Biomass fuel combustion device

A biomass fuel and combustion device technology, which is applied in the field of industrial combustion, can solve the problems of smoke exhaust, low degree of automation, and low heat conversion rate, and achieve the effects of eliminating black smoke, improving automation level, and increasing calorific value conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

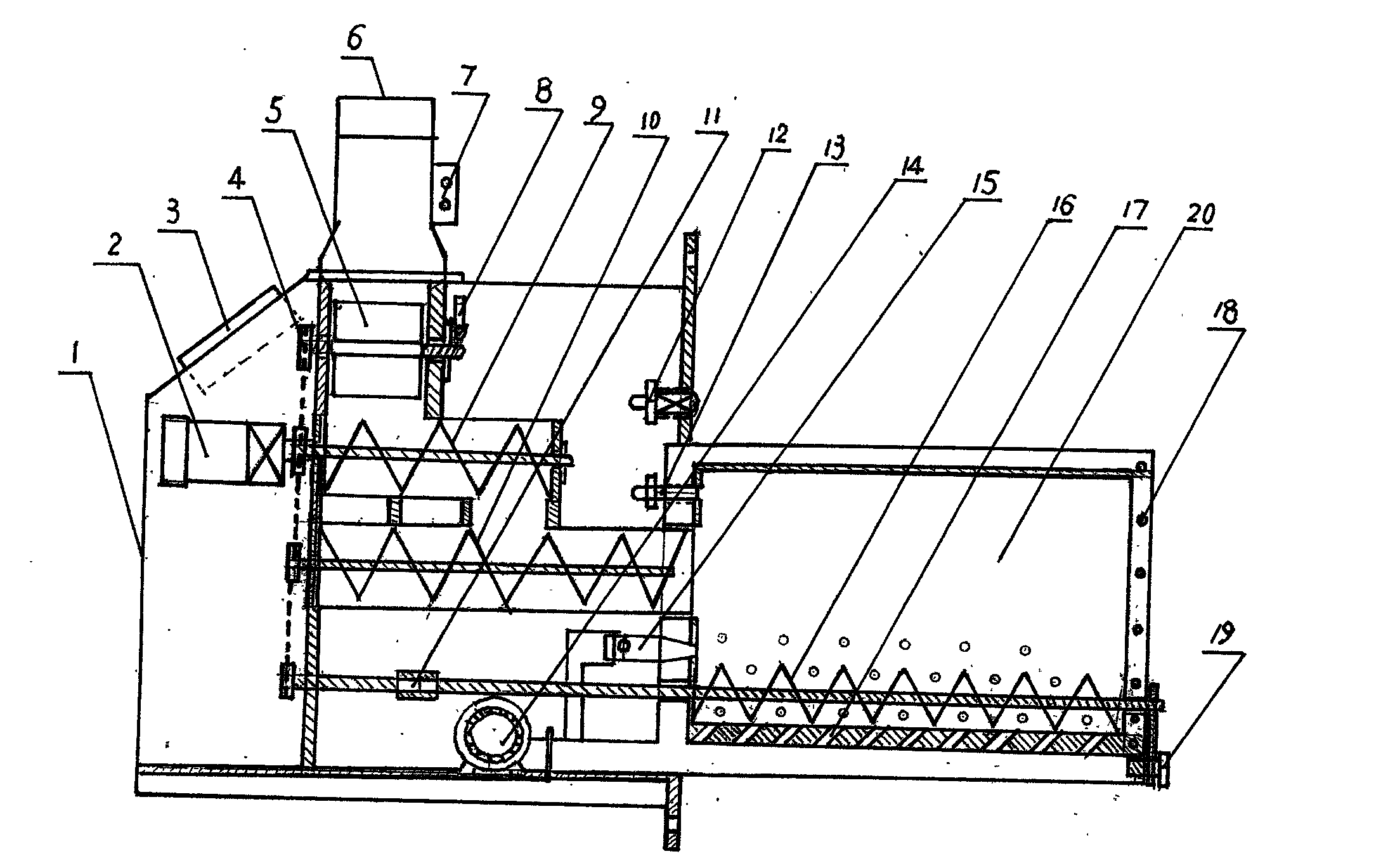

[0008] Embodiment 1. A biomass fuel combustion device, consisting of a housing 1, a feed port 6, a thermal switch 7, a material limiting gate 5, a photoelectric sensor 8, a screw feeder 9, a screw pusher 10, and a motor 2 , controller 3, igniter 15, sprocket 4, coupling 11, fan 14, air cooler, flame detector 13, oxygen sensor 12, combustion chamber 20, spiral slag remover 16, slag outlet 19, wherein There is a feed port 6 above the housing 1, the thermal switch 7 is installed below the feed port 6, the controller 3 is installed on the housing 1, the photoelectric sensor 8 is installed in the housing 1, and the material limiting gate 5 passes through the chain. The wheel 4 is installed under the feeding port 6, the screw feeder 9 is connected to the motor 2 through the sprocket 4, the screw pusher 10 is installed in the housing 1, connected to the motor 2 through the sprocket 4, and the screw slag remover 16 passes through The shaft coupling 11 is installed in the housing 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com