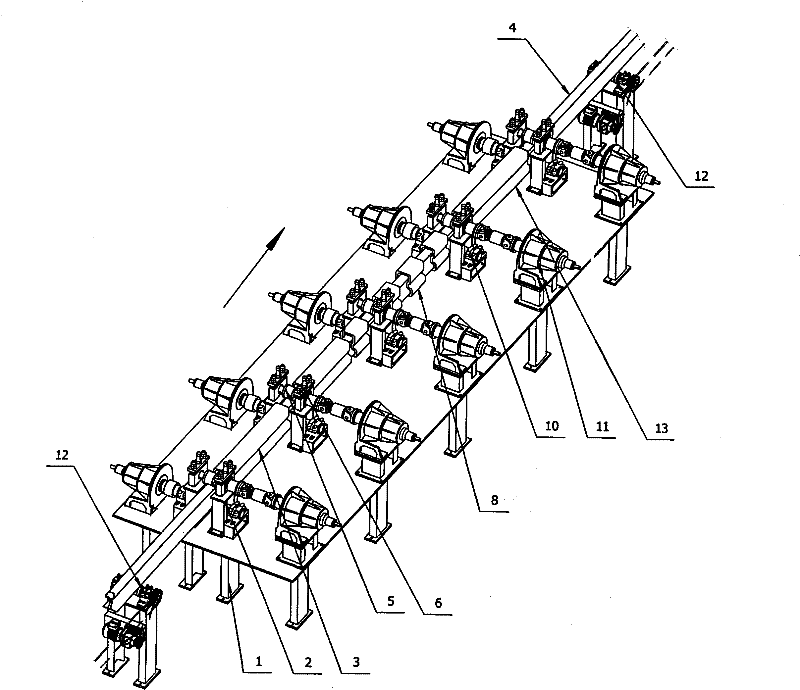

Offline or online integral quenching/tempering thermal treatment production line for standard steel rail and profiled steel rail

A rail and standard technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of difficult to eliminate internal stress, difficult to heat up at the same time, no uniform temperature rise, etc., to achieve fast heating speed, less oxide scale, and uniform heating temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

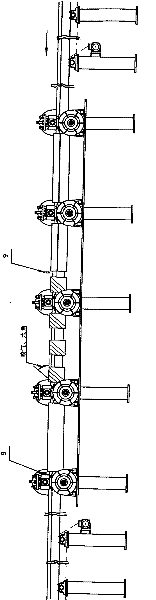

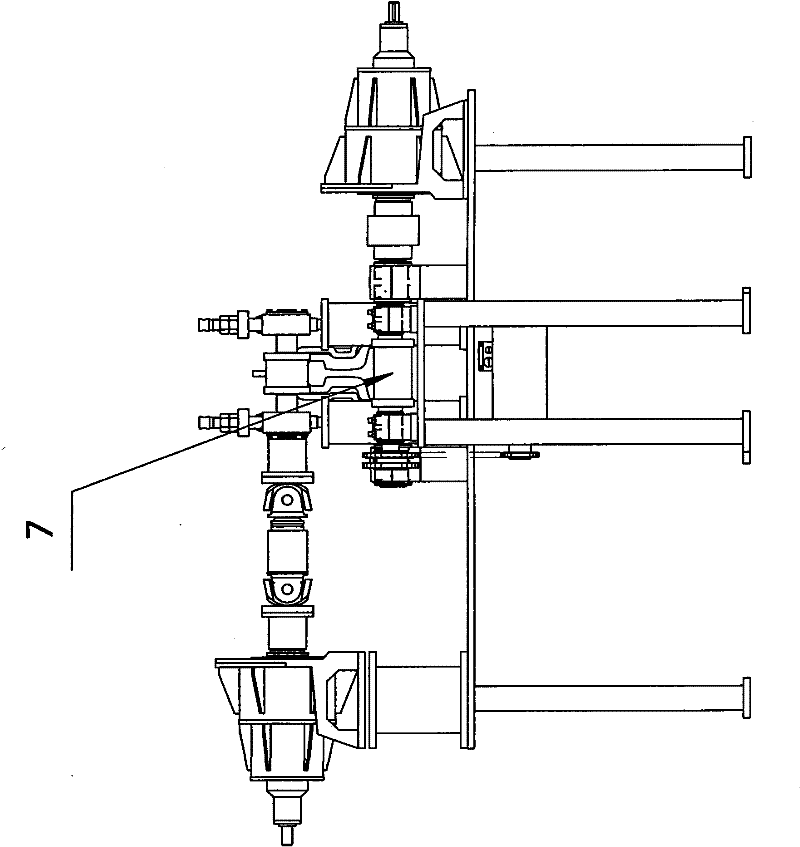

[0010] Referring to the accompanying drawings, its structure includes an underframe 1, an upper pinch roller support frame 2, an electromagnetic induction heater 3, a rail 4, an upper pinch roller 5, an upper pinch roller adjustment device 6, and a lower pinch roller 7. Air and water spray device 8, infrared thermometer 9, bearing housing 10, frequency conversion speed control reducer 11, feeding and unloading drive roller table 12, tempering induction heater 13; among them, the lower pinch roller 7 is installed In the bearing seat 10, the bearing seat 10 is fixed on the base frame 1; one end of the lower pinch roller 7 is equipped with a water-cooled rotary joint, through which the cooling water cools the roller shaft, and the other end is connected with the frequency conversion speed regulating reducer 11 through a coupling; The upper pinch roller adjustment device 6 supports the upper pinch roller 5 and can adjust the height of the upper pinch roller 5. One end of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com