Processing process of internal spline gear blank used in agricultural machinery equipment transmission case

A processing technology and internal spline technology, which is applied to the processing technology field of internal spline gear blanks, can solve the problems of reduced processing efficiency, low processing efficiency, unqualified materials, etc., to improve product quality and precision, and high processing efficiency. , The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The processing technology of the internal spline gear tooth blank used in the transmission box of agricultural machinery equipment includes the following steps in sequence:

[0016] (1) Material selection, select materials with the following chemical composition according to mass percentage: C, 0.17%; Si, 0.17%; Mn, 0.80%; Cr, 1.00%; Ti, 0.04%; Ni, 0.02%; S, 0.025 %; P, 0.025%; the balance is Fe and unavoidable impurities, Fe is not less than 95%;

[0017] (2) Cutting by cutting machine, the weight tolerance is controlled as diameter d≤50㎜, tolerance is ±0.01㎏; diameter is 55㎜65㎜, The tolerance is +0.03㎏~-0.01㎏;

[0018] (3) Blank forging, the raw material is placed in an intermediate frequency heating furnace for 5-10 seconds and the temperature is 1000-1200°C. After upsetting, forging, and edge trimming, the turning allowance on one side of the blank is controlled to be 0.8-1.2 mm;

[0019] (4) Isothermal normalizing, heating the blank at a temperature of 925-945°C,...

Embodiment 2

[0023] The processing technology of the internal spline gear tooth blank used in the transmission box of agricultural machinery equipment is the same as that of Example 1, the only difference is that the material selection is different, and the material with the following chemical composition is selected according to the mass percentage: C, 0.23%; Si, 0.37% %; Mn, 1.10%; Cr, 1.3%; Ti, 1%; Ni, 0.03%; S, 0.03%; P, 0.03%; the balance is Fe and inevitable impurities, Fe not less than 95%.

Embodiment 3

[0025] The processing technology of the internal spline gear tooth blank used in the transmission box of agricultural machinery equipment is the same as that of Example 1, the only difference is that the material selection is different, and the material with the following chemical composition is selected according to the mass percentage: C, 0.2%; Si, 0.3 %; Mn, 1%; Cr, 1.1%; Ti, 0.6%; Ni, 0.02%; S, 0.02%; P, 0.02%;

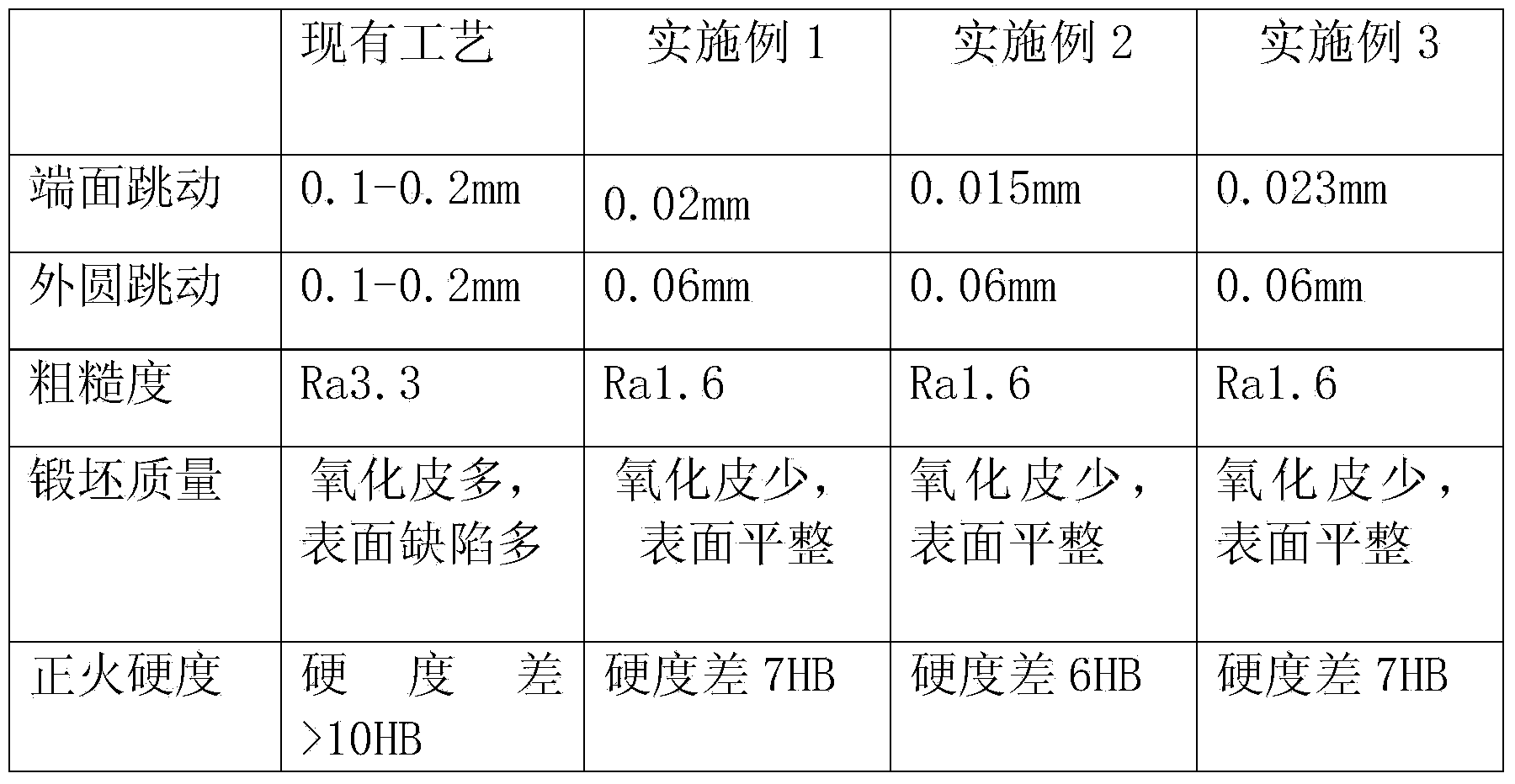

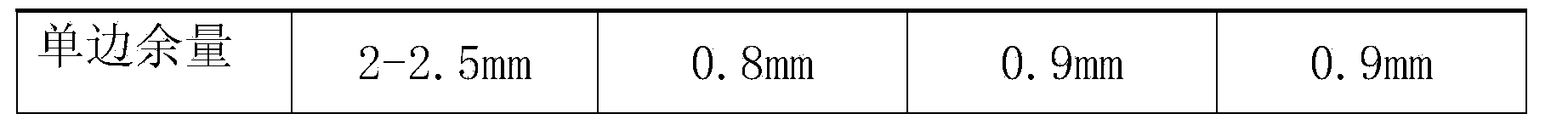

[0026] The performance data comparison table of the internal spline gear tooth blank used in the transmission box of agricultural machinery equipment made by the process of the above three embodiments and the internal spline gear tooth blank used in the transmission box of agricultural machinery equipment made by the existing technology as follows.

[0027]

[0028]

[0029] It can be seen from the above table that the precision of the rough-finish turning and internal spline drawing process of this patent is obviously better than the traditional process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com