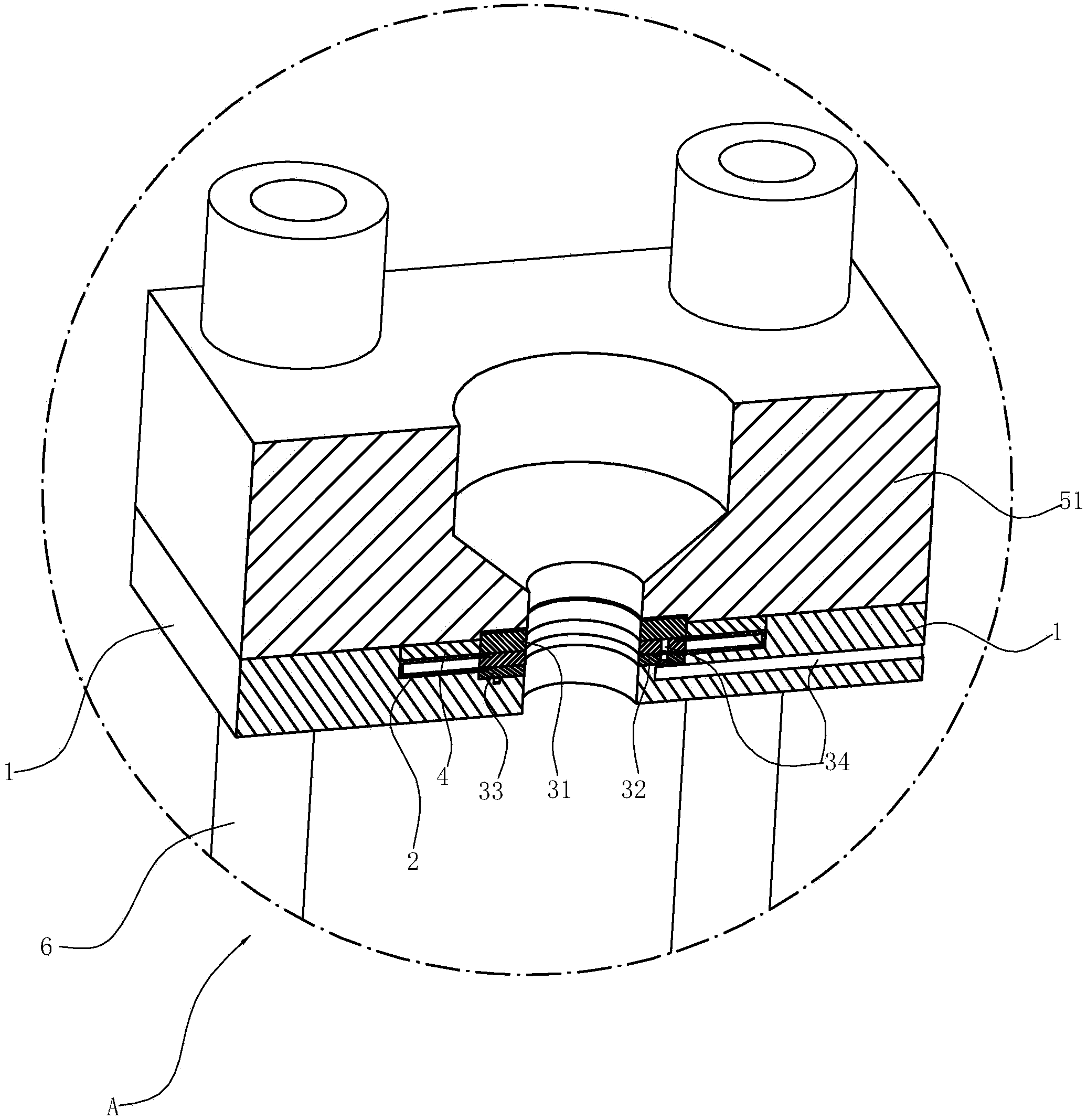

[0021] Such as figure 1 with figure 2 As shown, the pressure device for clamping includes:

[0022] The push plate 1 is arranged on the inner surface of the fixed mold plate 51 opposed to the movable template 52. The push plate 1 is provided with a groove, and the pressure bag 2 is accommodated in the groove.

[0023] The pressure bladder 2 can be filled with a pressure medium, such as hydraulic oil or compressed air. In this embodiment, it is made of plastic material, and it can also be made of other elastic materials suitable for bladder. The pressure bladder 2 is an integrally formed sheet-like structure. After the upper layer and the lower layer of the pressure bladder are laminated, a ring structure with an open inner edge is formed. The inner end edge of the upper layer is squeezed between the first fixing ring 31 and the second fixing ring 32, and the inner end edge of the lower layer is squeezed between the second fixing ring 32 and the third fixing ring 33 to form a seali...

Embodiment 2

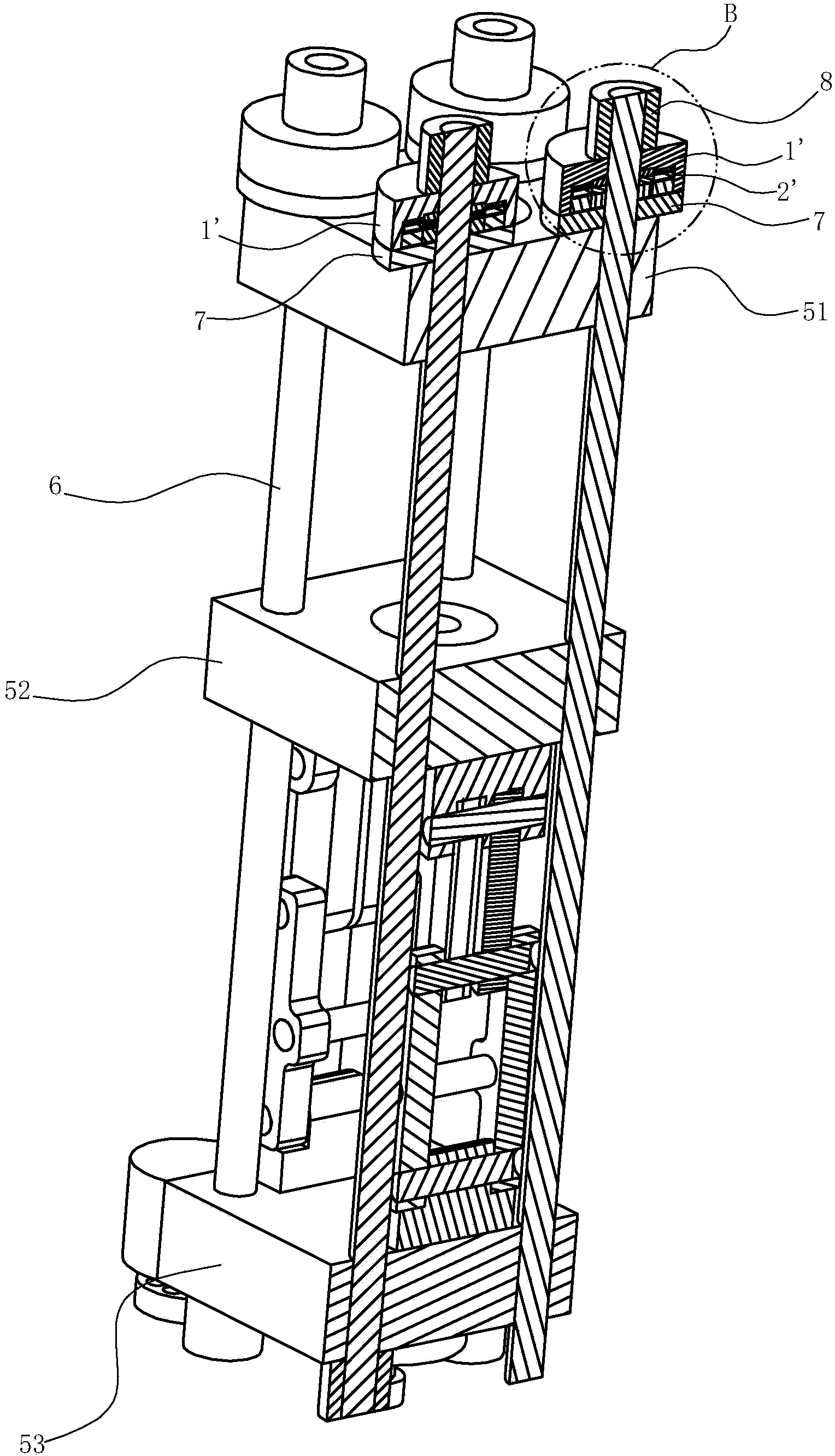

[0029] Such as image 3 with Figure 4 As shown, the fixed mold plate 51 and the movable mold plate 52 are connected together by four tie rods 6. These four tie rods 6 are not only the connecting parts of the fixed mold plate 51 and the movable mold plate 52, but also the guide parts of the movable mold plate when the mold is opened and closed. There are four sets of pressure devices for mold clamping, which are set corresponding to the four tie rods 6 respectively. The structure of each clamping device is the same.

[0030] Each clamping pressure device includes:

[0031] The bottom plate 7 is a ring structure, which is arranged on the tie rod 6 and abuts against the outer surface of the fixed template 51 away from the movable template. A push plate 1'is connected to the outer end surface of the bottom plate 7, and a groove is provided on the push plate 1', and the pressure bag 2'is accommodated in the groove. A second thrust ring 4'is also provided in the groove, and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com