Grate firing equipment

A fire bed combustion and fire bed technology, which is applied in the directions of combustion equipment, combustion methods, lighting and heating equipment, etc., can solve the problems of easy burnout and complex structure of the grate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

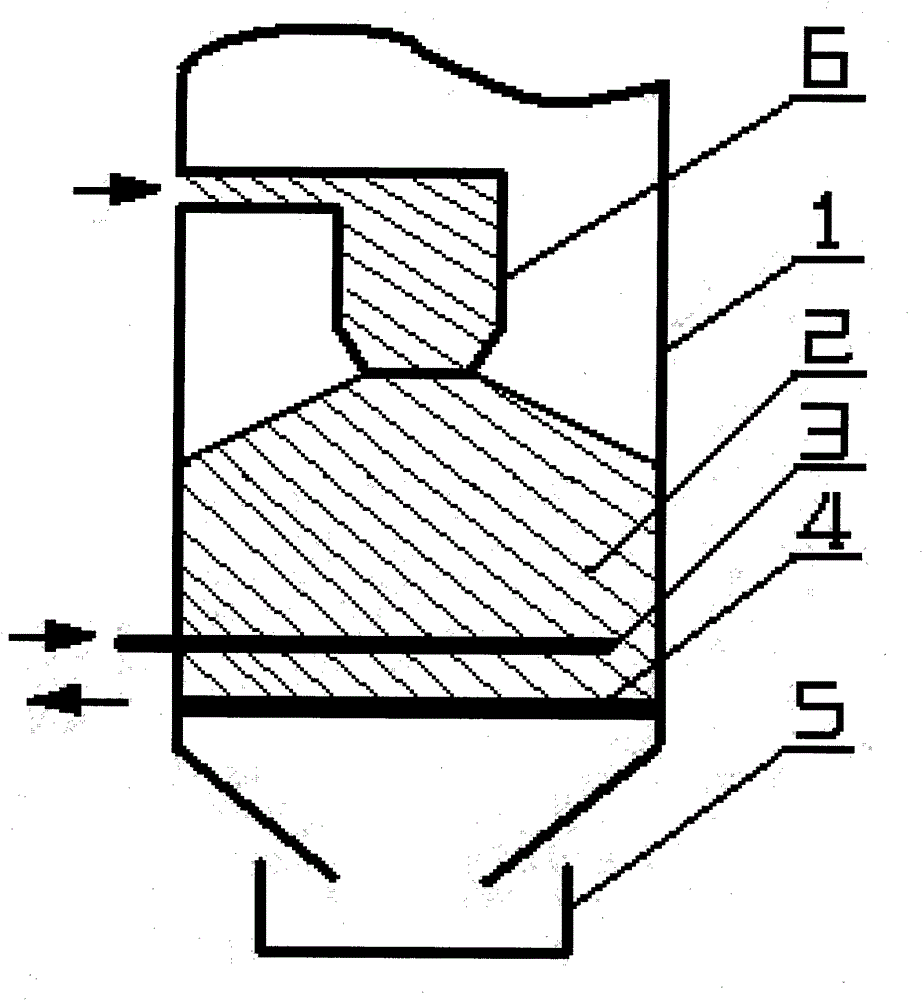

[0017] The solid fuel is pushed into the fuel preheating tank (6), and is preheated and dry-distilled in an oxygen-deprived state to precipitate moisture and volatile matter. As the fire bed layer moves down, the fuel falls on the burning fire bed surface, is quickly ignited in a "double-sided fire" manner, and starts to burn. The burning fuel creates a high temperature bed in the furnace, which is supported by the lower grate plate (4).

[0018] After the fire bed burns for a period of time, a layer of burnt ash layer is formed at the bottom of the fire bed.

[0019] Insert the upper grate plate (3) into the hearth so that the ash layer is separated from the fire bed and supports the fire bed.

[0020] The lower fire grate plate (4) is extracted out of the furnace, so that the ash layer loses support and falls into the ash box (5) outside the furnace.

[0021] Reinsert the lower grate plate (4) into the furnace chamber. Pull the upper grate plate (3) out of the furnace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com