Medium frequency induction heating treatment method for steel pipe, petroleum well pipe and drill pipe

A heat treatment method and induction heating technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as affecting the heating effect, automatic displacement of workpiece steel pipes or oil well pipes or drill pipes, and the surface brightness cannot be achieved. Achieving the effect of low cost, reduced production cost and less oxide scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

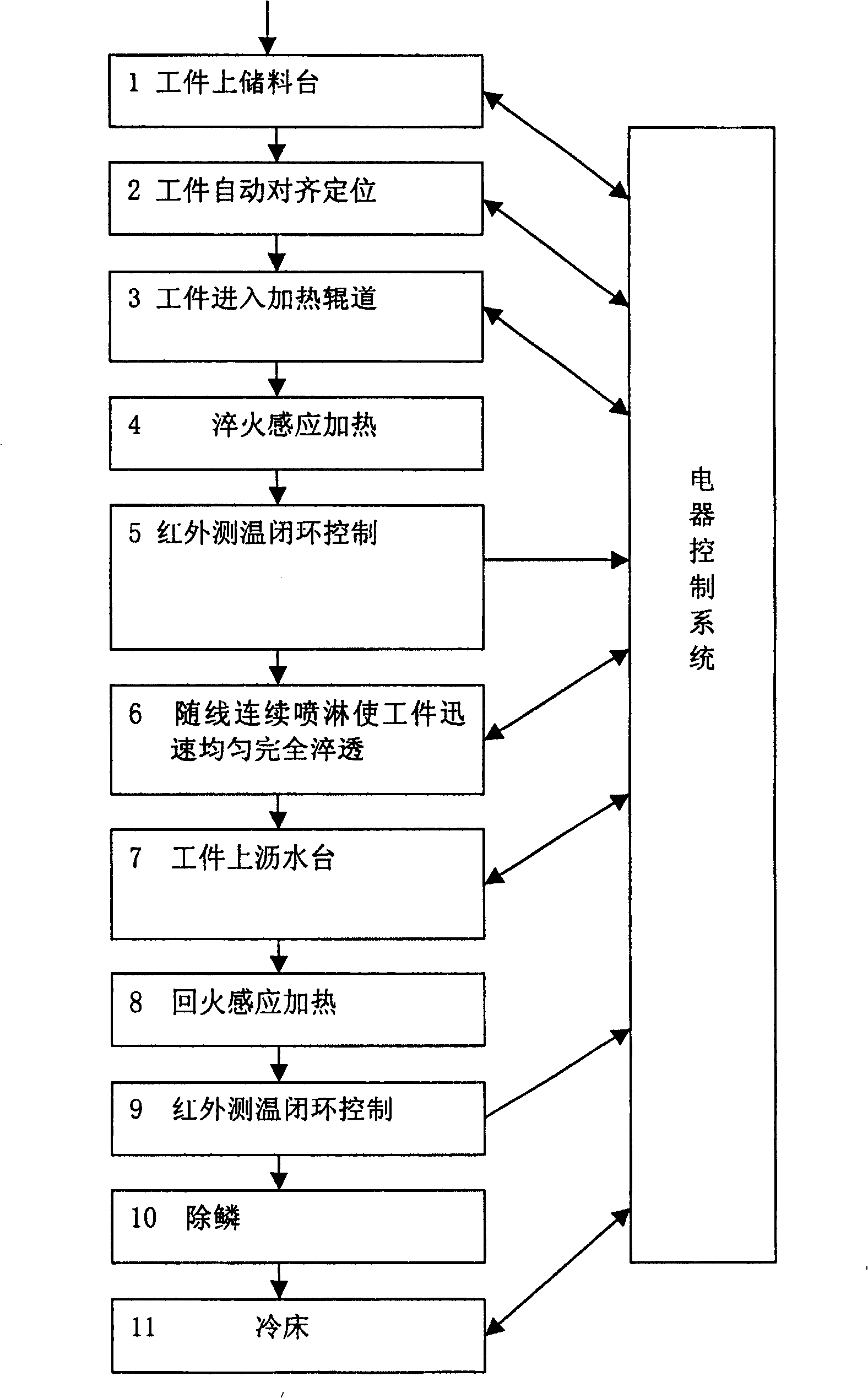

Method used

Image

Examples

Embodiment

[0037] The material storage platform is a slanted frame structure with an inclination of 2 to 5°. The workpiece steel pipe or oil well pipe or drill pipe rolls on the beam equipped with anti-noise nylon backing plate on the surface. The outlet end is designed with a material blocking device. Manual assistance during feeding can easily make the workpiece steel pipes or oil well pipes or drill pipes neatly arranged and distributed. The material storage platform is equipped with an eccentric wheel structure. For φ60~φ139.7, adjust the eccentric wheel at different angles to make the material turn over The device can only turn over one material at a time.

[0038] The workpiece steel pipe or oil well pipe or drill pipe is sent to the first station by the material rack of the storage table—aligned with the positioning roller table. The positioning roller table is composed of four rollers and is equipped with a material receiving switch. The rollers at both ends are The motor drives ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com