Defogging device and camera module with same

A technology of a defogging device and a camera module, applied in the optical field, can solve the problems of poor defogging effect of the camera module, etc., and achieve the effect of firm and reliable connection position, fast and effective defogging effect, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

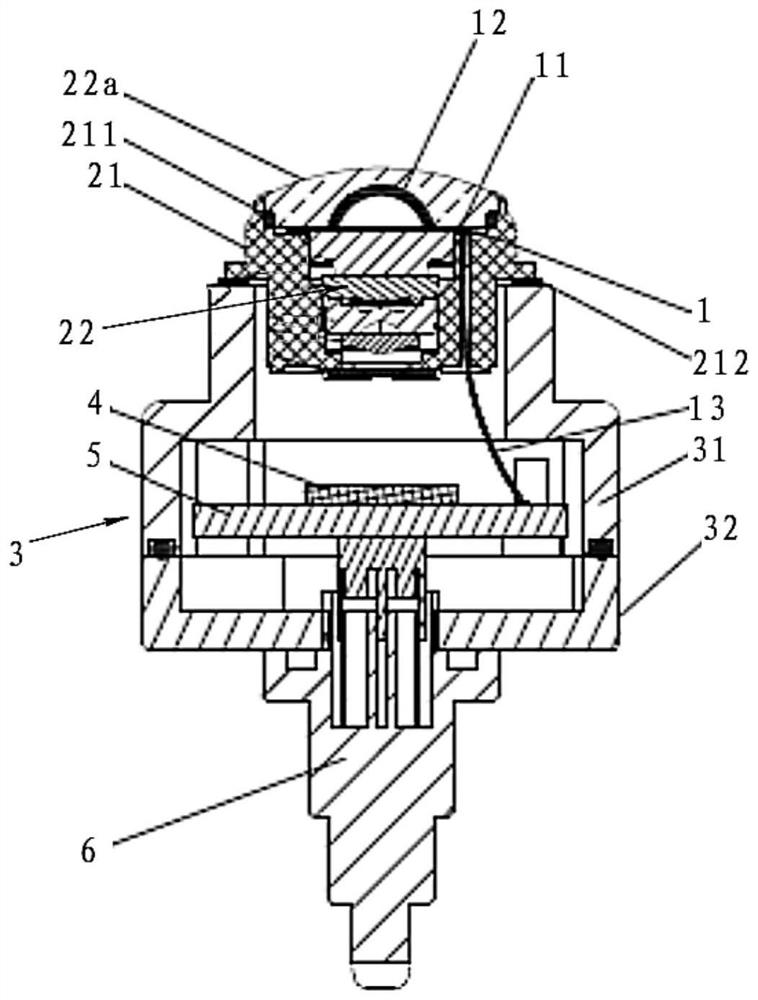

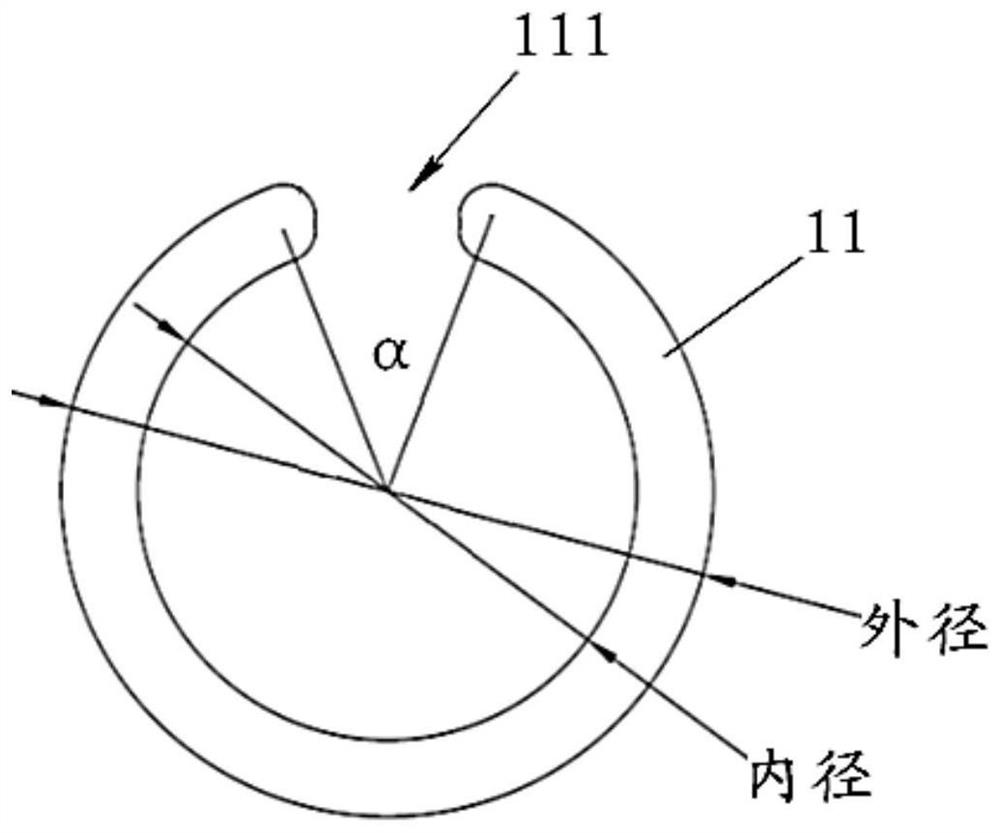

[0038] combine figure 1 with figure 2 As shown, according to an embodiment of the present invention, a defogging device of the present invention includes: a planar heating part 11 in the shape of a planar ring, a curved heating part 12 in the shape of a curved surface, and a conductive connection structure 13 . In this embodiment, the planar heating part 11 is arranged around the curved heating part 12 , and the inner ring edge of the planar heating part 11 is connected to the outer edge of the curved heating part 12 . In this embodiment, the planar heating part 11 and the curved surface heating part 12 are controlled as a whole to achieve synchronous heating effects. In this embodiment, the flat heating part 11 and the curved heating part 12 are connected by coating

[0039] Through the above setting, by adopting the combined heating method of the curved surface heating part in the middle position and the outer heating part in the ring edge, the defogging device of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com