Reverse burning type normal-pressure superheated steam furnace

A superheated steam furnace and reverse burning technology, applied in steam boilers, steam superheating, steam generation, etc., can solve the problems of inability to form conjunctiva, high energy consumption for heating and large fuel loss, etc., to reduce the generation of condensed water, The effect of improving heat conversion efficiency and improving heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

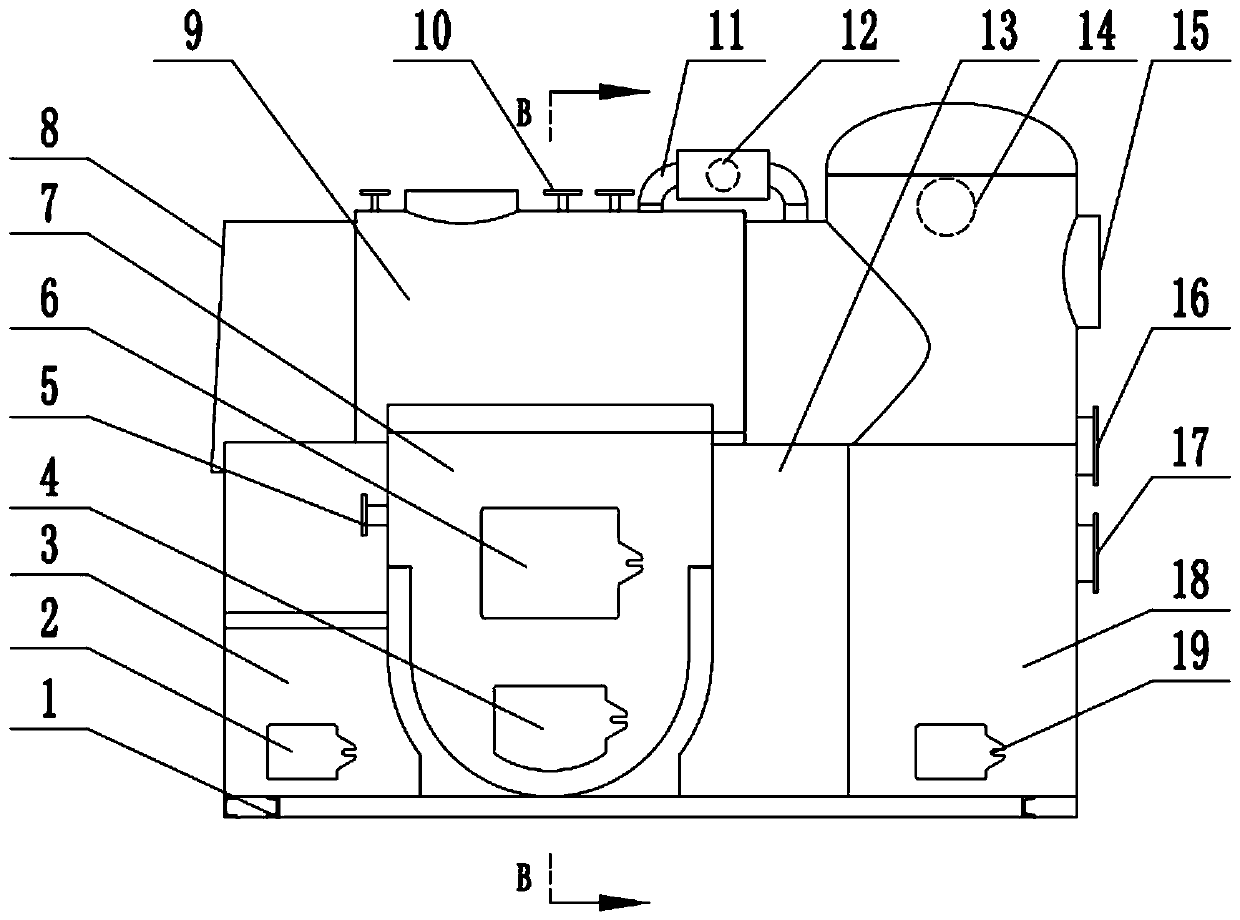

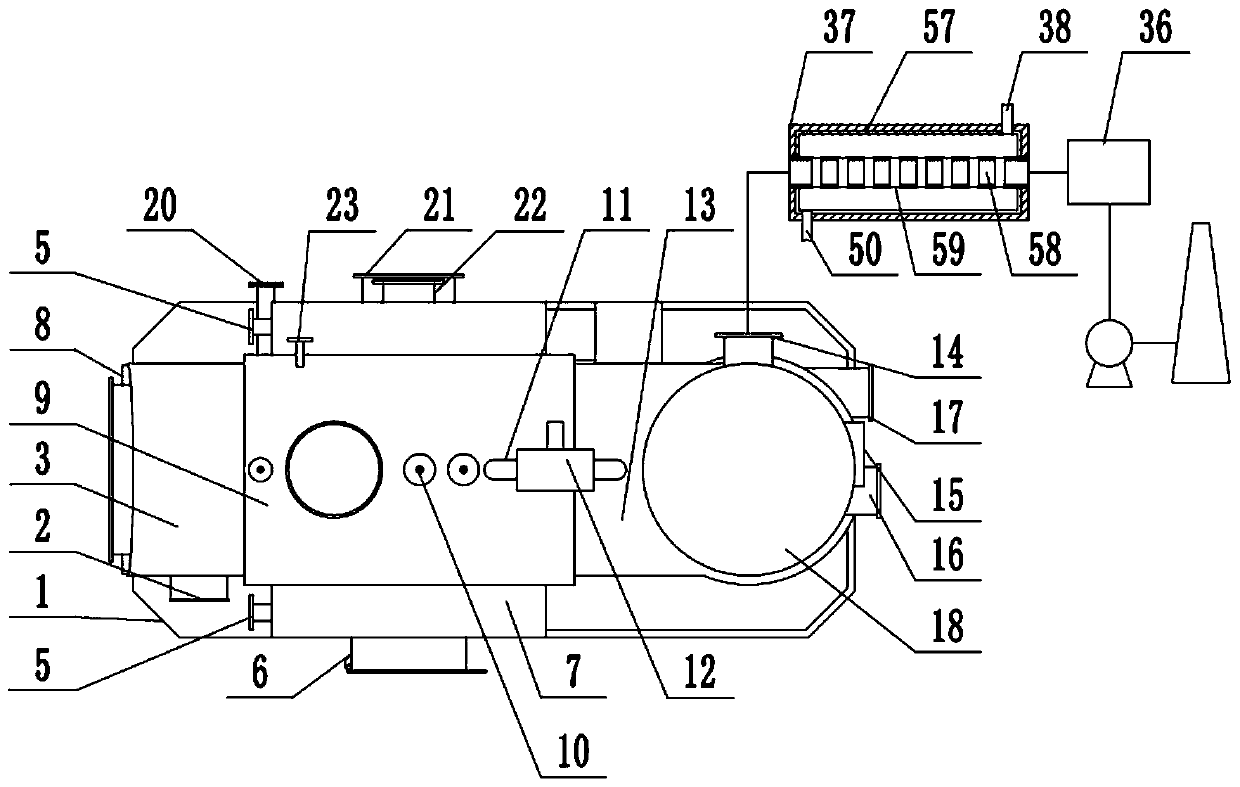

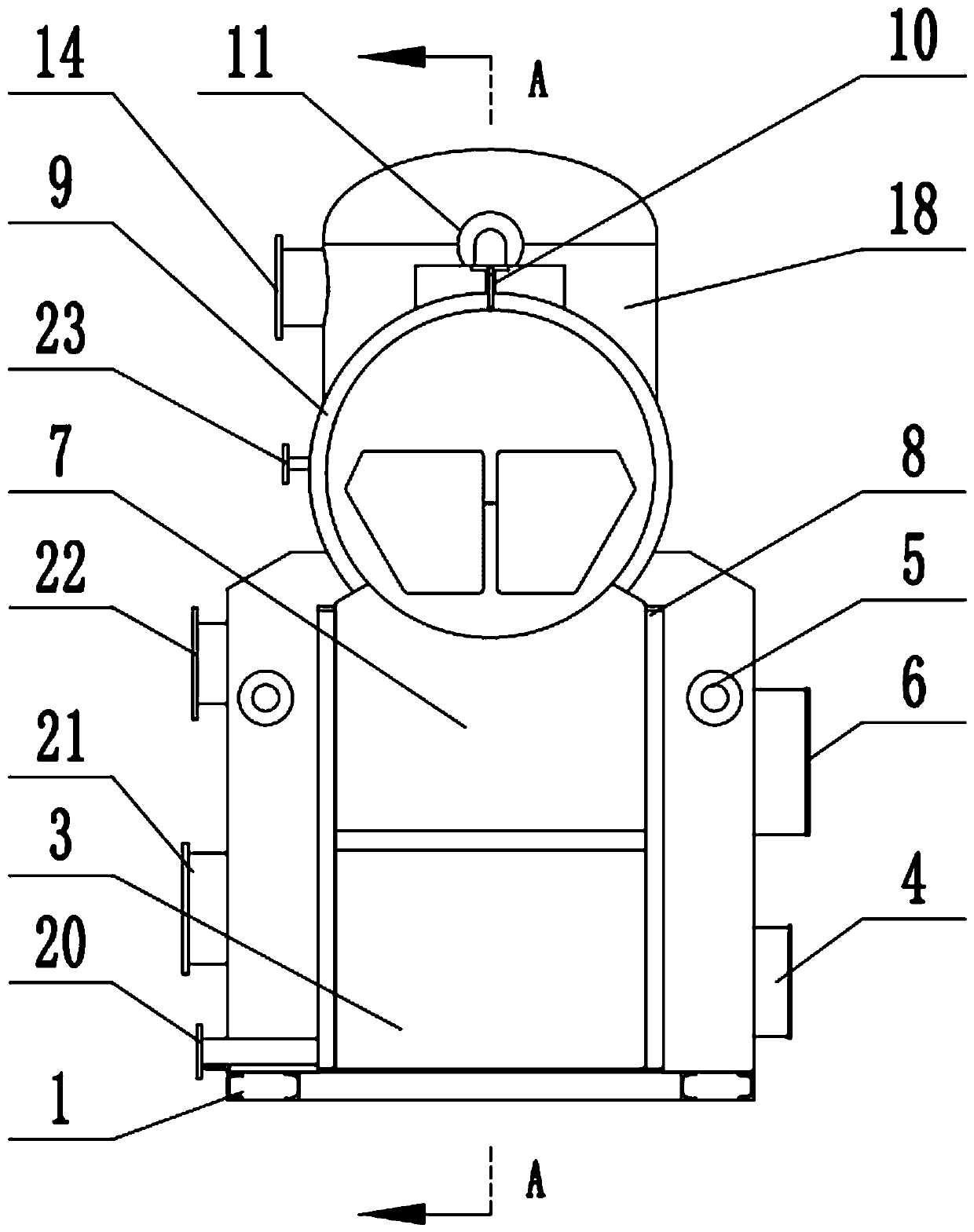

[0051] The reverse-fired atmospheric pressure superheated steam furnace includes a furnace base 1 and a furnace body 8, the furnace body 8 is installed on the furnace base 1; a furnace 7 is arranged inside the furnace body 8, and the furnace walls on both sides of the furnace 7 are provided with a water trap 31; The upper part of the furnace 7 is provided with a steam generator 9, and the steam generator 9 is provided with a pressure relief valve 10 and a water supply port 23; a plurality of water heating pipes 24 are arranged transversely through the steam generator 9; the lower part of the furnace 7 passes through the grate The mounting frame 25 is equipped with a water-cooled fire grate; the water-cooled fire grate is communicated with the interlayer 31, and the interlayer 31 is communicated with the steam generator 9 through the connecting pipe 30; the body of furnace 8 at the front portion of the furnace 7 is provided with an ash discharge port 4 and The furnace door 6; th...

Embodiment 2

[0053] The reverse-fired atmospheric pressure superheated steam furnace includes a furnace base 1 and a furnace body 8, the furnace body 8 is installed on the furnace base 1; a furnace 7 is arranged inside the furnace body 8, and the furnace walls on both sides of the furnace 7 are provided with a water trap 31; The upper part of the furnace 7 is provided with a steam generator 9, and the steam generator 9 is provided with a pressure relief valve 10 and a water supply port 23; a plurality of water heating pipes 24 are arranged transversely through the steam generator 9; the lower part of the furnace 7 passes through the grate The mounting frame 25 is equipped with a water-cooled fire grate; the water-cooled fire grate is communicated with the interlayer 31, and the interlayer 31 is communicated with the steam generator 9 through the connecting pipe 30; the body of furnace 8 at the front portion of the furnace 7 is provided with an ash discharge port 4 and The furnace door 6; th...

Embodiment 3

[0060] The reverse-fired atmospheric pressure superheated steam furnace includes a furnace base 1 and a furnace body 8, the furnace body 8 is installed on the furnace base 1; a furnace 7 is arranged inside the furnace body 8, and the furnace walls on both sides of the furnace 7 are provided with a water trap 31; The upper part of the furnace 7 is provided with a steam generator 9, and the steam generator 9 is provided with a pressure relief valve 10 and a water replenishment port 23; 34 and the partition 62 of the steam generating chamber 61; one end of the steam superheating chamber 34 communicates with the steam generating chamber 61 through the steam outlet 64, and the other end top of the steam superheating chamber 34 is provided with a steam conduit 11; A three-way valve 12 for distributing and transporting steam; a plurality of steam overheating pipes 63 are arranged transversely through the steam overheating chamber 34; a plurality of water heating pipes 24 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com