Automotive engine boost and tail gas purification technology and combination

An automotive engine and engine technology, which is applied to engine components, engine control, combustion engines, etc., can solve the problems of low-speed turbocharging of exhaust gas turbocharging, low-speed turbocharging, high maintenance costs, and expensive production costs. To achieve the effect of eliminating black smoke from the engine, being conducive to environmental protection and reducing pump gas loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] specific implementation

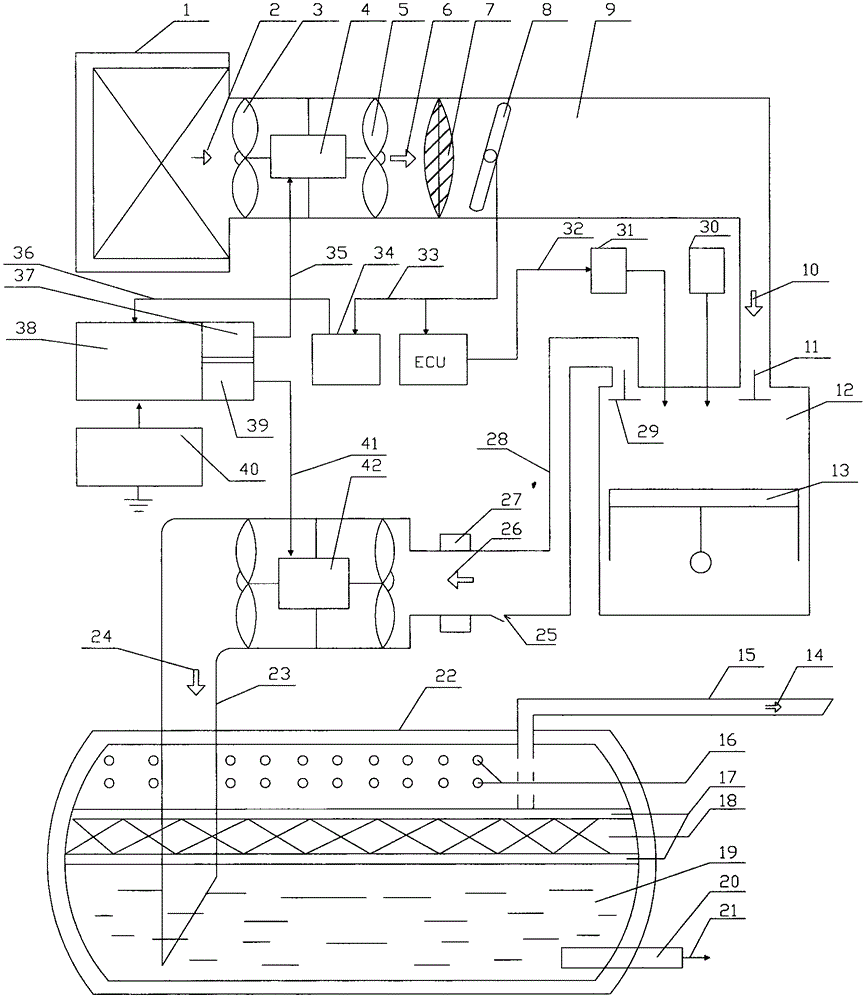

[0046] Install the twin-turbo air pumps (3) (4) (5) in the air filter (1), and install the synchronous controller assembly (38) in the corresponding gap in the engine compartment of the car, as close as possible to the position of the vehicle (ECU) , to keep the (ECU) ambient temperature roughly the same.

[0047] The exhaust gas purifier is installed and fixed on the inner side of the rear wing of the car. It is close to the original engine exhaust pipe for quick joint connection. The installation of the exhaust gas purifier does not affect the overall appearance of the car.

[0048] work process

[0049] The filtered air (2) passing through the air filter (1) passes through the twin-turbo air pump (3) (4) (5) to form a vortex airflow (6), and enters the throttle valve (8) through the foreign matter filter (7) for adjustment , into the intake manifold (9), forming a vortex airflow (10) and closing it dynamically. When the intake valve (11) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com