Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Eliminate black smoke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

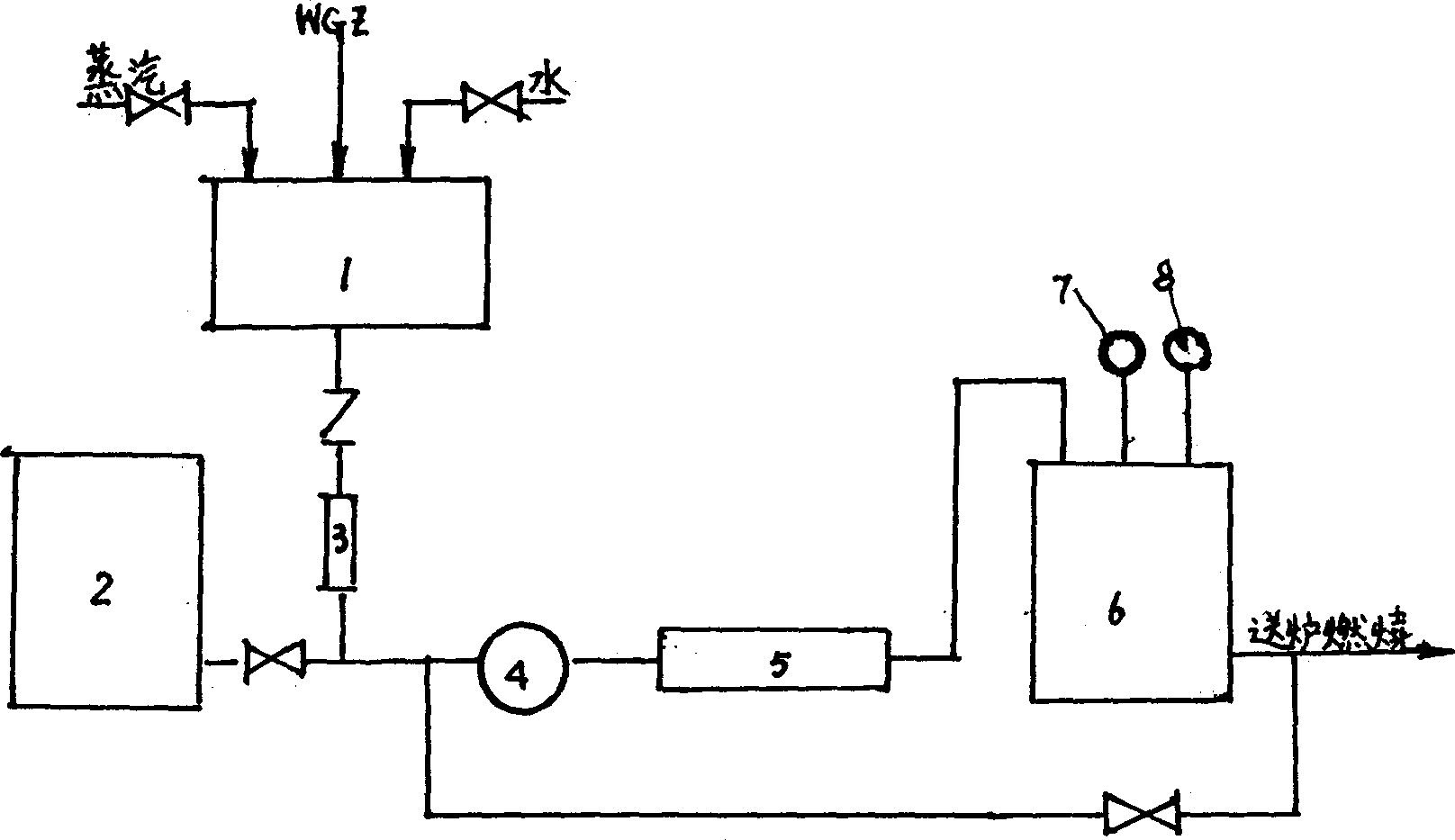

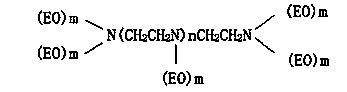

Multifunctional heavy oil and fuel oil additive, preparation and use thereof in preparing emulsified oil

InactiveCN1401745AWide emulsification rangeMix well and evenlyLiquid carbonaceous fuelsFuel oilDisperser

An oil-soluble multifunctional additive for heavy oil or fuel oil contains more surfactants, composite catalytic combustion adjuvant and detergent disperser, and is characterized by saving oil by 10-25%, increasing added water to 10-30% and eliminating black smoke. A process for preparing emulsified heavy oil or fuel oil is also disclosed.

Owner:WUHAN UNIV OF TECH

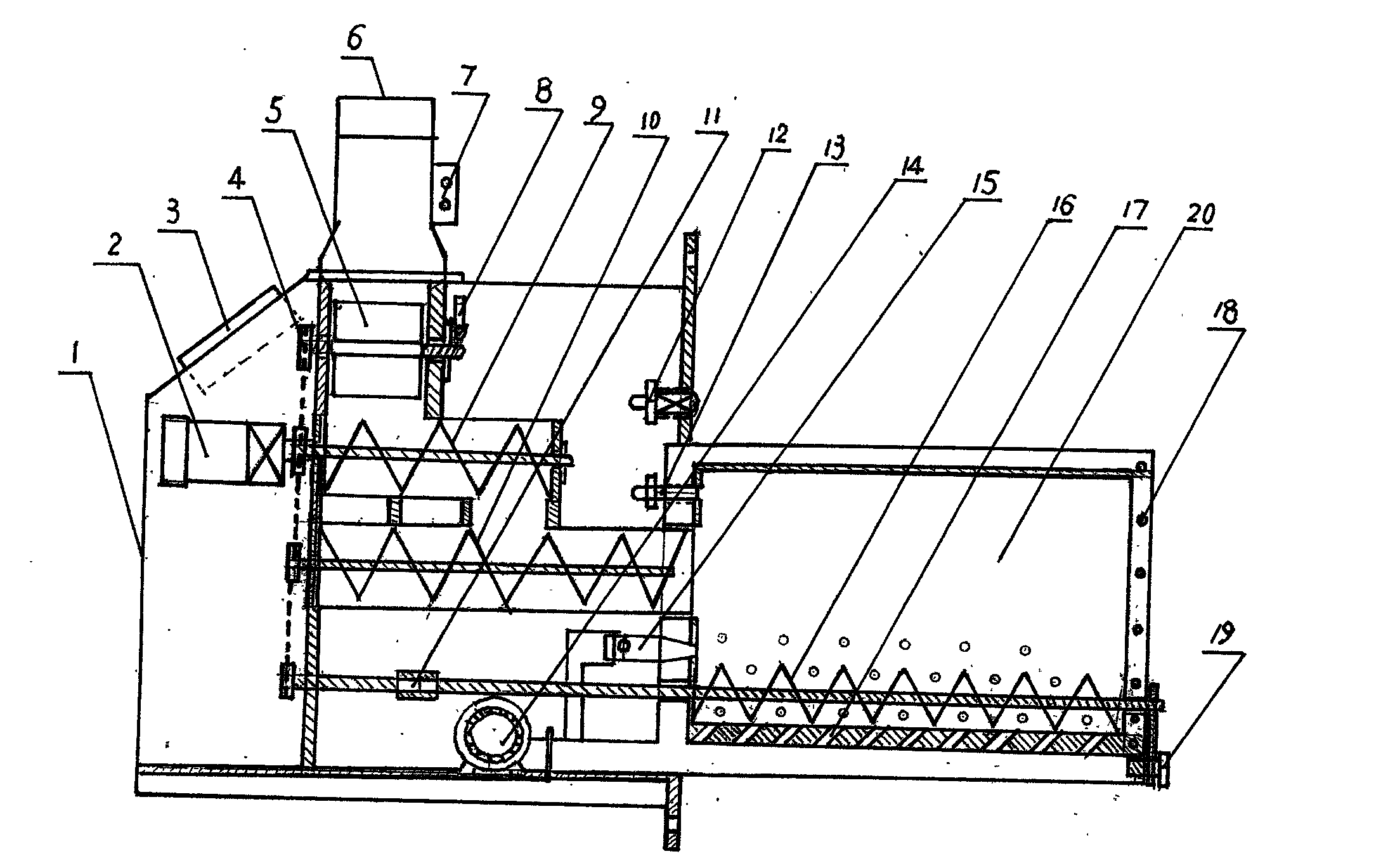

Biomass fuel combustion device

InactiveCN103697461AIncrease the level of automationIncrease the conversion rate of calorific valueSolid fuel combustionCombustion apparatusThermal energyAutomatic control

The invention belongs to an industrial combustion technology, in particular to a biomass fuel combustion device. The biomass fuel combustion device comprises a shell, a feed inlet, a thermal switch, a material limiting flashboard, a photoelectric sensor, a spiral feeder, a spiral pusher, a motor, a controller, an igniter, a chain wheel, a shaft coupling, a fan, an air cooler, a flame detector, an oxygen sensor, a combustion chamber, a spiral slag separator and a slag outlet. By adopting an automatic control system formed by the thermal switch, the photoelectric sensor, the flame detector the oxygen sensor, and in particular the added oxygen sensor, the automation level is integrally improved, by adopting secondary air supply and combustion support, gasified combustion is realized, the heat value conversation rate is greatly improved, clean combustion is realized, black smoke is completely eliminated, and meanwhile, the biomass fuel combustion device is suitable for improvement of the conventional boiler, has the characteristics of high efficiency and environmental friendliness, and is particularly suitable for using the heat by industrial production and lives of residents, including cultivation of agricultural greenhouses and villas.

Owner:闵毅

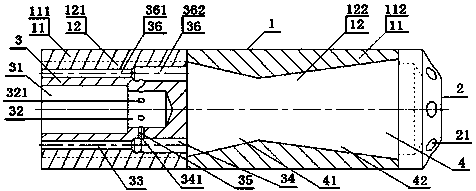

Enhanced atomization fuel spray gun

Owner:SHANGHAI WISEBOND TECH +1

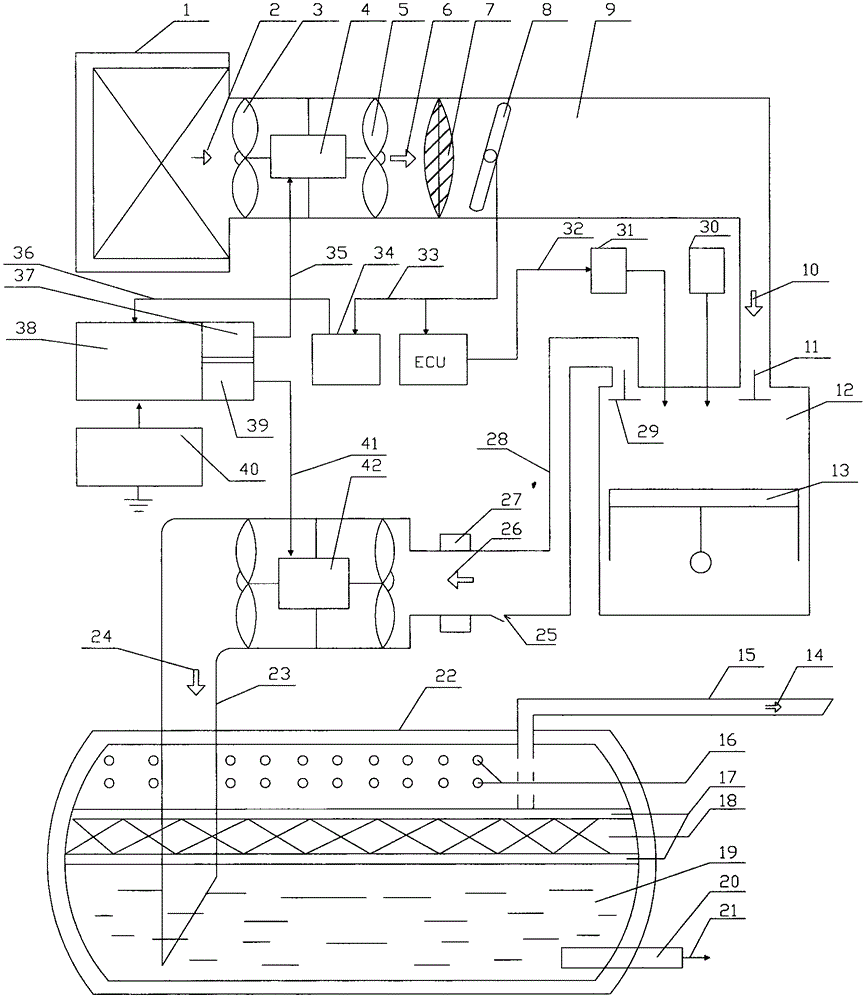

Automotive engine boost and tail gas purification technology and combination

InactiveCN104912653AIncrease relative compression ratioImprove powerElectrical controlExhaust apparatusAir filterEngine power

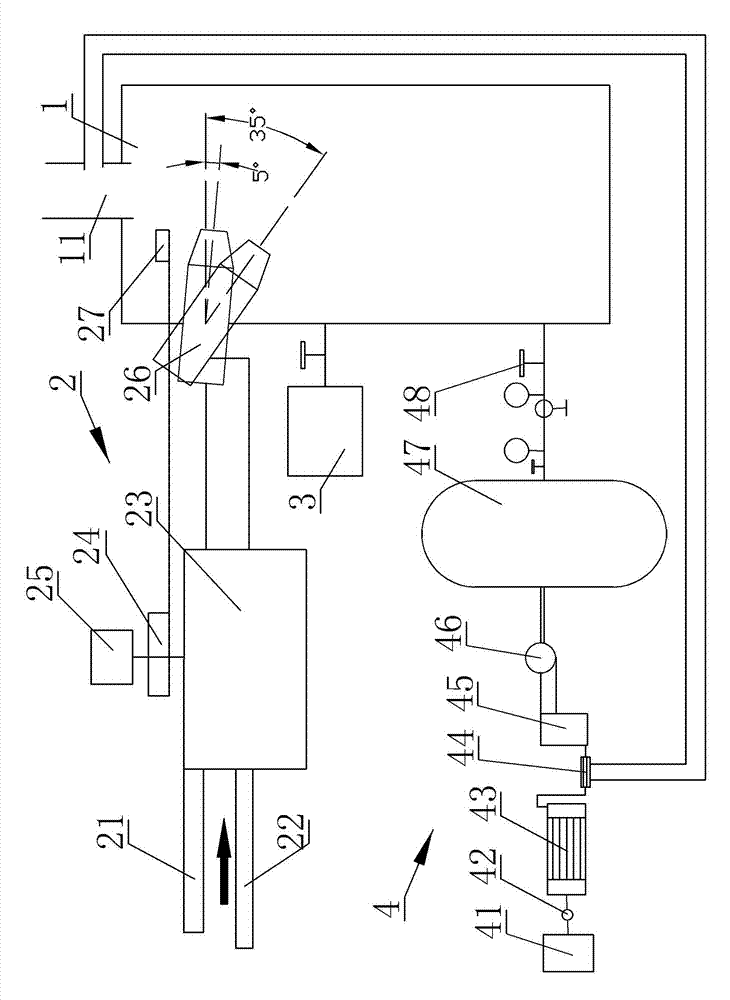

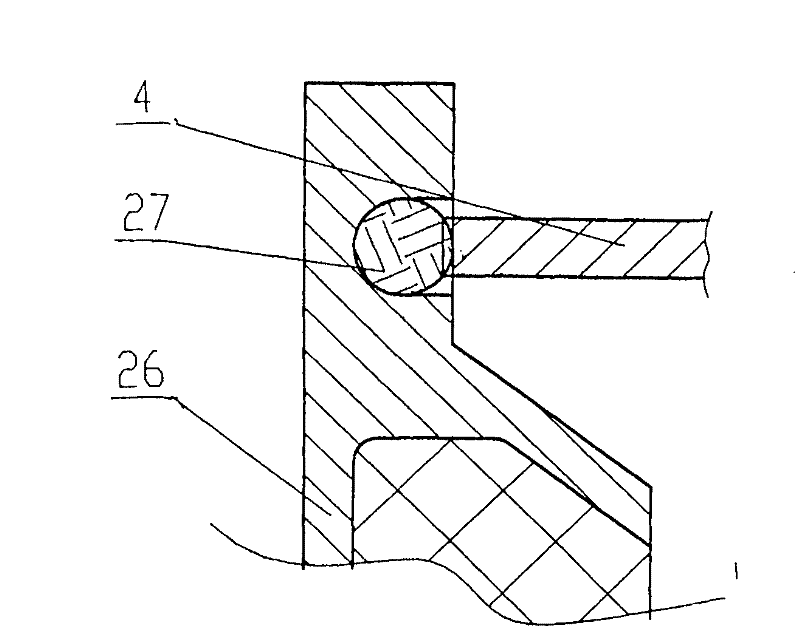

The invention discloses an automotive engine booster and a tail gas purifier technology; and the two are combined as a whole, so that the effects of oil saving and emission reduction of an automotive engine are the best, and the protection of natural environment atmosphere is facilitated. Two times of dual boost are performed for air (2) by a double-turbine air pump (4) mounted in an engine air filter (1) to form a boost eddy current (6); the boost eddy current is adjusted through a throttle valve (8), and enters an engine cylinder (12) for compressing to improve a relative compression ratio of the engine; and after mixed gas is combusted, the power of the engine is increased, and fuel is relatively decreased. Discharged tail gas pollutants (26, 24) enter tail gas purifiers (42, 18, 17, 16) for purifying; and the purifying treatment adopts two modes of an alkali liquid (19) absorption method and a solid (18, 16) absorption method. Purified gas (14) is exhausted to the atmosphere through a purifying exhaust pipe (15). A synchronous controller assembly (38) can keep synchronous implementation of the engine boost and the tail gas purification. A tail gas boost air pump (42) is mounted in a tail gas purifier air inlet pipe (23) for performing the gas boost for the tail gas pollutants. A vehicle-mounted accumulator (40) provides electric energy to the synchronous controller assembly.

Owner:郑春初 +1

Process for preparing organic molybdenum vehicle labricating oil and use

The vehicular organic molybdenum lubricating oil is prepared with internal combustion engine oil as base, and through indirect heating to 35-80 deg.c, adding organic molybdenum additive via stirring, filering and packing. The vehicular organic molybdenum lubricating oil has very high hardness, powerful lubricating, greatly reduced friction coefficient of machine and double raised extreme pressure performance, and can effectively inhibit temperature rising of engine, lower mechanical noise, reduce exhaust of harmful gas and lower power consumption. The lubricating oil integrates the maintenance, energy saving and environment protecting functions and has no need of adding any additive during use.

Owner:张志成

Fuel-saving stove firing wood assisted by combustible gas

InactiveCN102829492AEasy to igniteFierce firepowerDomestic stoves or rangesLighting and heating apparatusCombustible gasEngineering

The invention relates to a fuel-saving stove firing wood assisted by combustible gas. The fuel-saving stove comprises a stove body and a stove rack, wherein the inner cavity of the stove body comprises a front-end wood bin and a rear-end wood firing area; a fire outlet is arranged above the rear-end wood firing area; a stove plate is arranged on the fire outlet; a chimney port is arranged on the side wall of the stove plate; a soot barrel is arranged below the chimney; the stove body also comprises a wood fire assisting device which comprises a combustible gas switch, a combustible gas tube, a combustible gas tube connecting port, a blower, a blower switch, an oxygen tube, an ignition device and a gas cooker head, and the combustible gas tube is connected with the oxygen tube; the combustible gas tube and the ignition device are connected with the gas cooker head; and the gas cooker head is below the rear-end wood firing area. The fuel-saving stove firing wood assisted by combustible gas has the beneficial effect that through firing wood assisted by combustible gas, the combustible gas only participates in ignition and re-ignition, or a small amount of combustible gas participates in the whole process of firing wood, ignition is easy, no smoke is generated from beginning to end, the fire power is large, no soot leaks to the outside, stove ash is convenient to clear, and the stove is suitable to be popularized and applied in urban and rural households, hotels or cafeterias.

Owner:黄圭鹏

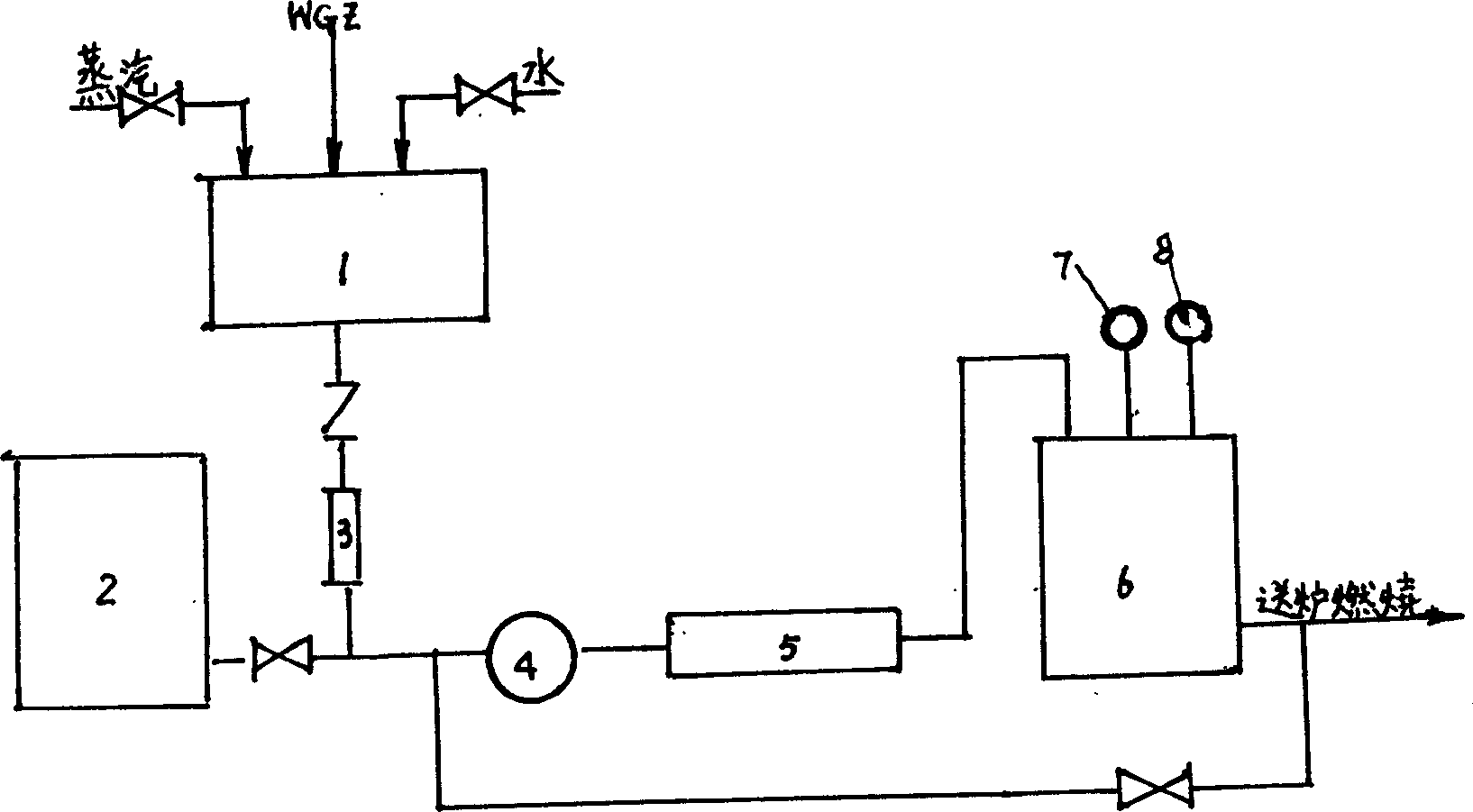

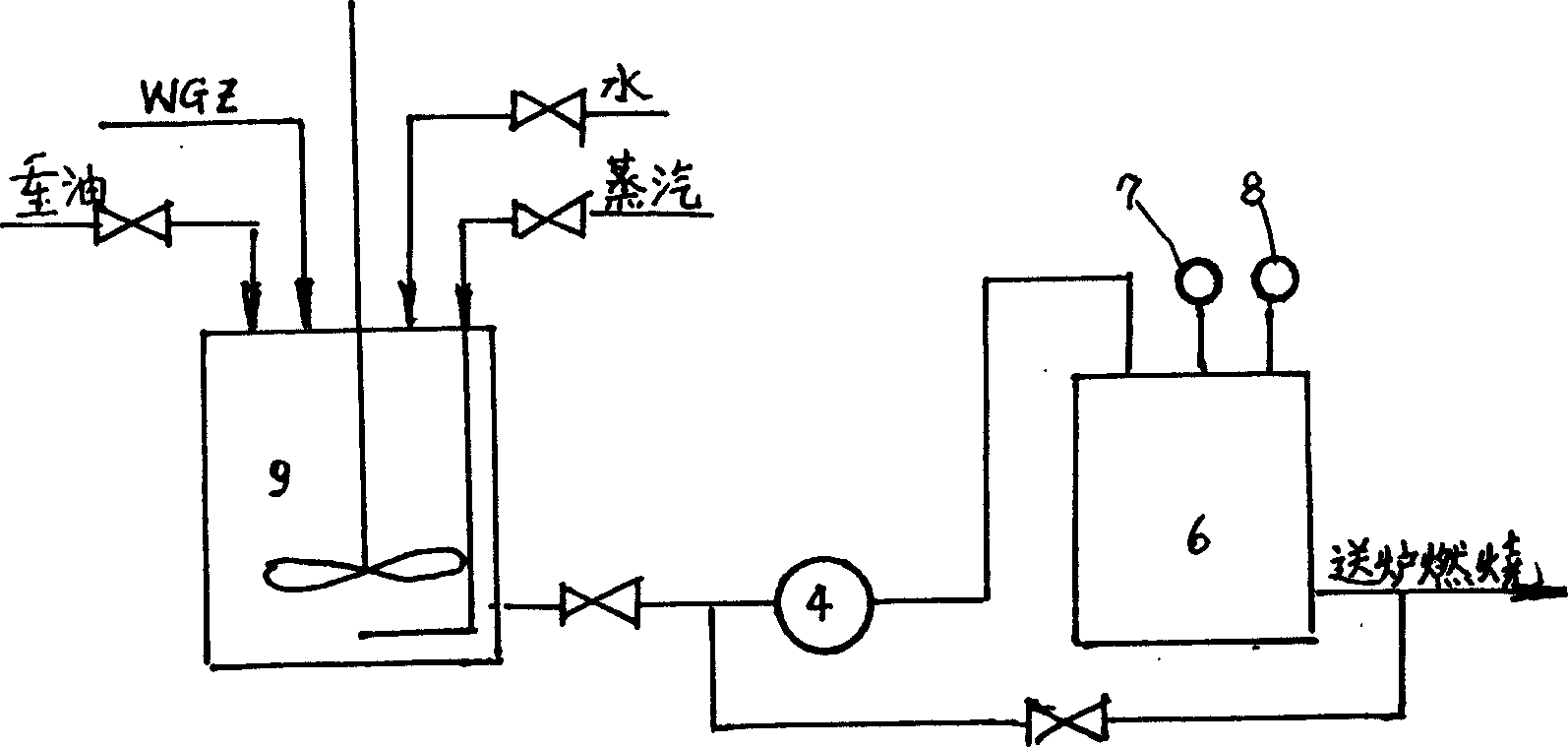

Environment friendly and energy-saving heavy oil additive

ActiveCN101705123AImprove performanceExtended shelf lifeLiquid carbonaceous fuelsCombustionOil additive

The invention discloses an environmental priendly and energy-saving heavy oil additive which comprises the following components in parts by weight: 8-20 parts of ampholyticsurfactant, 10-35 parts of cosurfactant, 10-20 parts of combustion improver, 20-35 parts of stablizing dispersant, 3-15 parts of corrosion inhibitor and 20-50 parts of water. The heavy oil additive greatly dilutes the viscosity of heavy oil, improves the flowability of the heavy oil, ensures that the heavy oil can be burnt completely, eliminates dark smoke, effectively reduces the pollution to the environment, ensures high watering rate of the heavy oil and long stable phase of the heavy oil and saves fuel resources. In addition, during combustion, an oil nozzle can not coke easily, thereby the maintenance frequency of the oil nozzle is greatly reduced, and the fuel cost and the maintenance expense of boilers and other combustion equipment are reduced.

Owner:SHANDONG TAIDE NEW ENERGY

Environment-friendly thermal insulation material

InactiveCN106946503AReduce dustReduce pollutionPetroleum wax refiningHydrocarbon oils treatmentThermal insulationSewage

Owner:HEFEI JINTONGWEI LOW TEMPERATURE TECH CO LTD

Multifunctional coal burning additive and application thereof

InactiveCN106867622AStrong combustion-supporting and energy-saving functionsStrong desulfurization and emission reduction functionsSolid fuelsFuel additivesAluminateCarrier system

The invention provides a multifunctional coal burning additive and an application thereof. The additive is prepared by compounding a natural macromolecular organic compound and natural ore rich in aluminate and silicate and having sponge-shaped structural pores as a carrier and a multi-element compound. The additive is of a double-carrier system, and meanwhile has functions such as burning assistance, sulfur fixation, smoke elimination, dust removal, decoking, corrosion inhibition; moreover, the using dosage is small and accounts for 0.1 to 0.15 percent of the coal burning amount, the multifunctional coal burning additive is easy to add, simple in process and low in cost, a cost-benefit ratio reaches 1: 6 or higher, the production cost is low, the economic benefit is good, and the market advantage is high.

Owner:谭坚忠

Photocuring skin wound adhesive

InactiveCN113521375APrevent respawnIncrease motivationSurgical adhesivesBandagesGas phasePolymethyl methacrylate

The invention aims to provide a photocuring skin wound adhesive. The photocuring skin wound adhesive is prepared from the following raw materials: n-butyl alpha-cyanoacrylate, fumed silica, polymethyl methacrylate, a stabilizer, a photoinitiator and an accelerant. Compared with the prior art, the skin can be tightly attached to the product, wound infection can be effectively prevented, wound healing is accelerated, and the wound can be immediately soaked in water, bathed, subjected to field work and the like after being glued and cured, so that the wound can be effectively protected.

Owner:东莞市瞬力新材料科技有限公司

Forming equipment for producing dried rolled bean curd under normal-pressure steam conditions

PendingCN111449141AImprove heat utilizationBurn fullyCheese manufactureSteam superheatersProcess engineeringSuperheated steam

The invention relates to forming equipment for producing dried rolled bean curd under normal-pressure steam conditions. The forming equipment comprises a back-burning type normal-pressure overheatingsteam oven and dried rolled bean curd forming devices, wherein the back-burning type normal-pressure overheating steam oven is used for providing steam for the dried rolled bean curd forming devices for heated forming. By the back-burning type normal-pressure overheating steam oven, generated saturated steam is continuously heated with heat of fume, overheated steam is generated in a normal-pressure state and then is applied to forming of the dried rolled bean curd, the efficiency of forming is high, and meanwhile, the requirements of pulp cooking and baking of a dried rolled bean curd production process on heat supply can also be met; the back-burning type normal-pressure overheating steam oven generates the overheated steam in the normal-pressure state, the steam supply of a plurality ofdried rolled bean curd forming devices can be met, and compared with the traditional normal-pressure steam ovens, the heat efficiency is high and the energy consumption is low; and with respect to pressure-bearing steam boilers, potential safety hazards are less, the technical requirements on design, manufacturing and use are relatively low, customer use is safer and more convenient, and use andoperating costs are lower.

Owner:广西格卡环保科技有限公司

Purple mixed copper smelting and oxidation-reduction system

ActiveCN103526043ASave man hoursIncrease excess oxygenReverberatory furnaceProcess efficiency improvementReverberatory furnaceGas cooler

The invention discloses a purple mixed copper smelting and oxidation-reduction system which comprises a reverberatory furnace body. A flame combustion device and a reduction device are arranged on the reverberatory furnace body, the flame combustion device comprises a fuel feeding pipeline, a combustion improver feeding pipeline and a combustor arranged on the reverberatory furnace body, and the reduction device comprises a reduction control system connected with the reverberatory furnace body. The flame combustion device further comprises a control valve set, a PLC, a computer operating screen and a material sensor, the reduction device further comprises a methyl alcohol feeding box, a feed pump, a smoke waste heat decomposer, a decomposed gas cooler, a decomposed gas molecule absorber, a compression system and a gas storage tank, and the methyl alcohol feeding box, the feed pump, the smoke waste heat decomposer, the decomposed gas cooler, the decomposed gas molecule absorber, the compression system and the gas storage tank are communicated in sequence. The purple mixed copper smelting and oxidation-reduction system is simple in structure, strong in practicality and especially suitable for a purple mixed copper reverberatory furnace.

Owner:湖南金龙国际铜业有限公司

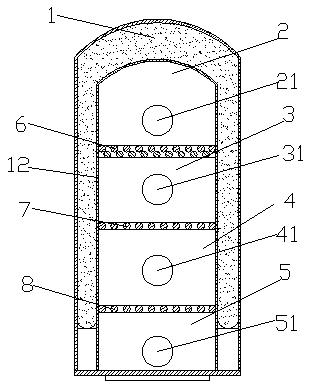

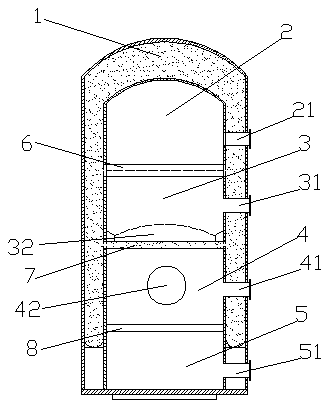

Smokeless combustion method of reverse combustion, roasting combustion and recombustion

PendingCN109780534AImprove combustion efficiencyHigh efficiency inhalationSolid fuel combustionIncinerator apparatusCombustion chamberHeat conducting

The invention belongs to the field of solid fuel combustion, and particularly relates to a smokeless combustion method of reverse combustion, roasting combustion and recombustion. The smokeless combustion method is suitable for all solid fuel combustion furnaces, such as the smokeless discharging of steam furnaces, heat conducting oil furnaces and the like. According to the smokeless combustion method of the reverse combustion, the roasting combustion and the recombustion, three combustion chambers arranged in a furnace body, three layers of grates separating the three combustion chambers, anash collecting chamber on the bottom layer, an air leading opening formed in the third combustion chamber and a high-power draught fan arranged in the leading opening are included; biomass materials are added into the first combustion chamber to form the reverse combustion; clean energy (coke or charcoal) is added into a roasting combustion layer of the second combustion chamber to form the roasting combustion; and the coke and the charcoal fall to the lower layer grate of the third combustion chamber to form the recombustion, and formed furnace ashes fall into the ash collecting chamber. According to the smokeless combustion method of the reverse combustion, the roasting combustion and the recombustion, a traditional combustion method is subverted, and black smoke and exhaust gas are notgenerated.

Owner:张金宝

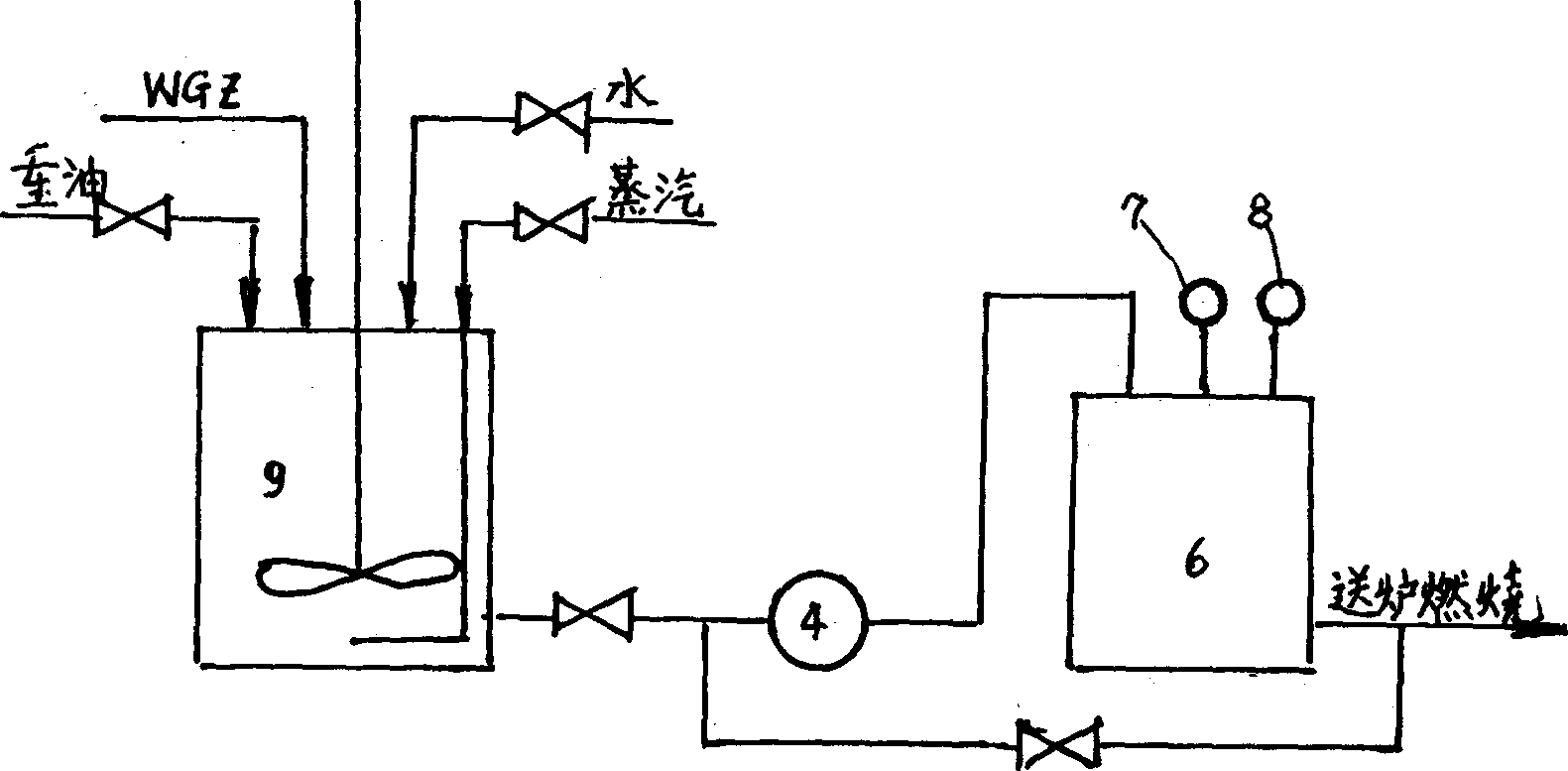

Heavy oil composite additive

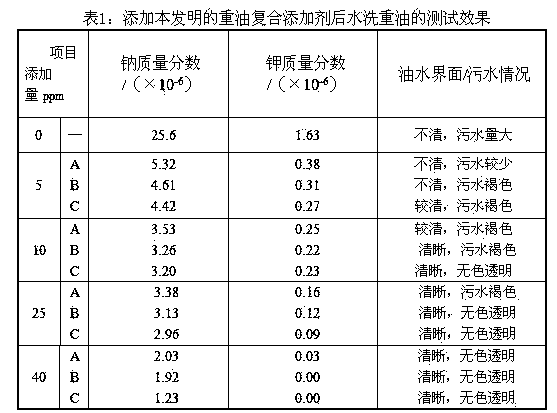

ActiveCN103695055ALong stable periodDilution viscosityLiquid carbonaceous fuelsDemulsifierActive agent

The invention belongs to the field of a heavy oil additive and particularly relates to a heavy oil composite additive. The heavy oil composite additive consists of the following components in part by weight: 10 to 35 parts of demulsifier, 8 to 20 parts of surfactant, 10 to 20 parts of combustion improver, 20 to 35 parts of stabilizing dispersant, 3 to 15 parts of corrosion inhibitor and 20 to 50 parts of water. The heavy oil composite additive has the benefits that the water-doped heavy oil has a long stable period and can be kept stable for 5 months; the additive using the water as the main body greatly dilutes viscosity of the heavy oil and improves liquidity of the heavy oil, and thus, the heavy oil has high dispersion, is in sufficient contact with the air and is completely burnt after being sprayed from a spray nozzle, black smoke is eliminated and the heavy oil composite additive is beneficial for protecting the environment; when 0 to 44ppm of the additive disclosed by the invention is added into washing heavy oil by mass of the heavy oil, the mass fraction of sodium is lower than 4*20-6 and the mass fraction of potassium is lower than 0.25*10-6, the oil-water interface is clear, sewage is colorless and transparent and a demulsification effect can be well achieved; and the heavy oil composite additive has obvious economic benefits and can reduce fuel cost of a using unit and maintenance cost of combustion equipment such as a boiler and the like.

Owner:SHANDONG TAIDE NEW ENERGY

Multifunctional heavy oil and fuel oil additive, preparation and use thereof in preparing emulsified oil

InactiveCN1169927CIncrease surface areaMix well and evenlyLiquid carbonaceous fuelsActive agentOil additive

An oil-soluble multifunctional additive for heavy oil or fuel oil contains more surfactants, composite catalytic combustion adjuvant and detergent disperser, and is characterized by saving oil by 10-25%, increasing added water to 10-30% and eliminating black smoke. A process for preparing emulsified heavy oil or fuel oil is also disclosed.

Owner:WUHAN UNIV OF TECH

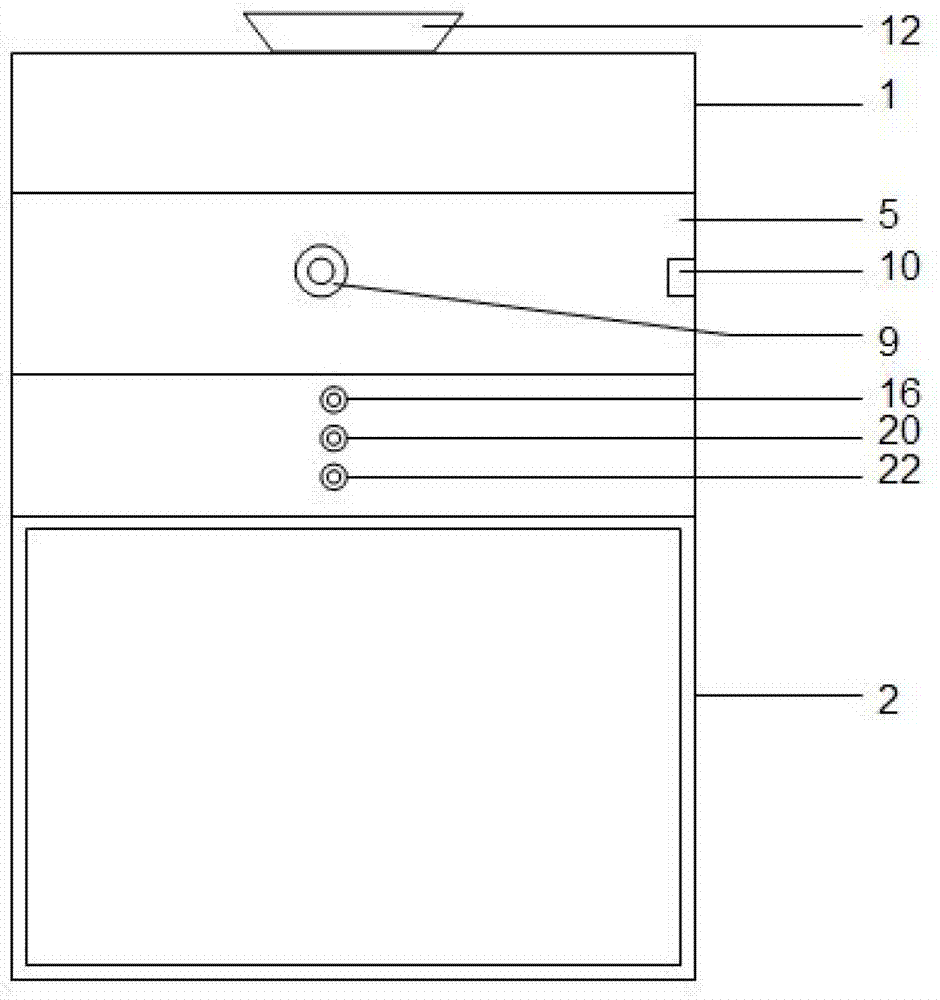

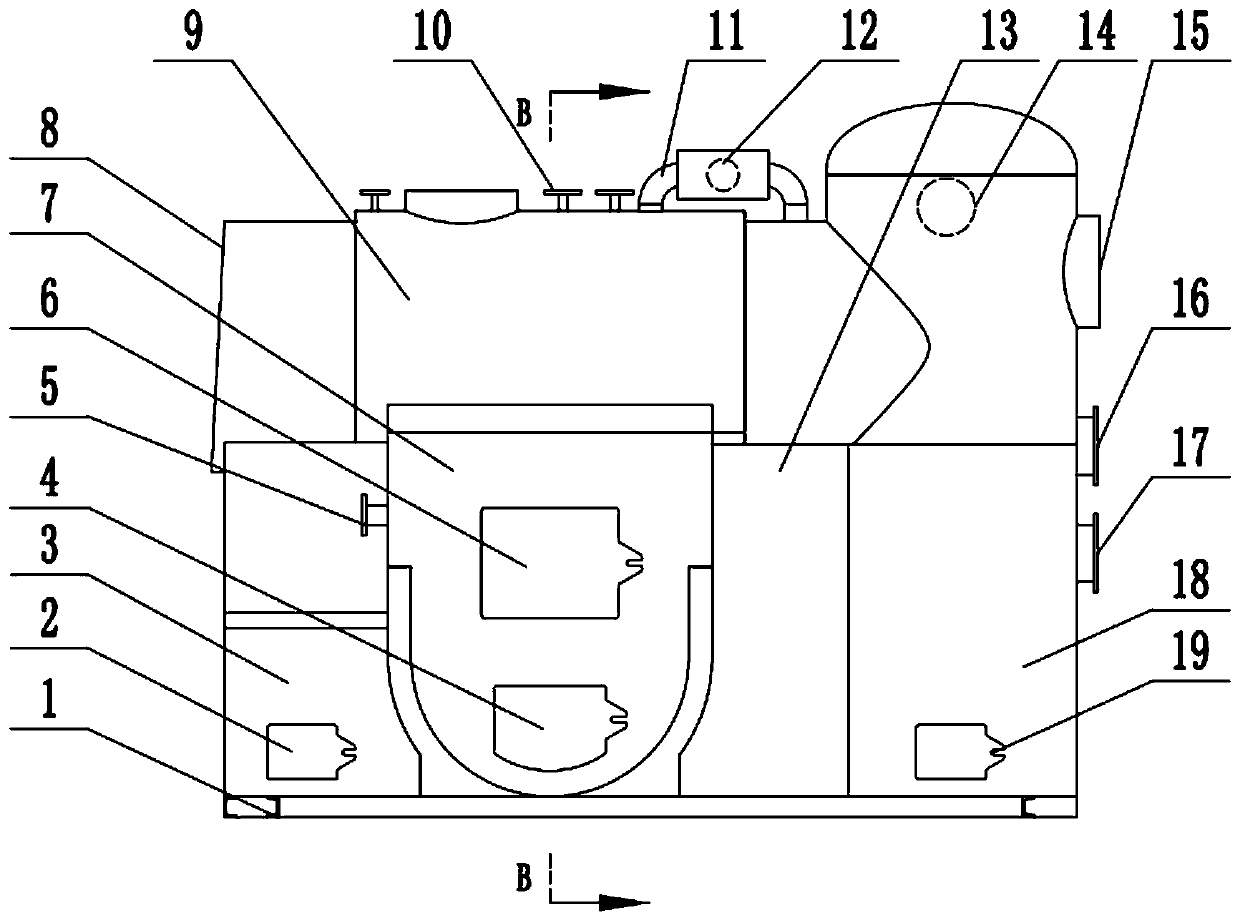

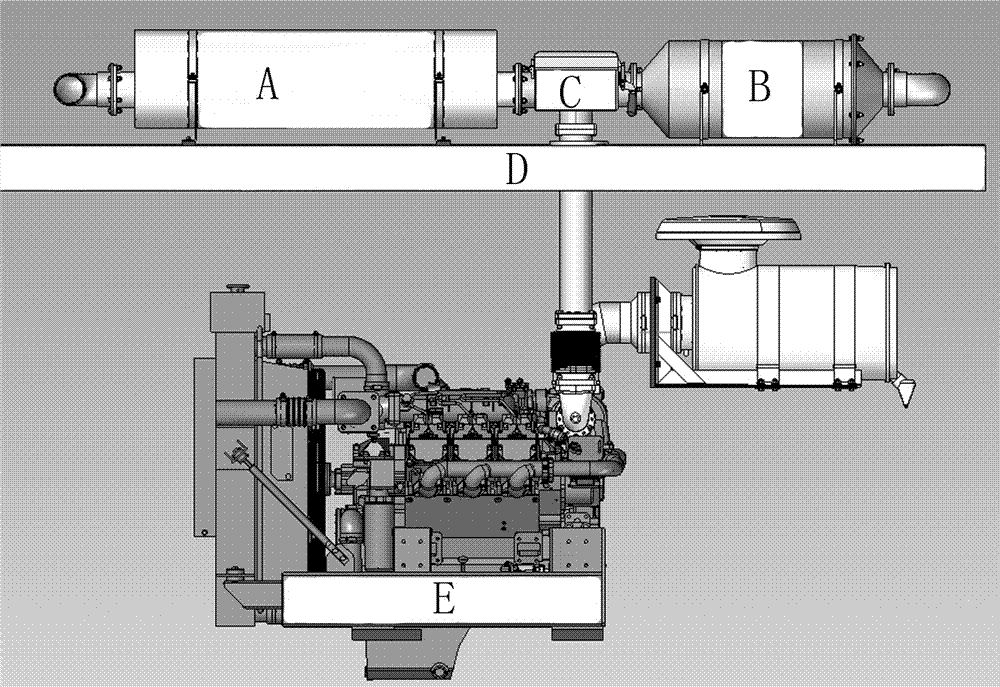

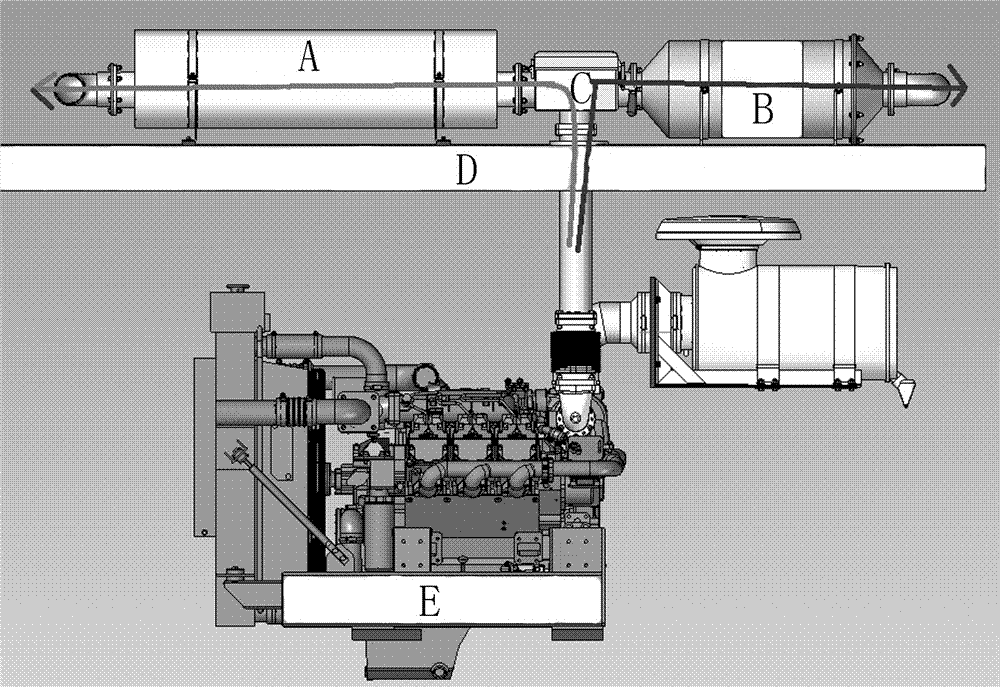

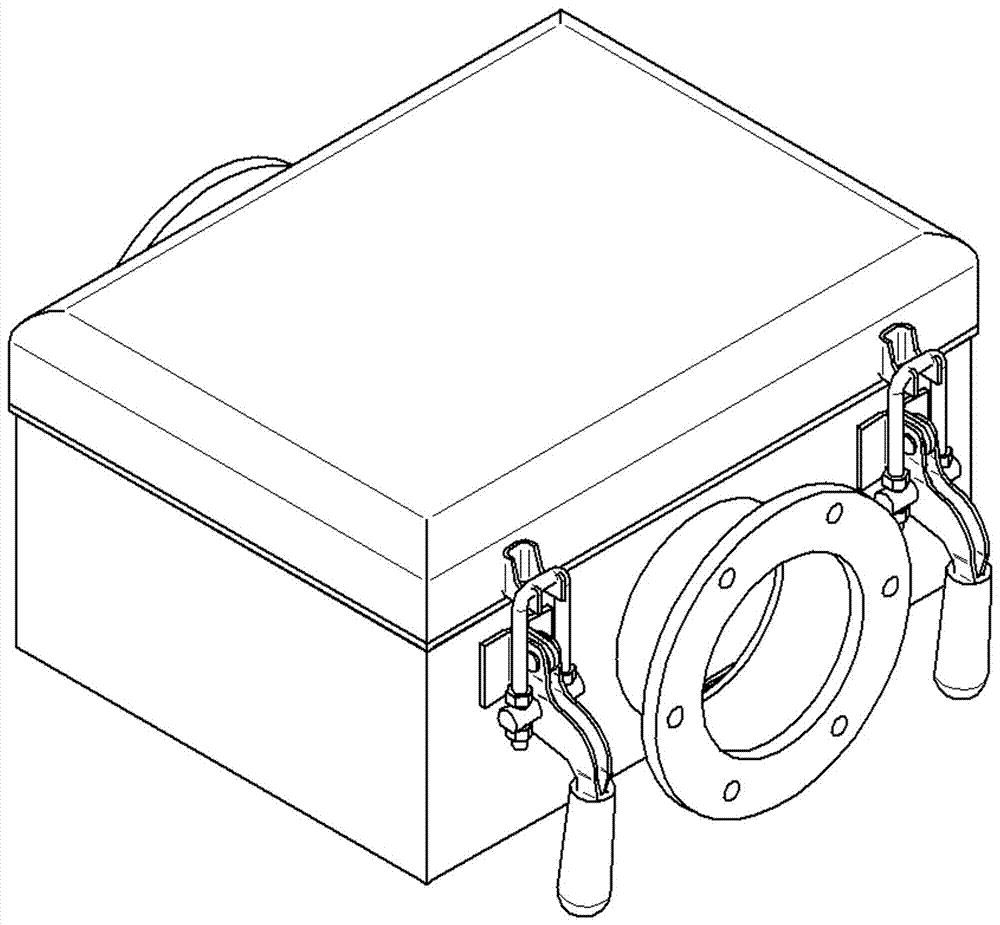

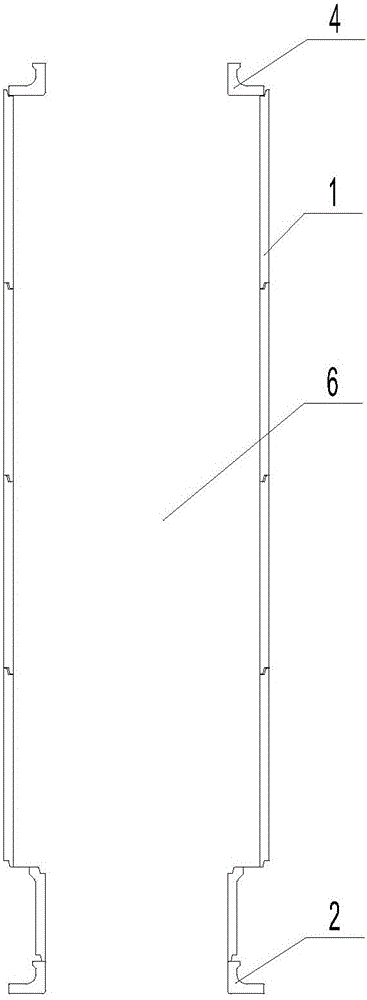

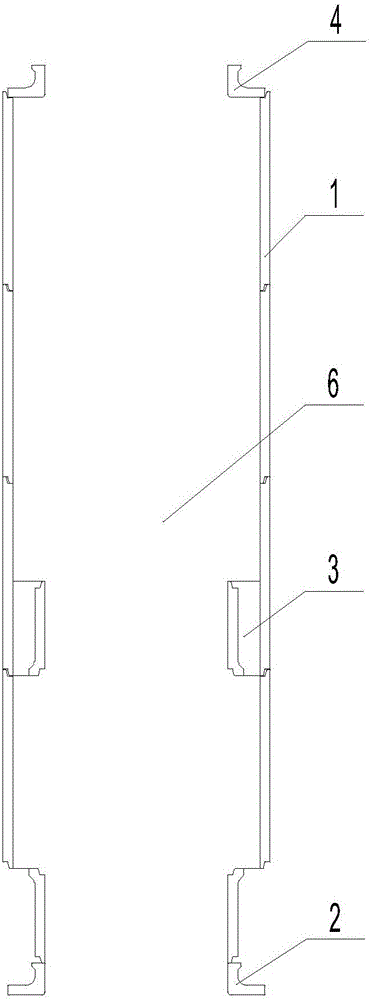

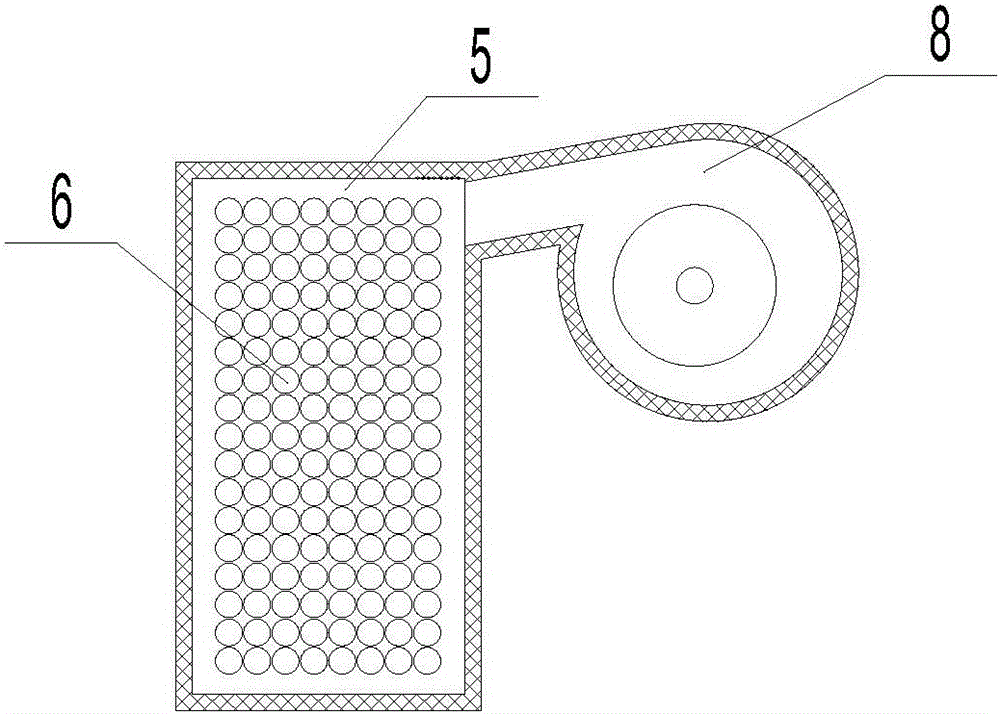

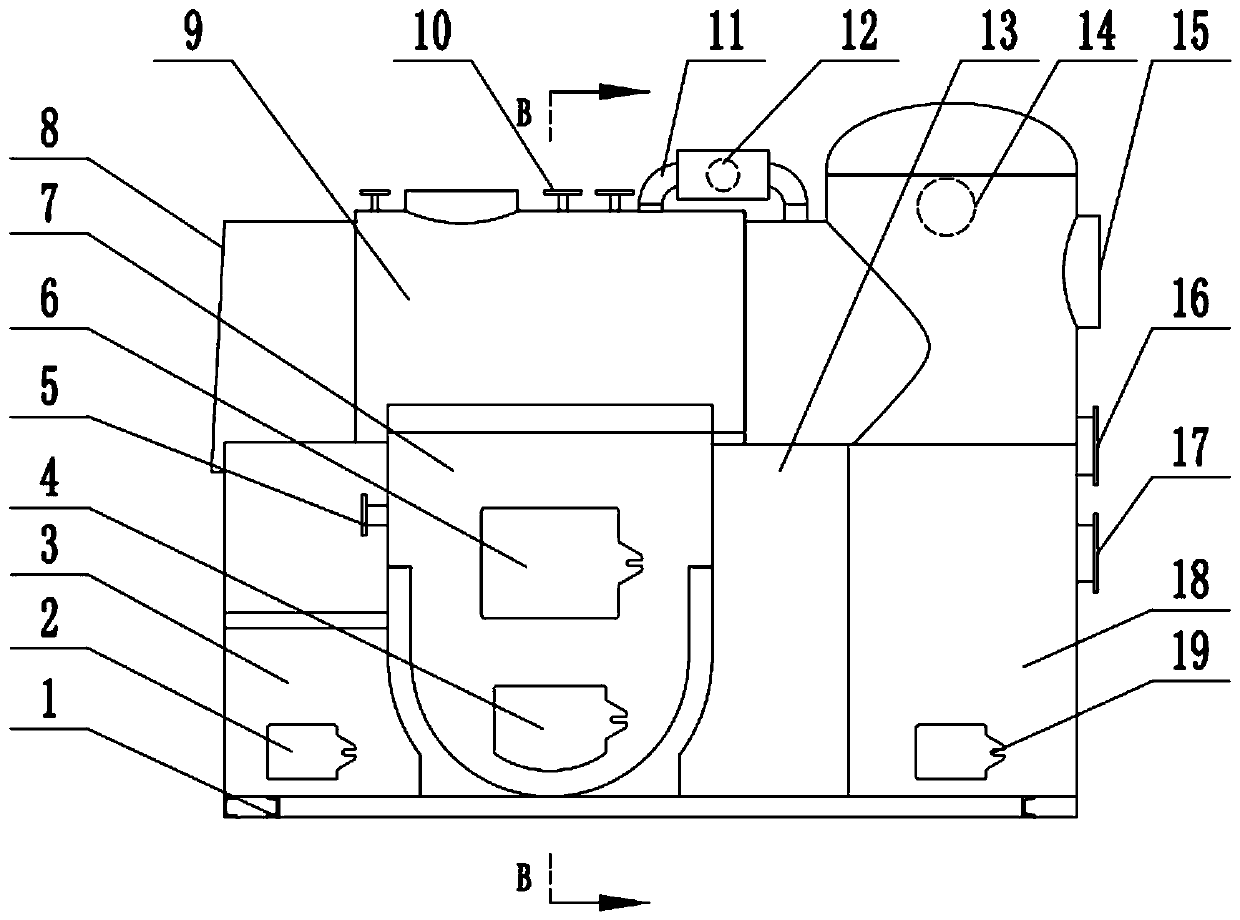

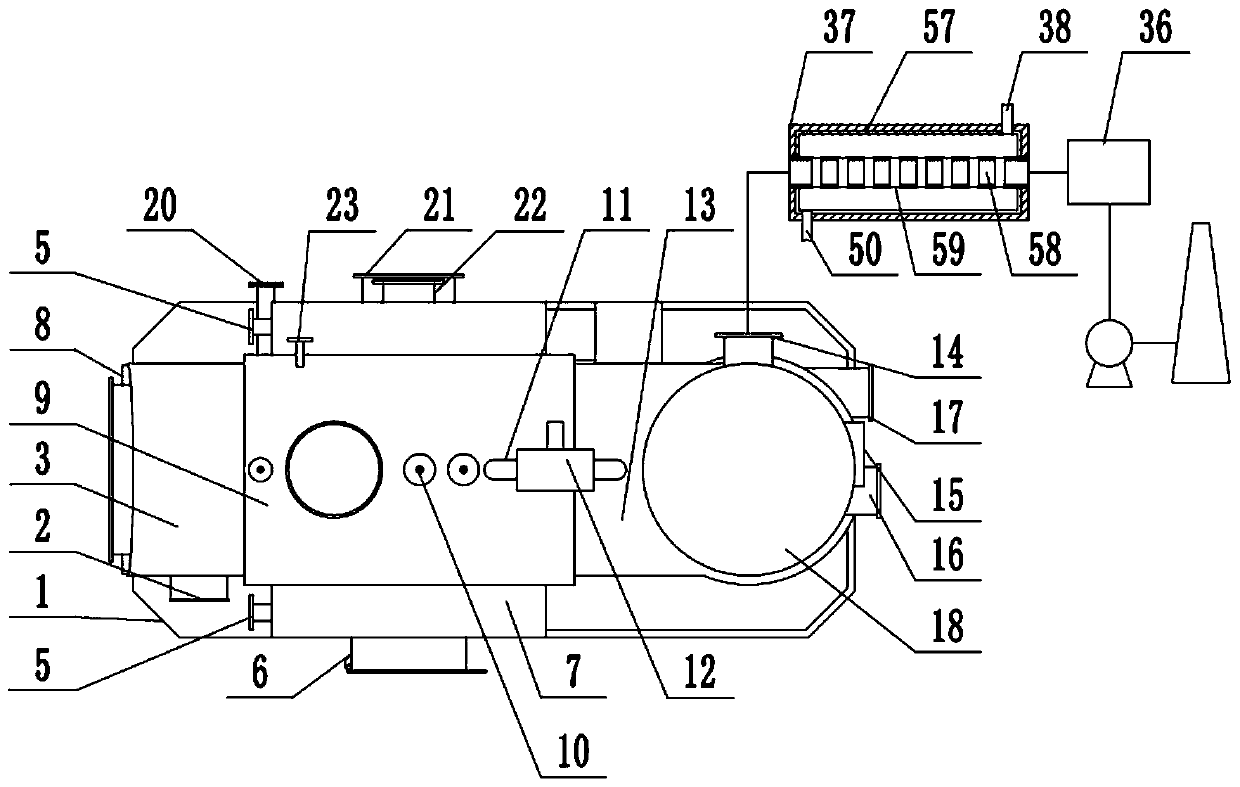

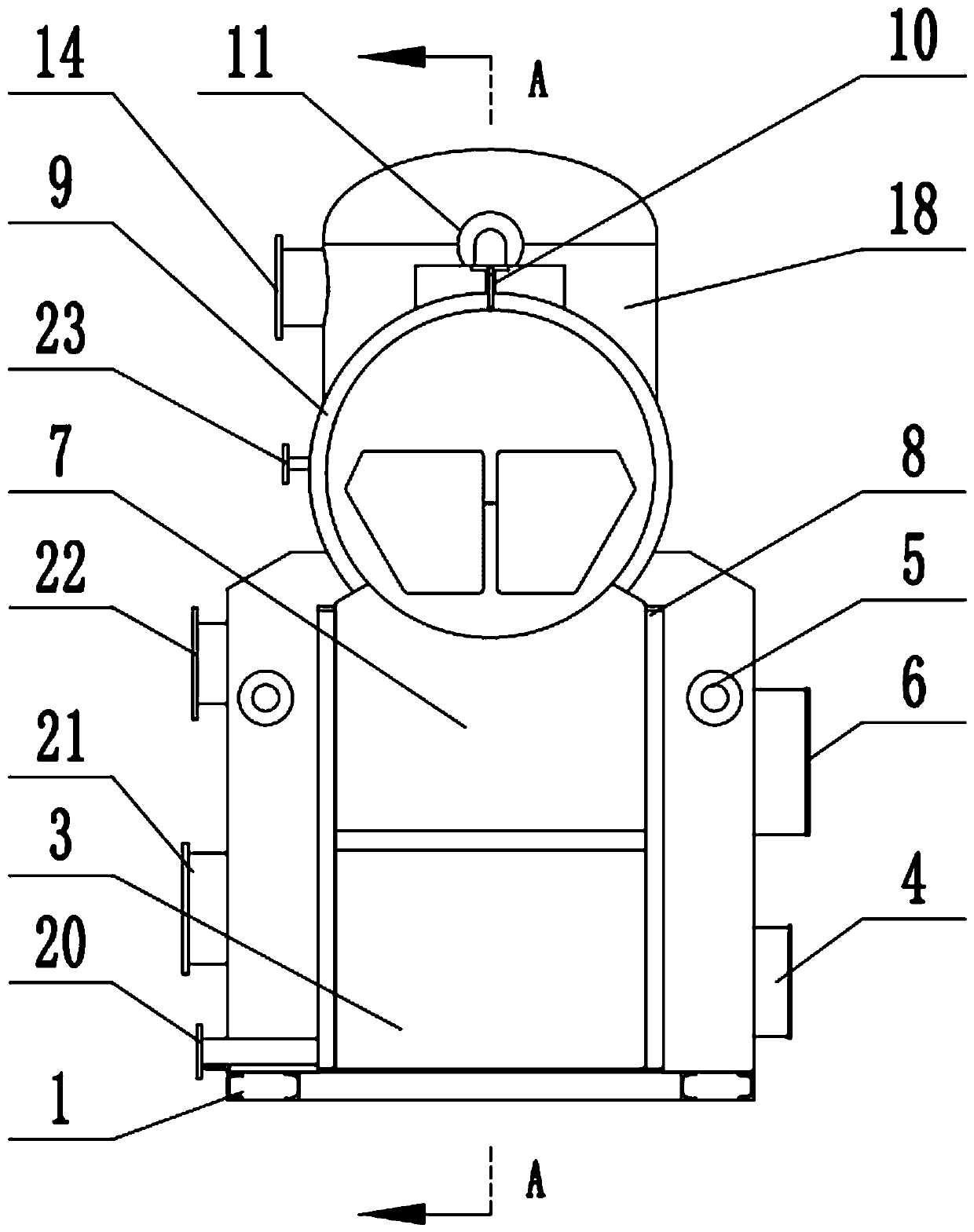

An optional exhaust gas purification device

ActiveCN104832252BEliminate black smokeIncrease capture rateInternal combustion piston enginesExhaust apparatusTrappingControl system

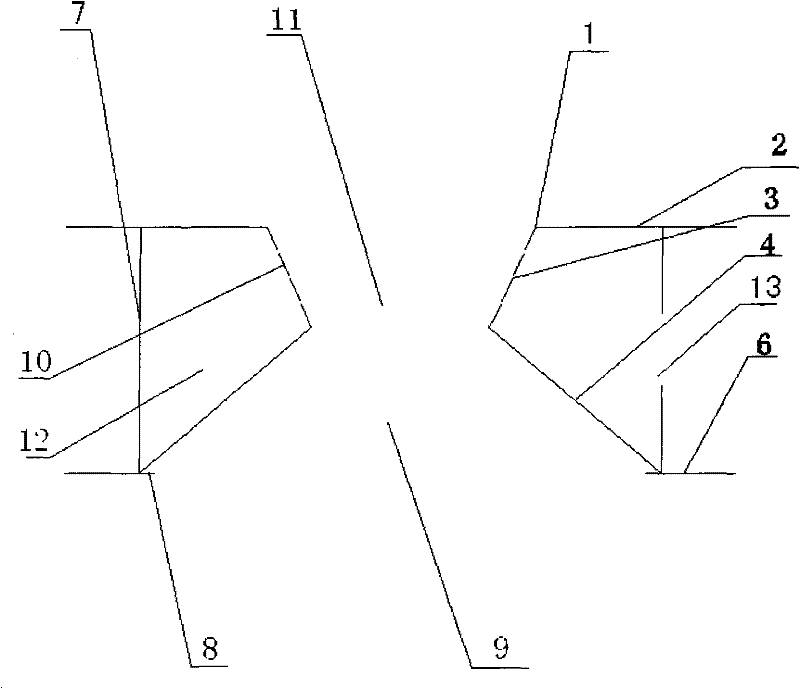

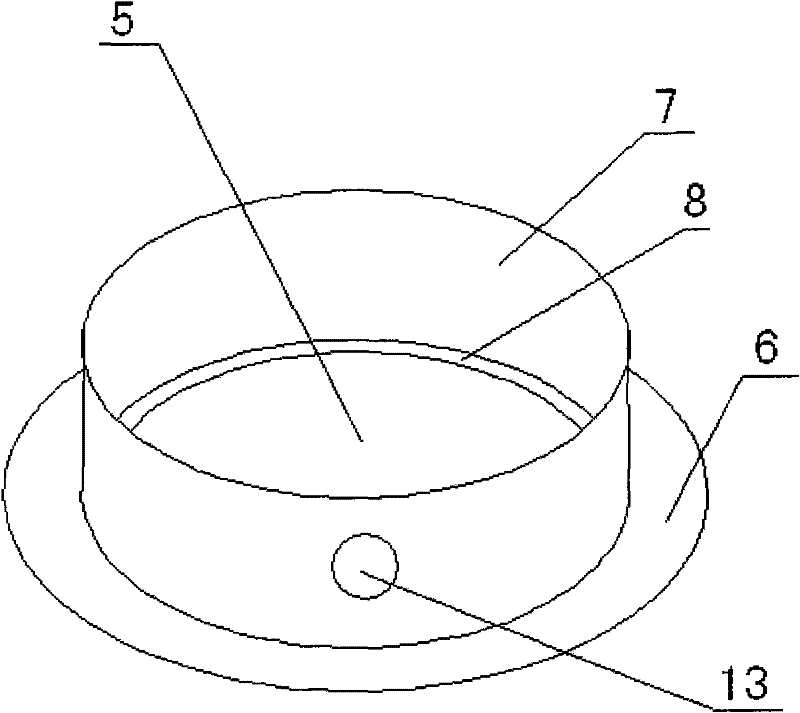

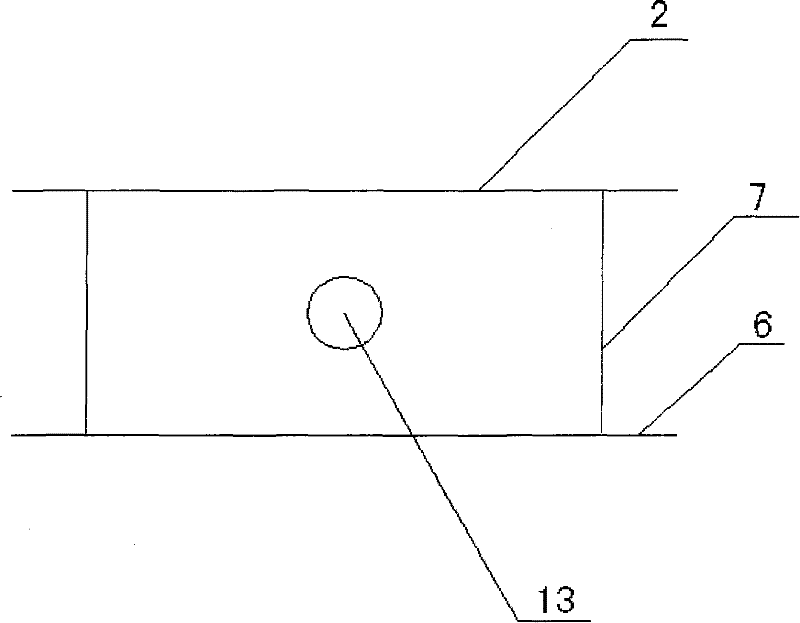

The invention relates to a selective type tail gas purifying device, which comprises a tail gas separating device (C), wherein the tail gas separating device (C) is connected with a gas exhaust opening of a diesel engine (E) of an operation vehicle; an inlet of the tail gas separating device (C) is connected with the gas exhaust opening of the diesel engine (E) of the operation vehicle; the tail gas separating device (C) comprises at least two outlets, namely an outlet I and an outlet II; the outlet I is connected with a silencer (A), and the outlet II is connected with a DPF (diesel particulate filter) particulate trapping device (B); the silencer (A) and the DPF particulate trapping device (B) are arranged above a ceiling (D) of the operation vehicle; the tail gas separating device (C) comprises a box body (6); the box body (6) comprises a bottom plate; the bottom plate is connected with a side plate; an overhauling cover plate is arranged above the side plate; a driving worm gear rod is embedded between a left side plate and a right side plate of the box body through a rotary bearing mounting seat (8) and a bearing (64). The selective type tail gas purifying device has the characteristics that when a filtering core is blocked by accumulated carbon, the detachment and replacement are performed, or the movable type regenerating servicing is performed; the limitation of single configuration on cost, tail gas temperature and a control system is avoided, and more flexibility in servicing or replacement is realized.

Owner:CRCC HIGH TECH EQUIP CORP LTD

Flue gas purifying device and circulating fluidized bed boiler with device

The invention discloses a flue gas purifying device and a circulating fluidized bed boiler with the device, and belongs to the technical field of boiler environment friendliness. The flue gas purifying device and the boiler are used for treatment of nitrogen oxides and sulfides. The flue gas purifying device comprises a plurality of pipelines which are arranged in parallel or alternatively, each pipeline comprises a middle segment, an inlet segment and an outlet segment, and the inner diameter of each inlet segment and each outlet segment is smaller than the inner diameter of a portion defined by the corresponding middle segment; and in view of the technical scheme, simultaneous and efficient treatment of the nitrogen oxides and the sulfides in flue gas through the enhanced SNCR technology can be achieved, equipment investment and operating maintenance cost can be reduced, and the pollution of secondary heavy metal pollution is completely eradicated.

Owner:ENVIRONMENTAL PROTECTION EQUIP CO LTD SHANDONG GIANT ASIA +1

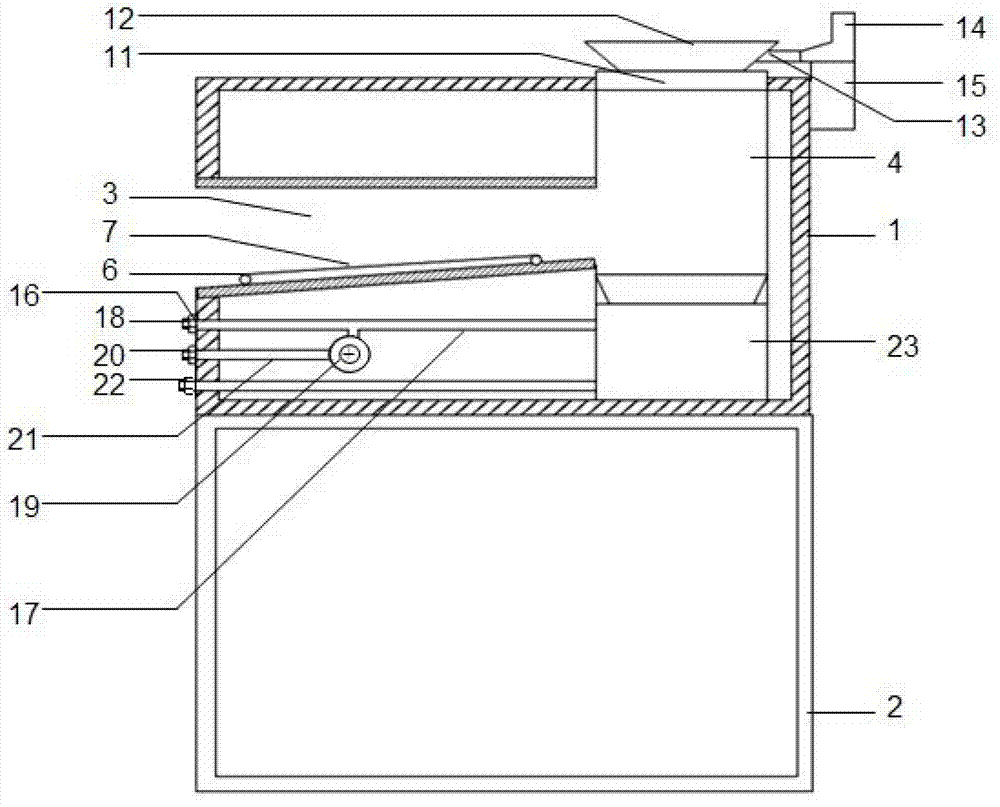

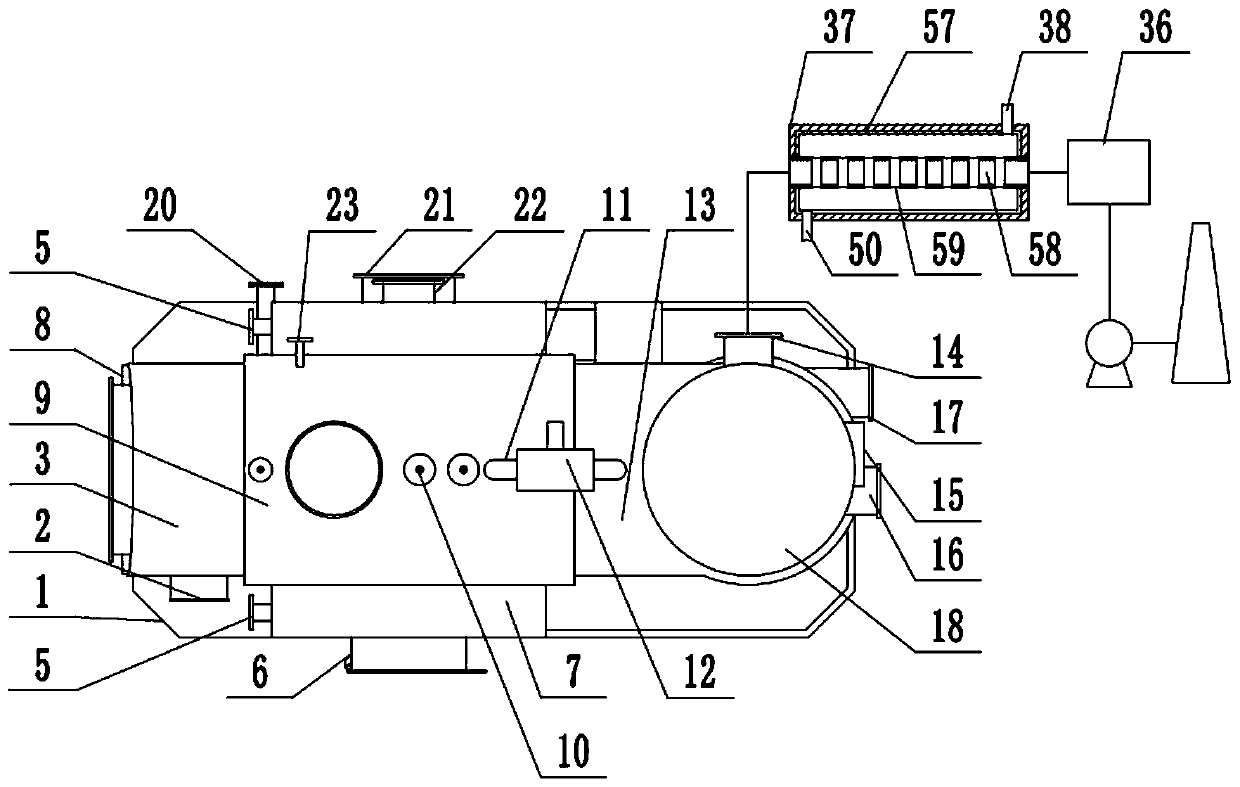

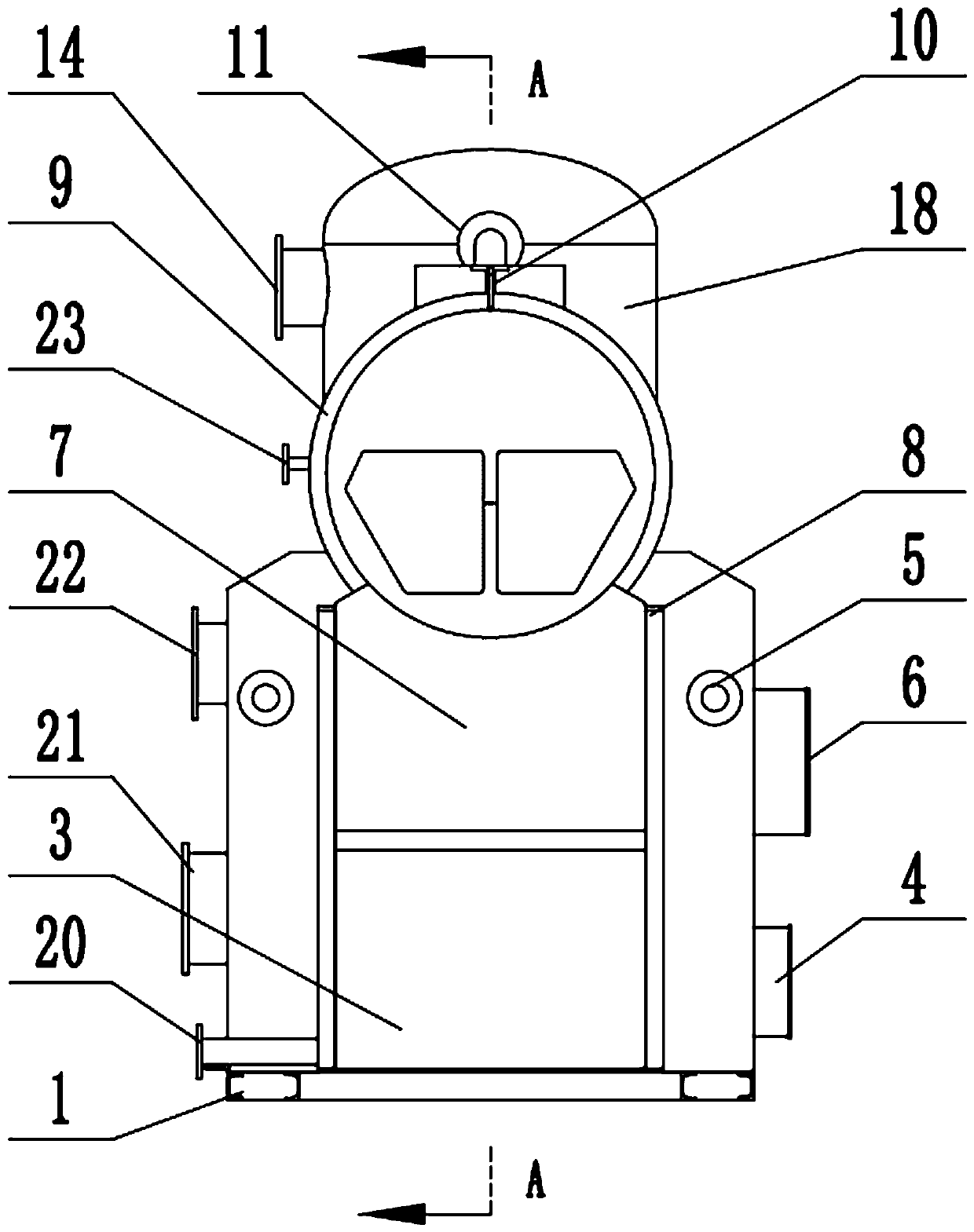

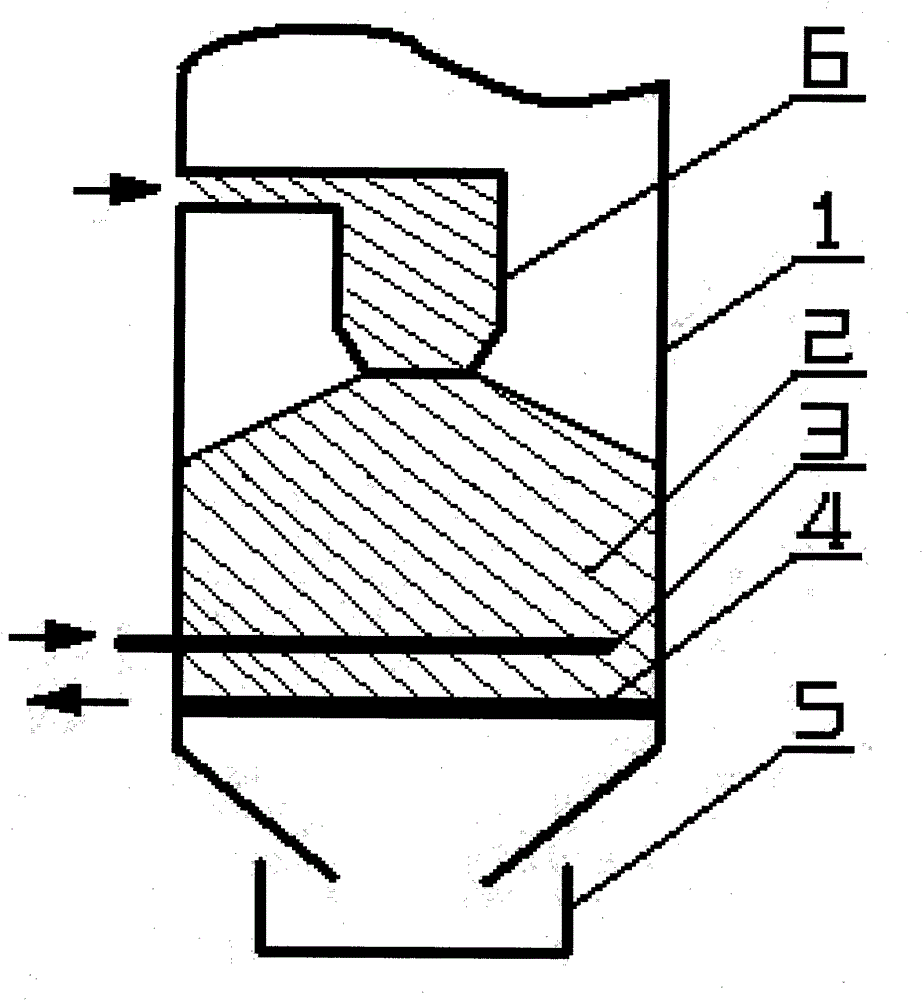

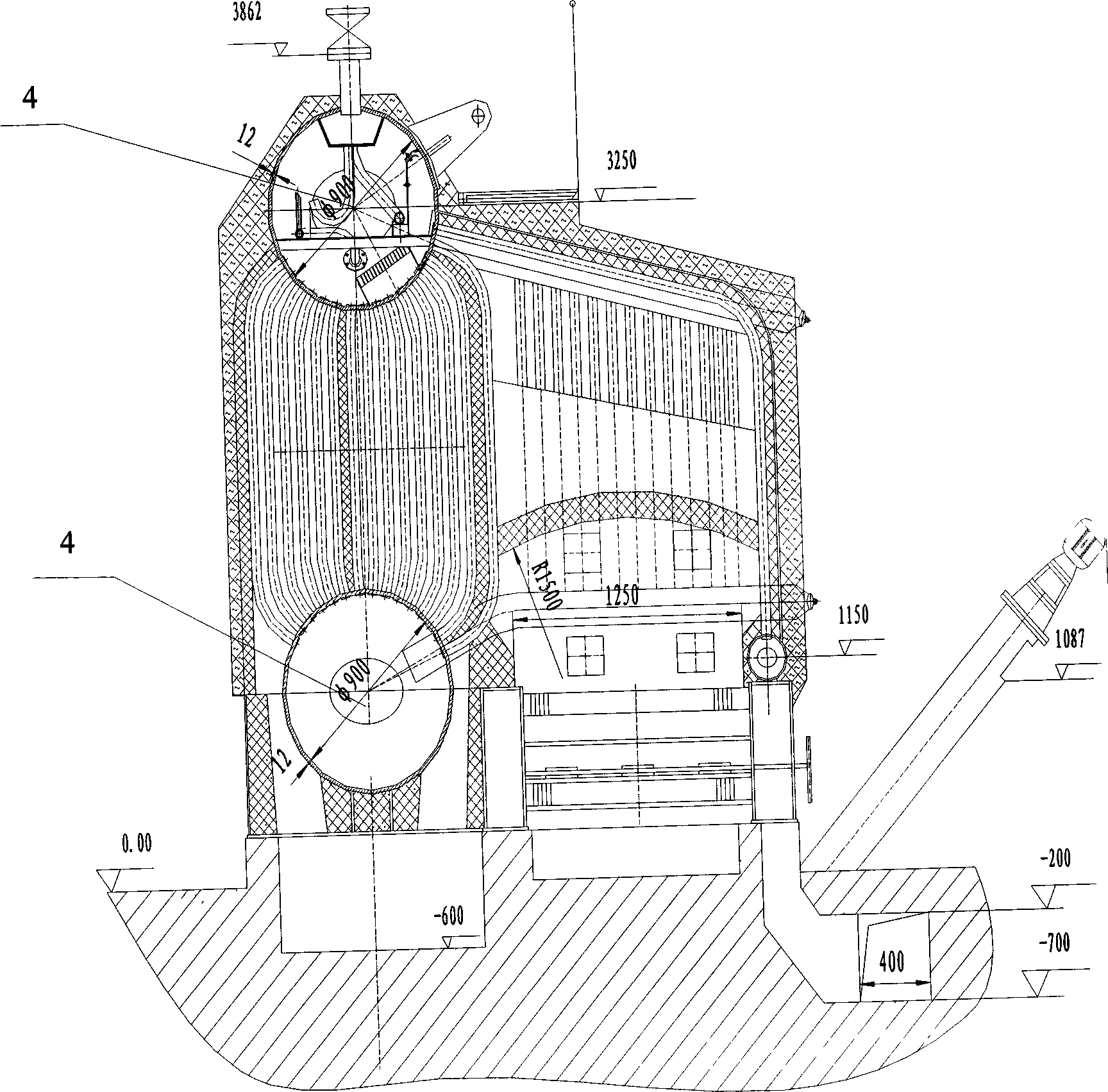

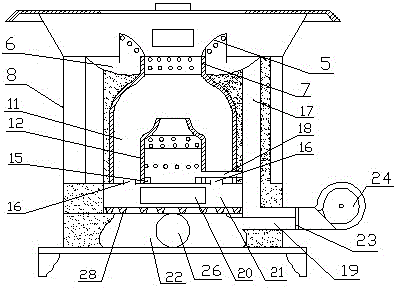

Reverse burning type normal-pressure superheated steam furnace

PendingCN111449142AImprove heat utilizationBurn fullyCheese manufactureSteam superheatersCombustion chamberEngineering

The invention relates to a reverse burning type normal-pressure superheated steam furnace. The reverse burning type normal-pressure superheated steam furnace comprises a furnace seat and a furnace body mounted on the furnace seat, wherein a hearth is arranged in the furnace body, and water-clamping layers are arranged on the two side hearth walls of the hearth; a steam generator is arranged at theupper part of the hearth; and a secondary combustion chamber is arranged on one side of the hearth; and the lower part of the secondary combustion chamber communicates with the hearth through a flamehole, a primary oxygen inlet is formed in the hearth, and a secondary oxygen inlet is formed in the secondary combustion chamber. By utilizing a reverse burning type secondary combustion technique, adequate combustion of fuels is realized, so that the thermal conversion efficiency is improved, and black smoke is eliminated; water is taken as a heating medium, heat exchange is carried out by virtue of heat and thermal radiation generated by a primary combustion chamber and the secondary combustion chamber of the steam generation furnace so as to generate saturated steam, the saturated steam iscontinuously heated by virtue of heat of high-temperature fume, and then superheated stream at the temperature higher than 135 DEG C is generated at a pressure lower than 0.1MPa.

Owner:广西格卡环保科技有限公司

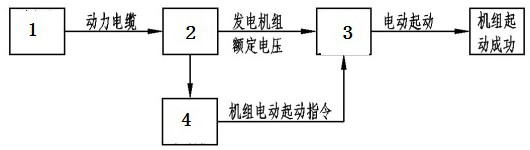

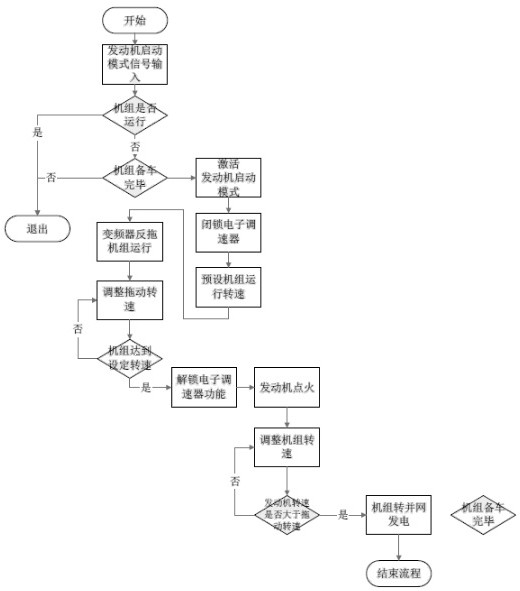

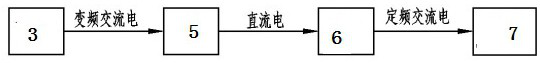

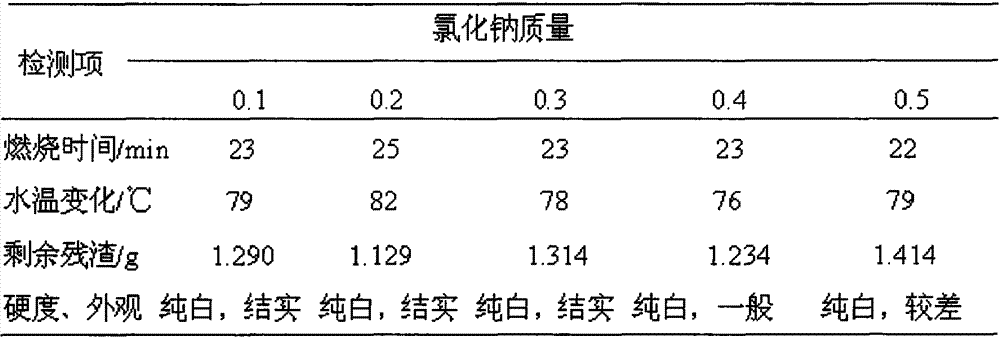

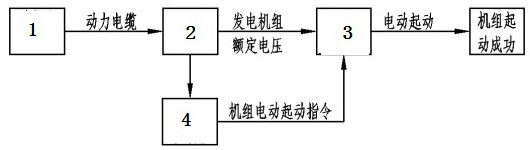

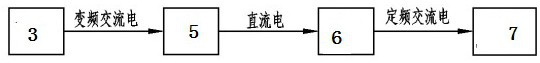

Starting mode of high power diesel engine driven by generator in reverse direction

ActiveCN111852715AAvoid abnormal wearAvoid inefficient combustionElectric motor startersMachines/enginesFrequency changerSprayer

The invention belongs to the technical field of machinery, and relates to a starting mode of a high power diesel engine driven by a generator in a reverse direction. According to the related startingmode of the high power diesel engine driven by the generator in the reverse direction, the generator adopts a combination of the diesel engine and an asynchronous generator, the starting mode is as follows: firstly, an outside high voltage alternating current power supply is connected with a converter, the converter converts voltage of the outside high voltage alternating current power supply intorated voltage of a frequency-variable and speed-variable generating unit, and the voltage is provided for the frequency-variable and speed-variable generating unit. Meanwhile, the converter activatesa unit control box and sends a generating unit electric starting instruction, the generating unit operates in an electric starting state after energization, and starts to rotate and drives the dieselengine to rotate in the reverse direction through a disc coupling or a high-elastic coupling, a generating unit control system instructs an oil sprayer to carry out oil spraying after the rotating speed of the diesel engine reaches a set rotating speed, and the diesel engine is ignited and started smoothly. The mode can reduce the waste of fuel oil, and reduce discharging pollution.

Owner:HENAN DIESEL ENGINE IND

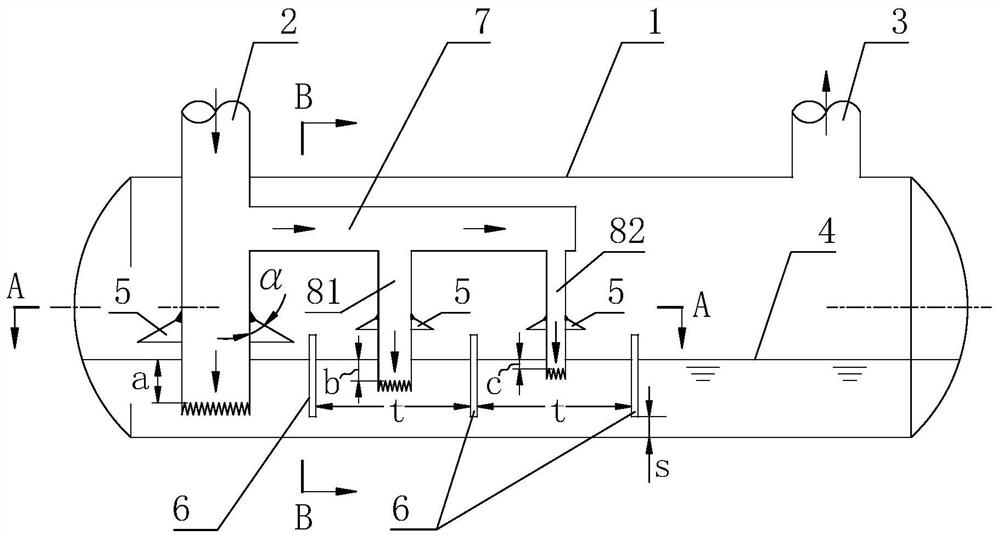

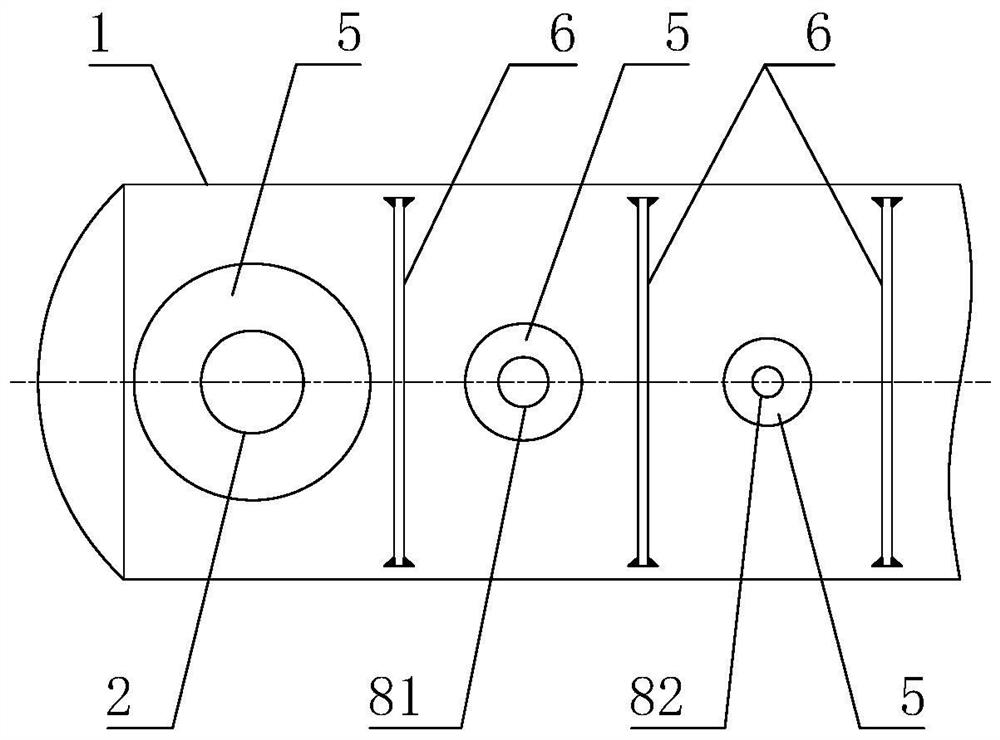

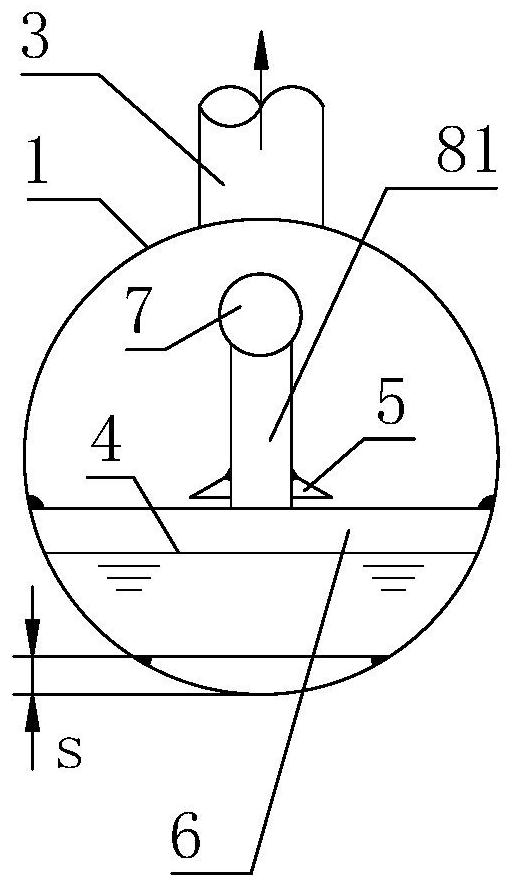

Water-sealed tank

InactiveCN112049966AAvoid violent fluctuationsReduce water seal differenceValve arrangementsPetrochemicalMechanical engineering

The invention discloses a water-sealed tank. The water-sealed tank is provided with a horizontal tank body (1), and a torch exhaust gas inlet main pipeline (2) and a torch exhaust gas outlet pipeline(3) are arranged on the horizontal tank body. One or more auxiliary pipelines are arranged on an auxiliary pipeline main pipe (7) in the horizontal tank body along the axial direction of the horizontal tank body. The diameter of the auxiliary pipeline adjacent to the torch exhaust gas inlet main pipeline and the depth of the bottom outlet immersed into sealing water in the horizontal tank body arerespectively smaller than the diameter of the torch exhaust gas inlet main pipeline and the depth of the bottom outlet immersed into the sealing water. When more than one auxiliary pipeline is arranged, between two adjacent auxiliary pipelines, the diameter of the auxiliary pipeline far away from the torch exhaust gas inlet main pipeline and the depth of the bottom outlet immersed in the sealingwater are respectively smaller than the diameter of the auxiliary pipeline close to the torch exhaust gas inlet main pipeline and the depth of the bottom outlet immersed in the sealing water. The water-sealed tank provided by the invention can be used for petrochemical enterprises.

Owner:SINOPEC GUANGZHOU ENG +1

Grate firing equipment

ActiveCN101936538BReduce generationEliminate black smokeLump/pulverulent fuel preparationDust controlMoisture

The invention provides grate firing equipment suitable for a solid fuel boiler, a waste incinerator, a heat furnace and a range. In the equipment, a fuel pre-heat tank is arranged in a hearth above a grate layer and is heated and baked by flame in the hearth; the fuel inside the fuel pre-heat tank is preheated and subject to the destructive distillation in an anaerobic state to separate moisture and volatile; and the fuel falls on the grate layer, and is oxidized by air in the hearth to fire. Furthermore, two grate plates which are parallel to each other and can be plugged are arranged on the bottom of the hearth, and the separation of the fuel and ashes and slagging can be realized by alternately plugging in and out the two grate plates. The grate firing equipment realizes mechanical, simple and reliable slagging function of the grate firing furnace, and simultaneously maintains the firing property of 'double-sided firing' to ensure that the grate furnace is applicable to various solid fuels, and has the advantages of sufficient firing, small pollution and good effect of smoke prevention and dust control.

Owner:蒋钧

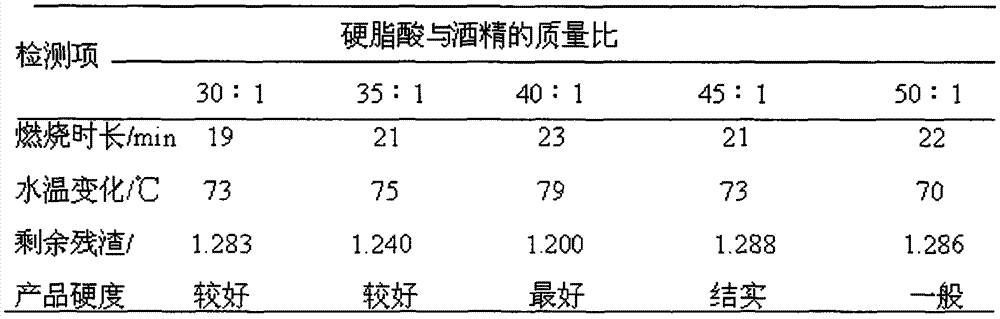

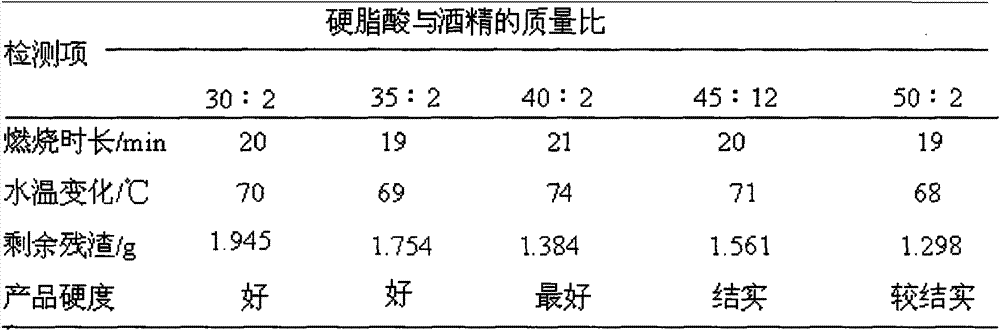

A kind of preparation method of solid alcohol

The invention discloses a preparation method of solid alcohol, and obtains the best preparation process of solid alcohol when potassium permanganate is used as a combustion aid and stearic acid is used as a curing agent: the mass ratio of alcohol to stearic acid is 40:1, adding When 4% distilled water is used, the hardness is better compared with other proportions, adding a mass ratio of 0.014% potassium permanganate combustion accelerant can improve the combustion performance of solid alcohol, eliminate black smoke, reduce calorific value loss, and reduce the amount of residue; and On the basis of no additional cost increase, the cooling conditions are changed to improve its combustion performance. Keeping the pH value at about 8 can make the solid alcohol coagulate best. The solid alcohol prepared under the above conditions has the characteristics of high hardness, less residue, high heat release, easy storage, safety and portability, and can be used in catering, tourism, field operations and other industries.

Owner:INNER MONGOLIA UNIV FOR THE NATITIES

A starting method of a generator reversely driving a high-power diesel engine

ActiveCN111852715BAvoid abnormal wearAvoid inefficient combustionElectric motor startersMachines/enginesControl systemCoupling

The invention belongs to the technical field of machinery, and relates to a starting method for a generator reversely driving a high-power diesel engine. It involves a starting method in which the generator reversely drives a high-power diesel engine. The generator adopts a combination of a diesel engine and an asynchronous generator. The starting method is as follows: firstly, connect an external high-voltage AC power The voltage of the power supply is converted into the rated voltage of the variable-frequency variable-speed generator set, and provides voltage for the variable-frequency variable-speed generator set; at the same time, the frequency converter activates the control box of the unit and sends out an electric start command for the generator set. Start to rotate and reversely drag the diesel engine to rotate through the disc coupling or high-elastic coupling. When the diesel engine speed reaches the set speed, the generator set control system instructs the injector to inject fuel, and the diesel engine ignites and starts smoothly. The invention reduces the waste of fuel oil and reduces the pollution of discharge.

Owner:HENAN DIESEL ENGINE IND

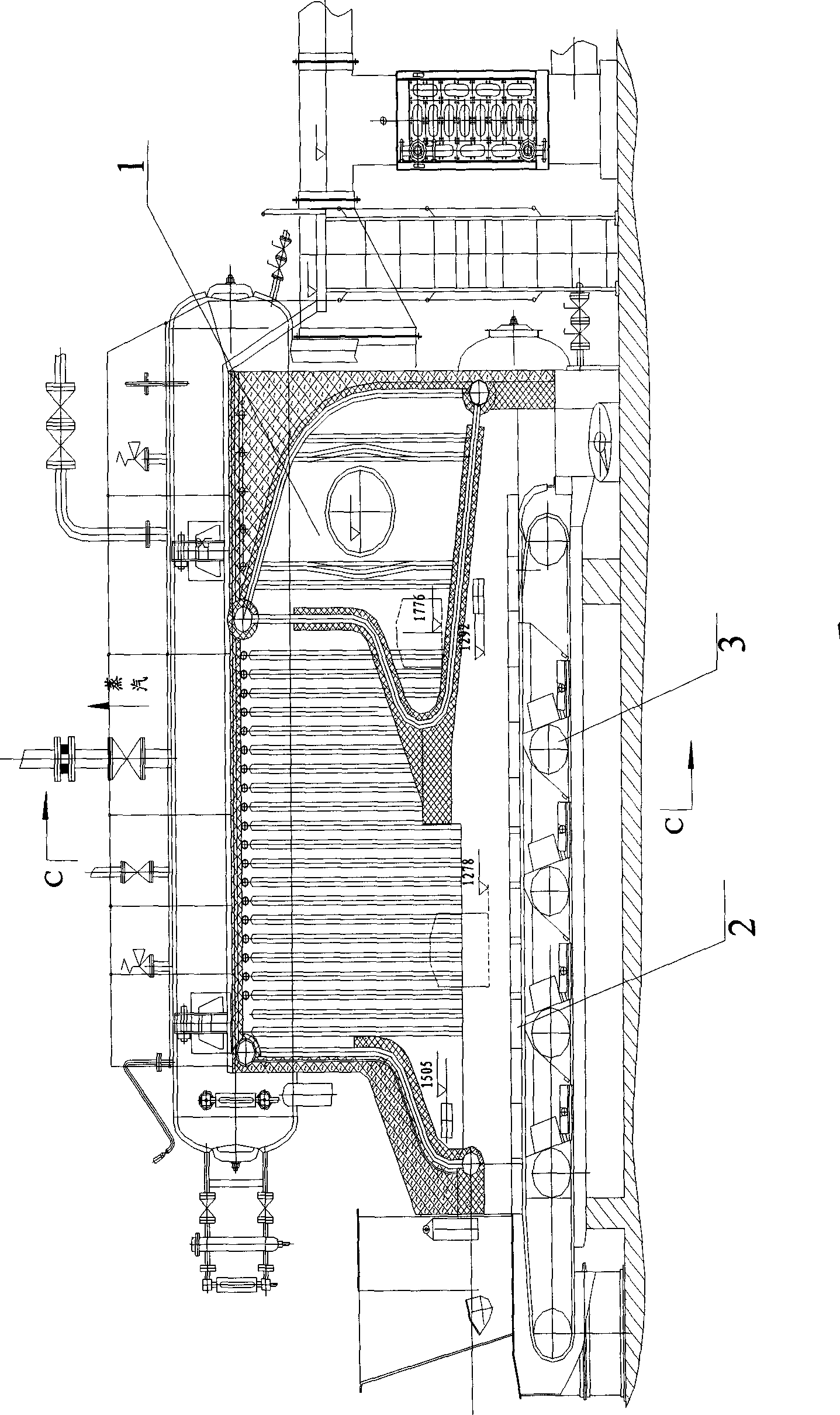

Biomass sawdust particle boiler

InactiveCN103206704AReduce the original dust concentrationExtended staySolid bar grateSolid fuel combustionEngineeringBiomass

The invention provides a biomass sawdust particle boiler, which comprises an offset hearth burning chamber (1), and the burning chamber is a horizontal whirlwind burning chamber. According to the biomass sawdust particle boiler, the function of once dust removal in a furnace is realized, a primitive dust exhaust concentration of the boiler is lowered, black smoke is eliminated, and fuels are enabled to be fully burnt.

Owner:赵军

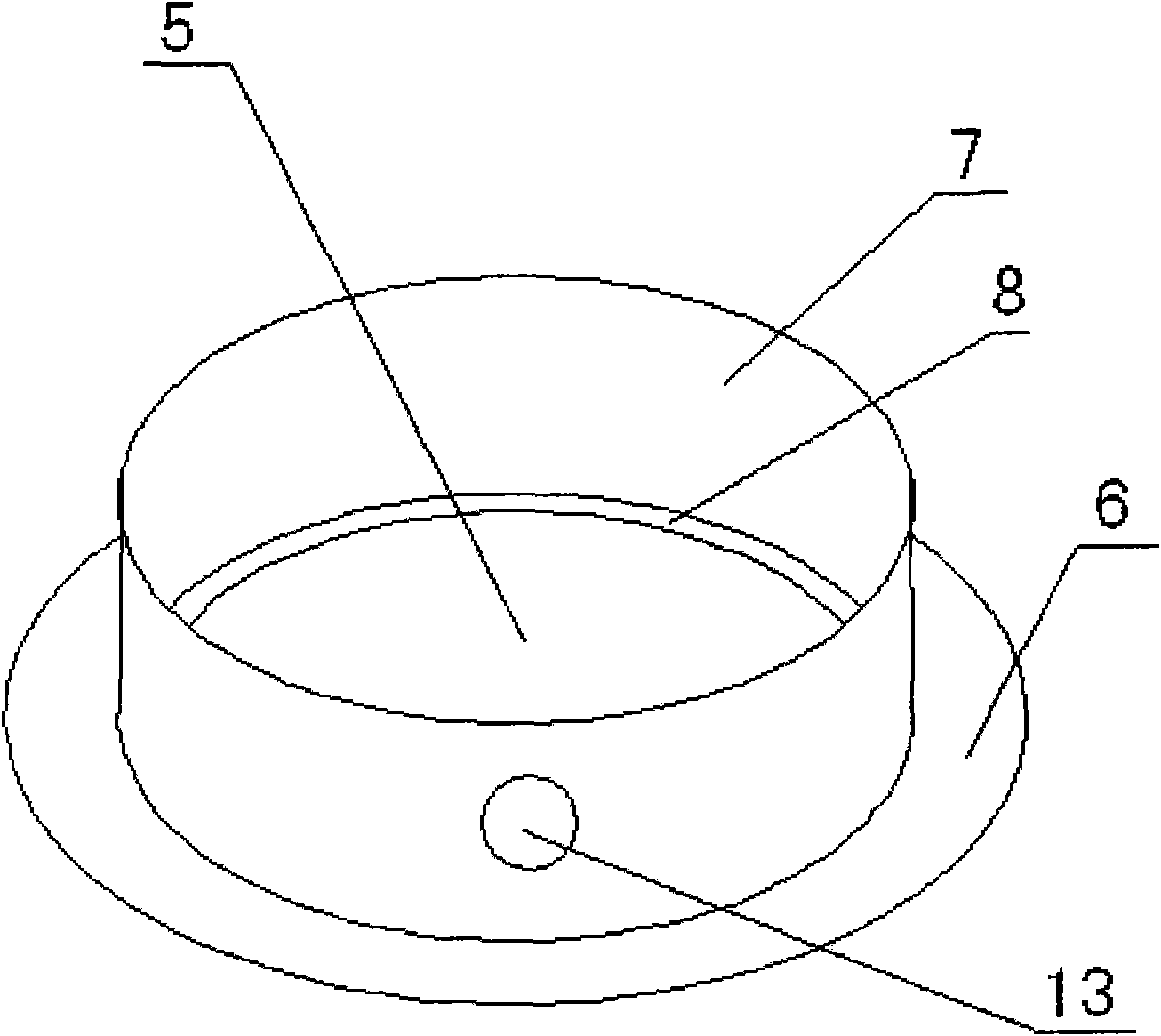

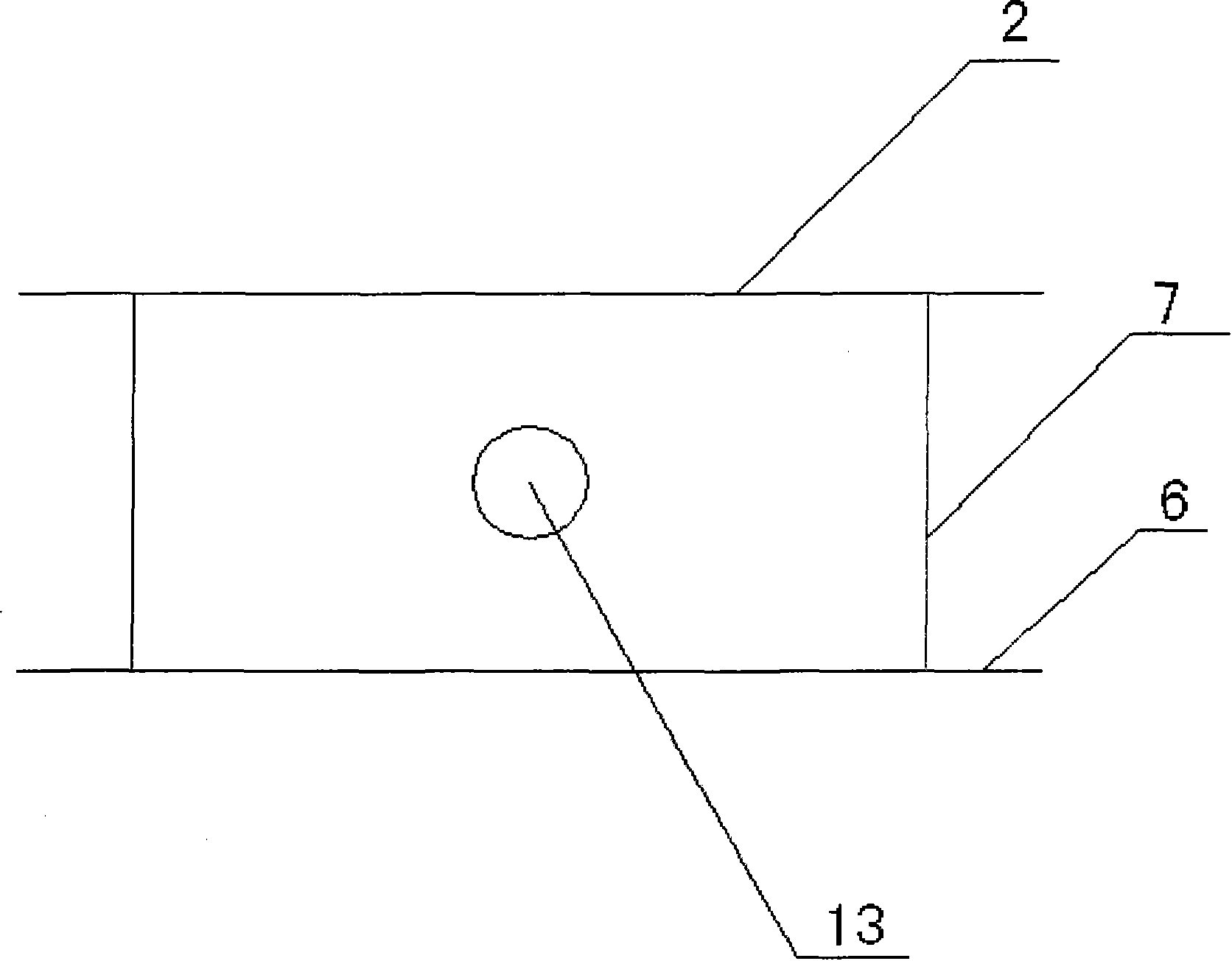

Biomass boiler oxygenation strong-fire burnout device

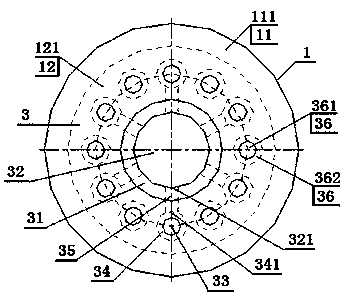

ActiveCN101852443AIncrease profitReduce pollutionNon-combustible gases/liquids supplyEngineeringBiomass boiler

The invention relates to a biomass boiler oxygenation strong-fire burnout device, comprising an upper cover board, a base board and an oxygenation cavity arranged between the upper cover board and the base board. The upper cover board is equipped with a burning port; the lower part of the burning port is equipped with a conical wide opening composed of an oxygenation board with oxygenation holes; the bottom of the oxygenation board is connected with a hearth fire-gathering port composed of a conical fire-gathering board; the hearth fire-gathering port is communicated with the air inlet on the base board; the bottom of the conical fire-gathering board is fixedly arranged on the inner edge of the base board inside an oxygenation cavity outer board; the oxygenation cavity is composed of the oxygenation board, the conical fire-gathering board and the oxygenation cavity outer board; the conical wide opening is communicated with the oxygenation cavity through the oxygenation holes on the oxygenation board; and the oxygenation cavity is communicated with outside through an oxygen supply pipe joint on the oxygenation cavity outer board. By adopting the burnout device, combustible components can be fully burned, thus achieving energy conservation and environmental protection and meeting the national specified environmental protection rules.

Owner:HENAN JUFENG BIO ENERGY DEV

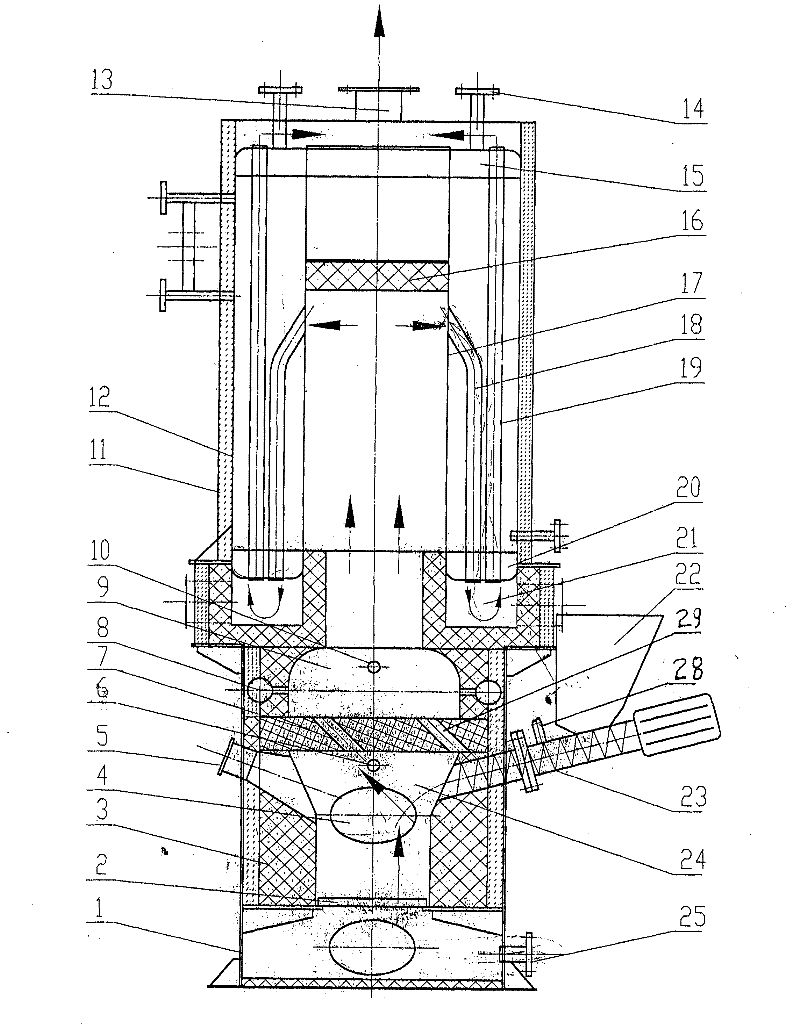

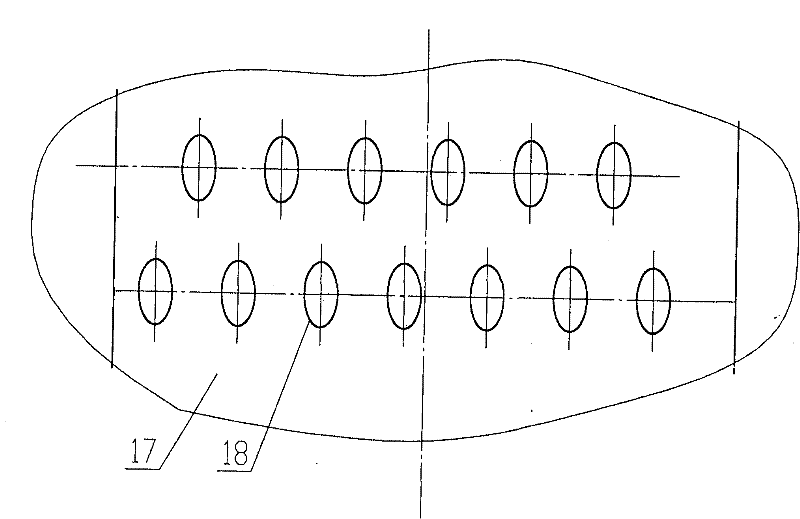

Vertical environment-friendly boiler for triple dedusting burning wood and biomass particle fuel in boiler

InactiveCN101907292BFully embersFully vaporizedSolid fuel combustionCasings/liningsDust controlHearth

The invention relates to a vertical environment-friendly boiler for triple dedusting burning wood and biological particle fuel in a boiler, belonging to heating technology. The invention is used for burning wood and biological particles to obtain hot water or steam, and overcomes the defects of black smoke emission, low thermal efficiency, and the like of the similar traditional boilers. The boiler comprises a wind chamber, a fire grate, a carbon powder and gas burning hearth, a first wind inlet, a secondary wind inlet, and a heat exchanger above the hearth. The boiler is characterized in that the hearth is provided with a porous boiler crown of an inclined air vent; the upper end of an inner liner is provided with a smoke blocking wall; a downward screwed smoke tube is arranged between the wall of the inner liner and a lower end socket; an upward screwed smoke tube penetrates through an upper closing plate and a lower closing plate; and a heat exchanger seat of a smoke diversion dedusting chamber in the shape of a ring cavity is arranged on the circumference of the lower end of the heat exchanger. The invention has the advantages of sufficient burning of carbon powders, sufficient gasification and high thermal efficiency. Smoke is dedusted three times in the boiler, and the exhausted smoke has low dust capacity. The invention can be manufactured in a split mode, and is convenient to transport. The tonnage can be greatly increased.

Owner:袁福林

Heavy oil additive

A heavy oil additive for decreasing viscosity, smoke and carbon deposit and improving flowability contains nonylphenol polyoxyvinylether (0.04-0.064 wt%), sulfate (0.02-0.032) and water (rest). Its dosage is 30-50% of heavy oil weight.

Owner:顾琦敏 +1

Low-carbon methanol diesel oil and preparation method thereof

PendingCN113637506AImprove modification effectGood liquidityLiquid carbonaceous fuelsAir quality improvementEnvironmental geologyIso butanol

The invention discloses low-carbon methanol diesel oil and a preparation method thereof. The low-carbon methanol diesel oil is prepared from vegetable oleic acid, methanol, a cetane number improver, isobutanol, n-butanol, a catalytic additive and base diesel oil, a traditional methanol diesel oil preparation method is changed, and substances added into the diesel oil can be better dissolved and combined. The problems that existing diesel oil is large in viscosity, prone to freezing, poor in fluidity and difficult to start at the low temperature at the low temperature are solved, the low-temperature fluidity is high, meanwhile, the combustion performance is not reduced, the content of CO and hydrocarbon in tail gas emission when a vehicle combusts the diesel oil is remarkably reduced, black smoke in the tail gas emission is eliminated, pollution to the atmosphere is greatly reduced, the effects of low carbon and environment friendliness are achieved, methanol diesel oil is easy to store for a long time, ignition startability is good, lubricity can be improved, and rod end abrasion and boundary abrasion of an air inlet valve and an air outlet valve of a piston ring of an engine are reduced.

Owner:GUIZHOU LONGHE ENERGY

Biomass boiler oxygenation strong-fire burnout device

ActiveCN101852443BIncrease profitReduce pollutionNon-combustible gases/liquids supplyEngineeringBiomass boiler

The invention relates to a biomass boiler oxygenation strong-fire burnout device, comprising an upper cover board, a base board and an oxygenation cavity arranged between the upper cover board and the base board. The upper cover board is equipped with a burning port; the lower part of the burning port is equipped with a conical wide opening composed of an oxygenation board with oxygenation holes;the bottom of the oxygenation board is connected with a hearth fire-gathering port composed of a conical fire-gathering board; the hearth fire-gathering port is communicated with the air inlet on thebase board; the bottom of the conical fire-gathering board is fixedly arranged on the inner edge of the base board inside an oxygenation cavity outer board; the oxygenation cavity is composed of the oxygenation board, the conical fire-gathering board and the oxygenation cavity outer board; the conical wide opening is communicated with the oxygenation cavity through the oxygenation holes on the oxygenation board; and the oxygenation cavity is communicated with outside through an oxygen supply pipe joint on the oxygenation cavity outer board. By adopting the burnout device, combustible components can be fully burned, thus achieving energy conservation and environmental protection and meeting the national specified environmental protection rules.

Owner:HENAN JUFENG BIO ENERGY DEV

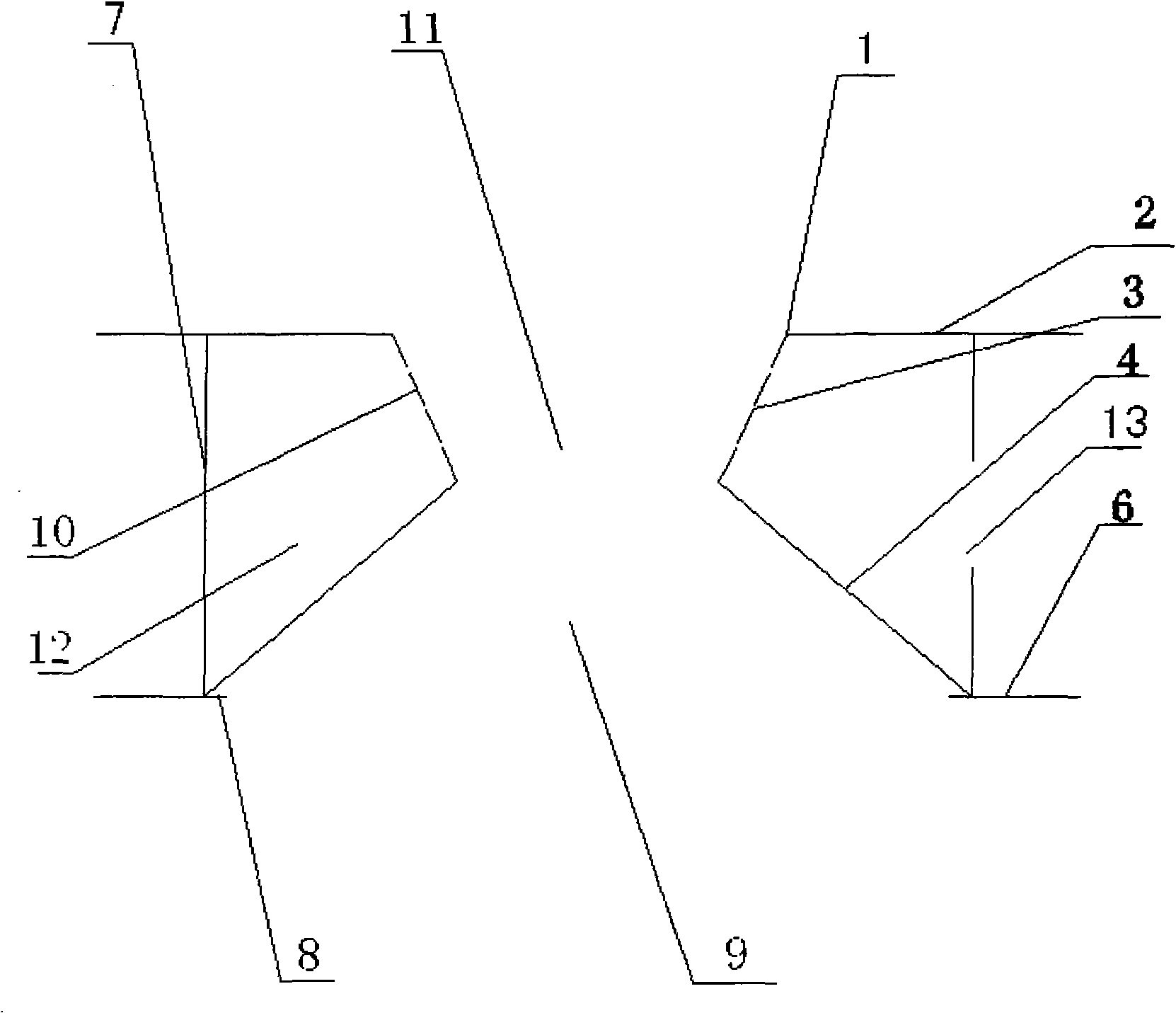

Biomass furnace with tertiary combustion structure

ActiveCN103134086BHigh heat conversion rateLow costDomestic stoves or rangesLighting and heating apparatusCombustion chamberThermodynamics

A biomass furnace with a triple-combustion-supporting structure comprises a furnace body, a furnace cavity in the furnace body and an ash hopper, the lower portion of the furnace cavity serves as a combustion chamber, the ash hopper is placed below the combustion chamber, a second-time combustion-supporting liner is installed on the lower portion of the furnace cavity, a third combustion-supporting device is arranged at the upper end of the furnace cavity, an air outlet of an air blower placed below the exterior of the furnace body is divided into two paths, one path leads to the upper portion of the ash hopper through a first-time combustion-supporting air channel, the other path leads to the third-time combustion-supporting device through a second-time combustion-supporting air channel, and meanwhile, the second-time combustion-supporting air channel is communicated with the second-time combustion-supporting liner through a liner air duct. Due to the multi-stage combustion-supporting structure, combustible gas and granular black carbon which are generated by direct combustion of coal or biomass solid fuel can burn completely step by step, black smoke can be eliminated, the heat energy conversion rate of the fuel is improved, and the biomass furnace with the triple-combustion-supporting structure has the advantages of saving fuel cost, protecting the environment and the like.

Owner:甘肃新农生态能源环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com