Particle combustion furnace

A combustion furnace and pellet fuel technology, applied in kitchen utensils, home utensils, roasters/barbecue grills, etc., can solve the problems of complex structure, inconvenient use, poor ash falling efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

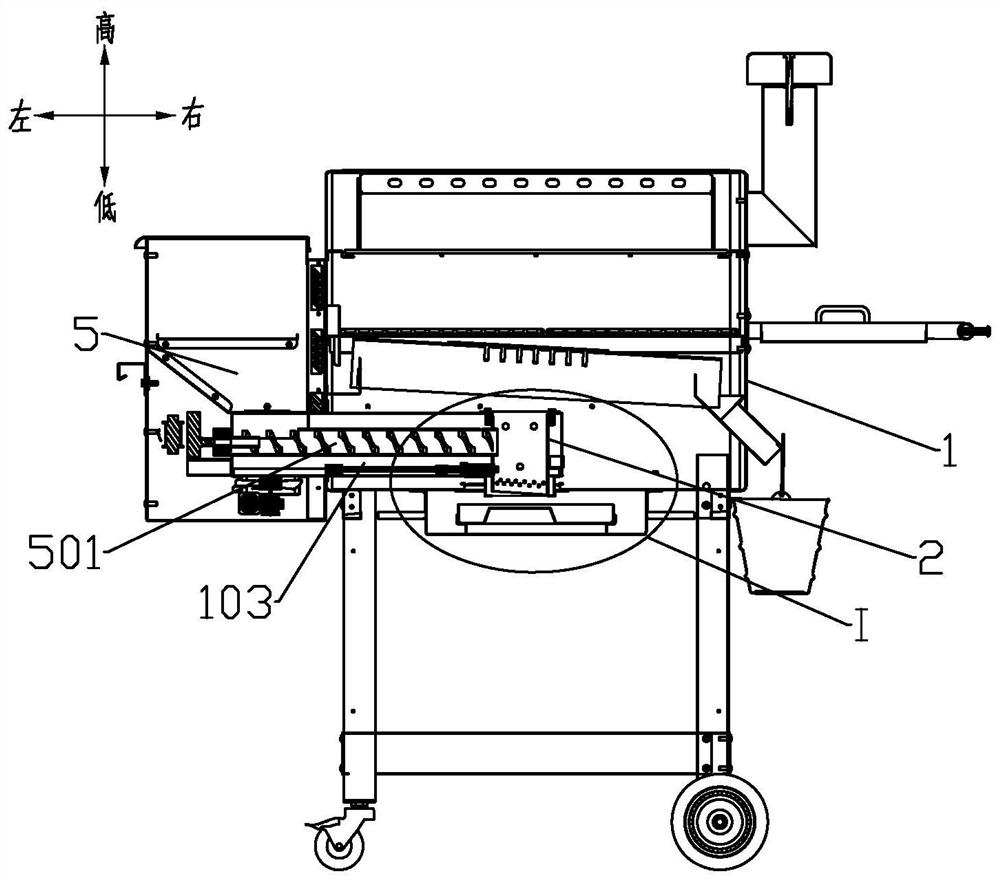

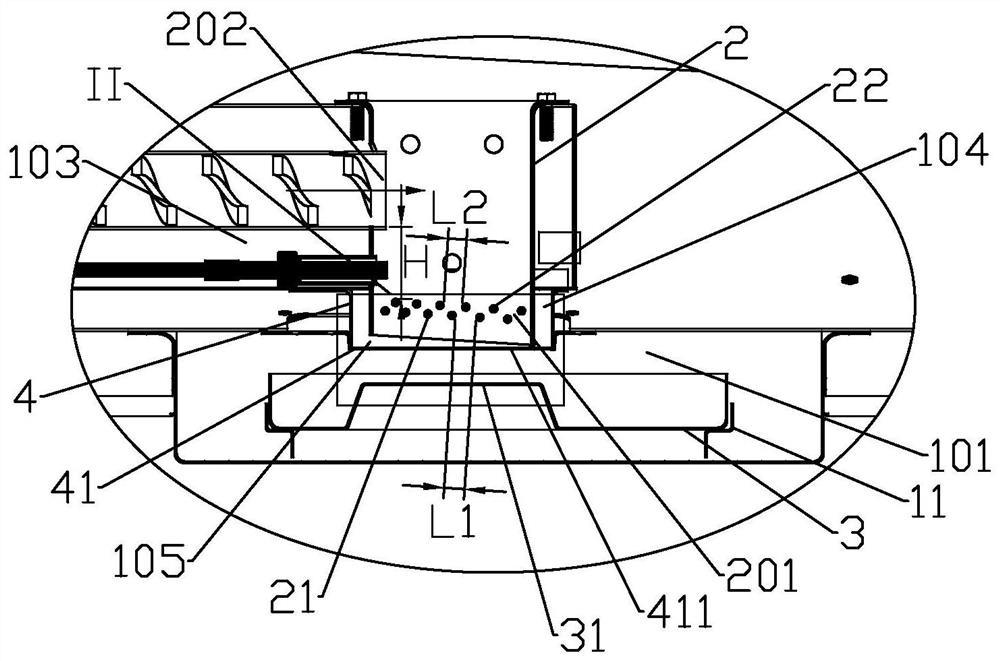

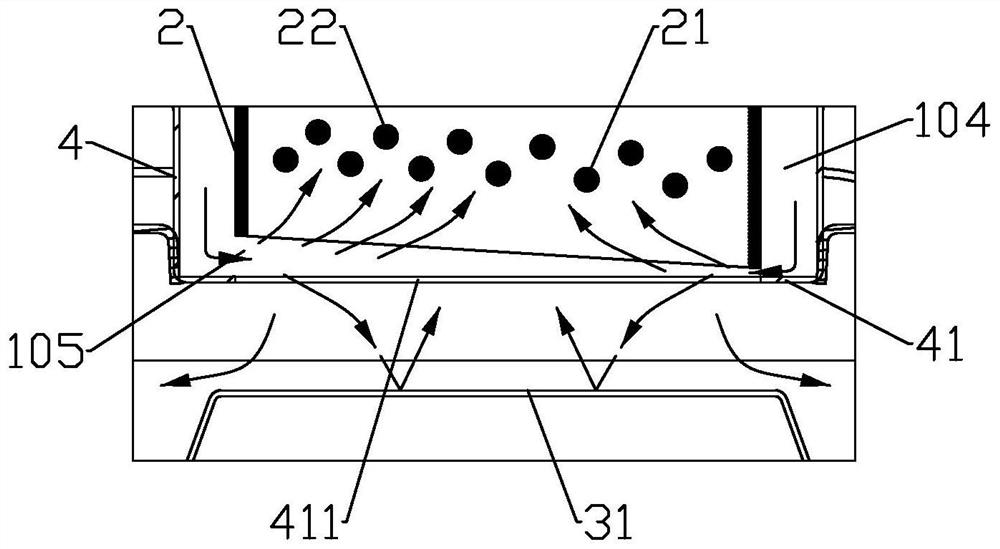

[0032] The present invention provides a particle combustion furnace, such as Figure 1 to Figure 6 As shown, including the body of furnace 1, the body of furnace 1 is provided with a burner 2, the top of the burner 2 is open, the side wall of the burner 2 is provided with a feed port 202, the outside of the body of furnace 1 is provided with a fuel hopper 5, and the fuel A feed channel 501 is provided between the bucket 5 and the feed port 202, and the bottom surface of the burner is provided with a through-hole for air intake and ash fall, and a grid structure supporting the granular fuel 9 is provided above the through-hole, and the grid structure includes The first layer of support 21 and the second layer of support 22 fixed to the burner 2, the first layer of support 21 is lower than the adjacent second layer of support 22, the second layer of support 22 is opposite to the first layer of support 21 are staggered in the vertical direction, and there is a first channel 201 b...

Embodiment 2

[0044] like Figure 7 As shown, the grid structure in this embodiment is formed by wavy sheet metal parts, the wavy troughs on the sheet metal parts form the first layer of support 21, and the wavy peaks on the sheet metal parts form the second layer The supporting body 22 is provided with a through hole forming the first channel 201 between the trough and the crest on the sheet metal part. The outer circumference of the sheet metal part can be adapted to the inner side wall of the burner 2, so there may be no interval mentioned in the first embodiment. In order to prevent ashes from accumulating on the first-layer support body 21, the upper surface of the first-layer support body 21 can be designed as a convex arc surface as much as possible.

[0045] For other content not described in this embodiment, reference may be made to Embodiment 1.

Embodiment 3

[0047] In addition to setting two layers of support, you can also increase the number of layers on this basis, such as Figure 8 As shown, the grid structure also includes a third layer of support 23 fixed to the burner 2, the third layer of support 23 is higher than the second layer of support 22, the gap between the third layer of support 23 and the second layer of support 22 There is a second channel 203 between them, the width W2 of the second channel 203 is smaller than D, and the distance L3 between two adjacent third-layer supports 23 is larger than D and smaller than 2D. It is understandable that according to actual needs, the number of layers of the support body can be increased, and the ash falling effect will be better.

[0048] For other content not described in this embodiment, reference may be made to the foregoing embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com