Drug-loaded structure of titanium metal surface pH controlled-release drug and preparation method of drug-loaded structure

A titanium metal, drug-carrying technology, applied in the field of material science and nanomaterials, can solve the problems of human body influence, the inability of antibiotics to intelligently controlled release, etc., to achieve the effect of less resource consumption, less difficulty in implementation, and improved antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A drug-loaded structure with pH-controlled drug release on the surface of titanium metal and a preparation method thereof, characterized in that it comprises the following steps:

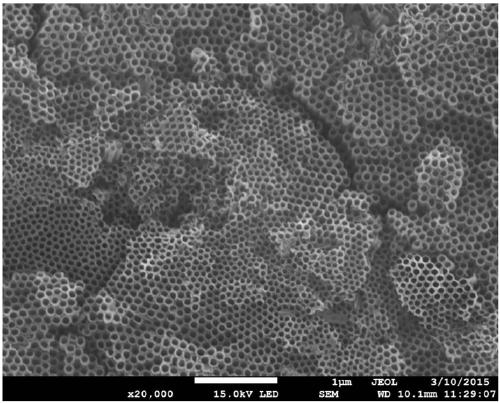

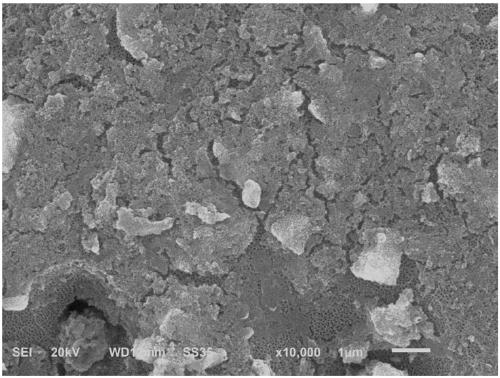

[0026] Step 1: After grinding the titanium metal with a diameter of 5.5-6.5mm and a thickness of 2.0-3.0mm with sandpaper step by step, then ultrasonically clean it in acetone, deionized water, and absolute ethanol in sequence, and perform anodic oxidation treatment after drying to prepare titanium dioxide nanotubes ;

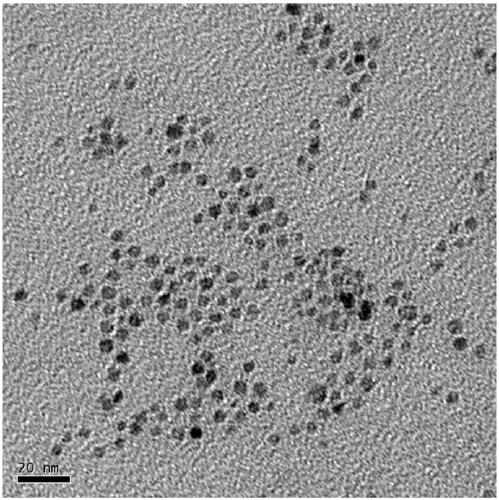

[0027] Step 2: Disperse 100 mg of zinc oxide quantum dots in dimethylformamide, add 20 mL of 3-aminopropyltriethoxysilane, and stir at 90° C. for 15 minutes to obtain a mixture containing aminated zinc oxide quantum dots; 1 mg of folic acid was dissolved in 0.5 mL of dimethyl sulfoxide, 1 mg of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride was added and stirred for 30 min to obtain a mixed solution, and the mixed The solution was added to the mixture containing z...

Embodiment 2

[0033] A drug-loaded structure with pH-controlled drug release on the surface of titanium metal and a preparation method thereof, characterized in that it comprises the following steps:

[0034] Step 1: After grinding the titanium metal with a diameter of 5.5-6.5mm and a thickness of 2.0-3.0mm with sandpaper step by step, then ultrasonically clean it in acetone, deionized water, and absolute ethanol in sequence, and perform anodic oxidation treatment after drying to prepare titanium dioxide nanotubes ;

[0035] Step 2: Disperse 100 mg of zinc oxide quantum dots in dimethylformamide, add 20 mL of 3-aminopropyltriethoxysilane, and stir at 90° C. for 15 minutes to obtain a mixture containing aminated zinc oxide quantum dots; 2 mg of folic acid was dissolved in 0.5 mL of dimethyl sulfoxide, 1 mg of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride was added and stirred for 30 min to obtain a mixed solution, and the mixed The solution was added to the mixture containing z...

Embodiment 3

[0041] A drug-loaded structure with pH-controlled drug release on the surface of titanium metal and a preparation method thereof, characterized in that it comprises the following steps:

[0042] Step 1: After grinding the titanium metal with a diameter of 5.5-6.5mm and a thickness of 2.0-3.0mm with sandpaper step by step, then ultrasonically clean it in acetone, deionized water, and absolute ethanol in sequence, and perform anodic oxidation treatment after drying to prepare titanium dioxide nanotubes ;

[0043] Step 2: Disperse 100 mg of zinc oxide quantum dots in dimethylformamide, add 20 mL of 3-aminopropyltriethoxysilane, and stir at 90° C. for 15 minutes to obtain a mixture containing aminated zinc oxide quantum dots; The folic acid of 5mg is dissolved in the dimethylsulfoxide of 0.5mL, the 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride of 1mg is added and stirred for 30min to obtain a mixed solution, and the mixed The solution was added to the mixture contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com