Ammonium ion sieve, its preparation method and application

An ammonium ion, ion sieve technology, applied in inorganic cation exchangers, ion-exchanged water/sewage treatment, crystalline aluminosilicate zeolite, etc., can solve the problems of complex process, high cost, low efficiency, etc., and achieve the preparation method. Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

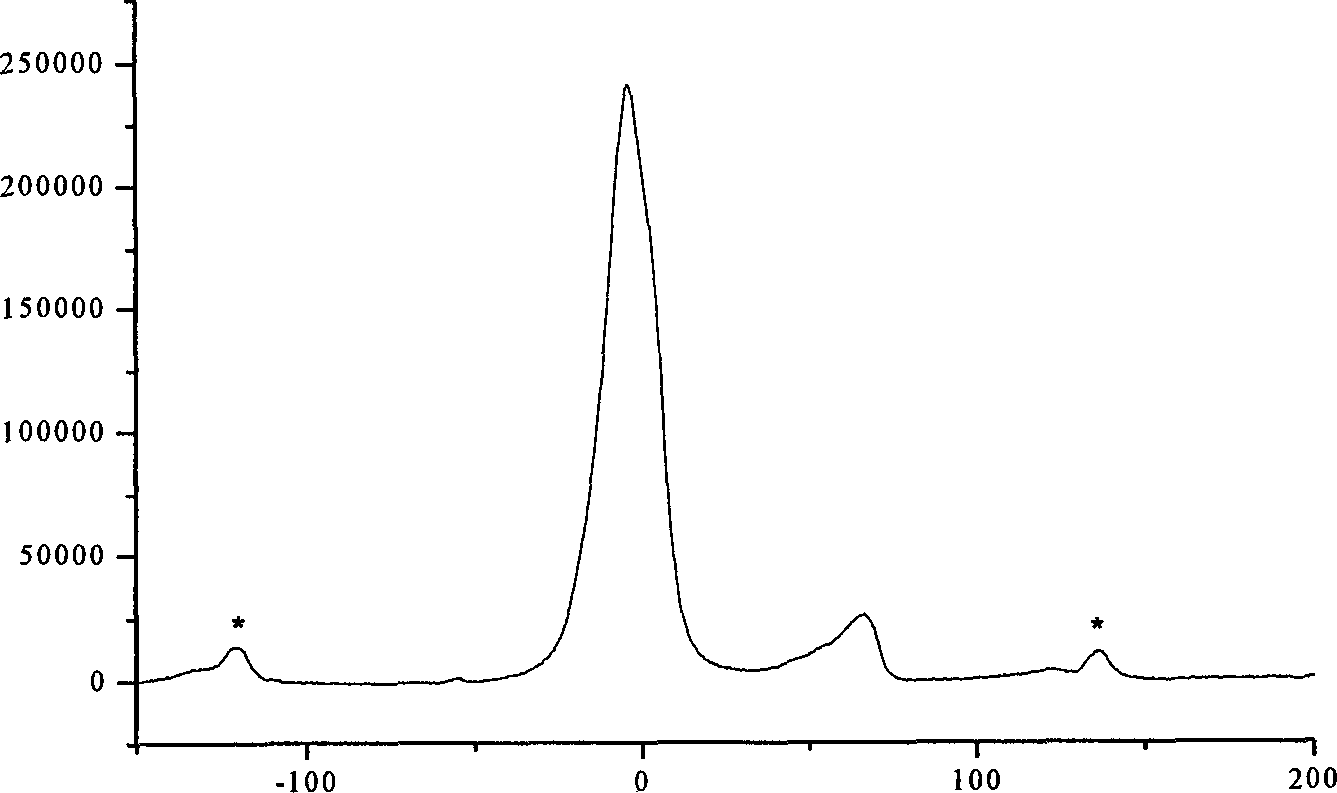

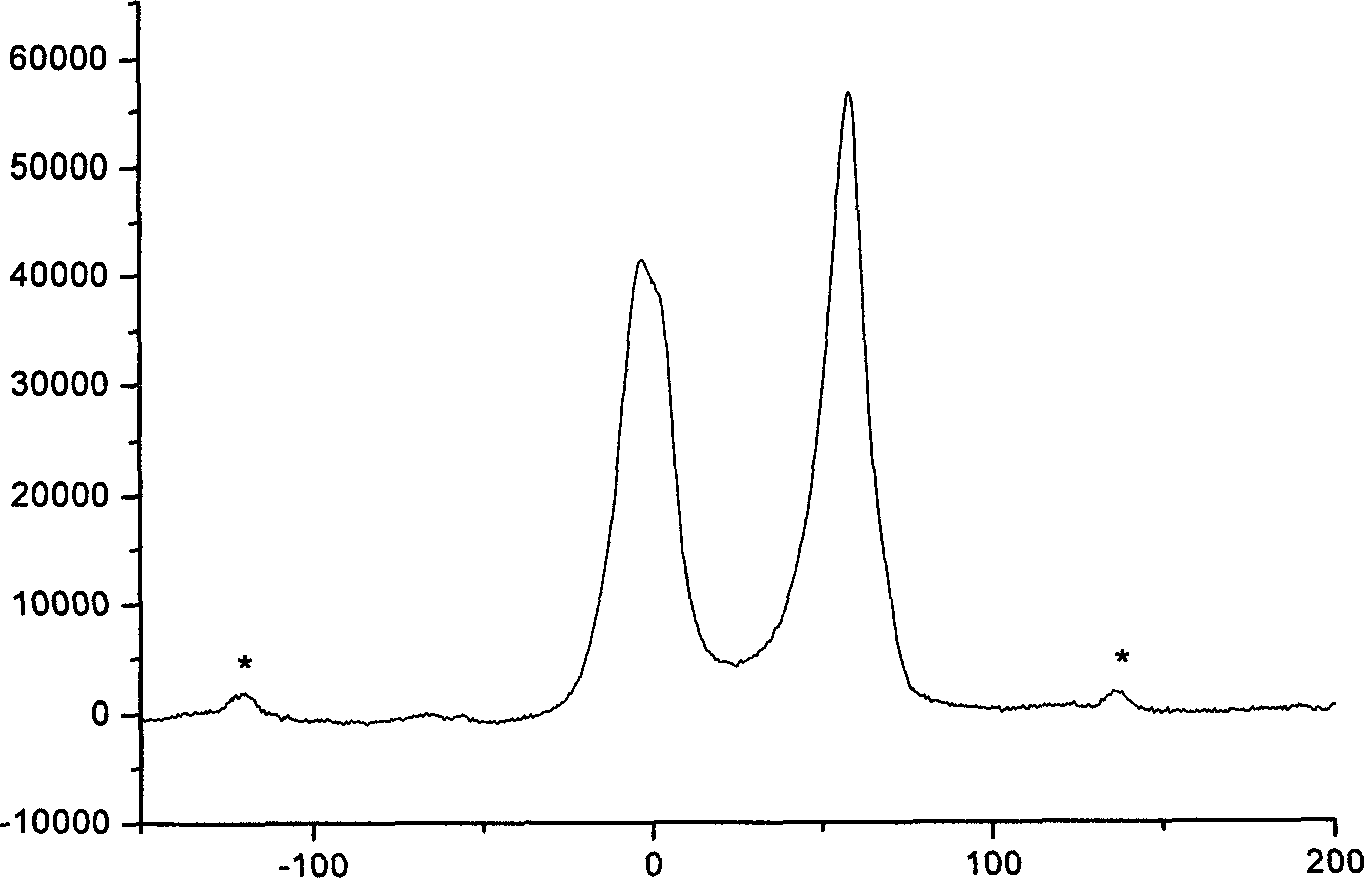

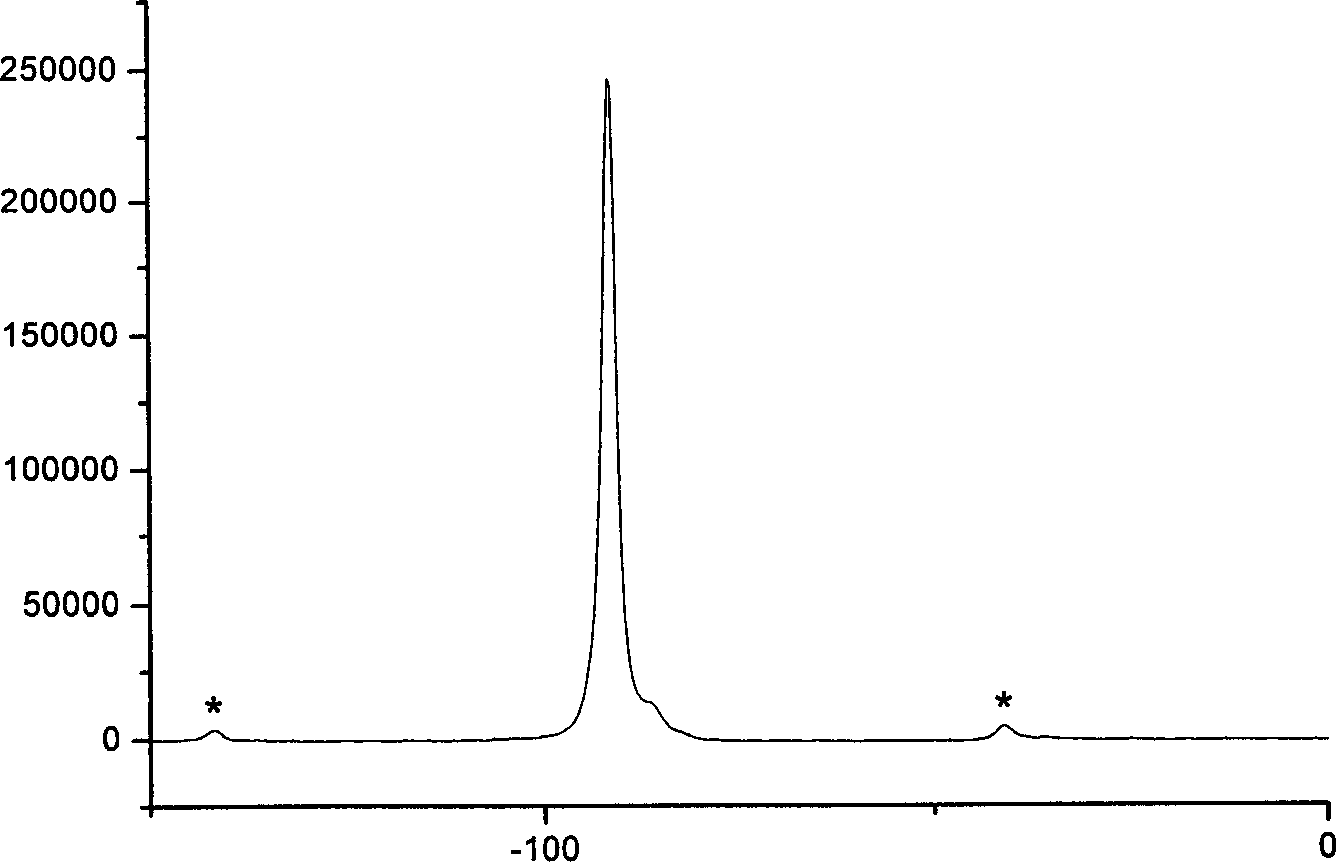

Image

Examples

Embodiment 1

[0029] The original kaolin soil was crushed, ground, and sieved to 200 mesh for later use. The sieved kaolin was pretreated at 300°C for 2 hours to be activated, and the activated kaolin was mixed with NaOH and distilled water at a mass ratio of 4:1:5, put into a muffle furnace and heated at 300°C for 2.5 hours, and taken out After cooling, soak and wash with distilled water several times, the pH value of the solid surface is 8, dry at 75°C for 2 hours, and pulverize to obtain a light yellow high-performance ammonium ion sieve powder with an ammonium ion exchange capacity of 61.2mg NH 4 + _N / g ion sieve.

Embodiment 2

[0031] The original kaolin soil was crushed, ground, and sieved to 100 mesh for later use. The sieved kaolin is pretreated at 150°C for 5 hours to be activated, the activated kaolin is mixed with NaOH and distilled water at a ratio of 1:1:1.25, put into a muffle furnace and heated at 500°C for 10 hours, take out and cool After soaking and washing with distilled water for many times, the pH value of the solid surface is 9, drying at 80°C for 4 hours, and pulverizing to obtain a light yellow high-performance ammonium ion sieve powder with an ammonium ion exchange capacity of 65.2mg NH 4 + _N / g ion sieve.

Embodiment 3

[0033] The original kaolin soil was crushed, ground, and sieved to 200 mesh for later use. The sieved kaolin is pretreated at 300°C for 20 hours to be activated, the activated kaolin is mixed with KOH and distilled water at a ratio of 10:1:5, put into a muffle furnace and heated at 300°C for 13 hours, take out and cool After soaking and washing with distilled water for several times, the pH value of the solid surface is 9, drying at 75°C for 2 hours, and pulverizing to obtain a light yellow high-performance ammonium ion sieve powder with an ammonium ion exchange capacity of 60.7mg NH 4 + _N / g ion sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com