Carbon monoxide gas phase coupling oxalate synthesis catalyst and preparation method and application thereof

A carbon monoxide and catalyst technology, applied in the field of carbon monoxide gas-phase coupling synthesis of oxalate ester catalyst, preparation and application, can solve the problems of low space-time yield of synthetic oxalate ester, low dispersion of active component Pd, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

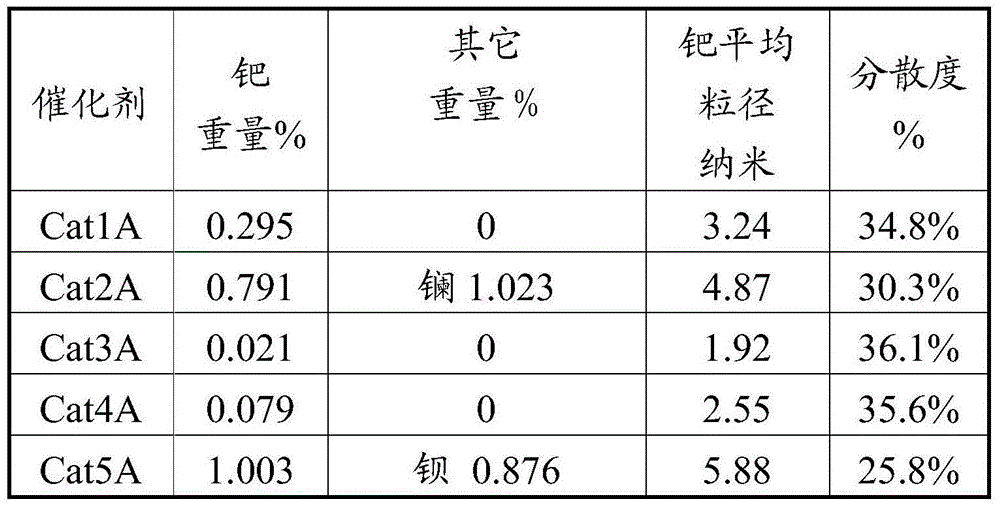

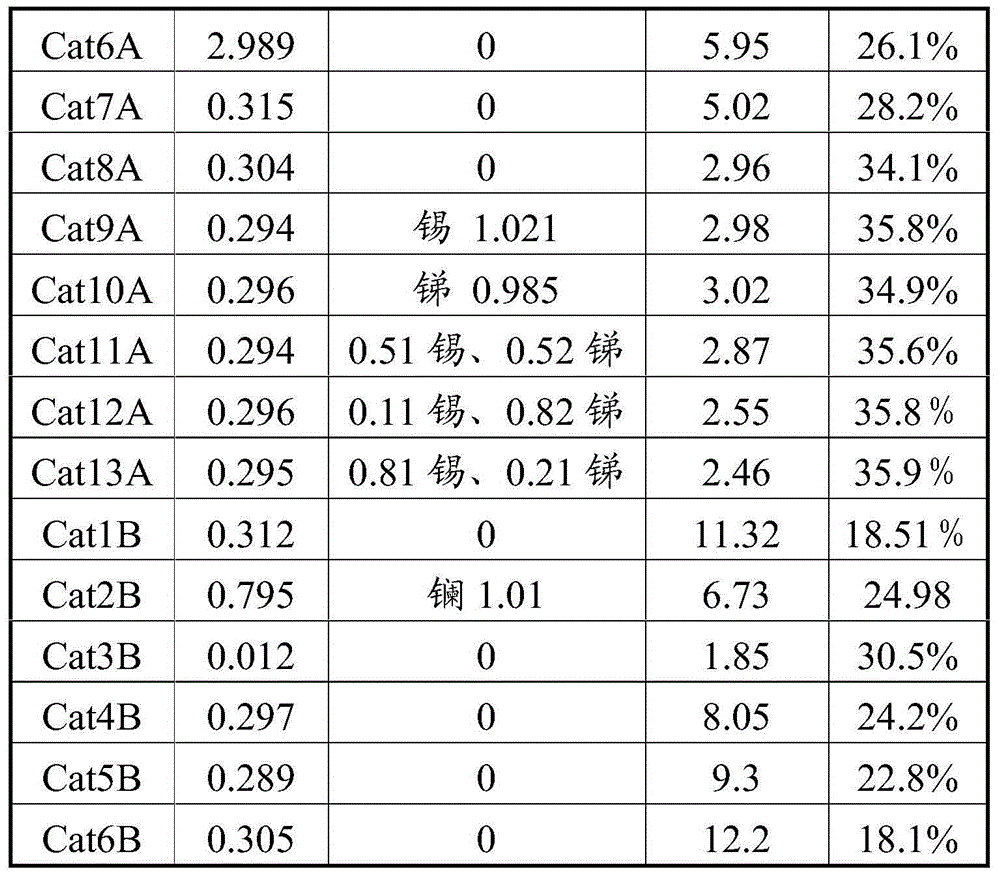

[0033] Take 60g of α-alumina carrier. Dissolve 0.3g of palladium chloride and add sodium carbonate to adjust the pH to 4.0 to obtain impregnation solution I. Slowly add the impregnating solution I into the carrier, and turn the carrier to make the solution impregnate evenly, so as to prepare the catalyst precursor. Pre-freeze the catalyst precursor at -20°C for 3 hours, then vacuum freeze-dry at -10°C and 10Pa for 8 hours, and then put it in a muffle furnace for 4 hours and roast at 450°C to obtain carbon monoxide gas-phase synthesis of oxalate Catalyst cat-1A.

[0034] See Table 1 for the test results of the components, palladium dispersion, and palladium grain average particle size of the analytical test catalyst.

Embodiment 2

[0036] Take 60g of α-alumina carrier. Dissolve 0.8g of palladium chloride and 1.2g of lanthanum nitrate and add sodium carbonate to adjust the pH to 1 to obtain impregnation solution I. Slowly add the impregnating solution I into the carrier, and turn the carrier to make the solution impregnate evenly, so as to prepare the catalyst precursor. Pre-freeze the catalyst precursor at -20°C for 3 hours, then vacuum freeze-dry at -15°C and 15Pa for 8 hours, and then put it in a muffle furnace for 4 hours and roast at 450°C to obtain carbon monoxide gas phase synthesis of oxalate Catalyst cat-2A.

[0037] See Table 1 for the test results of the components, palladium dispersion, and palladium grain average particle size of the analytical test catalyst.

Embodiment 3

[0039]Take 60g of silica carrier. Dissolve 0.02g of palladium chloride and add sodium carbonate to adjust the pH to 5 to obtain impregnation solution I. Slowly add the impregnating solution I into the carrier, and turn the carrier to make the solution impregnate evenly, so as to prepare the catalyst precursor. Pre-freeze the catalyst precursor at -10°C for 10 hours, then vacuum freeze-dry at -10°C and 10Pa for 8 hours, put it in a muffle furnace and bake it at 550°C for 4 hours, and obtain carbon monoxide gas phase synthesis of oxalate after roasting Catalyst cat-3A.

[0040] The test results of the components, palladium dispersion and palladium grain average particle size of the analysis test catalyst are shown in Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com