Thermal treatment method for thick die steel

A heat treatment method and die steel technology, applied in the field of die steel, can solve the problems of affecting polishing and performance, uneven distribution of hardness, difficulty in achieving basically consistent cooling rate control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Take the mold steel whose material is 1.2738. The thickness of the mold steel is 810mm, the width is 1300mm, and the length is 4000mm. The ingot quenching heating temperature is 890°C, and the hoisting time is 3 minutes, during which the air is naturally cooled. After the hoisting is completed, the quenching process begins.

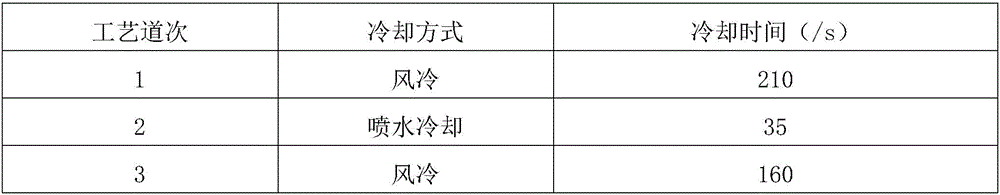

[0092] Table 1 Quenching Process of Thick Specification 1.2738 Die Steel

[0093] Craft pass cooling method Cooling time ( / s) 1 air cooled 310 2 spray cooling 45 3 air cooled 200 4 Fog cold 200 5 spray cooling 85 6 air cooled 420 7 spray cooling 85 8 air cooled 310 9 Fog cold 300 10 spray cooling 125 11 air cooled 610 12 Fog cold 610 13 spray cooling 155 14 air cooled 910 15 spray cooling 155 16 air cooled 910

[0094] After quenching by the above process, the cross-sectional hardness of the obtained die steel is 33.5-34...

Embodiment 2

[0096] Take the mold steel whose material is 1.2738. The thickness of the mold steel is 810mm, the width is 1300mm, and the length is 4000mm. The ingot quenching heating temperature is 850°C, and the hoisting time is 4 minutes, during which the air is naturally cooled. After the hoisting is completed, the quenching process begins.

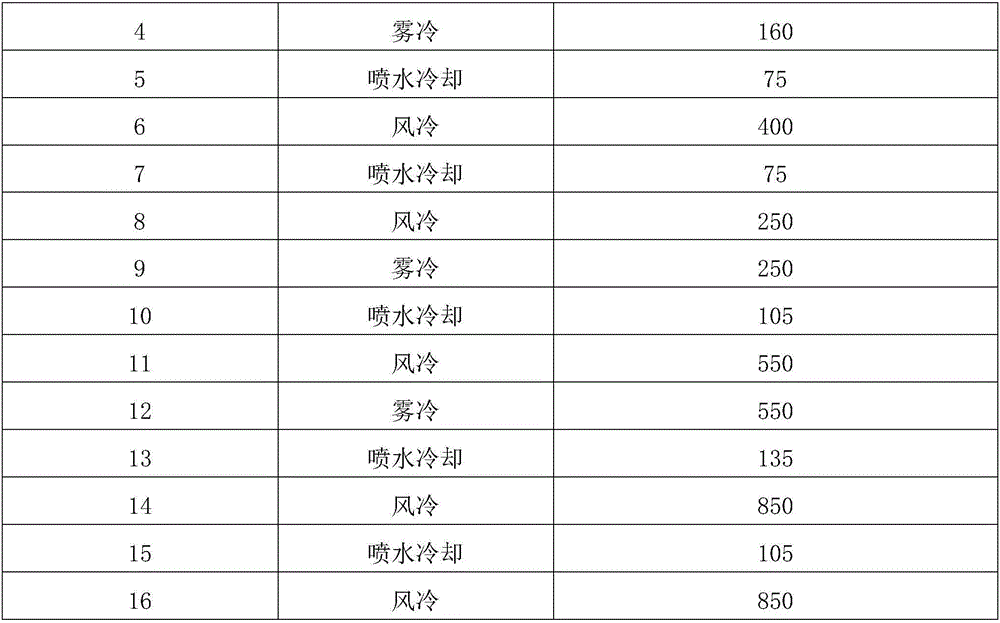

[0097] Table 2 Quenching Process of Thick Specification 1.2738 Die Steel

[0098]

[0099]

[0100] After quenching by the above process, the obtained die steel has a cross-sectional hardness of 33-35HRC.

Embodiment 3

[0102] Take the mold steel whose material is 1.2738. The thickness of the mold steel is 810mm, the width is 1300mm, and the length is 4000mm. The ingot quenching heating temperature is 800°C, and the hoisting time is 2 minutes, during which the air is naturally cooled. After the hoisting is completed, the quenching process begins.

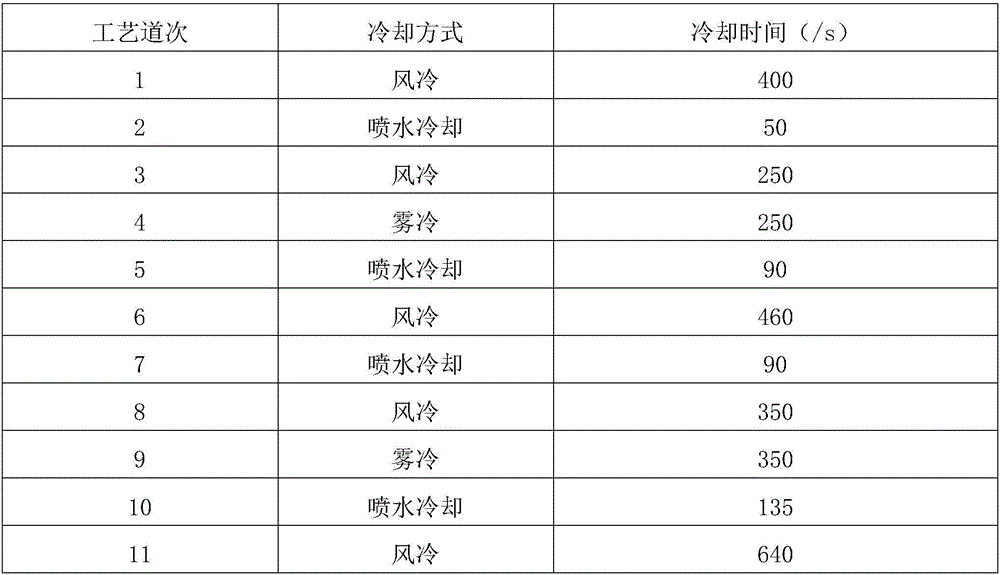

[0103] Table 3 Quenching process of thick specification 1.2738 die steel

[0104]

[0105]

[0106] After quenching by the above process, the obtained die steel has a cross-sectional hardness of 34-36HRC.

[0107] Embodiments 1 to 3 of the present invention quench the mold steel through a total of 16 cooling passes. The three cooling methods are carried out alternately and strictly in accordance with the cooling time, which improves the uniformity of quenching and cooling, reduces the deformation of the workpiece, and improves the The first pass rate of the product, the hardness difference of the edge and center of the section after heat tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com