Particle combustion furnace

A combustion furnace and particle technology, applied in the direction of combustion equipment, combustion methods, solid fuel combustion, etc., can solve the problems of inconvenient use, inconvenience, difficulty in maintaining the primer and extinguishing, and achieve the effect of avoiding backfire and extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

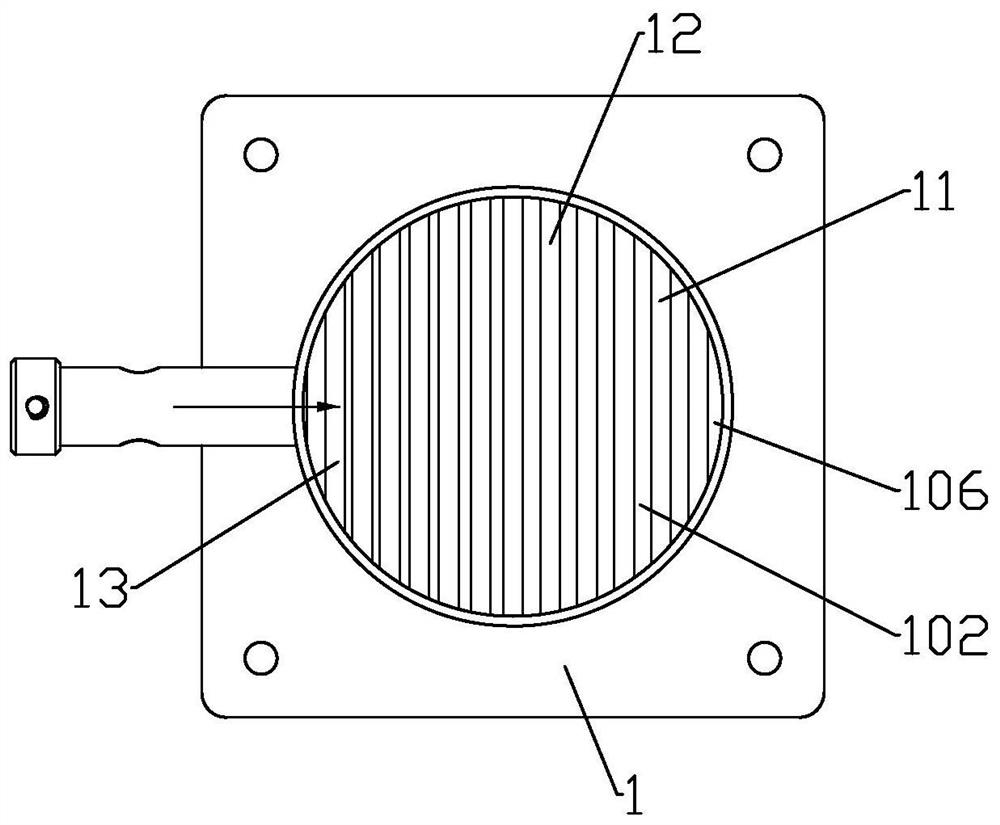

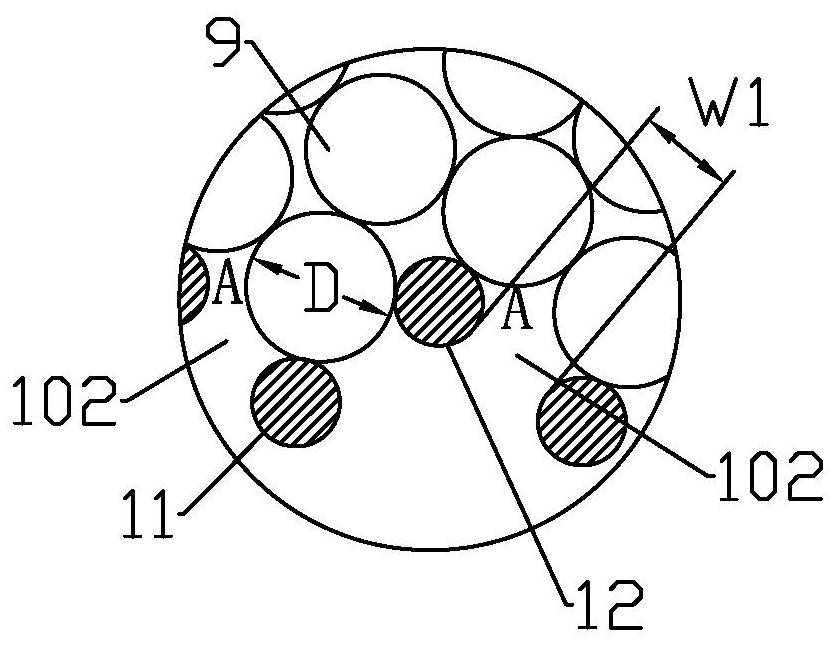

[0025] The invention provides a particle combustion furnace, comprising a furnace body, the furnace body is provided with a burner 1, such as Figure 1 to Figure 3 As shown, the top of the burner 1 is open, the side wall of the burner 1 is provided with a feed port 101, the bottom surface of the burner 1 is provided with a through-hole for air intake and ash fall, and a support particle fuel 9 is provided above the through-hole. The fire grate, the auxiliary support body 13 is provided under the fire grate, the auxiliary support body is higher than the through opening, the auxiliary support body 13 is located on the side below the feed port 101 and the setting range does not exceed 1 / 2 of the area covered by the fire grate, The 1 / 2 here is just an approximate number, so as not to affect the normal ash fall and air intake. The ash falling through the through opening avoids the accumulation of ashes after the combustion of the particulate fuel 9 at the bottom of the burner 1. Un...

Embodiment 2

[0032]In addition to designing the burner 1 into a cylindrical shape, it can also be Figure 4 and Figure 5 The shown design is a hollow prism. Specifically, the burner 1 includes a first side wall 1001 with a feed inlet 101 and a second side wall 1002 and a third side wall 1003 located on both sides of the first side wall 1001. The side wall 1002 and the third side wall 1003 expand to both sides along the feed direction of the feed port to form a figure-eight shape, and the auxiliary support 13 is connected to the bottom of the second side wall 1002 and the third side wall 1003 . The second side wall 1002 and the third side wall 1003 form a figure-eight shape, which can prevent particulate fuel from accumulating below the feed port 101 and is also beneficial to prevent tempering at the feed port 101 .

[0033] In this embodiment, the first layer of support 11 and the second layer of support 12 are parallel to the feeding direction of the feed port 101, and the auxiliary sup...

Embodiment 3

[0036] Such as Figure 6 and Figure 7 See, the body of furnace 2 is provided with a mounting frame 21 for installing the burner 1, and the mounting frame 21 is a cuboid structure. Refer to Figure 4 and Figure 5 , the burner 1 includes a first side wall 1001, a second side wall 1002, a third side wall 1003, a fourth side wall 1004, a fifth side wall 1005 and a sixth side wall 1006, and the feed inlet is located on the first side wall 1001, the second side wall 1002 and the third side wall 1003 are located on both sides of the first side wall 1001, the fourth side wall 1004 is connected to the second side wall 1002, the fifth side wall 1005 is connected to the third side wall 1003, and the sixth The side walls 1006 are respectively connected to the fourth side wall 1004 and the fifth side wall 1005 , and the fourth side wall 1004 , the fifth side wall 1005 and the sixth side wall 1006 are respectively parallel to the opposite side walls of the installation frame 21 . It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com