Combustion system and method for burning biomass black granular fuel

A pellet fuel, biomass black technology, applied in the combustion method, combustion type, combustion equipment, etc., can solve the problems of heating surface corrosion, boiler evaluation and renovation, insufficient combustion, etc., to prevent deflagration accidents, ensure safety, The effect of efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

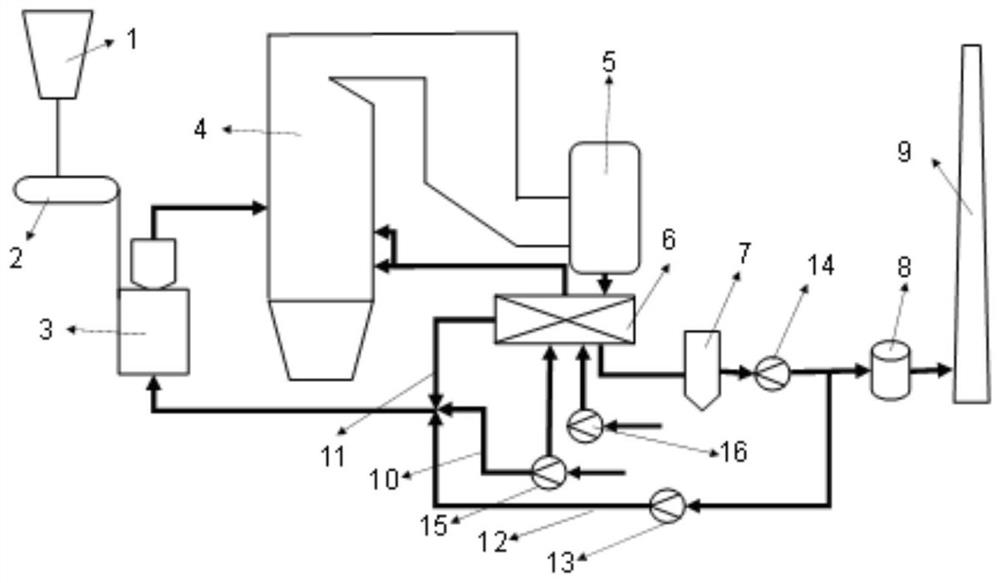

[0023] Such as figure 1 As shown, a combustion system for burning biomass black granular fuel provided by the present invention includes a raw material bin 1, a coal feeder 2, and a coal mill 3 in sequence. The outlet of the coal mill 3 is connected to the boiler body 4, and the boiler body 4. There is a denitrification device 5 at the tail. The outlet of the denitrification device 5 is connected to the flue gas inlet of the air preheater 6. The flue gas outlet of the air preheater 6 is connected to the dust collector 7 and the induced draft fan 14 in turn. The cold air of the air preheater 6 The air inlet is connected to the outlet of the blower 16 and the primary fan 15, and the hot air outlet of the air preheater 6 is divided into two routes, one of which communicates with the boiler body 4, and the other communicates with the coal mill 3 through the hot air pipe 11; the outlet of the primary fan 15 The outlet is also connected to the coal mill 3 through the cold air pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com