Smokeless combustion method of reverse combustion, roasting combustion and recombustion

A smokeless combustion and roasting technology, applied in the field of boiler combustion, can solve the problems of polluting the environment, no increase in calorific value, waste, etc., and achieve the effect of high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

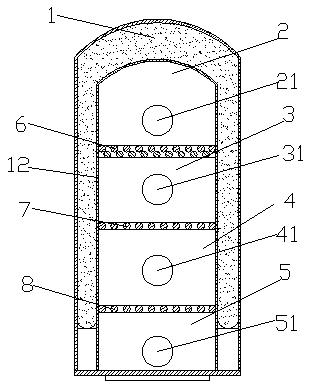

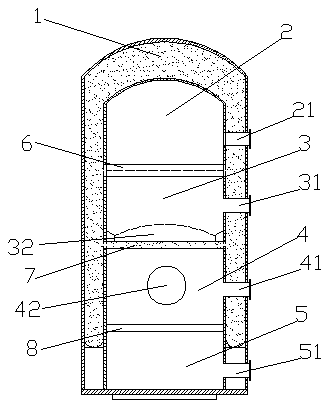

[0022] Such as figure 1 As shown, a smokeless combustion method of counter-burning, roasting and re-burning includes: (1) air and biomass materials enter the first combustion chamber 2 through the first air inlet 21, and the biomass materials are burned inside to form charcoal or coke and black smoke; (2) when burning garbage or leftovers in the first combustion chamber 2, the roasting layer 32 is formed by adding clean energy (coke or charcoal) into the second combustion chamber 3, when the first combustion chamber 2 The charcoal formed by the combustion of internally incinerated biomass materials falls into the middle grate 7 in the second combustion chamber 3 automatically through a hand hook or naturally to form a roasting layer 32; (3) the roasting layer 32 on the middle grate 3 burns and falls (4) The residue after combustion of the reburning layer in the third combustion chamber 4 falls into the ash collection chamber 5 at the bottom.

[0023] A smokeless combustion me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com