Purple mixed copper smelting and oxidation-reduction system

A technology of red miscellaneous copper and smelting furnace, which is applied in the field of metal smelting and processing, which can solve the problems of long melting time, high fuel consumption, and lower combustion temperature, and achieve the effects of increasing the amount of excess oxygen, strong practicability, and shortening working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

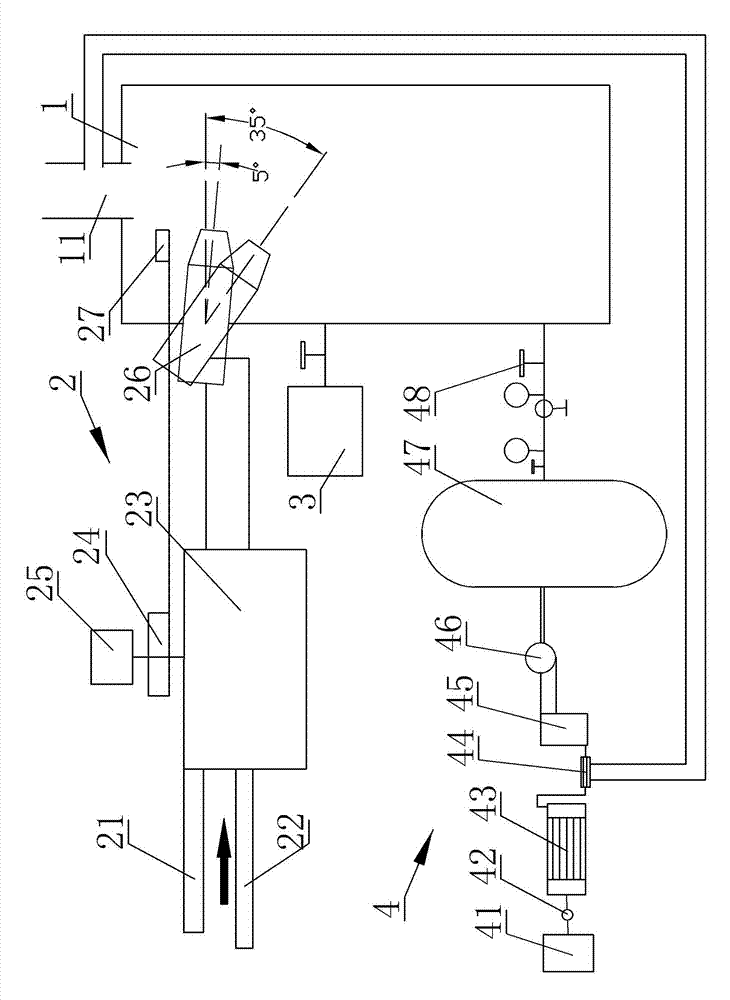

[0018] A copper melting reverberatory furnace with a capacity of 80 tons is used. The burner 26 adopts flaming combustion, and the length of the flame is controlled within 2 to 6 meters. Natural gas and pure oxygen enter through the fuel supply pipeline 21 and the combustion aid supply pipeline 22 respectively. Control valve group 23, the ratio of natural gas and pure oxygen in the control valve group 23 and the gas flow at the gas outlet of the control valve group 23 are controlled by the PLC controller 24, the oxygen is multiplied by 10%, and enters the burner 26, after mixing It is ejected and burned in the reverberatory furnace, and the material is tracked by the material sensor 27, and the driving signal is sent to the PLC controller, and the angle of the burner 26 is automatically adjusted to be between 5° and 35° horizontally, directly hitting the material, and The relevant data is displayed on the computer operation screen 25, the melting time is 6 hours, the slag is fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com