Enhanced atomization fuel spray gun

A technology of fuel oil and spray gun, which is applied in the direction of burners, lighting and heating equipment, etc. It can solve the problems of fuel utilization rate of boilers prone to black smoke, insufficient fineness of atomized fuel particles, and small emission range of atomized oil and gas injection. Achieve remarkable energy-saving effects, improve atomization efficiency, and ensure fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

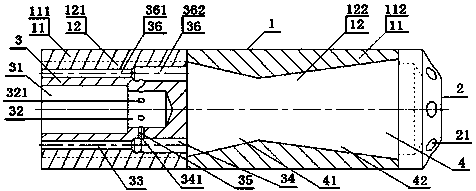

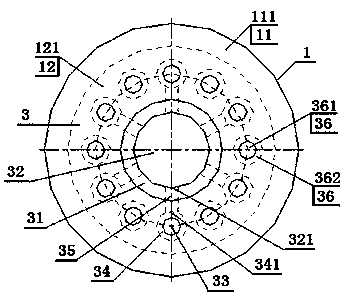

[0018] exist figure 1 and figure 2 Among them, the enhanced atomization type fuel spray gun of the present invention has a main body including a gun shaft 1, a spray head 2, an oil-gas mixing core 3 and an oil-gas mixing chamber 4, and is characterized in that the main body of the gun shaft 1 is in the shape of a hollow cylinder, and the outer casing 11 Consists of an inner barrel cavity 12, the outer shell 11 is formed by interconnecting the near-tail end shell 111 and the middle-front shell 112, and the inner barrel cavity 12 is interconnected by the near-tail end barrel cavity 121 and the middle-front barrel cavity 122 Composition; the spray head 2 is fixed on the top of the middle front housing 112, and a number of divergent inclined nozzles 21 are arranged on it; the main body of the oil-gas mixing core 3 is cylindrical, and it is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com