An optional exhaust gas purification device

An exhaust gas purification device and selective technology, which is applied in the direction of exhaust device, electric control of exhaust treatment device, noise reduction device, etc., can solve problems such as inability to achieve filtration and purification, high purchase cost of tamping vehicles, scrapped and sealed vehicles, etc. , to achieve the effect of ensuring personal health, flexible maintenance or replacement, and low implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

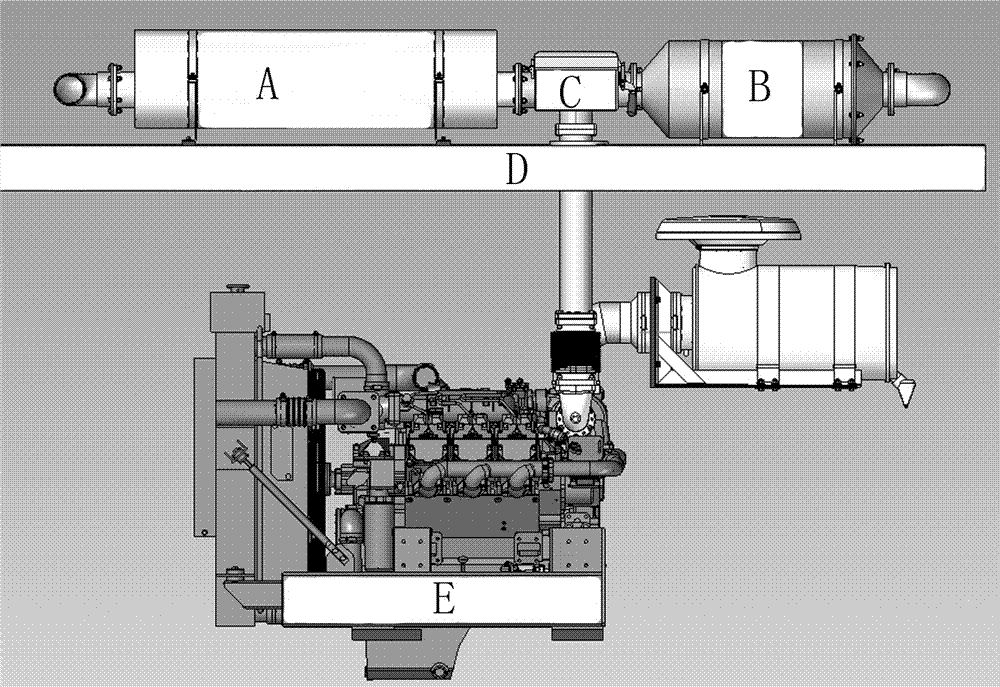

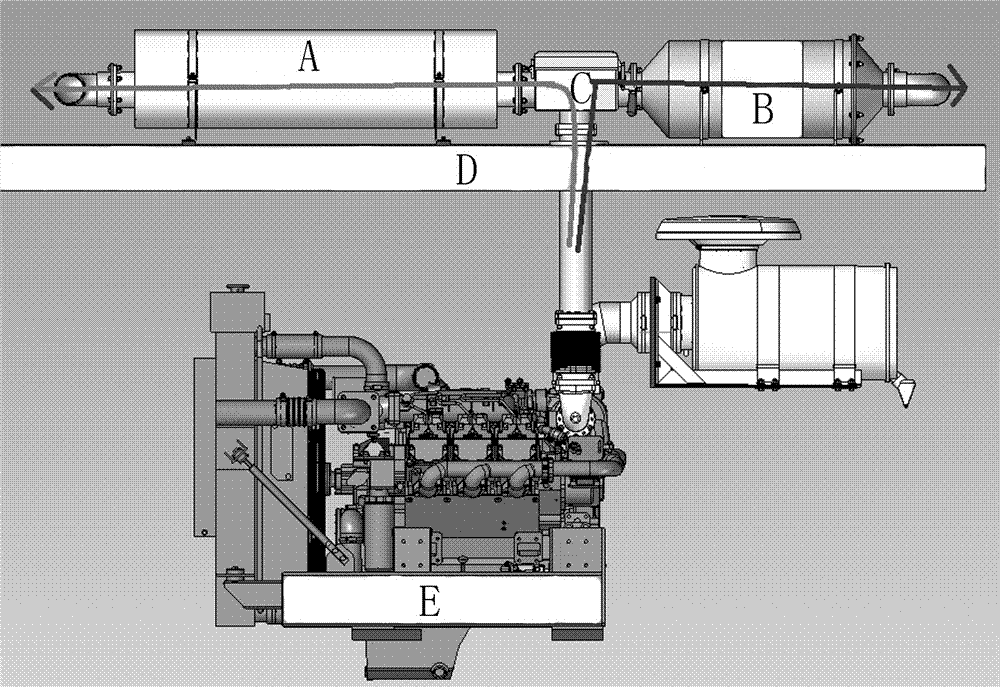

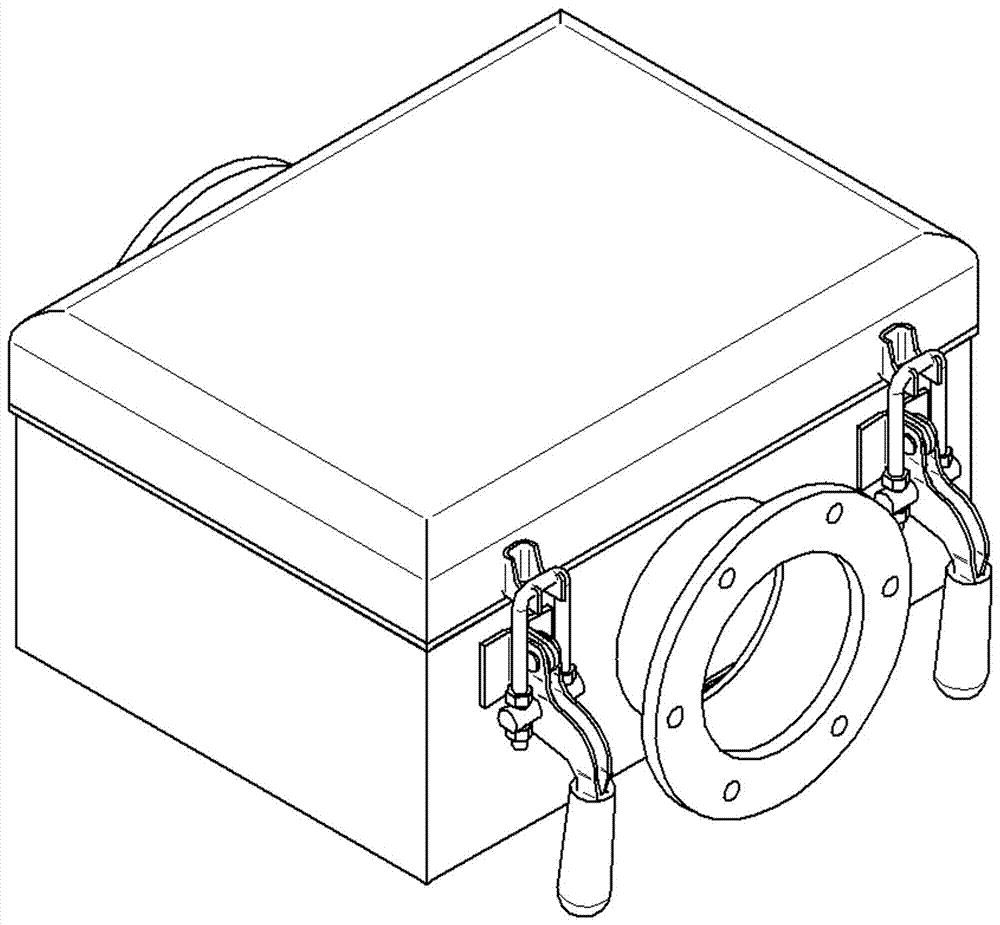

[0041] Embodiment 1.1: optional exhaust gas purification device, Figure 1-Figure 12The optional exhaust gas purifying device is assembled to a rail tamping vehicle as an example. The optional exhaust gas purifying device includes an exhaust gas splitting device C connected to the exhaust port of the diesel engine E of the work vehicle. The inlet of the exhaust gas splitting device C is connected to the The exhaust port of the diesel engine E of the work vehicle is connected. The exhaust gas splitter C also includes outlet I and outlet II respectively arranged on the left and right sides of the box body 6. The outlet I is connected to the muffler A, and the outlet II is connected to the diesel particulate filter. The particle trapping device (hereinafter referred to as DPF particle trapping device) B, the muffler A and the DPF particle trapping device B are installed above the roof D of the work vehicle, and the exhaust gas splitting device C includes a box body 6, which includ...

Embodiment 12

[0051] Embodiment 1.2: The optional exhaust gas purification device is the same as Embodiment 1.1, except that the air inlet of the exhaust gas splitting device is connected to the track stabilization vehicle through a conversion flange.

Embodiment 13

[0052] Embodiment 1.3: The optional exhaust gas purification device is the same as Embodiment 1.1, the difference is that the air inlet of the exhaust gas splitting device is connected to the track ballast truck through the conversion flange.

[0053] The working method of the optional exhaust gas purification device provided in the above embodiment is: when the work vehicle is in operation, the diesel engine is working, and the exhaust gas is continuously discharged, and the exhaust gas enters the exhaust gas diversion device through the exhaust pipe of the diesel engine. The particulate matter in the DPF particulate trapping device B at the position is less, and when it can work normally, the exhaust gas enters the air inlet of the DPF particulate trapping device B through the other outlet II of the exhaust gas splitting device C, and is filtered by the filter element and then passes through the exhaust pipe discharge, to achieve the purpose of purifying exhaust gas such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com