Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Particle combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

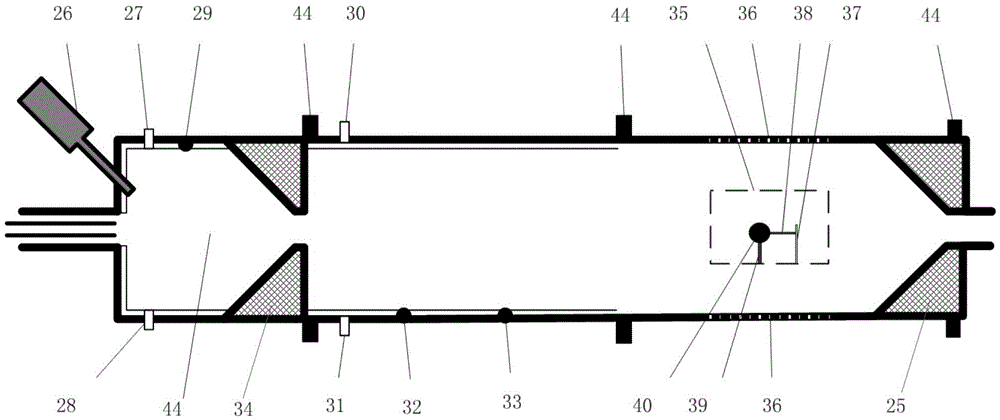

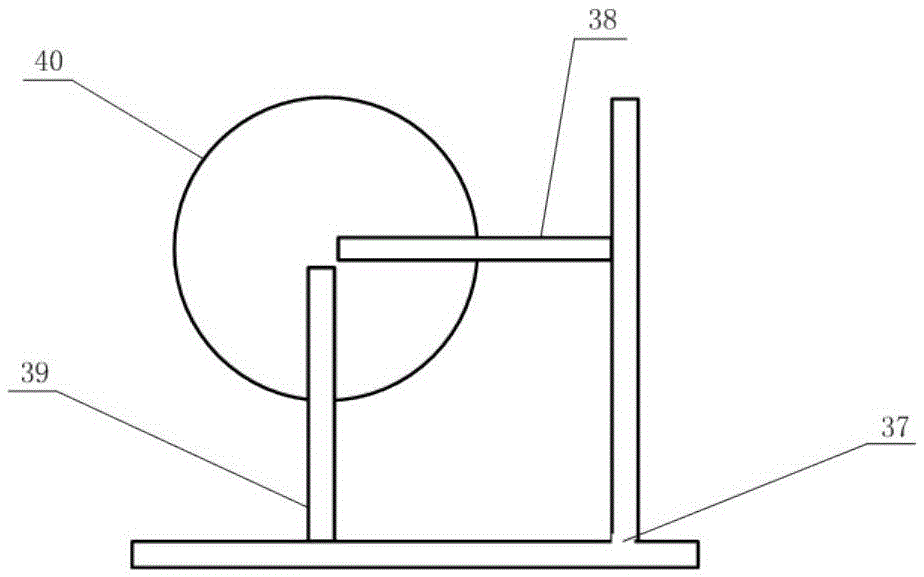

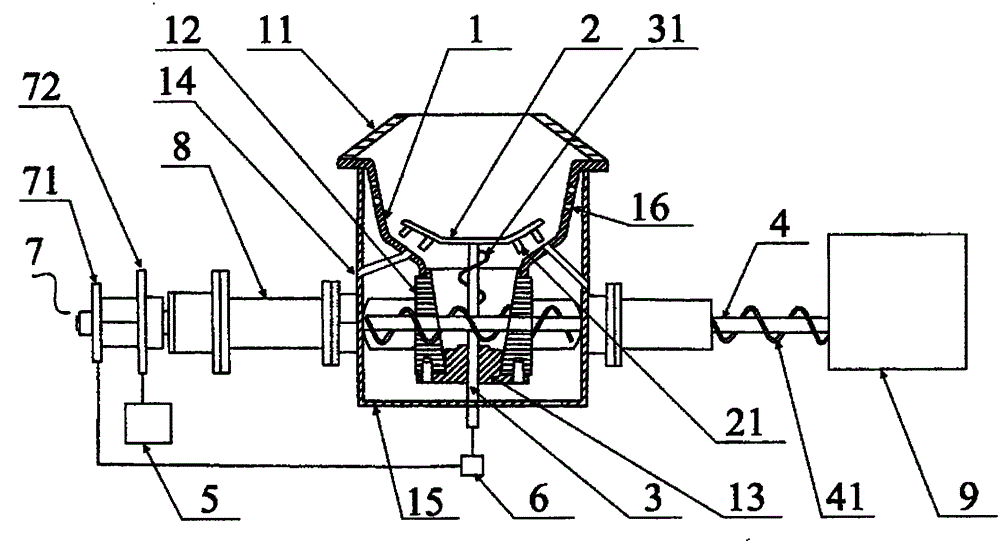

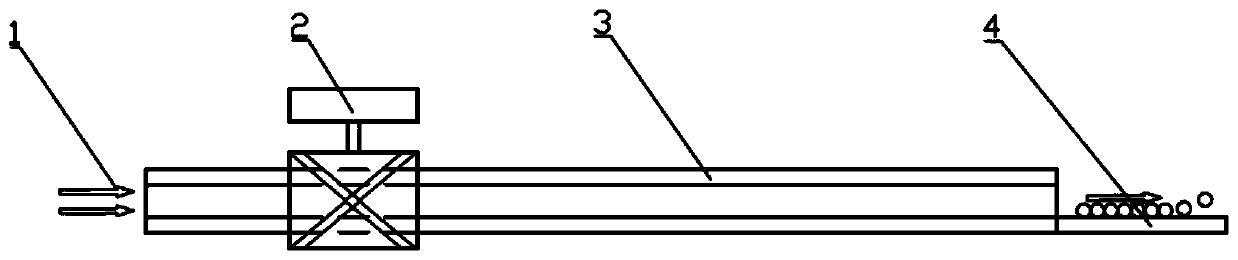

Experimental device for particle combustion under high speed air flow

InactiveCN105651809AMake sure it burnsControl initial temperatureMaterial heat developmentRamjetParticle combustion

The embodiment of the invention provides an experimental device for particle combustion under high speed air flow. The experimental device comprises a windowing test system, a pipeline supply system and a measuring-controlling system. Solid particles are fixed in high-temperature and high-speed combustion air; a current stabilizing segment and an experimental time sequence are designed, so that the particles fully burn in approximately-one-dimensional uniform high temperature airflow; quartz glass which is resistant to a high temperature of over 1,000 DEG C and is transparent and through which a particle combustion characteristic spectrum can penetrate through is taken as a material of a viewing window at a windowing test stage, and the ignition-combustion process of the particles is observed through the window, so that the ignition and combustion mechanisms of the particles in the high speed airflow are researched, and knowledge about the internal combustion process of a solid rocket ramjet containing the particles and a fuel-rich propellant is improved.

Owner:NAT UNIV OF DEFENSE TECH

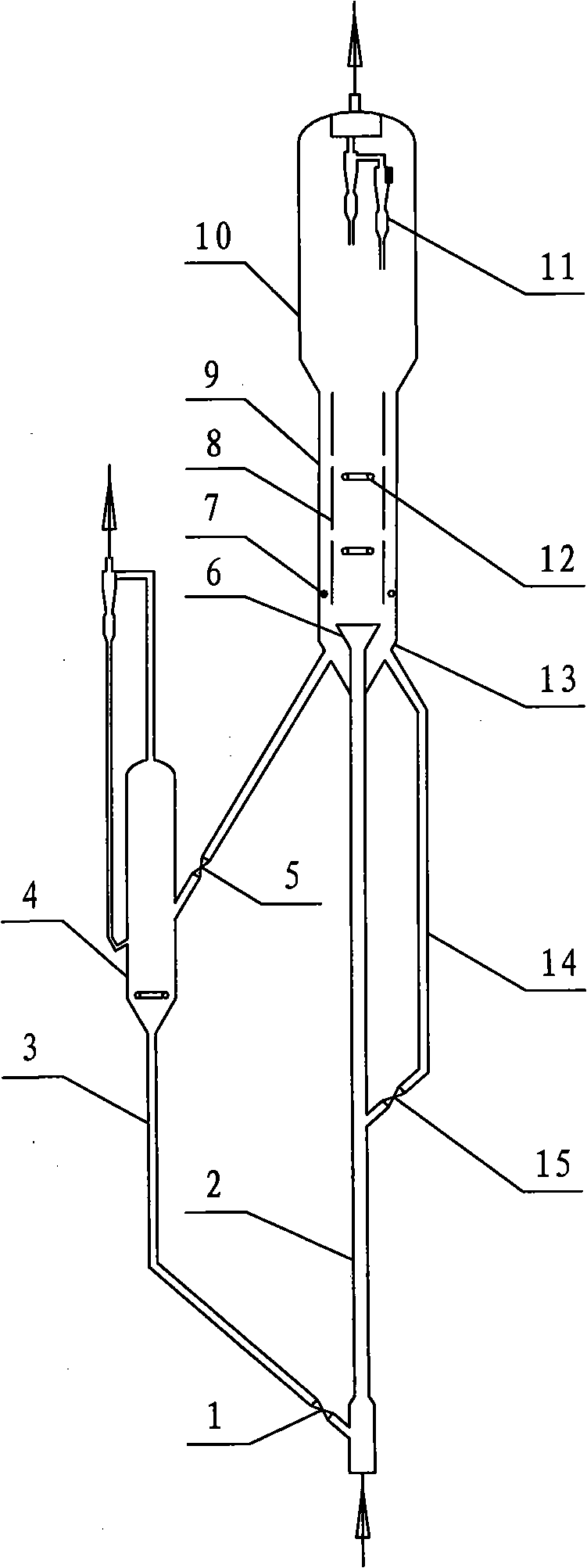

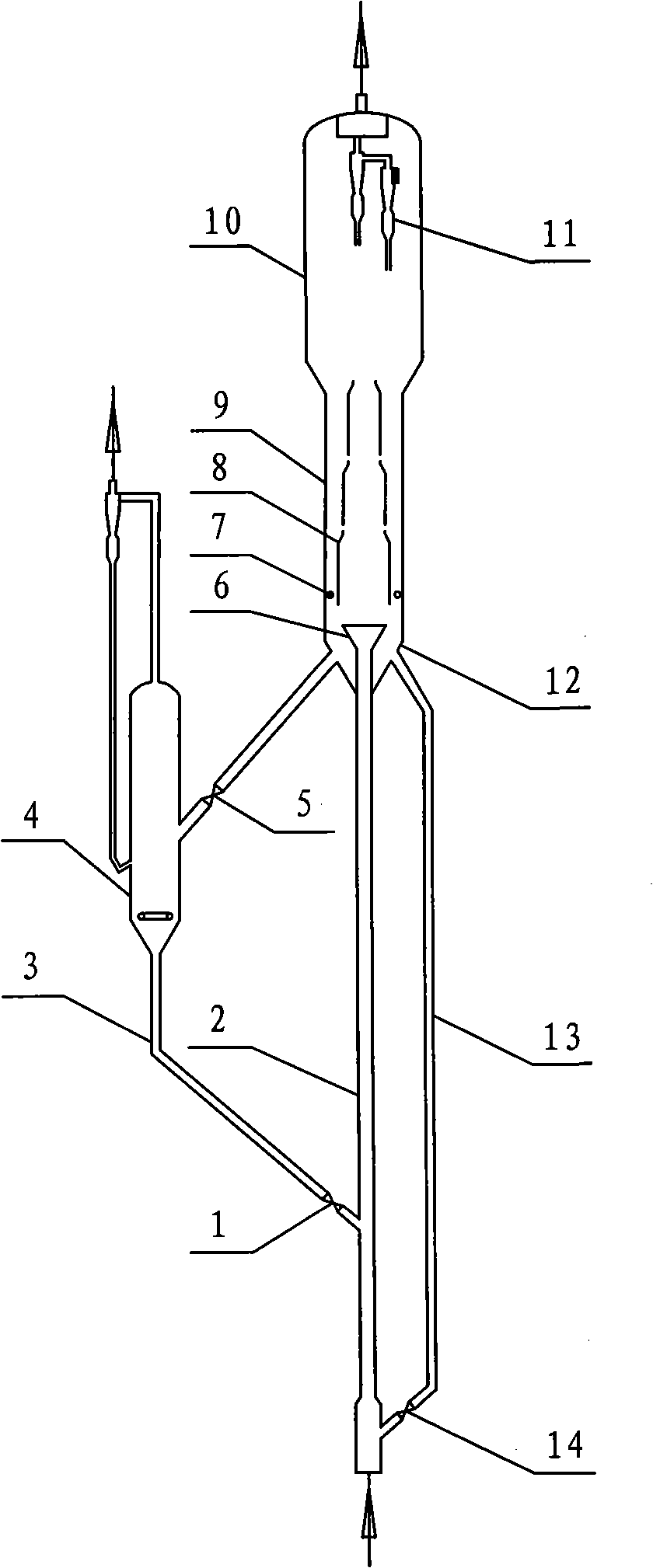

Device for improving pipe and gas-solid circumfluence bed coupling reaction

ActiveCN101259398AExtended reaction timeReduce resistanceFluidized bed combustionChemical/physical processesChemical industryGas solid

The invention provides a lift pipe and air-solid circulation bed coupling reaction device which at least includes a lift pipe, a shower head distributor, a guide cylinder, an annular space air distribution ring, an outer cylinder, an inner circulation pipe, an outer circulation fluidized bed, an outer circulation pipe and an air-solid separating system. Particles and air are transmitted upwards along the lift pipe, pass through the shower head distributor and enter the upper annular fluidized bed to form a central air lifting type circumfluence between the guide cylinder and the annular space. Part of the particles below the outer cylinder enters the lift pipe through the inner circulation pipe and another part enters the outer circulation fluidized bed to be mixed with the original particles in the outer circulation fluidized bed; the mixed particles enter the lift pipe through the outer circulation pipe; the positions where the inner circulation pipe and the outer circulation pipe enter the lift pipe can be flexibly arranged; the lift pipe and air-solid circulation bed coupling reaction device overcomes the limitations of system pressure balance and short reaction time and has the advantages that each area is flexible to be operated and controlled, the air-solid contact efficiency of the annular fluidized bed is high and the resistance above the distributor is small, etc. The device can be broadly applied to the fields of energy supply, chemical industries and particle combustion, etc.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

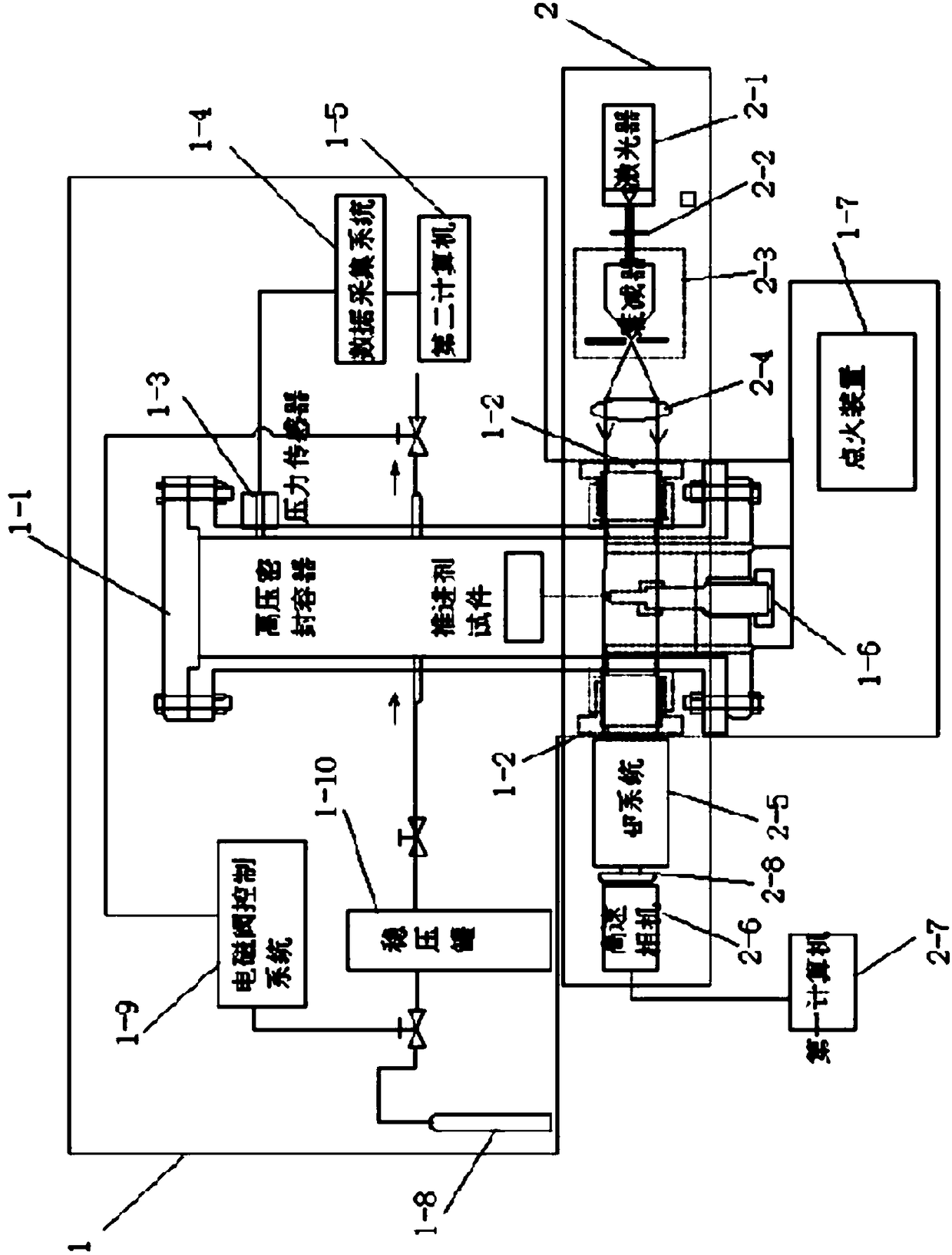

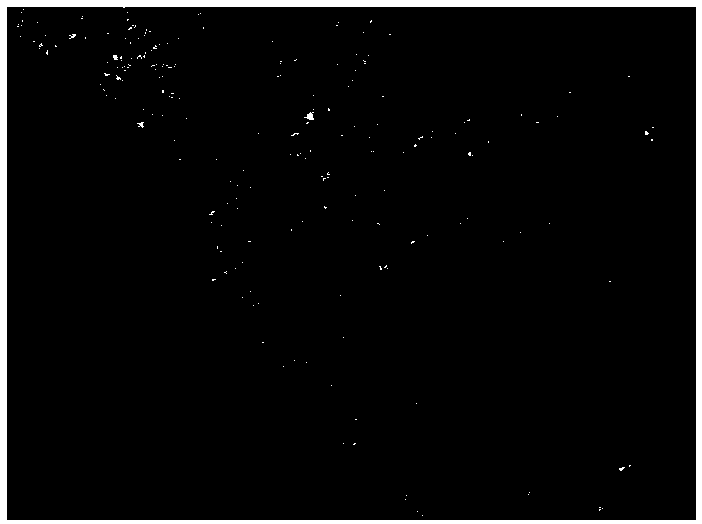

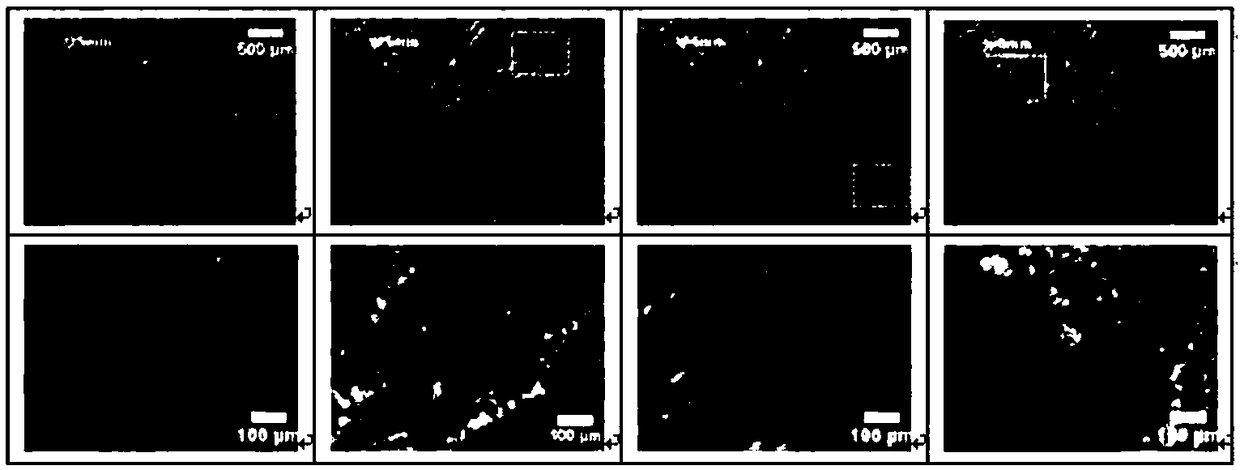

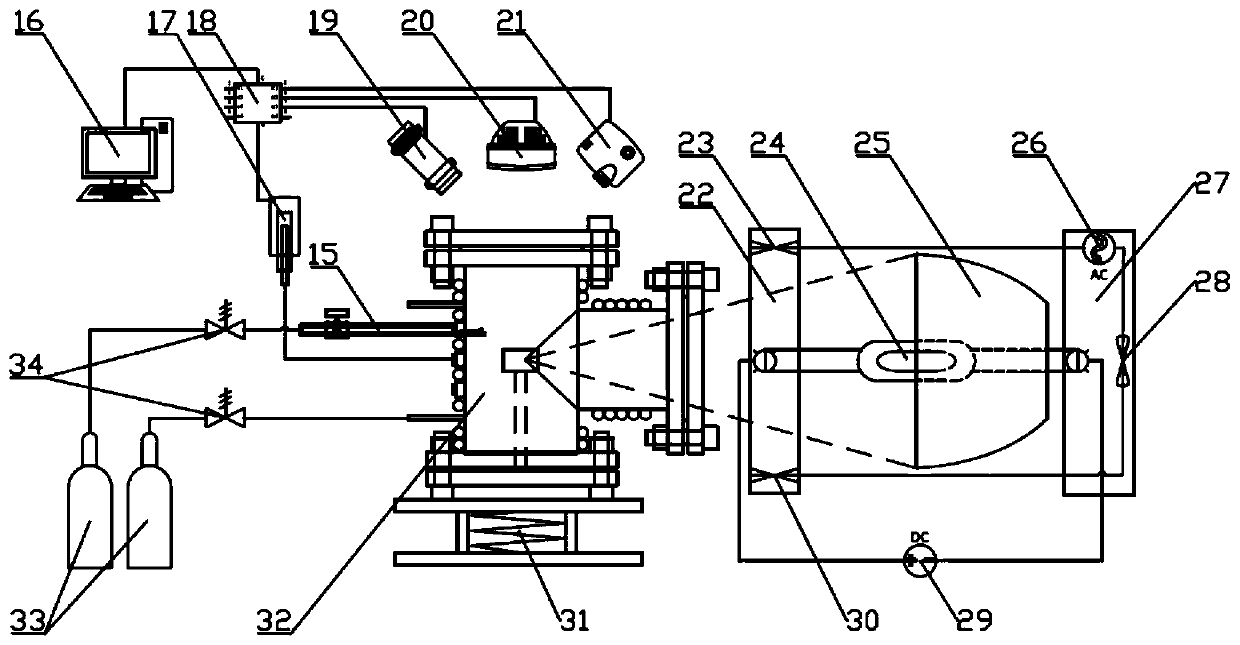

Apparatus and method for measuring aluminium combustion of solid propellant based on coaxial digital holographic method

The invention discloses an apparatus and method for measuring aluminium combustion of a solid propellant based on a coaxial digital holographic method. The apparatus comprises a high-pressure sealed tester used for simulating combustion of a propellant in a combustion chamber of a solid rocket engine and a digital holographic system used for measuring aluminium particle combustion of a propellant,wherein the digital holographic system and the high-pressure sealed tester are vertically intersected, and the plane coherent light of the digital holographic system passes through the high-pressuresealed tester for measuring aluminium particle combustion of the propellant. The apparatus is used for dynamic measurement of aluminium particle combustion of a solid rocket engine propellant in a high-temperature high-pressure complex combustion flow field.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

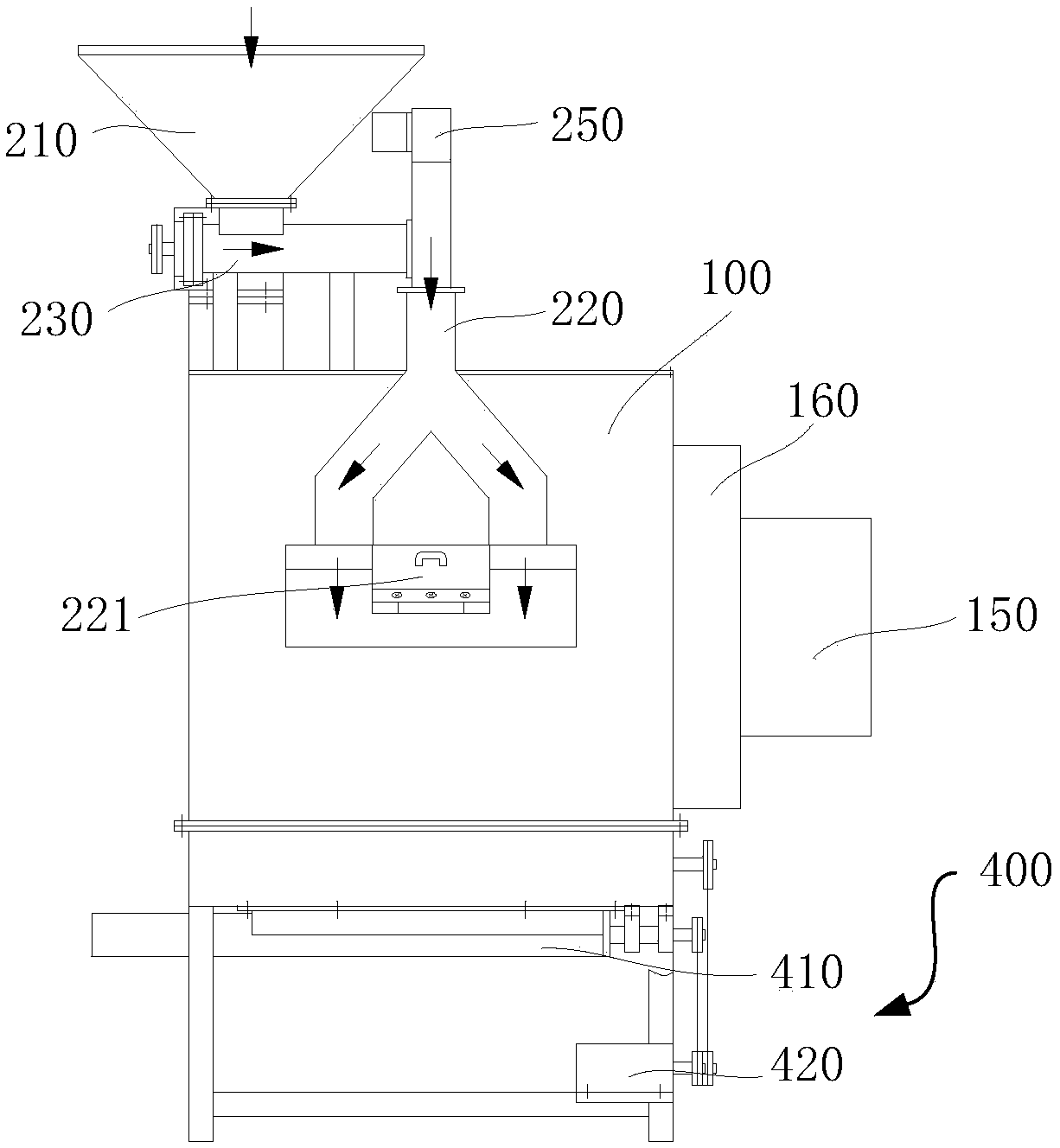

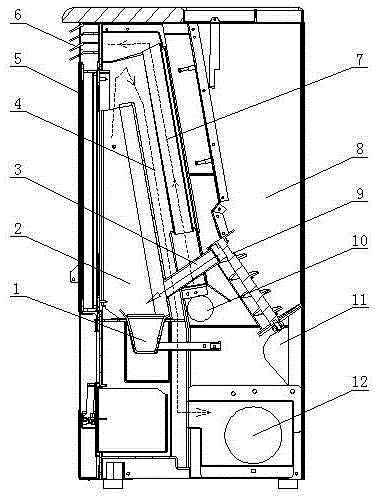

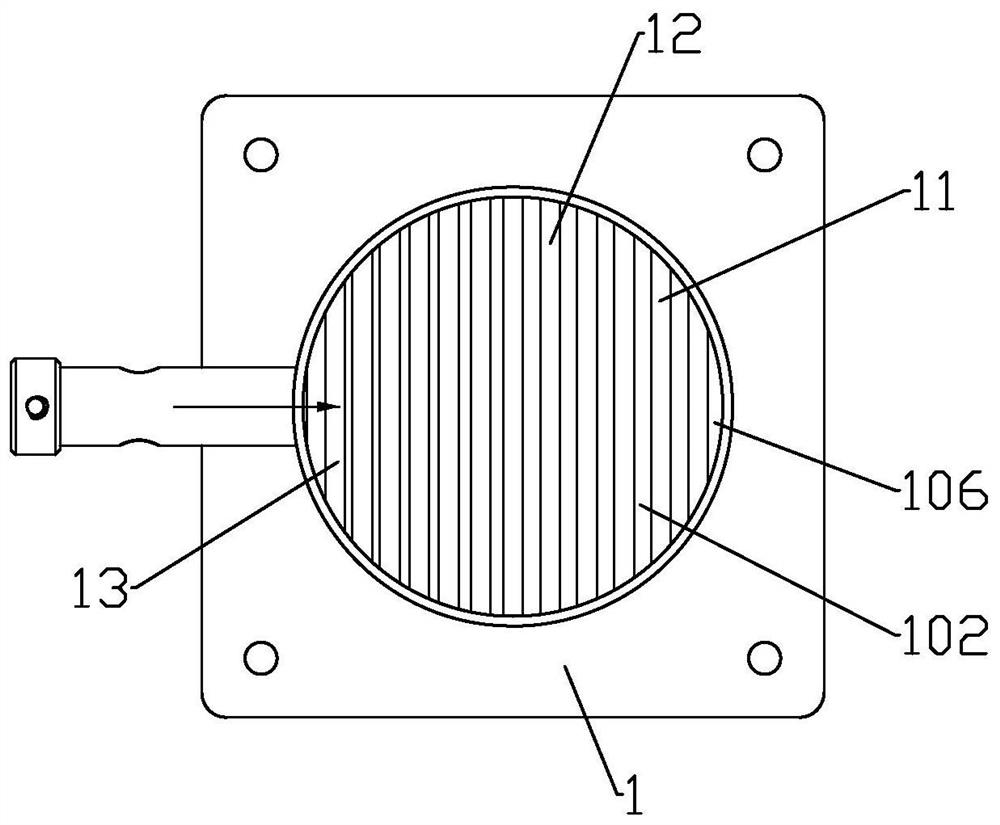

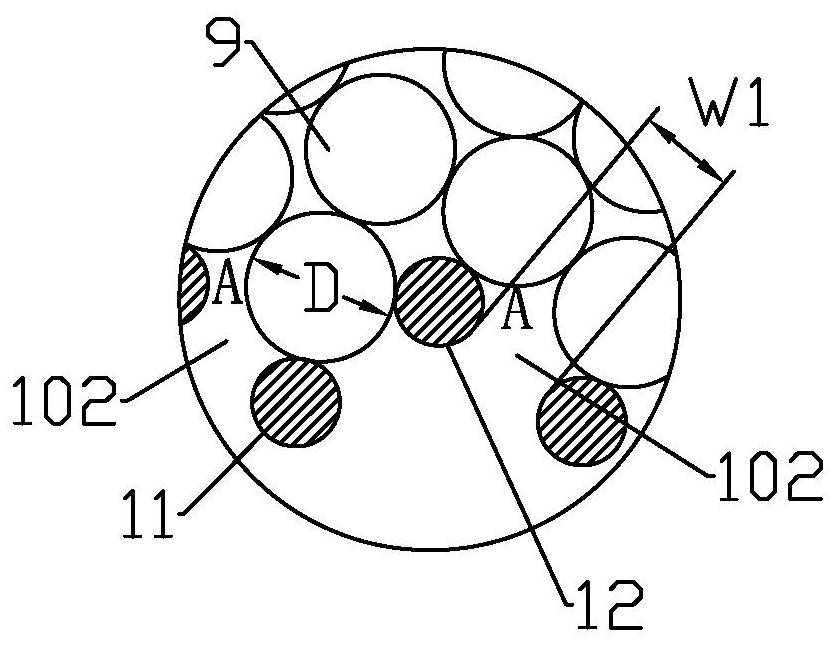

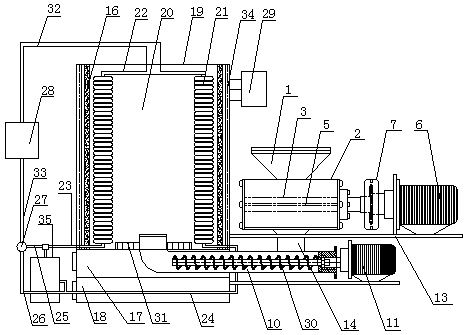

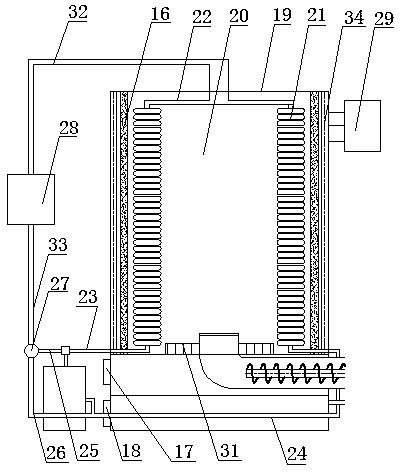

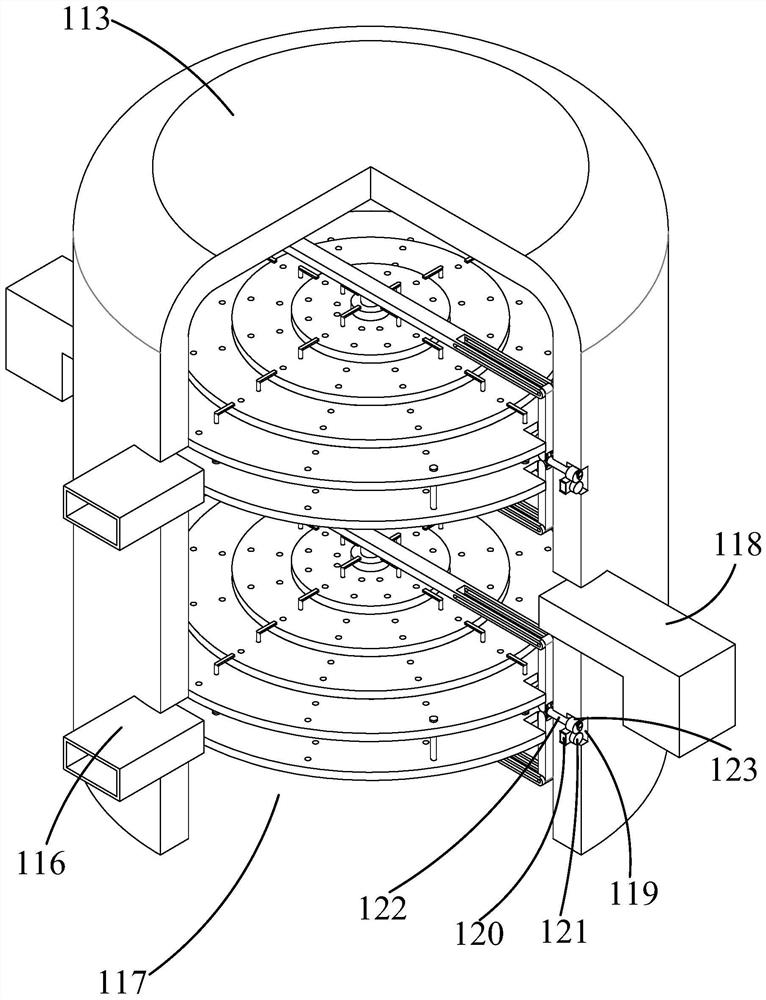

Multi-channel gasification bio-particle combustion engine and work method thereof

InactiveCN103542402AEasy to cleanImprove processing efficiencySolid fuel combustionCombustion apparatusParticle combustionEngineering

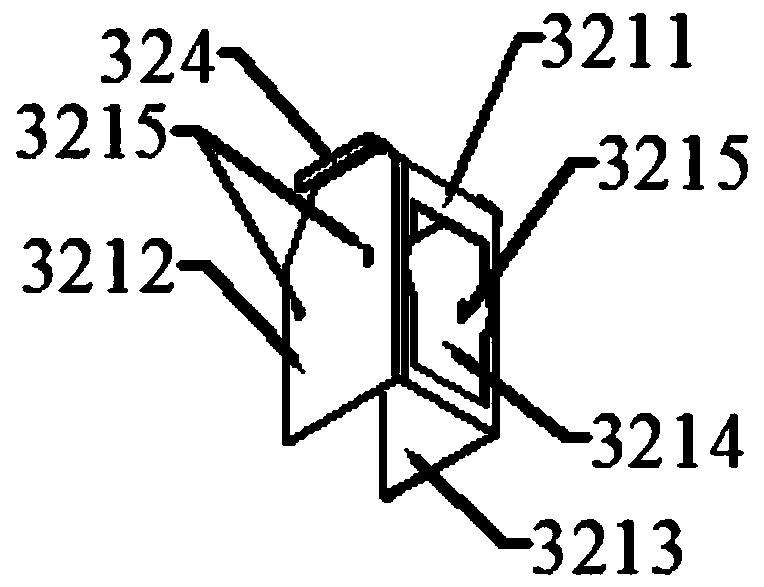

The invention discloses a multi-channel gasification bio-particle combustion engine which comprises a particle combustion box, a feeding box connected with the particle combustion box and a base on the lower portion of the particle combustion box and the lower portion of the feeding box. The feeding box comprises a material storage hopper, a first motor protection shell in the material storage hopper, a first motor in the first motor protection shell, a first screw rod connected with the first motor, a first feeding pipe connected with the tail end of the material storage hopper, a second motor below the first feeding pipe, a second screw rod connected with the second motor and a second feeding pipe communicated with the first feeding pipe. The particle combustion box comprises a combustion box outer chamber, a combustion box inner chamber inside the combustion box outer chamber, a combustion box openable door and a fire ejection opening, wherein the combustion box openable door and the fire ejection opening are in the combustion box outer chamber. The combustion box inner chamber comprises a first gasification chamber, a second gasification chamber, a combustion box inner chamber openable door and a third gasification chamber. The multi-channel gasification bio-particle combustion engine has the advantages of being complete in combustion, convenient to clean and high in efficiency.

Owner:浙江和西东新能源科技有限公司

No-waste-discharge biomass straw particle combustion stove

ActiveCN104534516AAchieve emissionsImprove fuel efficiencyDomestic stoves or rangesSolid heating fuelCombustorSlag

The invention discloses a no-waste-discharge biomass straw particle combustion stove. The no-waste-discharge biomass straw particle combustion stove has the functions of decoking, combustion supporting and fire keeping, combustion products of the combustion stove are dust ash and small clinkers and can be reused as high-quality potash fertilizer, and therefore zero discharge of wastes is achieved. The combustion stove comprises a storage device, an automatic feeding device and a combustor. A combustion-supporting cover is arranged on the combustor, a connecting sleeve is arranged underneath the combustor, and a feed port is formed inside the combustor. The combustor is provided with a decoking combustion supporter and a slag discharge hole. The decoking combustion supporter comprises a decoking rod and decoking teeth arranged at the lower end of the decoking rod. The automatic feeding device comprises a horizontal spiral feeding device, a vertical spiral feeding device and a gear motor, wherein the vertical spiral feeding device is installed in the manner of being perpendicular to the horizontal spiral feeding device. The storage device is connected with the connecting sleeve through the horizontal spiral feeding device. The vertical spiral feeding device is arranged in the connecting sleeve. The decoking rod is connected with the top end of the vertical spiral feeding device. A discharge port of the vertical spiral feeding device is connected with the feed port of the combustor.

Owner:天津市特斯达食品机械科技有限公司

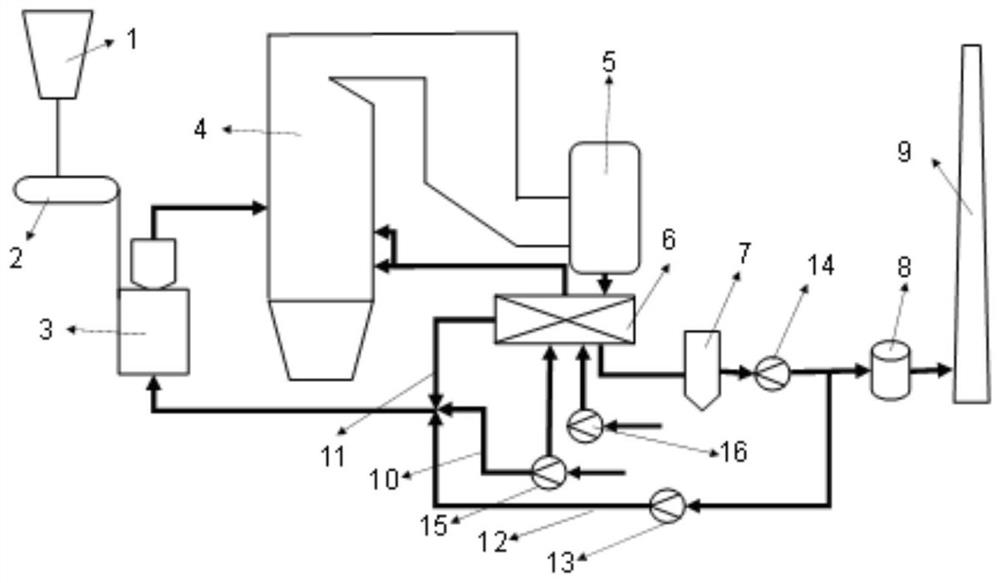

Burning device and process for oil shale fluidized bed

InactiveCN1253673CWide adaptabilityAvoid depositionFluidized bed combustionCement productionAir volumeParticle combustion

The invention relates to a device and craft for using fluidized bed to burn kerogen. The raw oil and kerogen are transmitted into the boiler combustion device through the transmission system. The device includes fluidized bed boiler, vortex separator, and ash particle combustion system and ash dredge reclaiming device. In the boiler, the hot wind enters with small aperture speed and hot fluidized speed through the directional cap, the wind is divided into the first wind and the secondary wind; the wind quantity can be adjusted, maintains the stability of the bed and homogeneity of temperature, the temperature is maintained between 850deg.C-920deg.C. The smoke is separated through the separator, the raw particle returns into the furnace to be burned, the residue tail gas reclaims heat through several heat exchangers, and the ash dredge in the furnace is discharged out of the dredge colder with high wind quantity and pressure through the electric dust eliminator, which can be used as cement mixing material. The combustion intensity and efficiency are high, the contamination is little.

Owner:广东亨达利水泥厂有限公司

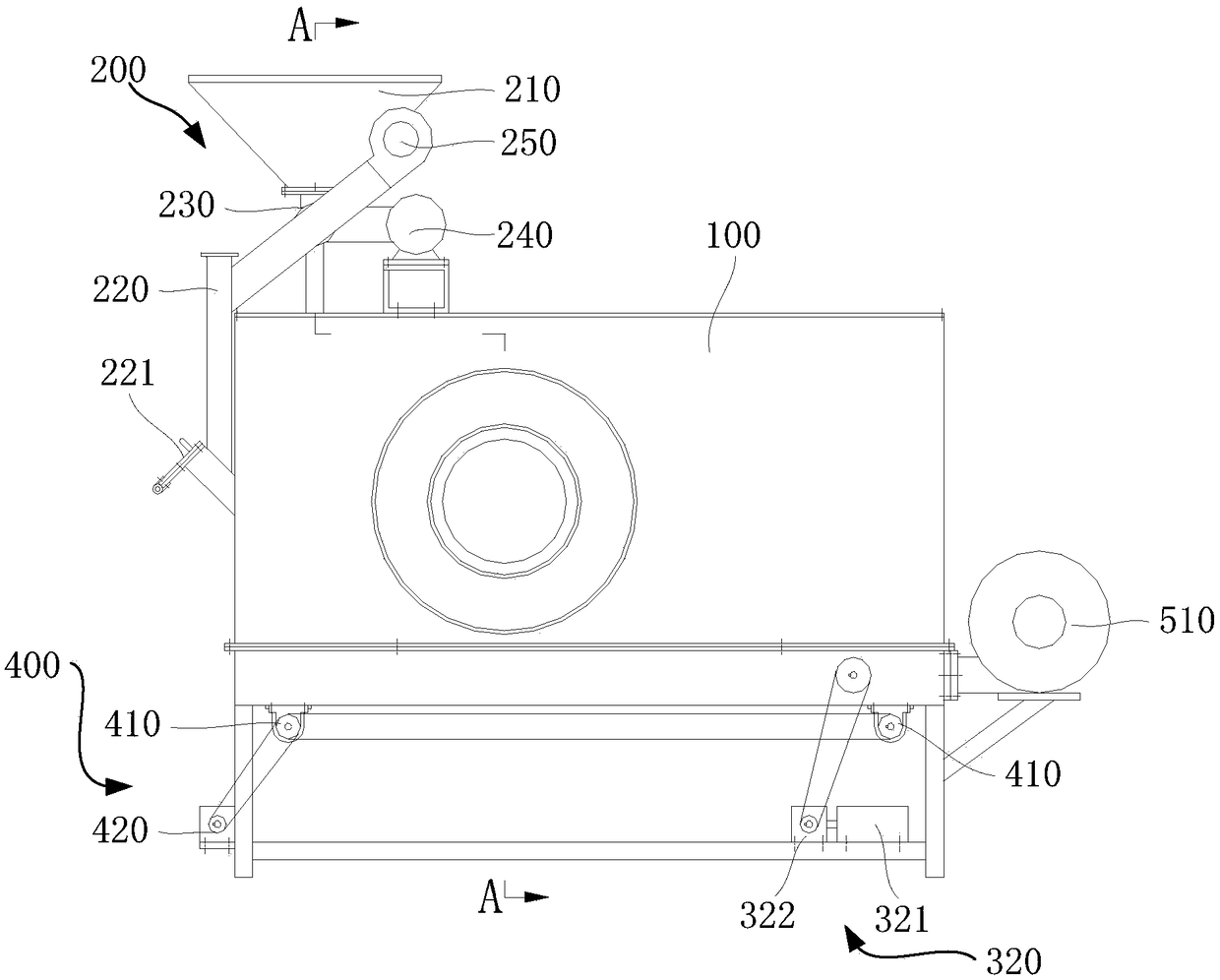

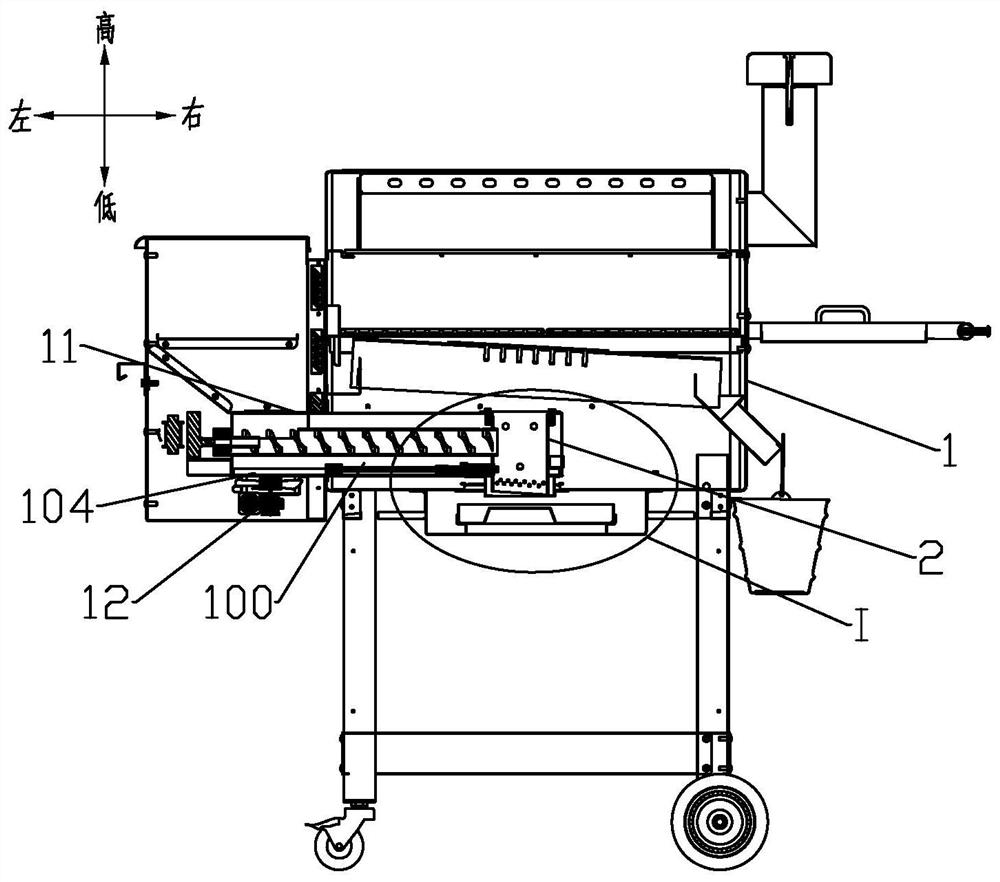

Plant straw particle combustion machine

The invention discloses a plant straw particle combustion machine and relates to the technical field of combustion equipment. The technical problem that in the prior art, plant straw cannot be used asfuel is solved. The plant straw particle combustion machine comprises a combustion furnace body, a feeding device, a fire grate device and an ash discharging device. A hearth is formed in the combustion furnace body, and a flame spraying opening communicating with the hearth is formed in the side wall. The feeding device is installed at the outer portion of the combustion furnace body, and one end of the feeding device communicates with the hearth. The fire grate device is installed in the hearth and located below the outlet end of the feeding device and can bear plant straw particles to movein the direction away from the outlet end of the feeding device. The ash discharging device is installed below the combustion furnace body, communicates with the hearth and is used for discharging carbon ash in the hearth. The ash discharging device below the furnace body of the plant straw particle combustion machine can be used for discharging the carbon ash in the hearth in time, the phenomenon that the hearth is blocked by the carbon ash is avoided, and plant straw with much carbon ash can be used as fuel through the plant straw particle combustion machine.

Owner:柏家乐

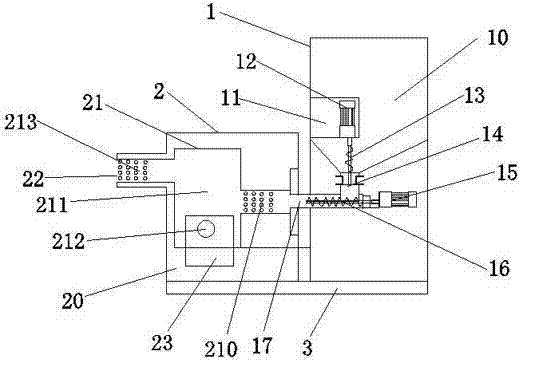

Ignition device for discrete particles of flowing metallic fuel

InactiveCN110133045AAchieve ignitionDiscretizationIncandescent ignitionMaterial heat developmentCombustorParticle combustion

The invention discloses an ignition device for discrete particles of flowing metal fuel, which comprises a jet burner module, a xenon lamp ignition module, a combustion diagnosis module and a controlmodule. According to the invention, a pressure burner is adopted as a metal fuel particle combustion environment, ignition of metal fuel particles within a pressure range of 0-5 Mpa can be realized, interference on combustion flame of the metal fuel particles is avoided, and flame overlapping is avoided.

Owner:SOUTHEAST UNIV

Straw particle combustion furnace

A straw particle combustion furnace is characterized in that a hearth is reserved in the front portion in a vertical-cabinet-shaped furnace body, a combustion hopper is arranged at the lower portion of the hearth, a hot air port is formed in the front face of the part, on the upper side of the hearth, of the furnace body, and a vertical flue is reserved on the rear side of the hearth; the upper end of the flue is communicated with the upper end of the hearth, and a suction and discharge ventilator is arranged at the lower end of the flue; a blowing pipe is arranged on the rear side of the flue, the upper end of the blowing pipe is communicated with the hot air port, and a blower is assembled at the lower end of the blowing pipe; a storage chamber is reserved on the rear side of the blowing pipe, a feeding pipe is arranged between the lower portion of the storage chamber and the hearth, and a front end opening of the feeding pipe is located on the upper side of the combustion hopper; and a downwards-arranged screw rod is arranged at a rear end opening of the feeding pipe, and a feeding motor is arranged at the lower end of the screw rod. The straw particle combustion furnace solves the problems that according to a straw heating stove, fuel is constantly added in a hearth manually, operation is complex, and the indoor air is polluted, and is an ideal stove for combustion of straw particles.

Owner:QINGDAO HICHANSE GRP

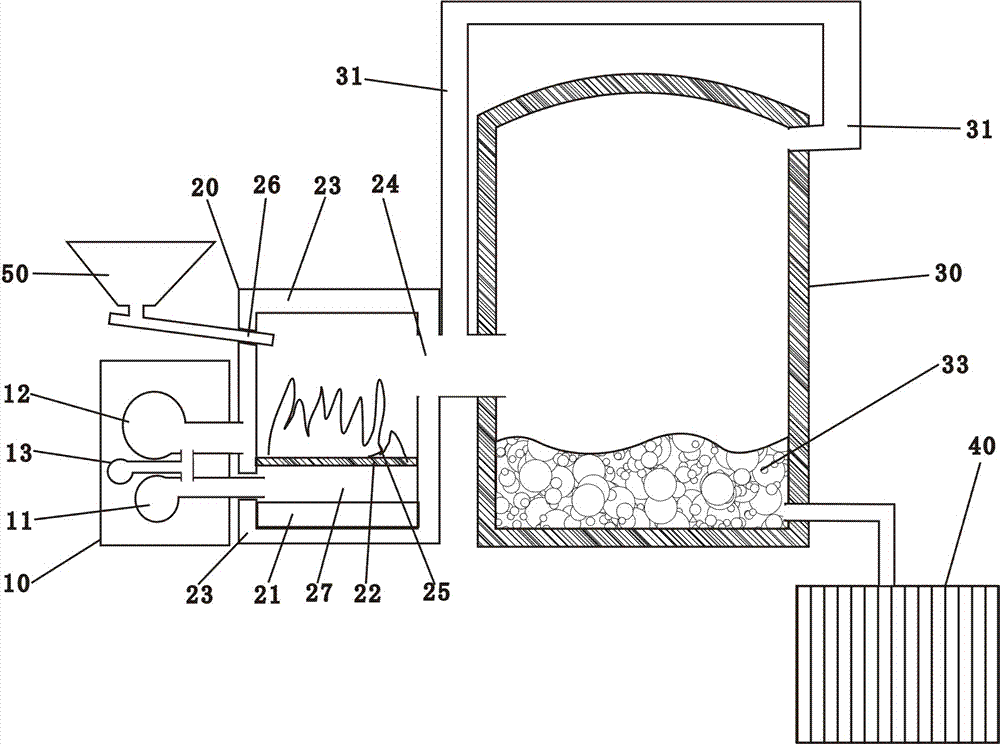

Efficient biofuel casting furnace and method of improving thermal efficiency

InactiveCN104748547AEmission reductionHigh densityClimate change adaptationCrucible furnacesBiofuelParticle combustion

The invention discloses an efficient biofuel casting furnace and a method of improving thermal efficiency, relates to an industrial casting furnace, and particularly relates to an aluminium product casting furnace using a novel fuel. The casting furnace is characterized in that the method of improving the thermal efficiency adopts a flowing air layer for surrounding a combustion furnace, the dissipated hot air is recycled to reduce heat loss and the water temperature is improved by the waste heat of burned stove ash; meanwhile, the air flow on a water surface is accelerated, the water vaporization is quickened, and the vaporized water is mixed with air in a combustion flame; liquid water can absorb a lot of heat during the vaporization, the heat loss is reduced, and the density and the specific heat capacity of the air in the combustion flame are increased, finally the combustion flame and the air in the combustion flame, the flowing air surrounding the combustion furnace and the recycled dissipated hot air are collected together, and the combustion temperature and the combustion thermal efficiency are improved. According to the invention, a bio-particle combustion material is adopted, so that the emission of sulfur dioxide, nitrogen dioxide, PM2.5, black smoke and the like is greatly reduced; the sustainability of energy sources is realized; the fuel temperature and the production efficiency are increased; and the energy consumption and the production cost are reduced.

Owner:FOSHAN GAOMING JIADEJIN METAL PROD

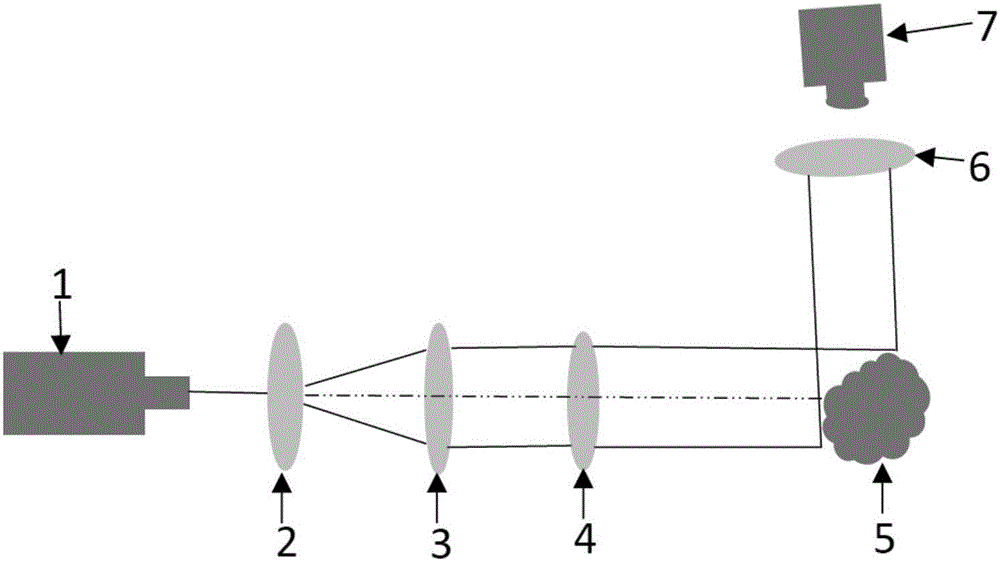

Combustion particle image acquisition device and method

InactiveCN106525671AIncrease success rateImprove accuracyParticle size analysisParticle combustionMethod of images

The invention belongs to the field of optical imaging and particularly relates to a combustion particle image acquisition device and method, aiming at mainly solving the problem that a particle shape and a flame frontal surface cannot be distinguished in a combustion particle imaging process, and obtaining high-quality combustion particle and flame images. The device comprises a laser active light source, an expanded beam lens, a collimation lens, an attenuation sheet, a combustion particle placement platform, an optical filter and a camera. The laser active light source provided by the invention is used for illuminating, and the optical filter guarantees the passing of reflecting light of a wave band of the laser active light source and is used for an acquisition method of images photographed by the camera matched with the wave band of the laser active light source, so that a clear particle combustion image is obtained; the method is simple and easy to operate; the acquired image has high quality and less background noises; the difficulty that particles and flame form bright spots in a passive detection process is overcome; and in the obtained image, the particle shape and the flame frontal surface in the obtained image are clear and have a good distinction degree, and the success rate and accuracy of dividing the particles and flame can be improved.

Owner:湖南七迪视觉科技有限公司

Particle combustion furnace

ActiveCN112856387AAvoid accumulationLow efficiencyCombustion-air/flue-gas circulation for stovesSolid fuel combustionThermodynamicsCombustor

The invention discloses a particle combustion furnace, and belongs to the field of combustion equipment. The problems that in the prior art, the situation of backfire possibly happens to a combustor from a feed port in a big fire state, and the situation that primers are hard to maintain and are extinguished is prone to happening in a small fire state are solved. According to the main technical scheme for solving the problems, a combustor is arranged in a furnace body, the top end of the combustor is open, a feeding port is formed in the side wall of the combustor, a through port used for air inlet and ash falling is formed in the bottom face of the combustor, a fire grate used for supporting particle fuel is arranged above the through port, an auxiliary supporting body used for maintaining primers is arranged below the fire grate, the auxiliary supporting body is higher than the through port, the auxiliary supporting body is located on one side below the feeding port, and the set range does not exceed 1 / 2 of the area covered by the fire grate. The particle combustion furnace is mainly used for achieving the aims that backfire is not prone to happening to the feeding port in a big fire state, and extinguishing can be avoided in a small fire state.

Owner:深圳市艾斯默克科技有限公司

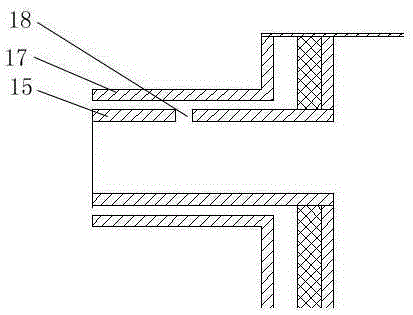

Reed particle combustion transverse fire grate

PendingCN113063156ARealize positive and negative adjustmentAvoid pollutionRevolving grateRocking grateGear driveDrive shaft

The invention discloses a reed particle combustion transverse fire grate. The reed particle combustion transverse fire grate comprises a transverse fire grate assembly, a driving shaft fire bar, a driven shaft fire bar, an ash discharging opening and a dust falling net. According to the reed particle combustion transverse fire grate, combusted reed particles enter an external frame body through a bell and spigot type ash groove, a driving motor is started, the driving motor drives an internal linkage gear to rotate reversely through a connecting rod, the internal linkage gear and a driving shaft gear are meshed with each other, the internal linkage gear drives the driving shaft gear to rotate in the forward direction, the driving shaft gear and a driven shaft gear are meshed with each other, the driving shaft gear drives the driven shaft gear to rotate in the reverse direction, and ash is discharged into an ash collecting groove through the dust falling net and then discharged to the outside in a centralized mode through an external ash discharging pipe. Through the structure, the ash sinks, and the ash is collected, so that environment pollution is avoided.

Owner:孙路军

Biomass fuel combustion device

InactiveCN105240839ACompact structureHelp exportSolid fuel combustionLump/pulverulent fuel feeder/distributionCombustion chamberParticle combustion

The invention provides a biomass fuel combustion device. The biomass fuel combustion device comprises a combustion chamber, a blower device and a feeding device. The feeding device comprises a feeding pipe. The combustion chamber comprises a shell, a hearth, a grate, an ash box and a flame outlet pipe. An air cooling interlayer is arranged between the shell and the hearth. The grate and the ash box are arranged under the hearth. The flame outlet pipe is arranged at one side of the combustion chamber and communicated with the hearth and stretches out after penetrating through the air cooling interlayer and the shell. The blower device comprises a draught fan, an air pipe I, an air pipe II and an air pipe III. The draught fan is communicated with the air pipe I, the air pipe II and the air pipe III. The air pipe I is communicated with the feeding pipe. The air pipe II is communicated with the ash box. The air pipe III is communicated with the air cooling interlayer. According to the biomass fuel combustion device, the defects that in the prior art, a combustion device is low in combustion efficiency, complicated in structure and large in heat loss are overcome; the biomass fuel combustion device has the characteristics that the structure is compact and simple, oxygen supply is sufficient, the particle combustion efficiency is high, and the heat transferring effect is good.

Owner:广西节得乐生物质能源科技有限公司

Environment-friendly industrial flue gas pipeline and application method thereof

PendingCN113091469ATake advantage ofIncrease heatIncreasing energy efficiencySolid removalThermodynamicsFlue gas

The invention relates to the technical field of industrial flue gas emission, in particular to an environment-friendly industrial flue gas pipeline. The invention aims to solve the technical problems that the utilization rate of coke particle combustion heat and the utilization rate of flue gas waste heat are low, a large amount of heat is wasted, and an impurity accumulation layer on the inner wall is difficult to clean. In order to solve the technical problems, the environment-friendly industrial flue gas pipeline provided by the invention is composed of a boiler, a water tank, a support mechanism, an ash scraping mechanism and a worm gear mechanism. Coke particles are filtered out in the boiler and are fully combusted in a filter plate, and heat in the boiler is increased, so that the heat can be more fully utilized, energy waste is reduced, and the cost is reduced; through a metal exhaust pipe and a surrounding metal water pipe, water in a water inlet pipe can be preliminarily heated through preheating of a flue gas in the exhaust pipe, so that the energy utilization rate is increased; and the flue gas is cooled, and the heat emitted to the environment is reduced, so that the environment is protected.

Owner:严富山

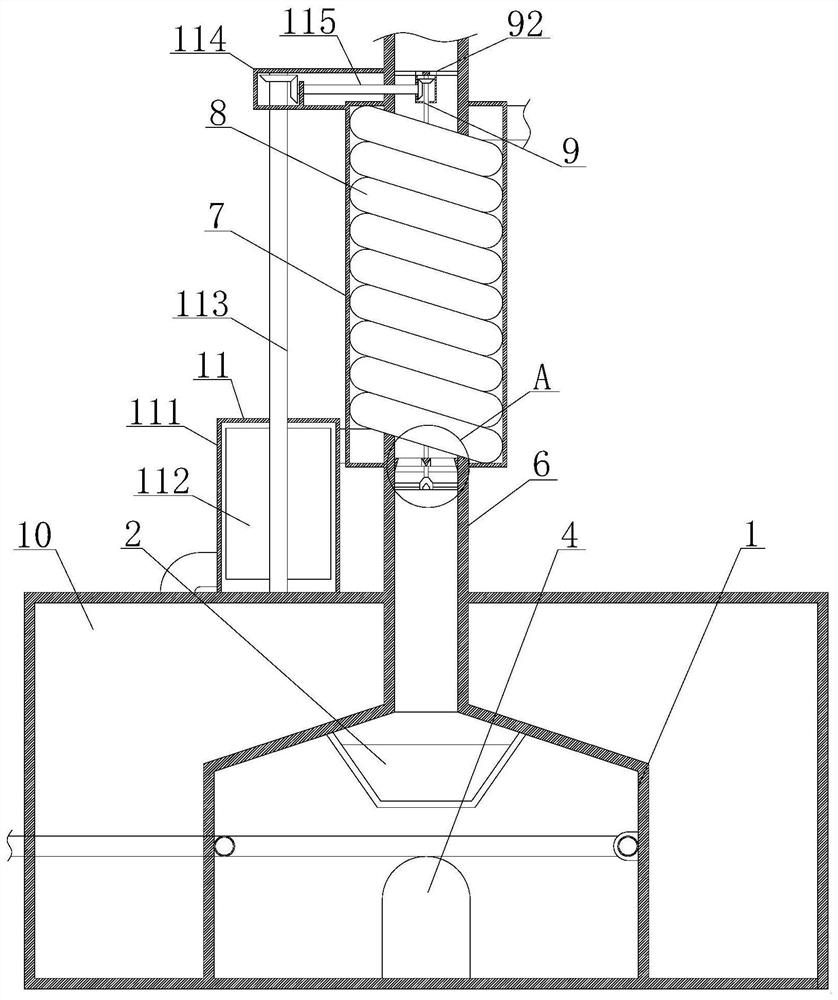

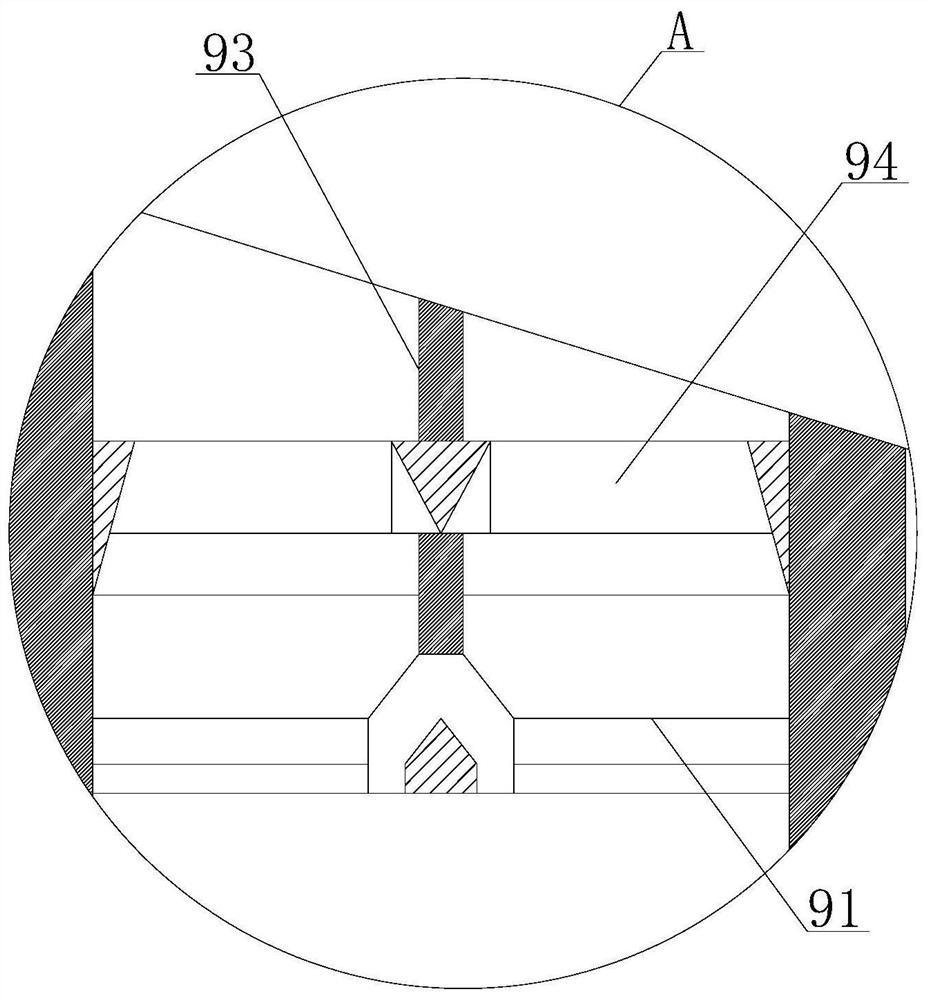

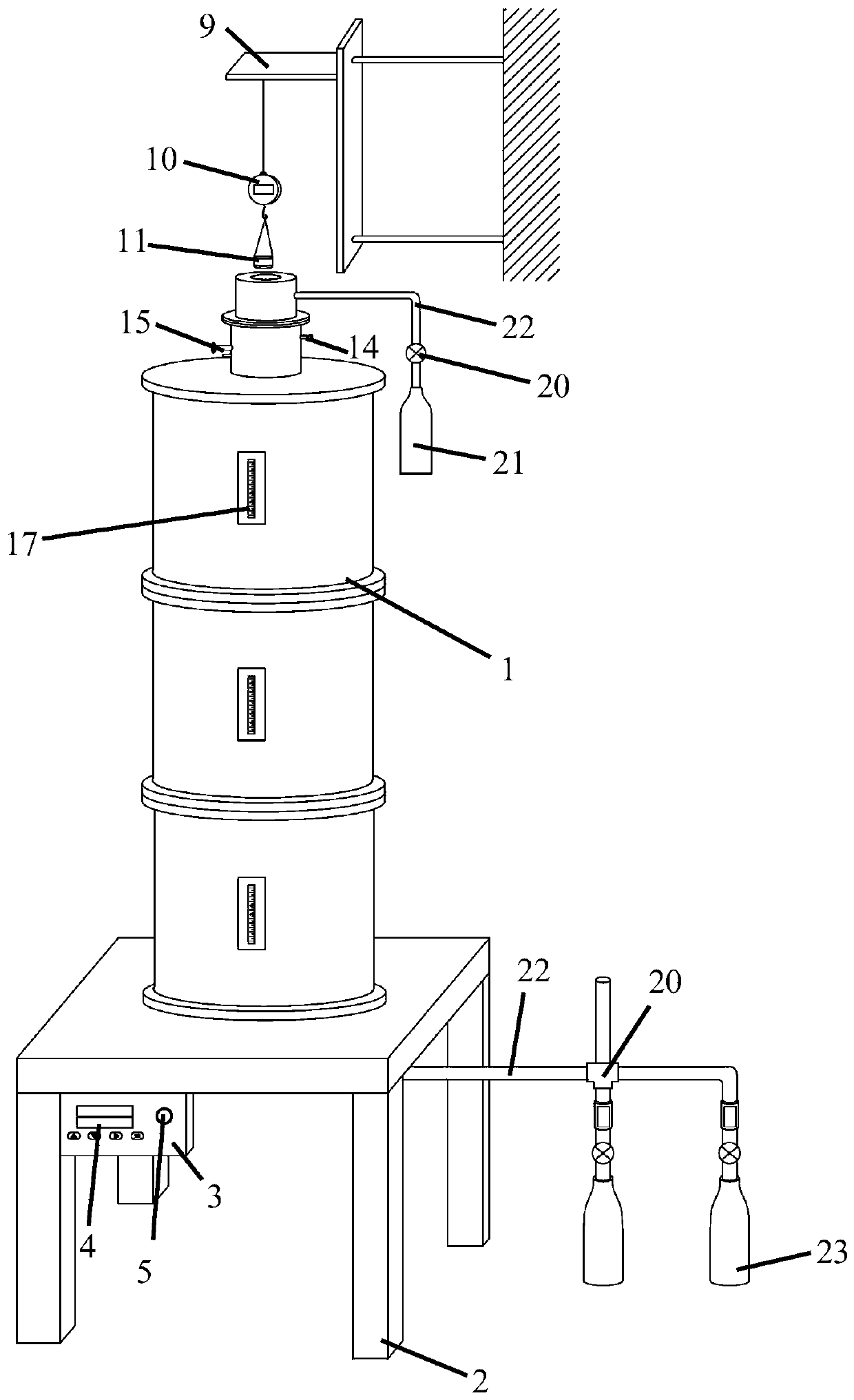

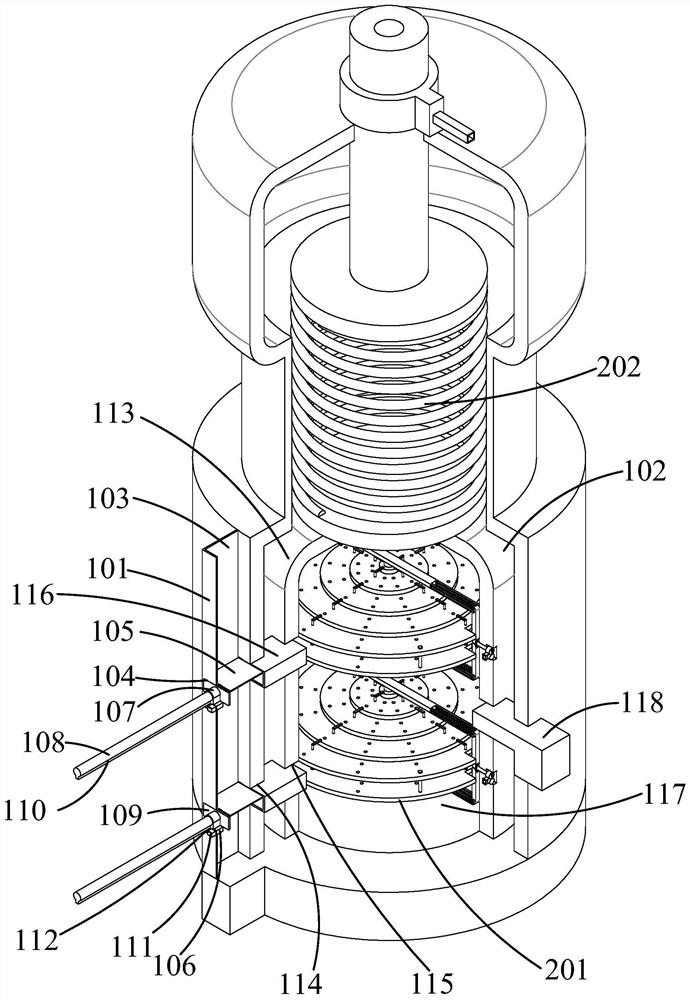

Large-particle coke combustion characteristic testing system

InactiveCN111505198AEmission reductionReduce carbon contentChemical analysis using combustionInvestigating phase/state changeCokeParticle combustion

The invention discloses a large-particle coke combustion characteristic testing system, and belongs to the technical field of experimental equipment. The testing system comprises a furnace body and abracket for supporting the furnace body, the testing system further comprises a workbench, a lifting device, a water cooling device and an air inlet and equalizing device. The boiler body is divided into the three sections of heating areas, the highest heating temperature of the upper section of heating area and the lower section of heating area is 1350 DEG C, the highest heating temperature of the middle section of heating area is 1600 DEG C, and the large-particle combustion high-temperature requirement of the grate-fired boiler can be actually simulated. The lifting speed and the lifting height of the fuel are controlled by adopting a double-guide-rail lifting platform so as to simulate the processes of heating, burning and burnout of the fuel of the grate-fired boiler after the fuel enters the boiler. The testing system disclosed by the invention can effectively solve the technical problems existing in researching the reaction characteristics of coal coke by adopting a thermogravimetric analyzer at present, provides theoretical support for optimizing the combustion of the grate-fired boiler, and is suitable for popularization and application.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST +2

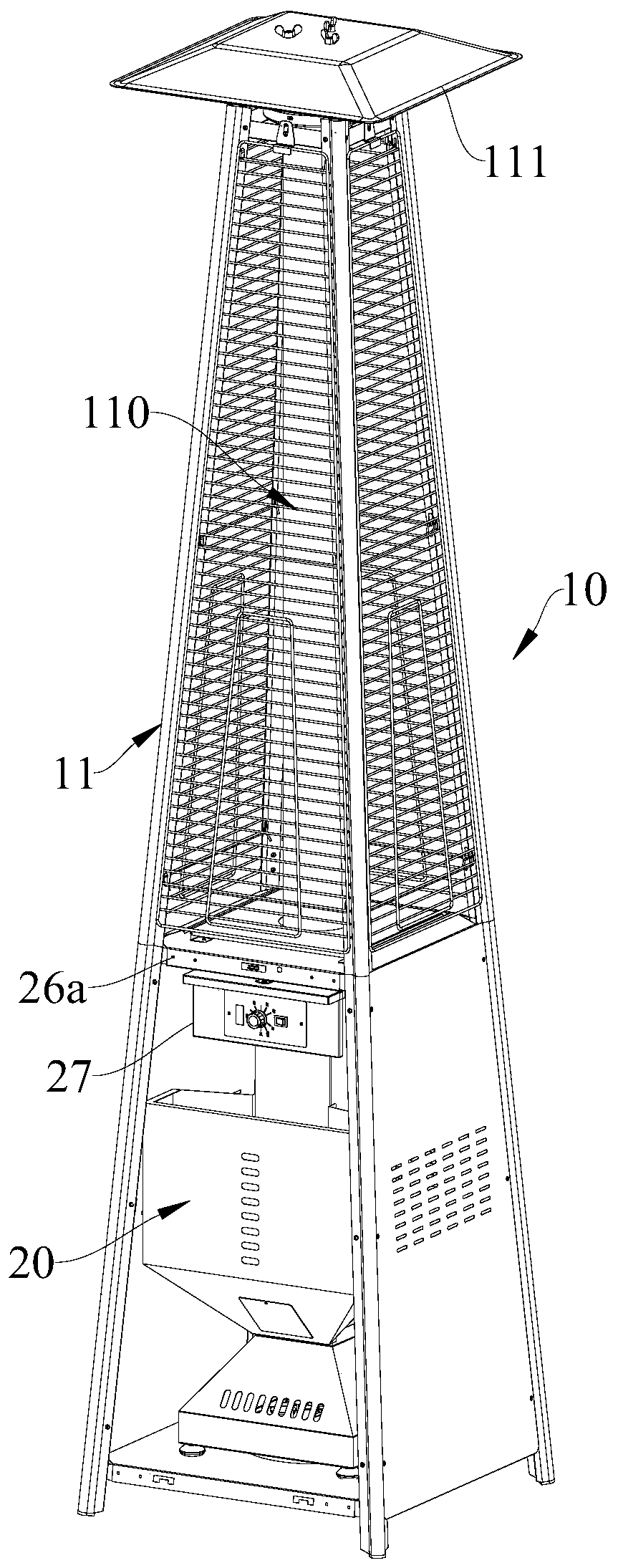

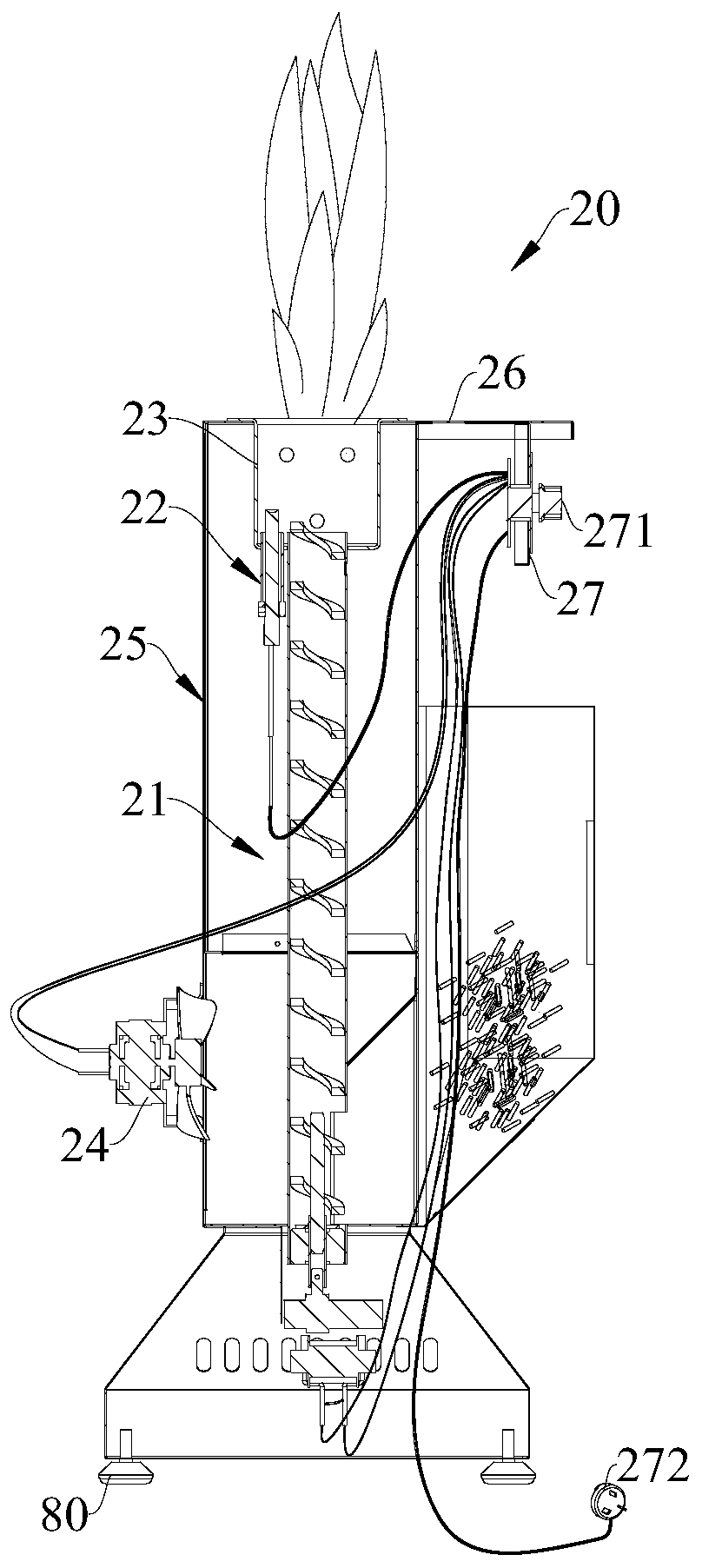

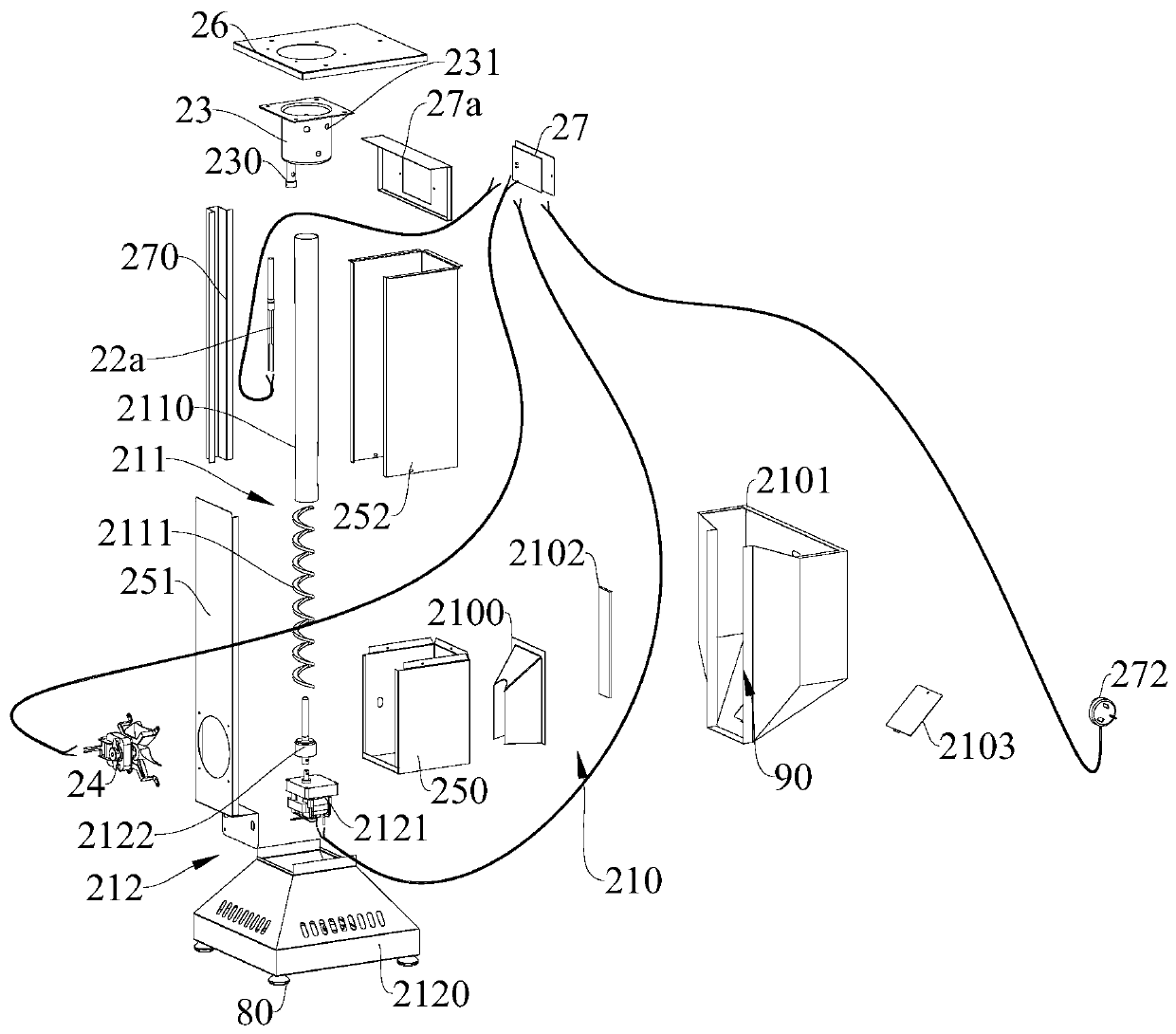

Granular fuel warmer

PendingCN110793063ACombustion of various fuelsLower heating costsDomestic stoves or rangesLighting and heating apparatusThermodynamicsCombustion chamber

The invention discloses a granular fuel warmer. The granular fuel warmer comprises a tower-shaped warming housing and a particle combustion device arranged inside the tower-shaped warming housing, wherein the particle combustion device comprises a feeding mechanism, a heating mechanism and a combustion chamber; the feeding mechanism and the combustion chamber are sequentially arranged from bottomto top along the axis of the tower-shaped warming housing; the feeding mechanism is used for conveying granular fuels into the combustion chamber; and the heating mechanism is arranged at the combustion chamber for combusting granular fuels in the combustion chamber. The granular fuel warmer provided by the invention is various in combustion fuels, and is low in warming cost.

Owner:JIANGSU GARDENSUN FURNACE

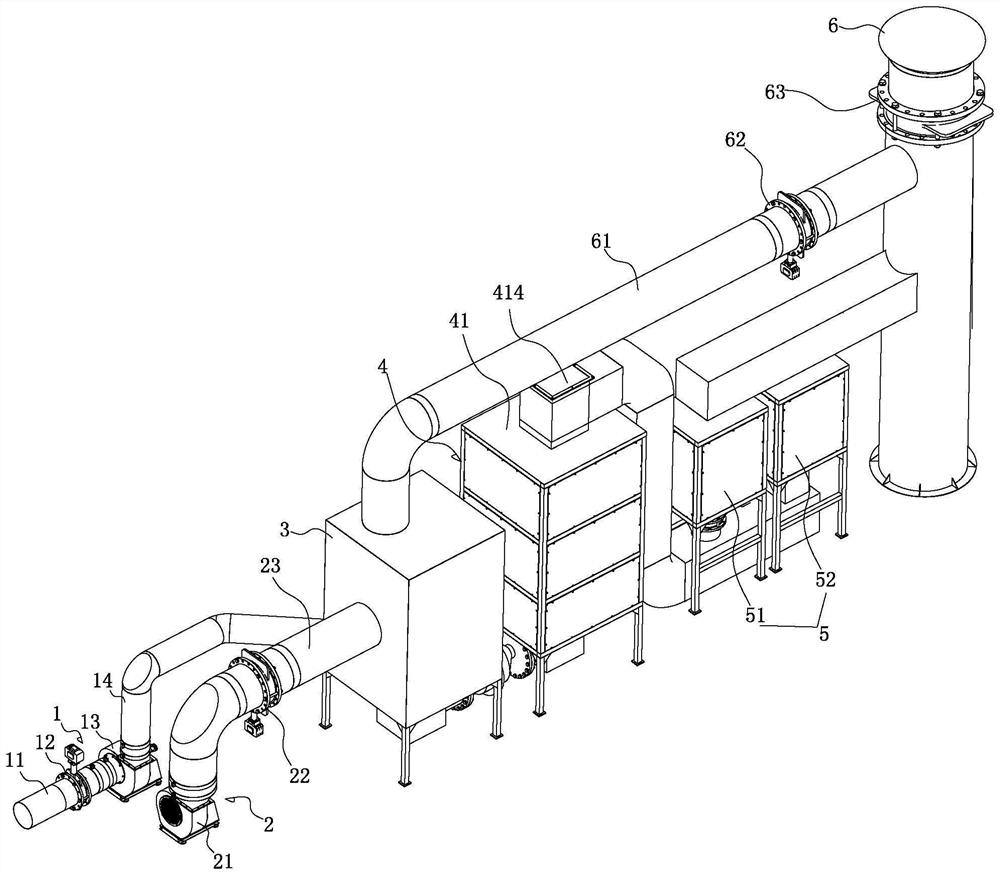

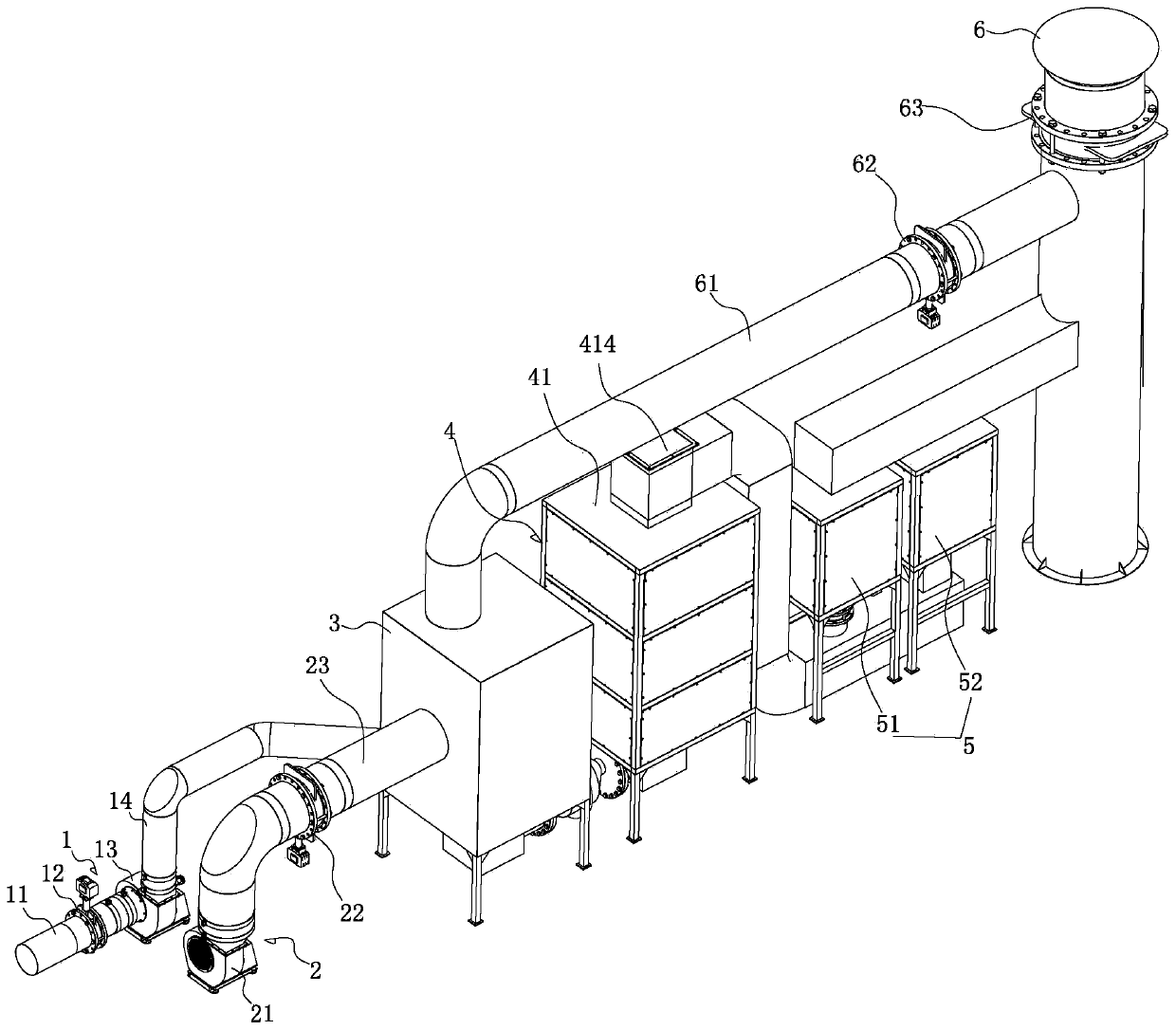

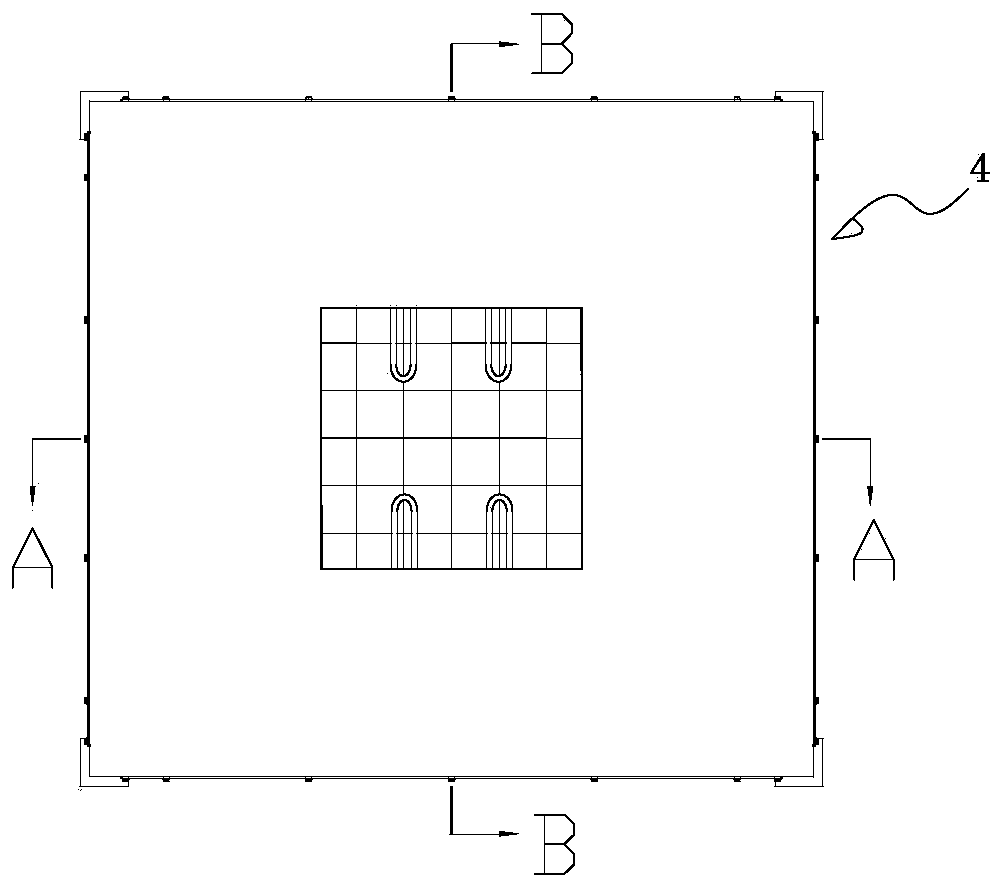

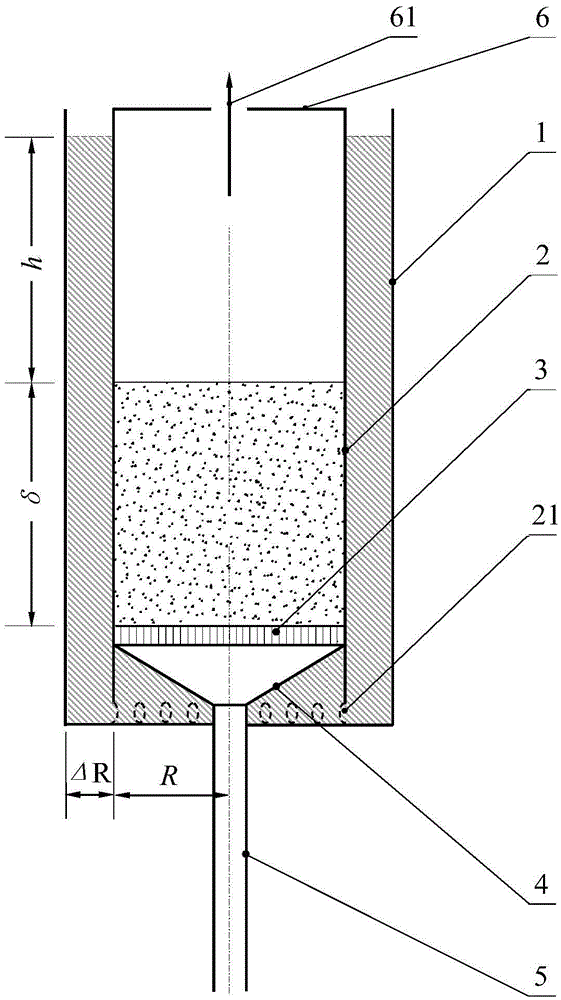

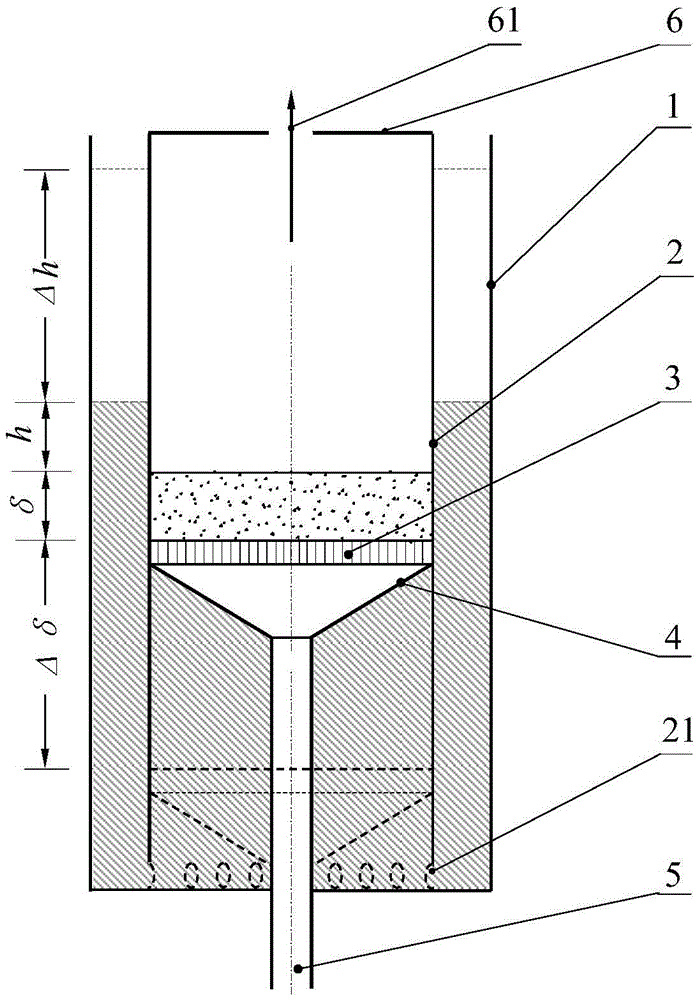

Motor dipping vocs treatment - catalytic combustion equipment

ActiveCN110056894BTo achieve the purpose of preheatingExplosion does not causeIncinerator apparatusFlame arresterExhaust fumes

The invention discloses motor dip coating VOCs treatment-catalytic combustion equipment. The motor dip coating VOCs treatment-catalytic combustion equipment comprises an exhaust gas sucking mechanism,a natural air supplementing mechanism, a buffering mixing box, a primary catalytic combustion device, a secondary catalytic combustion device and a chimney; the natural air supplementing mechanism and the VOCs sucking mechanism are both connected with an inlet of the buffering mixing box; the primary catalytic combustion device comprises a first catalytic combustion box, a first preheating module, a first catalytic combustion module and a second catalytic combustion module, and the first catalytic combustion box is connected with a first fire barrier and then connected with the buffering mixing box; the secondary catalytic combustion device comprises at least two first catalytic combustion mechanisms and second catalytic combustion mechanisms which are installed in parallel and have the same structure, the first catalytic combustion mechanisms and the second catalytic combustion mechanisms are both connected with the first catalytic combustion box, each second catalytic combustion mechanism comprises a second catalytic combustion box, a second preheating module, a particle combustion bed and a third catalytic combustion module, and the second catalytic combustion boxes are connected with the first catalytic combustion box; and second outlets formed in the upper ends of the first catalytic combustion mechanisms and the second catalytic combustion mechanisms are both connected with the chimney.

Owner:袁华贤

Smokeless particle combustion machine

InactiveCN104566340AEmission reductionSimple structureSolid fuel combustionLump/pulverulent fuel feeder/distributionThermodynamicsParticle combustion

The invention provides a smokeless particle combustion machine which comprises a feeding device, a combustion machine, a heat energy utilizing system and a waste heat recycling system. A circulating fan is connected with a heat channel formed between an inner container and an inspection door of the heat energy utilizing system and is connected to a drying oven; an exhaust fan of the waste heat recycling system is connected to an excess heat recycling pipeline, and the tail end of the excess heat recycling pipeline is connected to an induced draft fan by a cyclone separator. The smokeless particle combustion machine has the advantages of simple structure, sufficient combustion, high heat utilization efficiency and smokeless emission.

Owner:DONGGUAN LIXIN AUTOMATIC SPRAYING EQUIP

Motor dip coating VOCs treatment-catalytic combustion equipment

ActiveCN110056894ATo achieve the purpose of preheatingExplosion does not causeIncinerator apparatusParticle combustionEngineering

The invention discloses motor dip coating VOCs treatment-catalytic combustion equipment. The motor dip coating VOCs treatment-catalytic combustion equipment comprises an exhaust gas sucking mechanism,a natural air supplementing mechanism, a buffering mixing box, a primary catalytic combustion device, a secondary catalytic combustion device and a chimney; the natural air supplementing mechanism and the VOCs sucking mechanism are both connected with an inlet of the buffering mixing box; the primary catalytic combustion device comprises a first catalytic combustion box, a first preheating module, a first catalytic combustion module and a second catalytic combustion module, and the first catalytic combustion box is connected with a first fire barrier and then connected with the buffering mixing box; the secondary catalytic combustion device comprises at least two first catalytic combustion mechanisms and second catalytic combustion mechanisms which are installed in parallel and have the same structure, the first catalytic combustion mechanisms and the second catalytic combustion mechanisms are both connected with the first catalytic combustion box, each second catalytic combustion mechanism comprises a second catalytic combustion box, a second preheating module, a particle combustion bed and a third catalytic combustion module, and the second catalytic combustion boxes are connected with the first catalytic combustion box; and second outlets formed in the upper ends of the first catalytic combustion mechanisms and the second catalytic combustion mechanisms are both connected with the chimney.

Owner:袁华贤

Hollow fiber net-shaped perovskite catalyst, and preparation method and applications thereof

InactiveCN110102289AEasy to operateRaw materials are easy to getExhaust apparatusHeterogenous catalyst chemical elementsFiberParticle combustion

The invention discloses a hollow fiber net-shaped perovskite catalyst, and a preparation method and applications thereof. The chemical general formula of the catalyst is La<1-x>Sr<x>MnO3, 0<=x<=0.4; the catalyst is designed to shape like a net, and is provided with hollow tubular channels, the pore diameter is controlled to be 200 to 300nm. According to the preparation method, water-ethanol is taken as a solvent system for static spinning, so that introduction of organic solvents harmful for human body is avoided, and the system is safe, and is friendly to the environment. The hollow fiber net-shaped perovskite catalyst is capable of capturing carbon smoke particles in diesel car tail gas, increasing contact opportunity of catalyst active sites with carbon smoke and nitrogen oxides, realizing cooperative removing of carbon smoke and nitrogen oxides, and reducing pollutant discharge amount of tail gas. In a simulation test of eliminating of carbon smoke and nitrogen oxides in diesel cartail gas, high activity is achieved, carbon smoke particle combustion peak temperature is 360 DEG C, NO largest conversion rate is 40%, and the peak temperature is 380 DEG C.

Owner:SOUTH CHINA UNIV OF TECH

Petroleum coke particle combustion device

InactiveCN105627294AEasy to understandEmission reductionSolid fuel combustionCombustion apparatusCombustion chamberSulfur

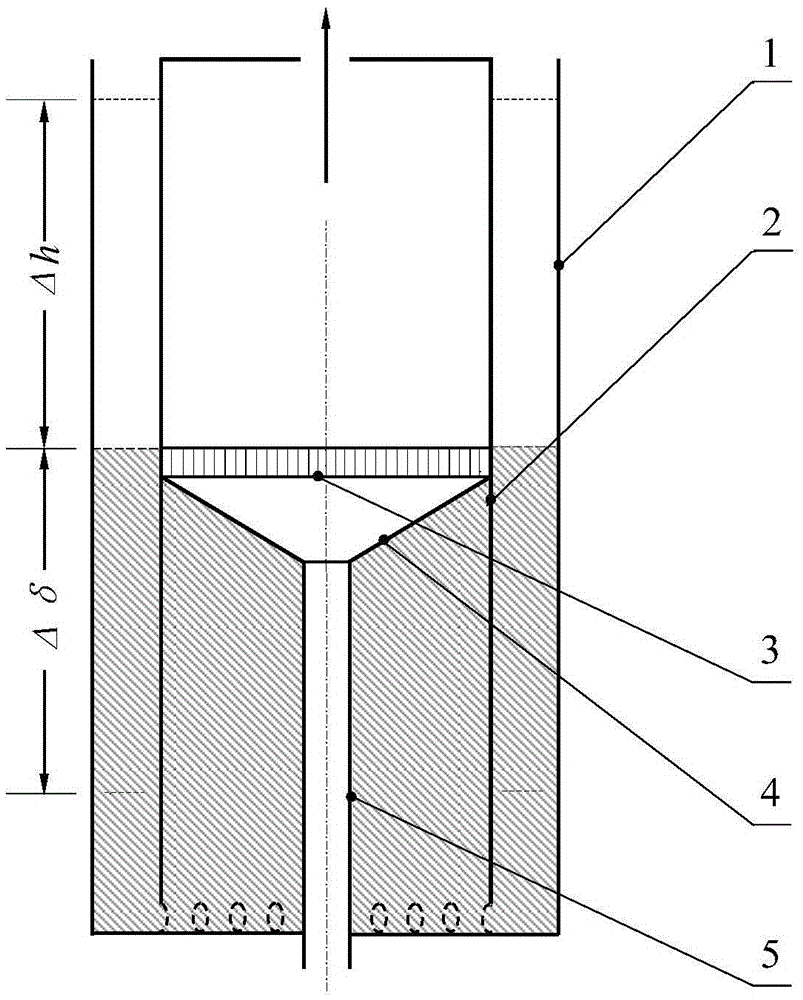

A petroleum coke particle combustion device mainly comprises an upright cylindric furnace shell, a cylindric furnace inner container, a furnace grate and an air inlet pipe, wherein the central axis of the upright cylindric furnace shell, the central axis of the cylindric furnace inner container, the central axis of the furnace grate and the central axis of the air inlet pipe are collinear. The bottom edge of the furnace inner container is connected with a bottom plate of the furnace shell in a welded manner. The width of a ring cylinder area between the furnace inner container and the furnace shell is 0.41-0.43 time the radius of the furnace inner container. The side wall of the furnace grate is attached to the furnace inner container to vertically move in a seamless manner. Coke particles are stacked above the furnace grate. A combustion chamber is arranged above the coke particle layer. The ring cylinder area between the furnace inner container and the furnace shell and a cylinder area of the furnace inner container are communicated through a plurality of communicating openings in the bottom of the furnace inner container. After the communicating area is filled with pure water, an outer ring cylinder area-inner cylinder area type communicating device is formed, and the height of an outer ring cylinder water column higher than the top face of the coke particle layer is equal to the thickness of the inner cylinder coke particle layer. The petroleum coke particle combustion device can be used for a low-sulfur petroleum coke particle furnace kiln for combustion. According to the petroleum coke particle combustion device, the energy saving rate is larger than 5%-15%, and smoke pollutant discharge meets the requirement of the Integrated Emission Standard of Air Pollutants (GB16297-1996).

Owner:CENT SOUTH UNIV

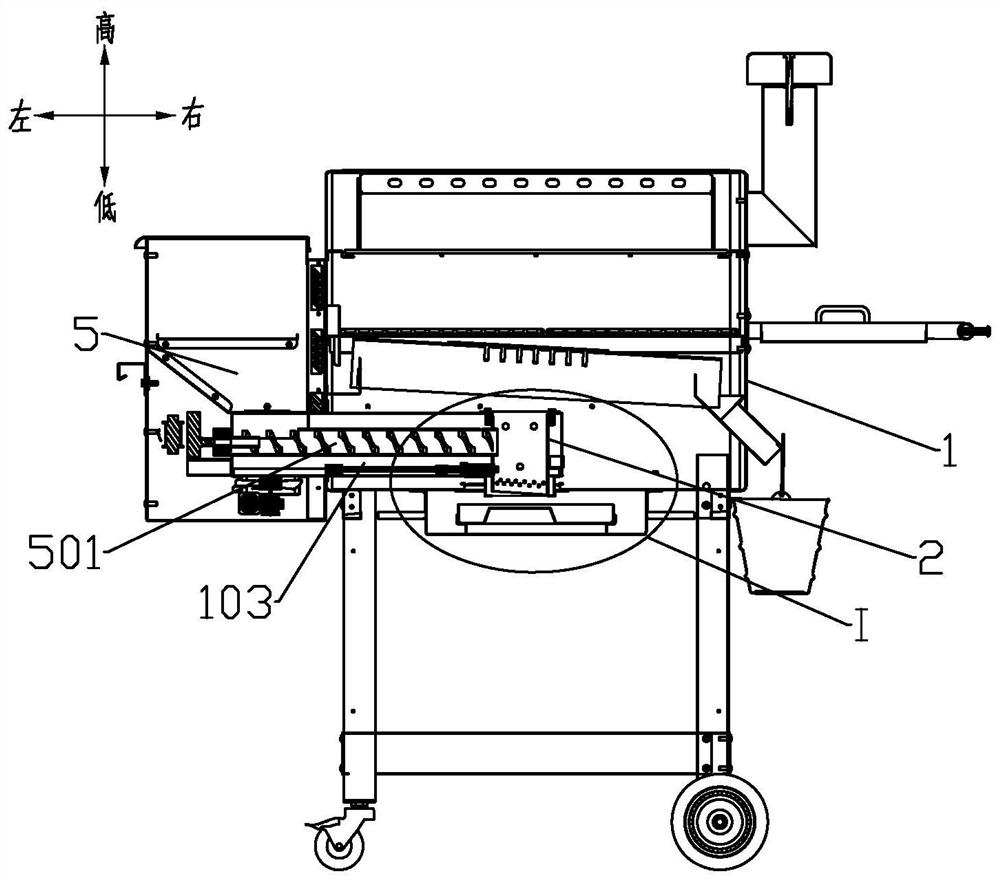

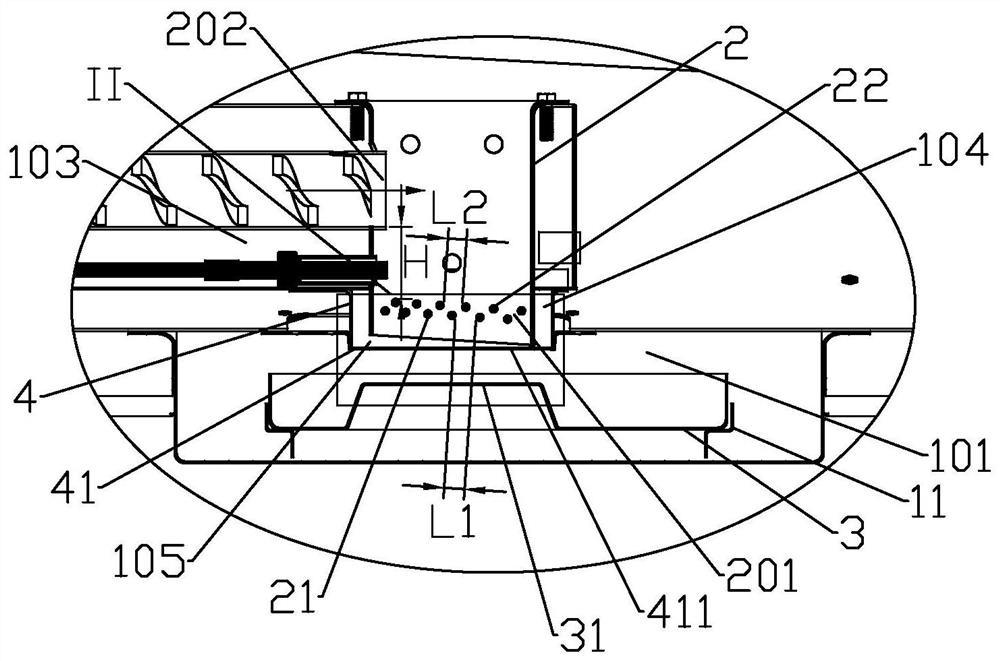

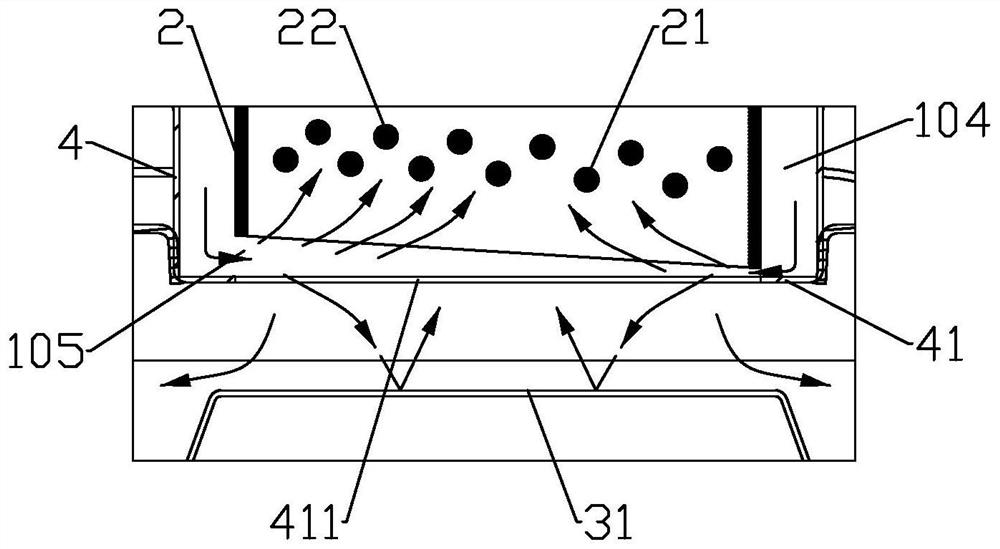

Particle combustion furnace

The invention discloses a particle combustion furnace, belongs to the field of combustion equipment, solves a problem of inconvenience in ash removal or poor ash falling effect of a combustor in the prior art, and adopts the technical scheme that a through hole for air intake and ash falling is formed in the bottom surface of the combustor, and a grid structure is arranged above the through hole; the grid structure comprises a first-layer supporting body and a second-layer supporting body which are fixed to the combustor, the first-layer supporting body is lower than the adjacent second-layer supporting body, the second-layer supporting body is distributed in a staggered mode in the vertical direction relative to the first-layer supporting body, and a first channel is formed between the first-layer supporting body and the second-layer supporting body; the width of the first channel is smaller than the diameter D of granular fuel, a distance L2 between every two adjacent second-layer supporting bodies is larger than D and smaller than 2D, the feeding port is located above the grid structure, the height difference is H, H is not smaller than 3D, and an ash receiving disc is arranged at the position, located below the combustor, of the bottom of the furnace body. The particle combustion furnace is mainly used for automatic ash falling, good in ash falling effect and convenient for users to clean ash.

Owner:郑颖

Organic heat carrier heating equipment

ActiveCN105135678BTake advantage ofClean up thoroughlyStorage heatersHeat carrierParticle combustion

The invention discloses an organic heat carrier heating device, which comprises a furnace body and a heat-conducting oil tank. The furnace body is provided with a furnace, the outer wall of the furnace is provided with a ring of heat-insulating jackets, and the bottom of the furnace body is respectively provided with air inlet cylinders. And ash chamber, including heating system, secondary circulation system, rotary quantitative feeding system and ash cleaning system; the advantage of the present invention is that it can feed quantitatively and orderly, strictly control the feeding speed and feeding amount, and prevent tempering The phenomenon occurs, the combustion reaction is sufficient, and the utilization rate of the combustion of biological particles in the furnace body is improved, the heat can be fully recycled for the second time, and the heating surface of the spirally coiled tube group can be made uniform, which greatly saves resources and saves biological energy. The usage of pellets saves cost.

Owner:ANHUI SANDING BOILER MFG CO LTD

A wood-burning pellet stove

ActiveCN107131525BRealize intelligent growthRealize automatic controlLighting and heating apparatusCombustion-air/flue-gas circulation for stovesCombustion chamberFrequency conversion

The invention provides a wood particle combustion furnace comprising a charging device arranged inside a shell, a combustion device arranged at an outlet of the charging device and an operation panel arranged on the shell. The charging device comprises a charging hopper fixed on the upper portion of the inner side of the shell and a conveying belt arranged under the charging device. The combustion device comprises a combustion chamber and a combustion box arranged inside the combustion chamber. An ignition bar stretches into the combustion box from the exterior of the combustion chamber. An air supplying motor and an air suction motor are arranged on the two sides of the combustion chamber correspondingly. The wood particle combustion furnace further comprises a water circulation system connected with the shell, a safety door arranged at the front end of the shell and a control system used for controlling turn-on or turn-off a switch, operation of the conveying belt, heating of the ignition bar and operation of the air supplying motor and the air suction motor. According to the wood particle combustion furnace, automatic changing, automatic ignition, frequency conversion regulation and control, automatic dust removing and easy operation can be achieved, and meanwhile intelligent growth of the control system can be achieved.

Owner:烟台炉旺节能科技有限公司

Biomass fuel particle combustion equipment

InactiveCN112984498AImplement autofillBurn fullySolid fuel combustionCombustion apparatusParticle combustionProcess engineering

The invention discloses biomass fuel particle combustion equipment. The biomass fuel particle combustion equipment structurally comprises a furnace barrel; a filler furnace is fixedly arranged on one side of the furnace barrel; a furnace barrel inner cavity is formed in the filler furnace; a feeding component used for pushing fuel into the equipment is arranged in the furnace barrel inner cavity; the furnace barrel inner cavity is formed in the furnace barrel; the furnace barrel inner cavity is filled with water; a fire grate component used for achieving fuel combustion is arranged in the furnace barrel inner cavity;a smoke discharging component used for achieving smoke discharging is arranged in the furnace barrel inner cavity;and an ash discharging component used for taking out furnace ash is arranged at the bottom of the furnace barrel. According to the biomass fuel particle combustion equipment, fuels can be automatically filled,fire grates can be driven to be staggered in a laminated mode, and can rotate to enable the fuel to be sufficiently burned, so that the combustion efficiency is improved, and the flue can be fully utilized to heat water inside.

Owner:上海旖琥环境工程技术发展有限公司

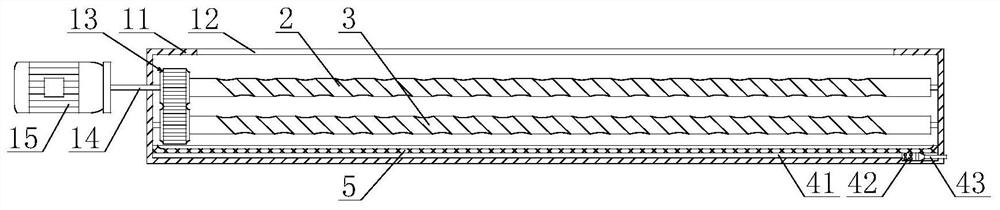

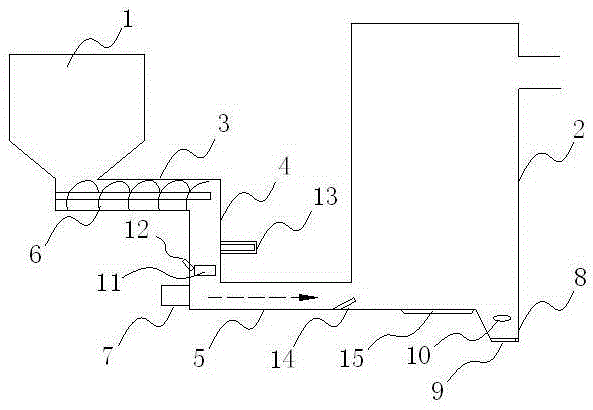

Horizontally-feeding biomass particle combustion machine

InactiveCN105387451AEasy to fall automaticallyAvoid blowingSolid fuel combustionLump/pulverulent fuel feeder/distributionParticle combustionEngineering

The invention provides a horizontally-feeding biomass particle combustion machine. According to the particle combustion machine, ash removal is easily achieved, and tempering danger is avoided. The horizontally-feeding biomass particle combustion machine comprises a hopper and a vaporizing chamber, wherein the hopper is connected with the vaporizing chamber through a feeding pipe; and the horizontally-feeding biomass particle combustion machine is characterized in that the feeding pipe is formed by sequentially connecting a first horizontal pipe, an anti-backfire pipe and a second horizontal pipe, and the first horizontal pipe is higher than the second horizontal pipe; the first horizontal pipe is connected with the bottom of the hopper, and a spiral feeding device driven by a motor is arranged in the first horizontal pipe; the second horizontal pipe is connected with the side of the bottom of the vaporizing chamber, the second horizontal pipe is provided with a feeding fan, and the blowing direction of the feeding fan faces the vaporizing chamber from the connecting position of the second horizontal pipe and the anti-backfire pipe; and an ash collecting concave portion is arranged on one side, far away from the second horizontal pipe, of the bottom of the vaporizing chamber. An ash removal door is arranged at the bottom of the ash collecting concave portion.

Owner:DONGGUAN BAIDA NEW ENERGY CO LTD

Particle combustion furnace

ActiveCN112856388AImprove fuel efficiencyGuaranteed ash effectSolid fuel combustionAir/fuel supply for combustionCombustorParticle combustion

The invention discloses a particle combustion furnace, belongs to the field of combustion equipment, and solves the problem of low combustion efficiency of particle fuel in the prior art. According to the technical scheme, the bottom surface of a combustor is provided with a through hole for air intake and ash falling, a fire grate is arranged above the through hole, and the outer side wall of the bottom of the combustor is provided with an air guide channel; and the top end of the air guide channel is connected with an air supply channel, an annular air baffle is arranged at the bottom end of the air guide channel, an annular air inlet gap is formed between the annular air baffle and the bottom end of the combustor, a through hole is formed in an inner ring of the annular air baffle, and a rebound air baffle is arranged below the annular air baffle and penetrates through the through hole to face the fire grate. The particle combustion furnace is mainly used for promoting the combustion-supporting effect and improving the fuel efficiency of particle fuel.

Owner:深圳市艾斯默克科技有限公司

Combustion system and method for burning biomass black granular fuel

PendingCN114198745AGuaranteed uptimeLong runFuel feeding arrangementsSolid fuel pretreatmentAir preheaterCombustion system

The invention discloses a combustion system and method for burning biomass black granular fuel. The combustion system comprises a raw material bin, a coal feeder and a coal mill, an outlet of denitration equipment is connected with a flue gas inlet of an air preheater, a flue gas outlet of the air preheater is sequentially connected with a dust remover and an induced draft fan, and a cold air inlet of the air preheater is connected with an air feeder and an outlet of a primary fan. A hot air outlet of the air preheater is communicated with the boiler body and the coal mill; the outlet of the primary fan is also communicated with the coal mill; and an outlet of the induced draft fan is connected with a chimney and a coal mill. Low-temperature circulating flue gas is fed into a hot air pipe to be mixed and then fed into a coal mill, unheated primary air generated by a primary air fan is also fed into the hot air pipe to be mixed, and three media of cold air, cold flue gas and hot air are mixed and fed into the coal mill to be pulverized. The temperature and oxygen concentration of the outlet of the hearth can be adjusted, the combustion condition of black particle fuel is adjusted, and the adaptability of the boiler to black particle combustion is higher.

Owner:SHANGHAI INST OF SPECIAL EQUIP INSPECTION & TECHN RES

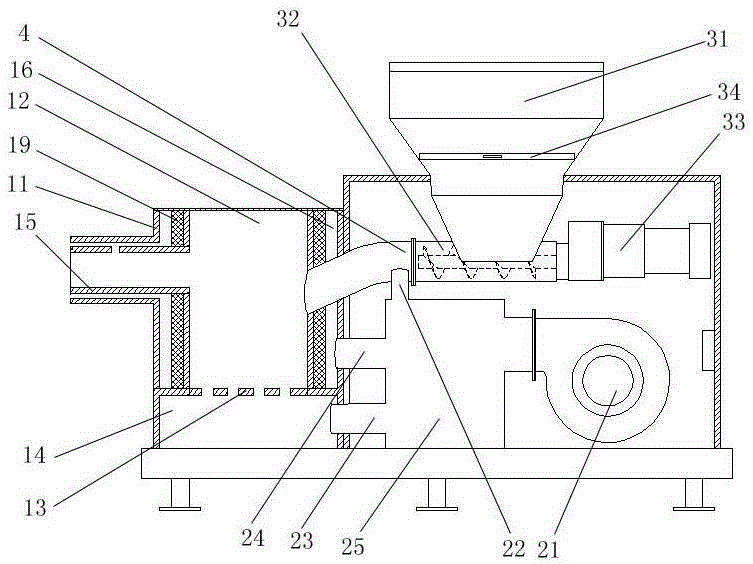

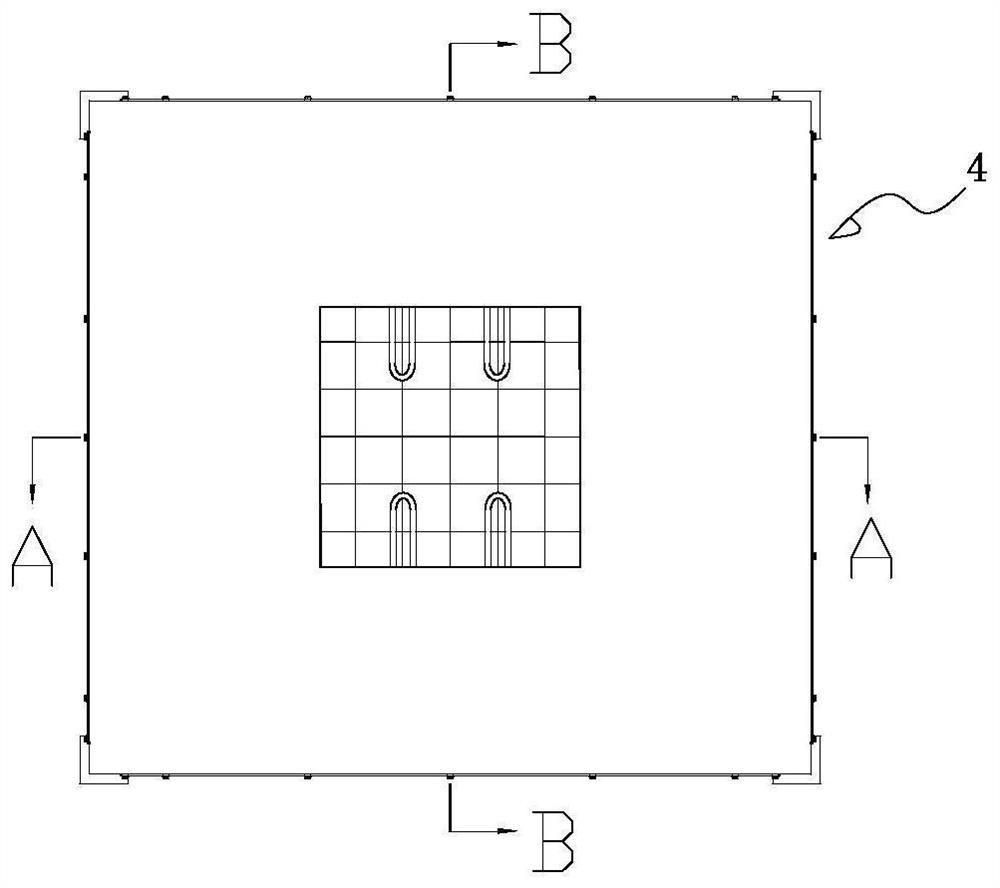

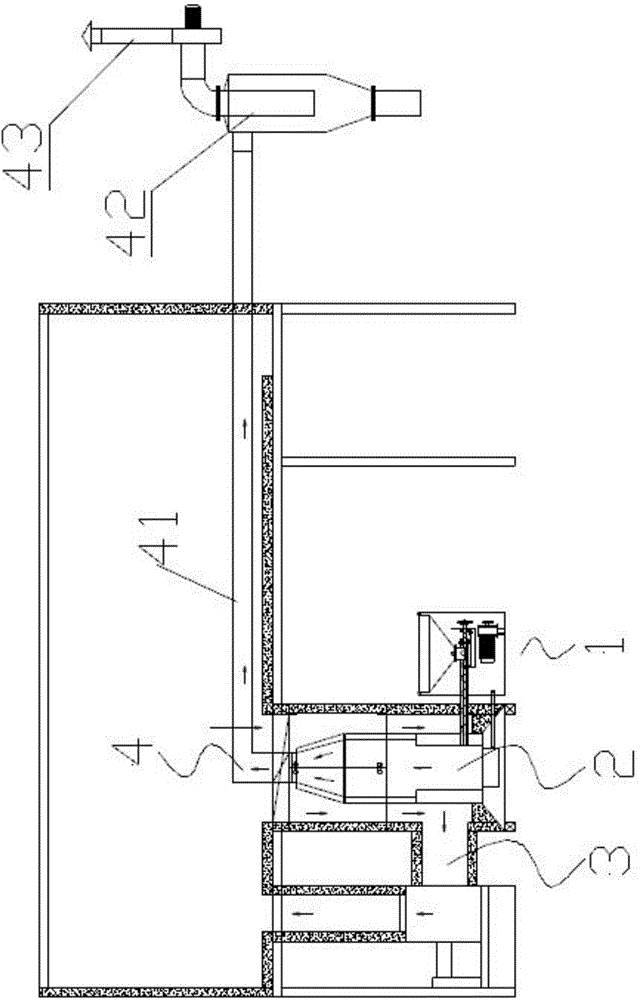

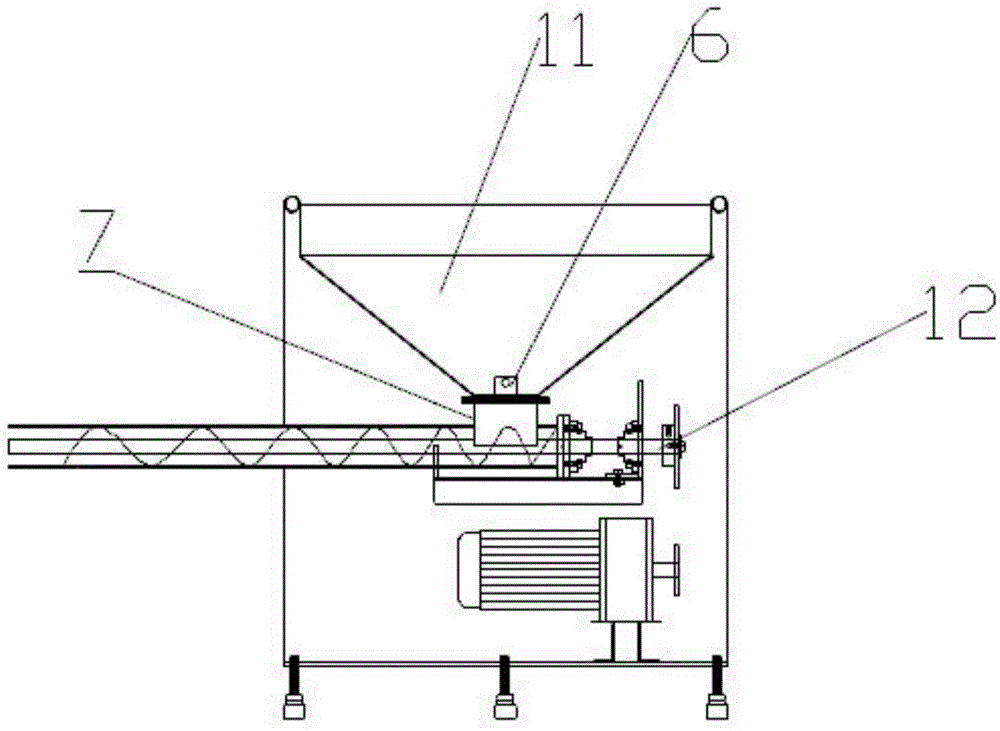

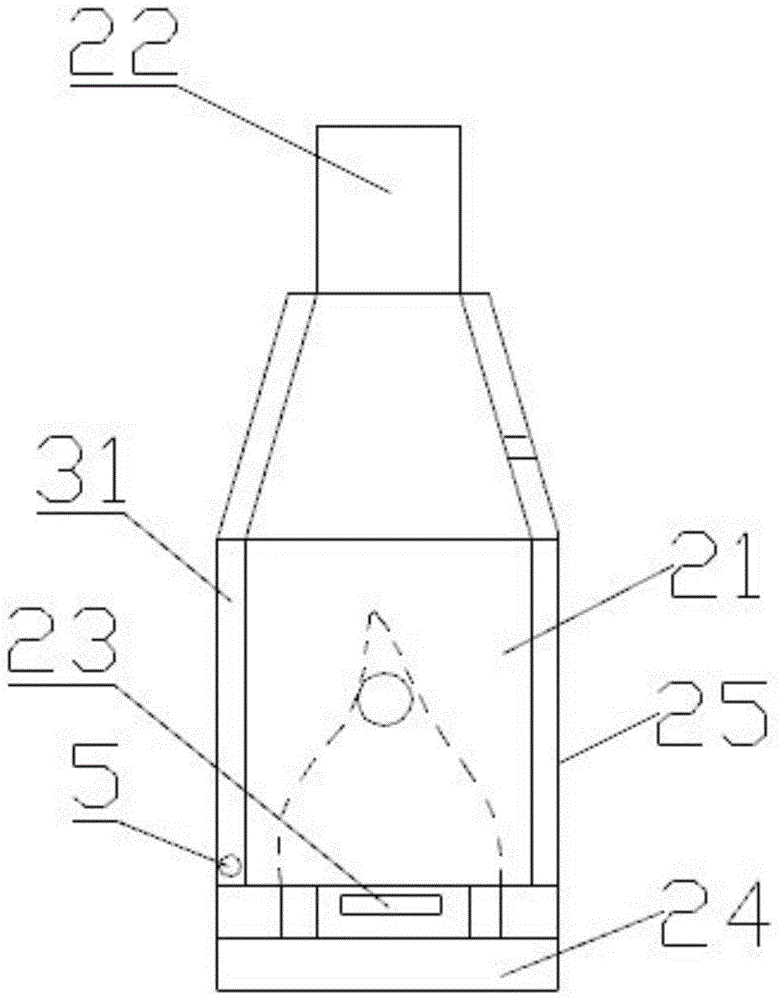

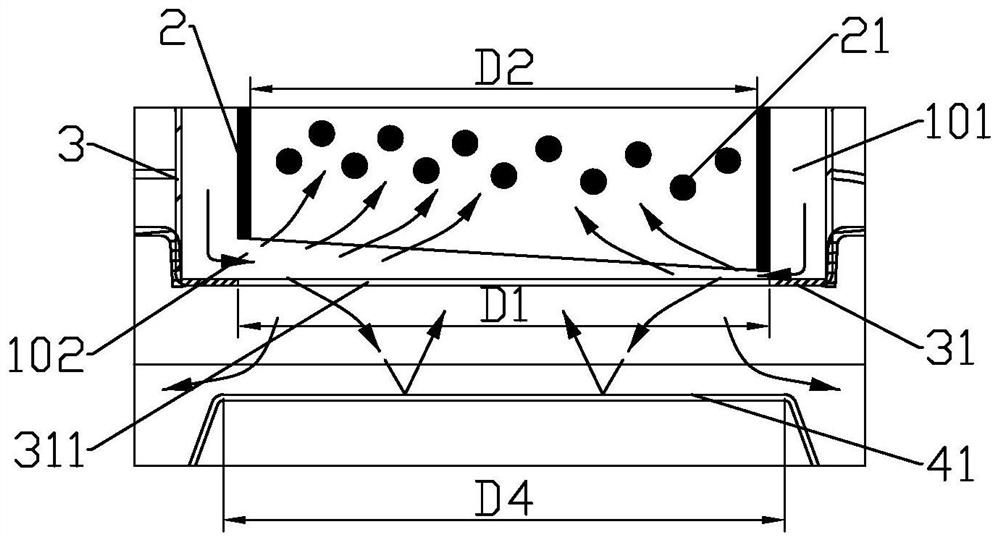

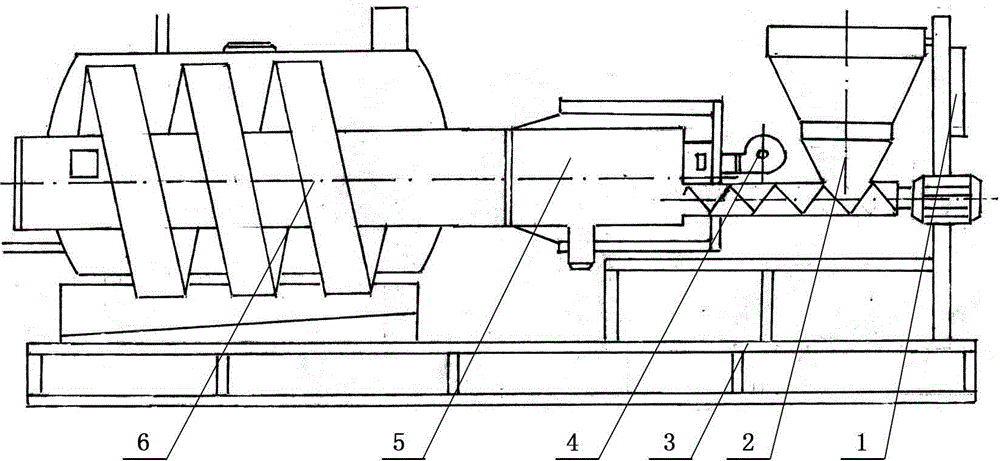

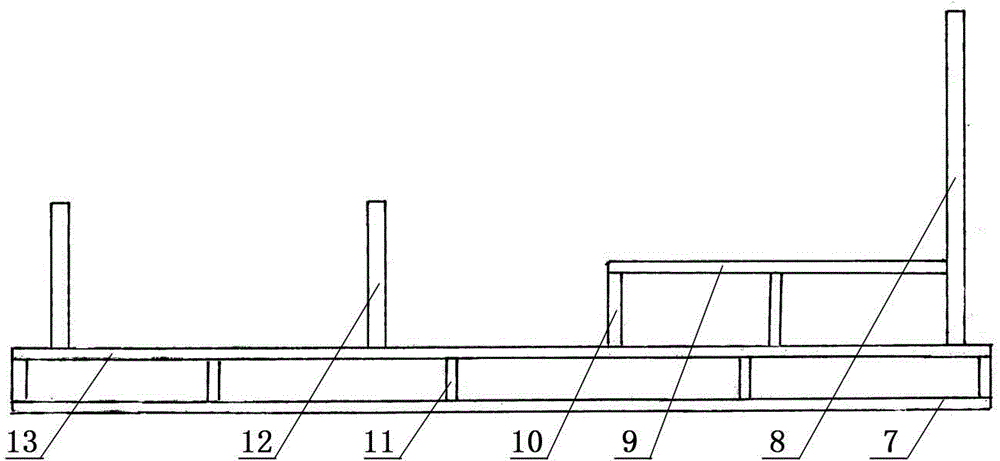

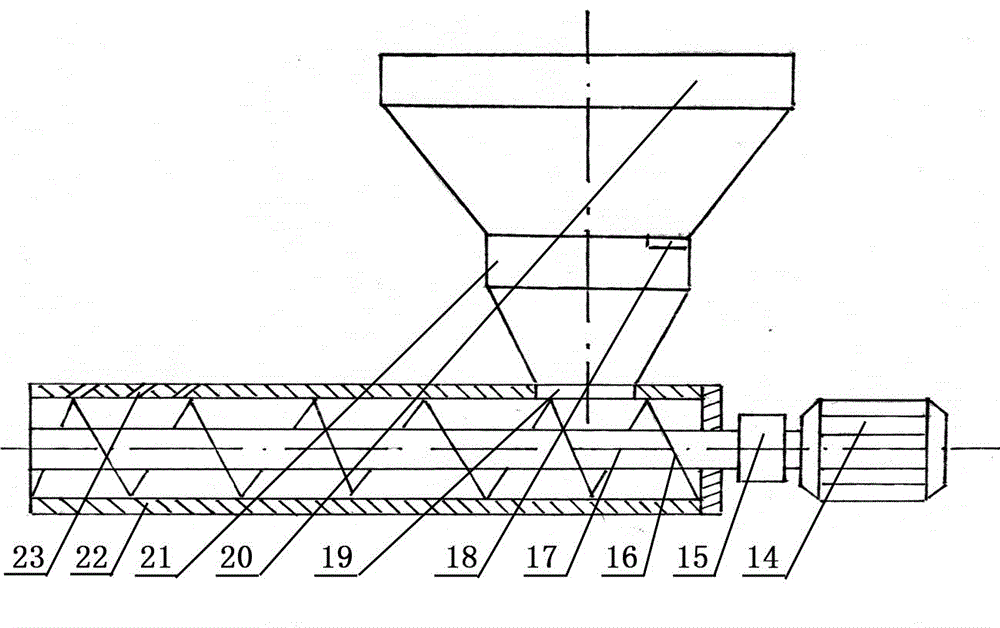

Horizontal type biomass-particle heat energy generating and purifying device

InactiveCN106152511AGood rigidityGood precisionFluid heatersBlast-producing apparatusChemical industryCombustion chamber

The invention discloses a horizontal type biomass-particle heat energy generating and purifying device. The horizontal type biomass-particle heat energy generating and purifying device comprises a complete machine frame, a material supplying device, an oxide supplying device, a particle combustion chamber, a separation purifying and heating device and an operation controller. Through multiple creative technological measures on the key technology aspects such as material supplying, oxide supplying, combustion and separation purifying, the horizontal type biomass-particle heat energy generating and purifying device has the operation functions of spiral continuous quantitative material supply, double-layer eddy flow controlled oxide supply, particle enough-oxygen complete combustion, cyclone water-absorbing separation purification, matching and coordination between material supply and oxygen supply and the like and solves the technical difficult problems that by the adoption of an existing biomass energy hot blast furnace, oxygen supply to a combustion chamber is not uniform, particle combustion is incomplete, the temperature of hot air is low, and inhalable particle emission and flue gas emission exceed the standards. The horizontal type biomass-particle heat energy generating and purifying device can meet the winter heating demands in production workshops, markets, warehouses and other large-area production and life sites in the northern area and can also meet the technical requirement for hot air in the drying production places such as the paint spraying industry, the grain industry, the food industry, the chemical industry and the pharmacy.

Owner:SIPING CITY DONGSHENG HEAT EXCHANGER MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com