Polymer supported quaternary ammonium salt ion catalyst as well as preparation method and application thereof

A quaternary ammonium salt ion and polymer technology, which is applied to a polymer-supported quaternary ammonium salt ion catalyst and its preparation and application fields, can solve the problems of poor reusability, harsh reaction conditions, and high preparation costs, and achieve reusable performance. Good, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

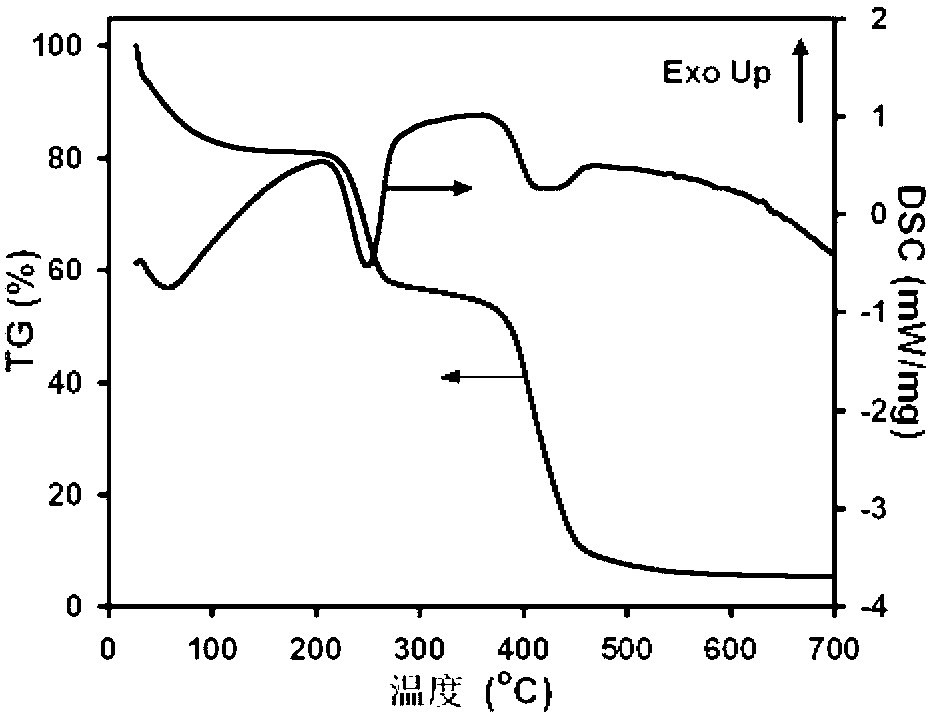

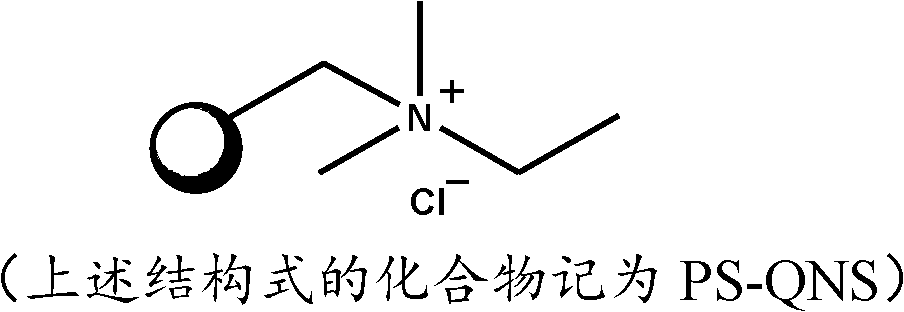

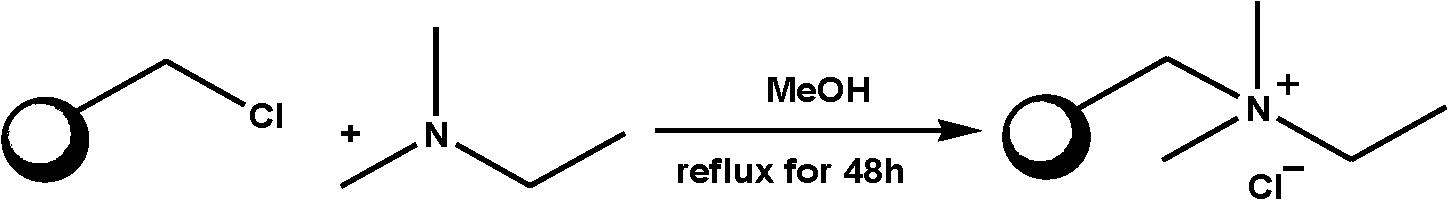

[0028] S1: Mix chlorine balls and N,N-dimethylethylamine at a molar ratio of 1:[1-3], vacuumize, add methanol as a solvent at 5-10 times the molar amount of chlorine balls under the protection of an inert gas, The reaction system was heated to reflux at 60-90°C for 24-48h.

[0029] S2: After the reaction, cool to room temperature, filter, wash with methanol to remove unreacted N,N-dimethylglycine, and dry in vacuum to obtain a light yellow solid, which is the heterogeneous catalyst of quaternary ammonium salt ionic liquid supported by chlorine balls , denoted as PS-QNS.

[0030] Preparation of cyclic carbonates:

Embodiment 2

[0032] Add 0.2 g of polymer-loaded quaternary ammonium salt ion catalyst, 0.2 g of internal standard biphenyl, and 2 mL of propylene oxide in sequence in a 30 mL autoclave. 2 2.0MPa, react in an oil bath reactor with magnetic stirring at 150°C for 3h, after the reaction, place the reactor in a mixture of ice and water, and release the remaining CO after the reactants are cooled. 2 , Take out reactant, get supernatant after centrifugation and carry out GC analysis: the productive rate of propylene carbonate is 98.9%, and selectivity is 99.2%.

Embodiment 3

[0034] Add 0.2 g of polymer-loaded quaternary ammonium salt ion catalyst, 0.2 g of internal standard biphenyl, and 2 mL of propylene oxide in sequence in a 30 mL autoclave. 2 2.6MPa, react in an oil bath reactor with magnetic stirring at 150°C for 3h, after the reaction is completed, place the reactor in a mixture of ice and water, and release the remaining CO after the reactants are cooled. 2 , Take out reactant, get supernatant after centrifugation and carry out GC analysis: the productive rate of propylene carbonate is 96.1%, and selectivity is 99.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com