Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

590 results about "Green house gas emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

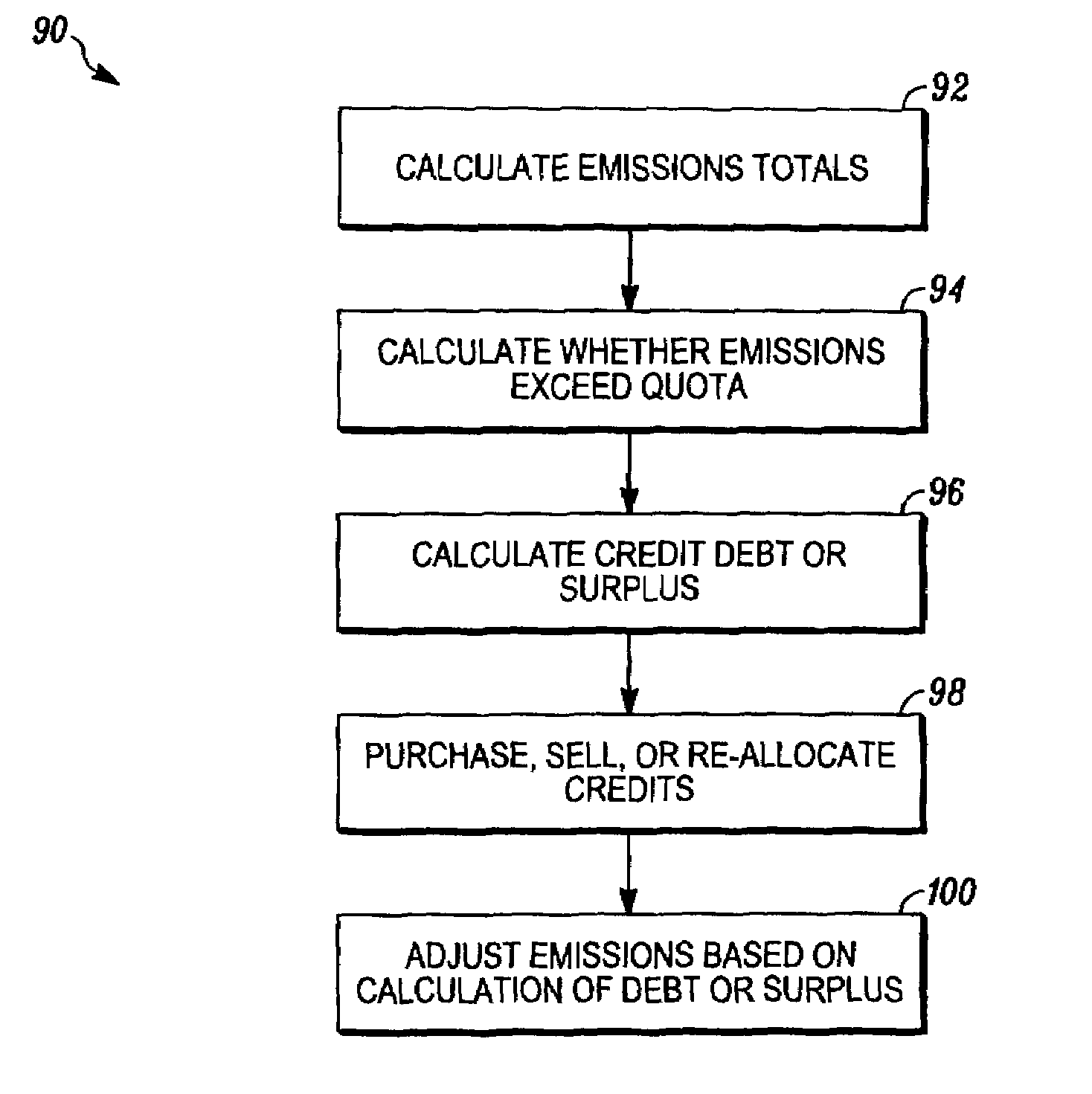

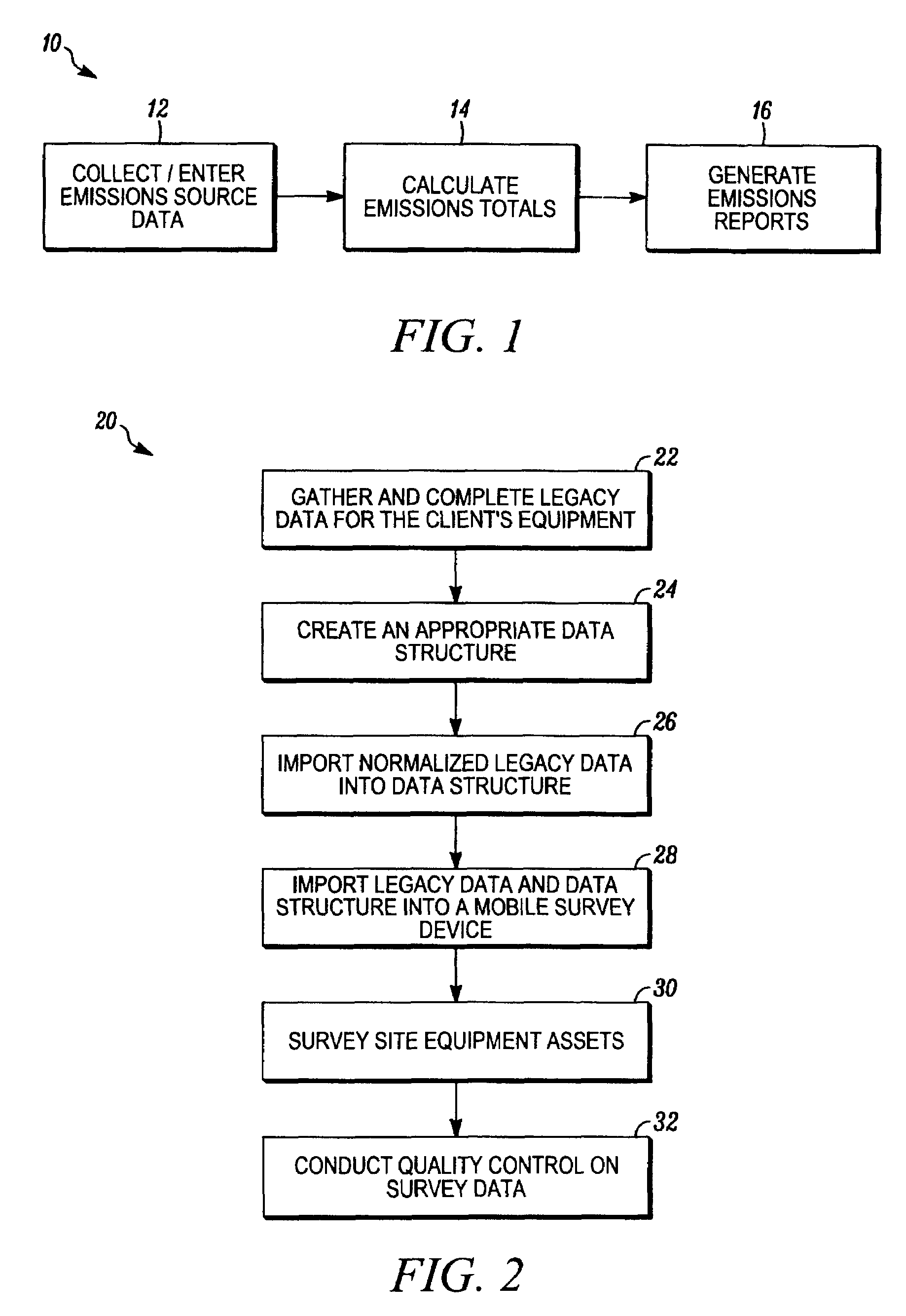

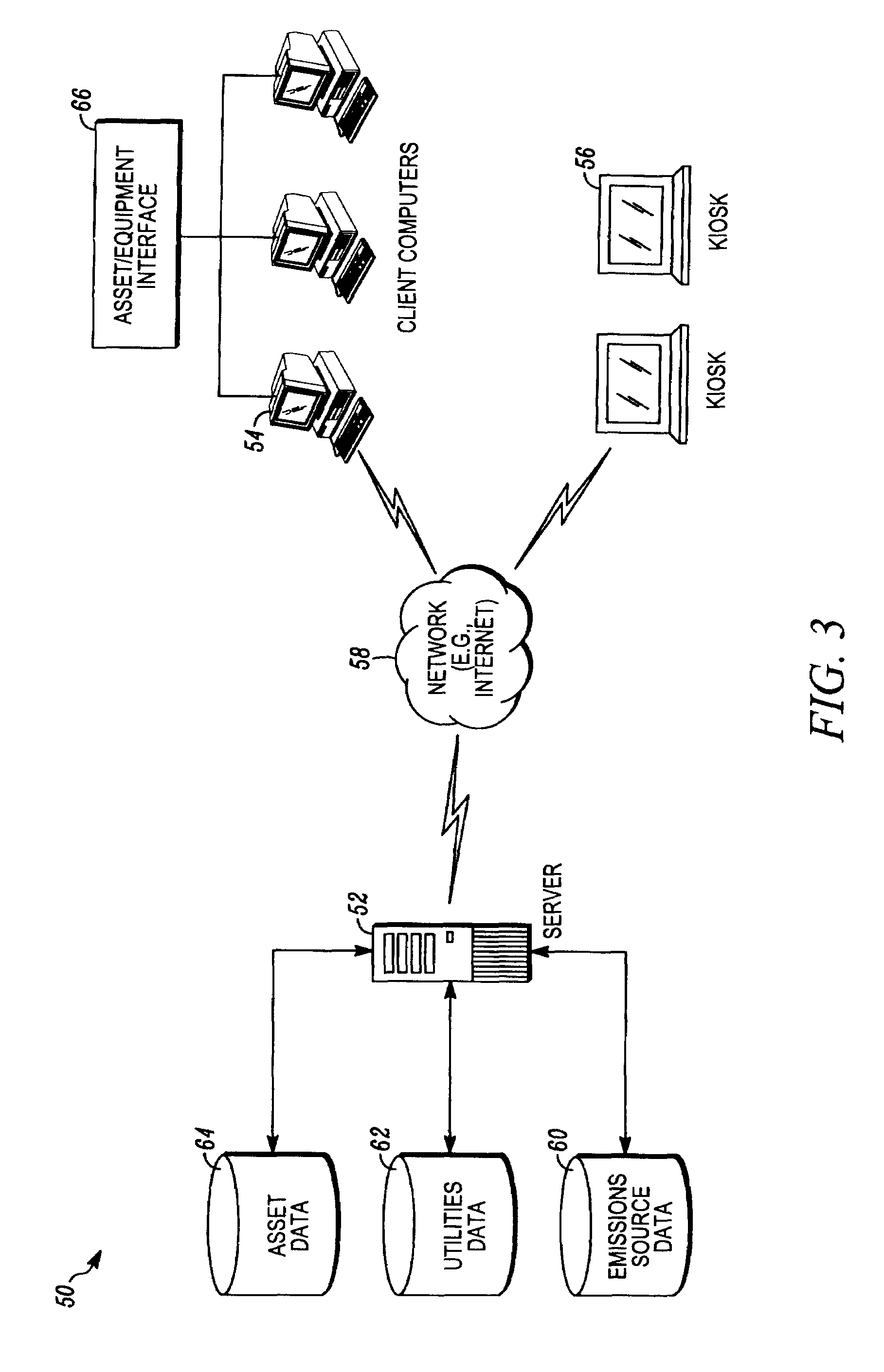

Method and system for tracking and reporting emissions

The present invention relates to methods and systems of tracking enterprise gas emissions such as greenhouse gas emissions. The systems and methods relate to collecting or entering data relating to one or more emissions source of an enterprise or an enterprise location, calculating emissions totals, and, according to certain embodiments, generating emissions reports.

Owner:VERISAE

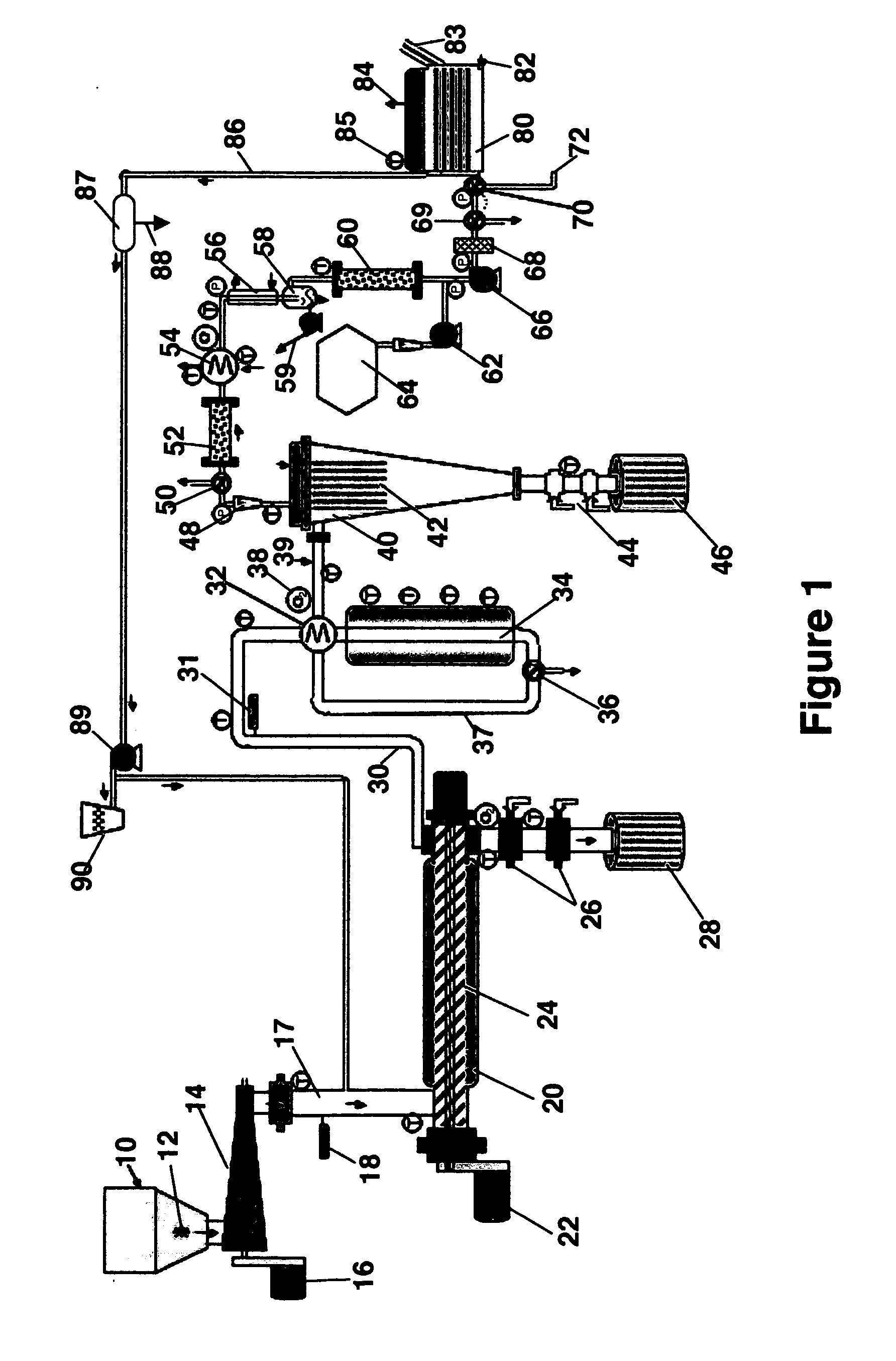

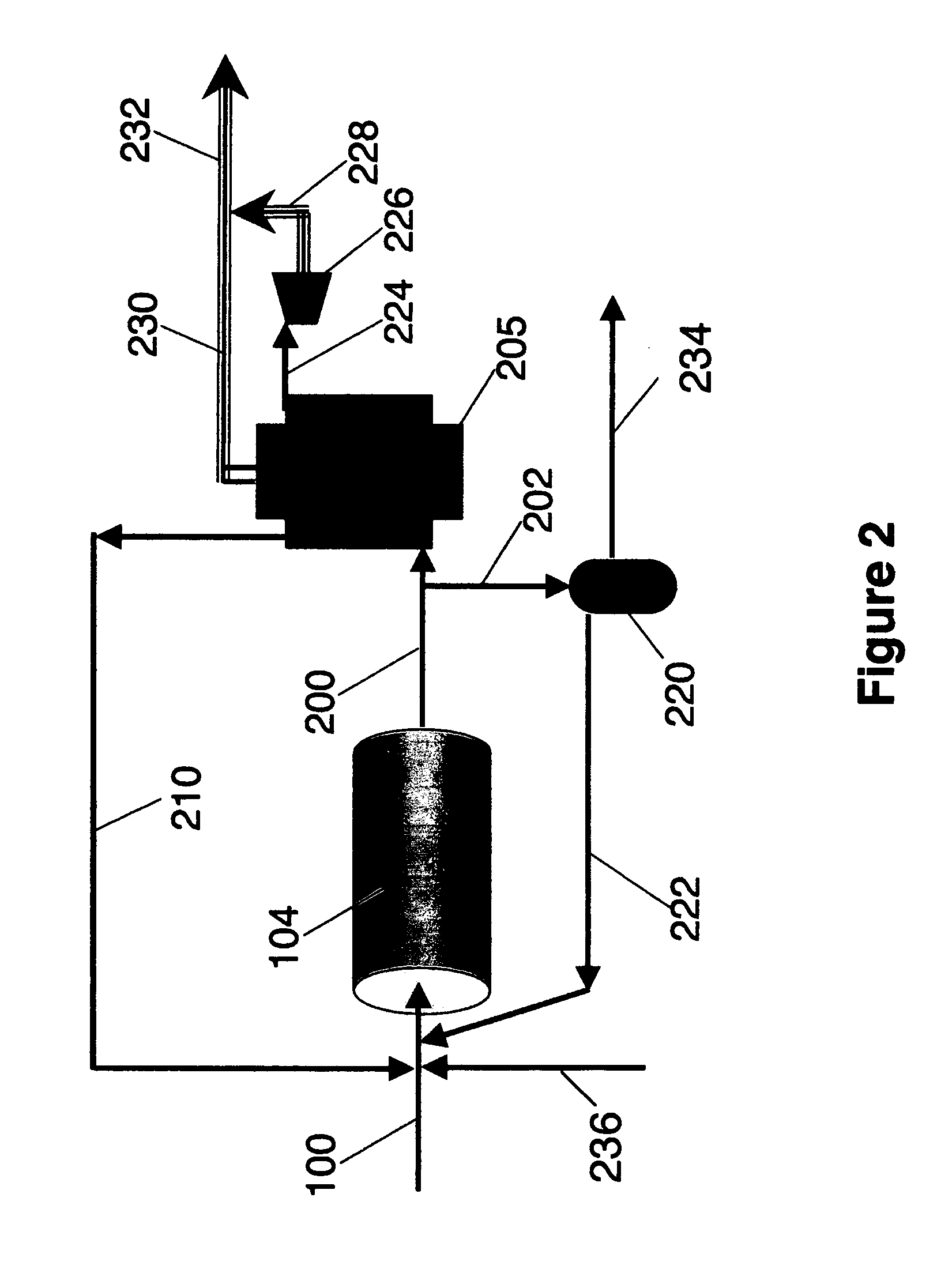

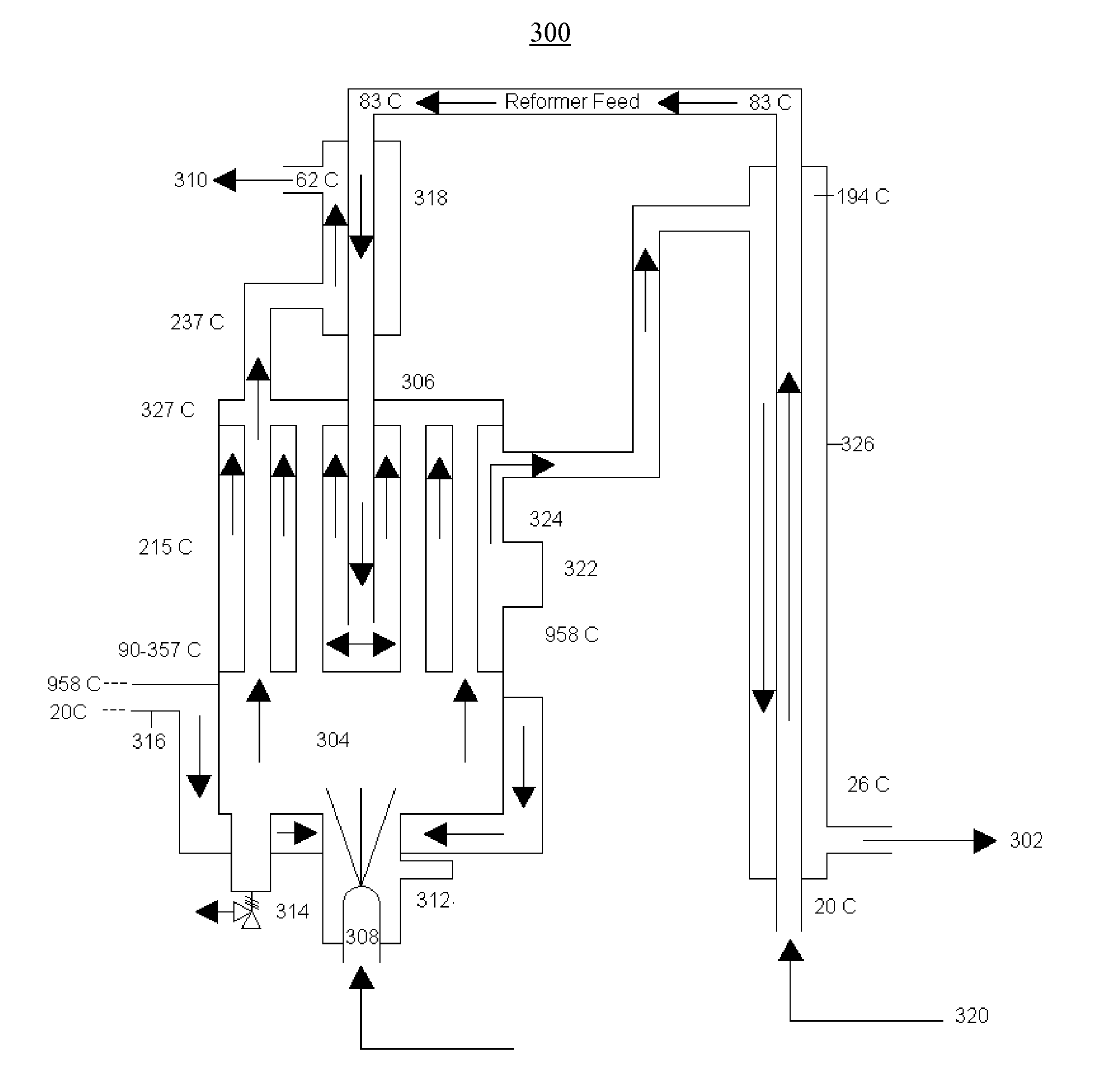

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

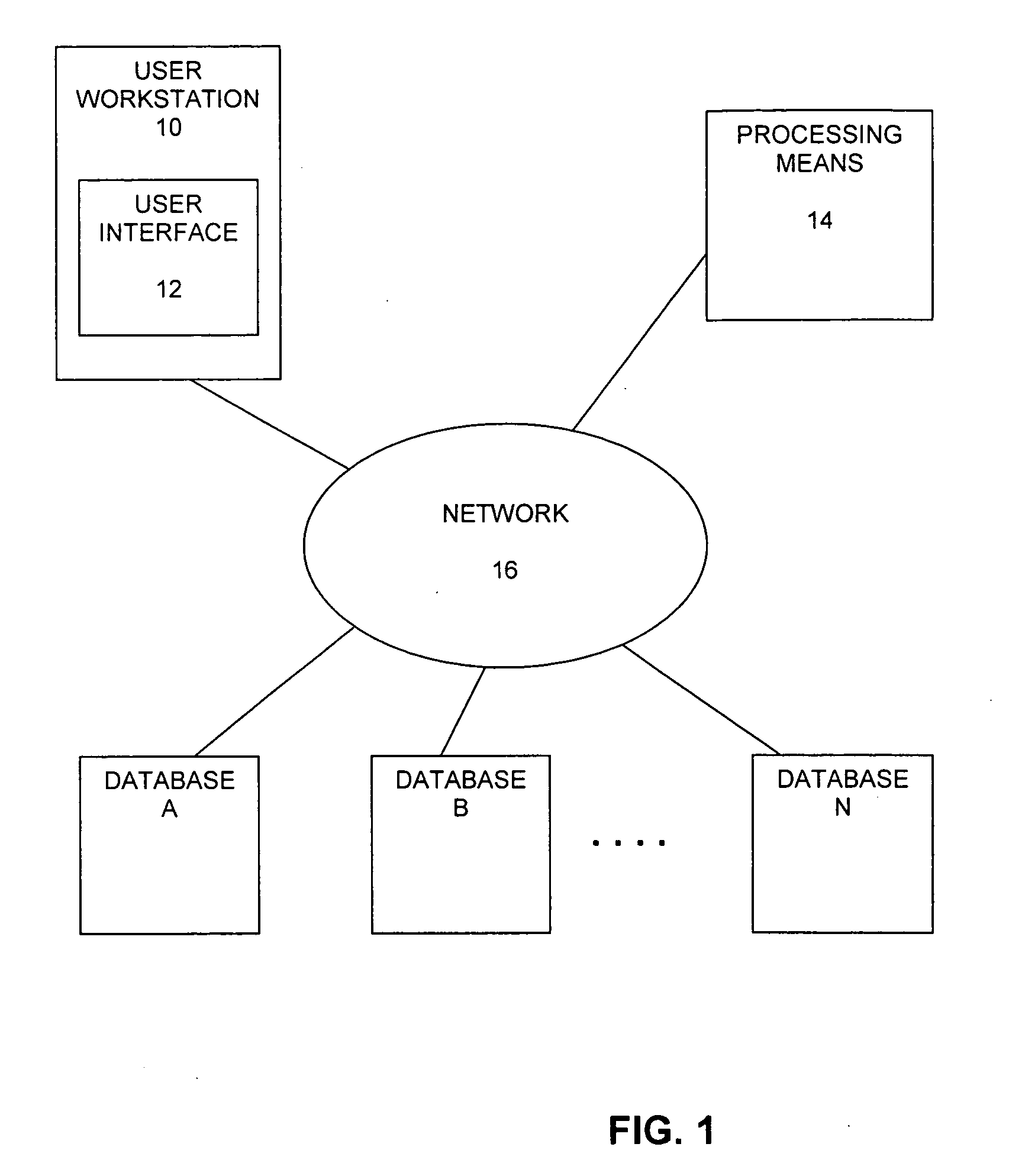

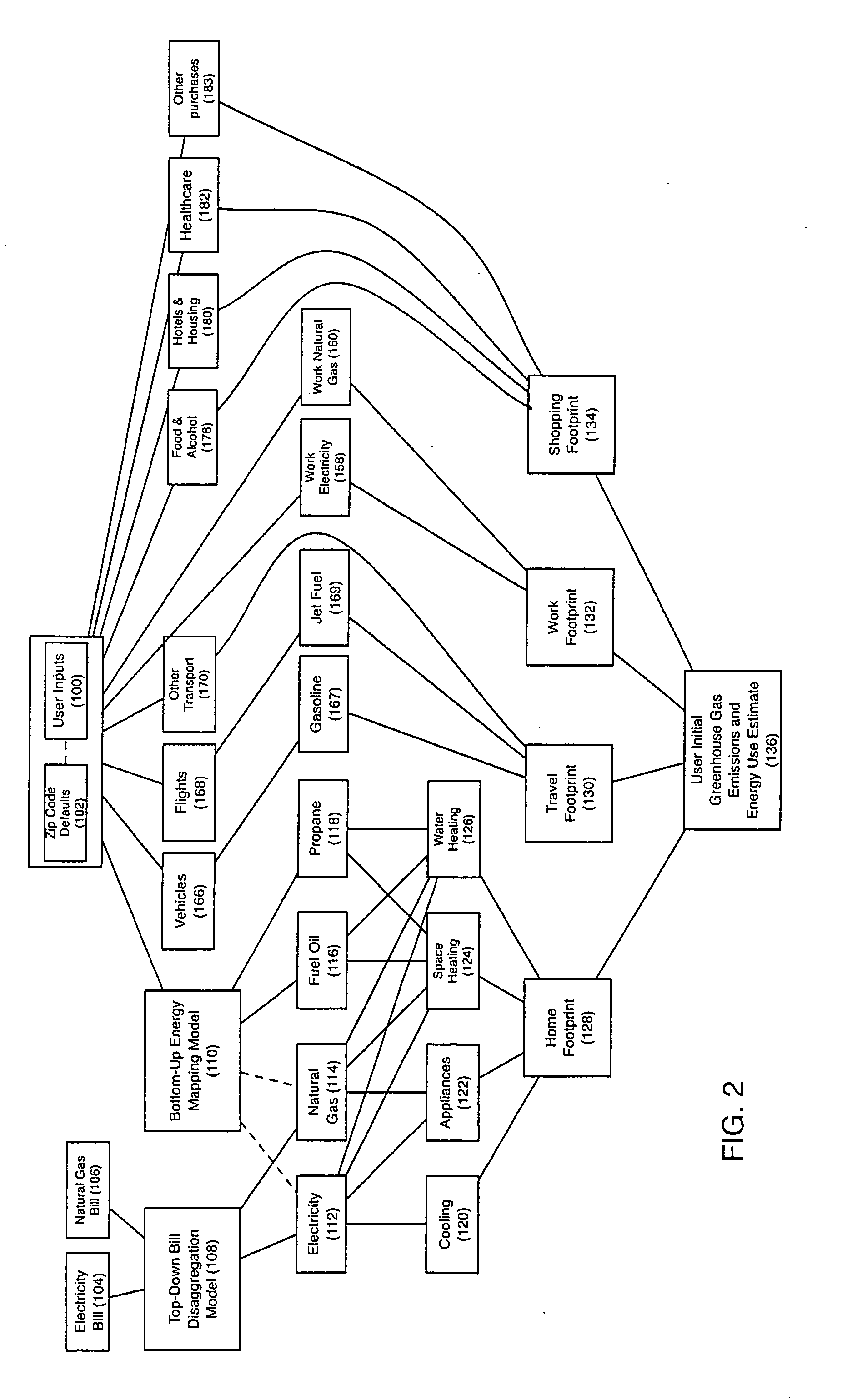

Methods and apparatus for greenhouse gas footprint monitoring

InactiveUS20100042453A1Decrease its global warming impactReduce their global warming impactSustainable waste treatmentTechnology managementGreenhouseUser input

The present invention invention provides methods, apparatus, and systems for determining greenhouse gas (including carbon dioxide) emissions and energy usage, costs and savings of individuals, families, homes, buildings, businesses, or the like. User inputs specific to an end user are accepted, and one or more of the user inputs are correlated with at least one of historic data and modeled characteristics pertaining to greenhouse gas emissions and energy usage to obtain at least one of greenhouse gas emissions and energy usage corresponding to said one or more of said user inputs. An overall greenhouse gas emissions and energy usage can then be determined for the end user based on the greenhouse emissions and energy usage corresponding to the one or more of the user inputs. A specific impact of a particular user action on the end user's overall greenhouse gas emissions and energy usage may also be calculated.

Owner:EFFICIENCY 2 0

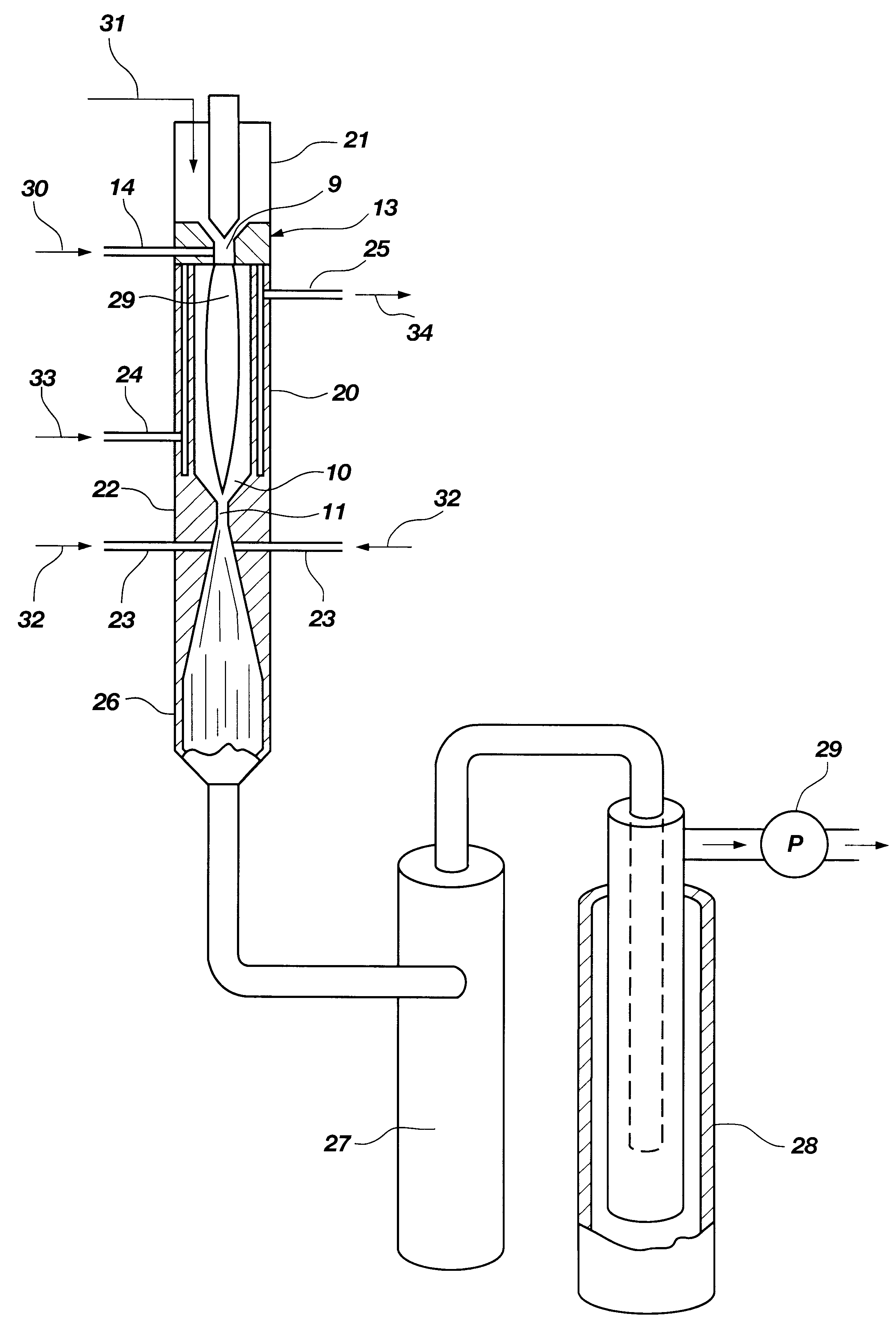

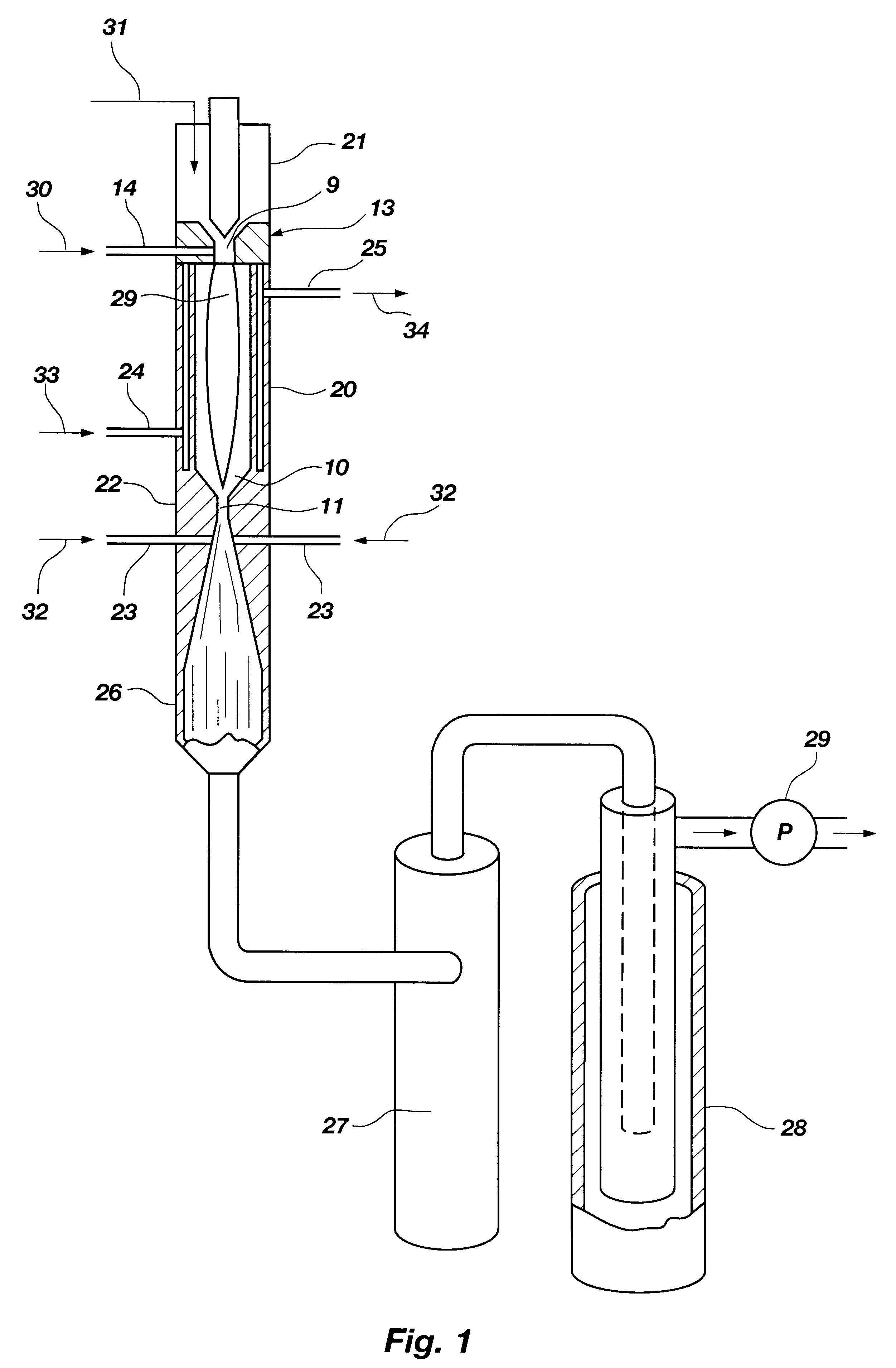

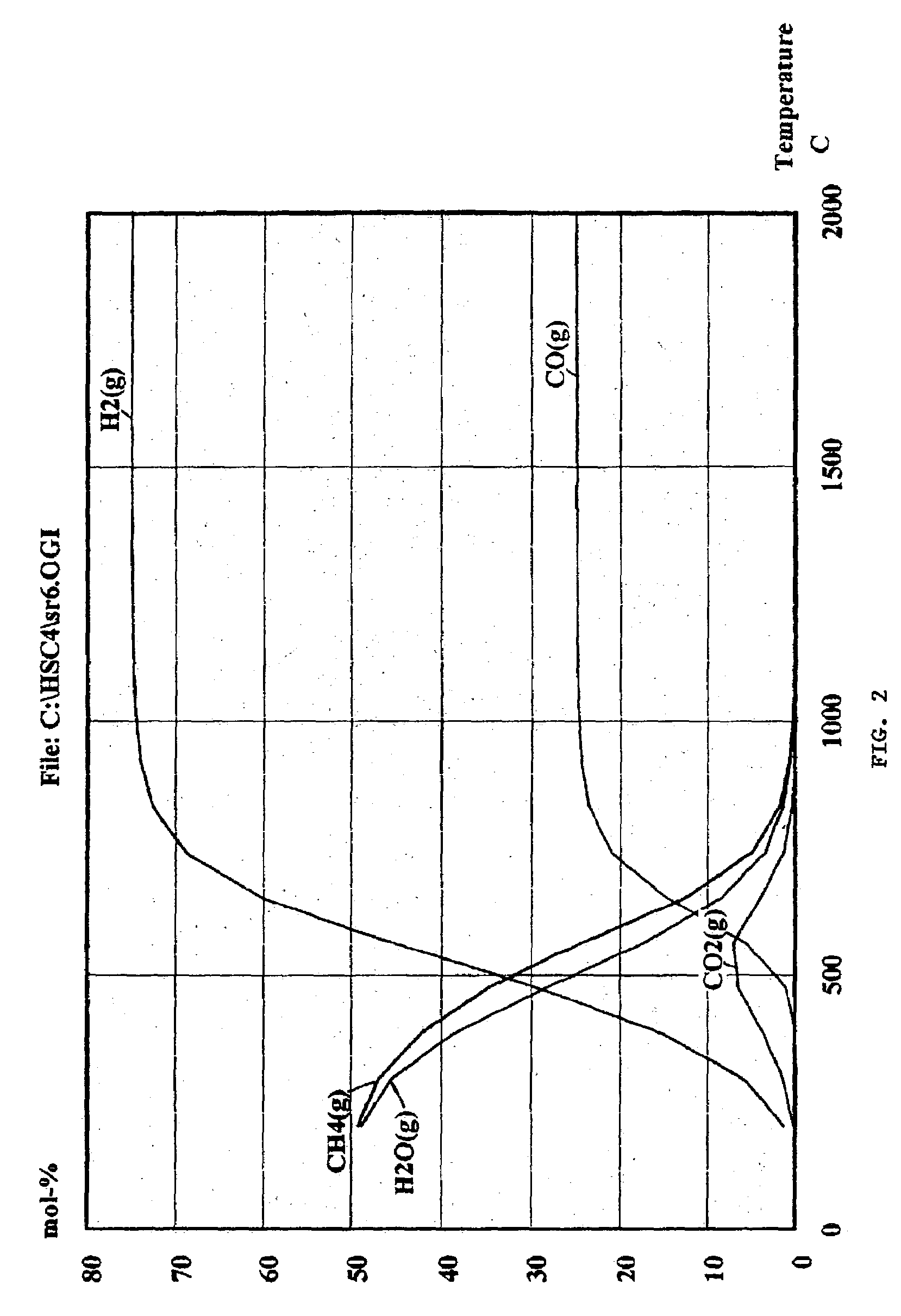

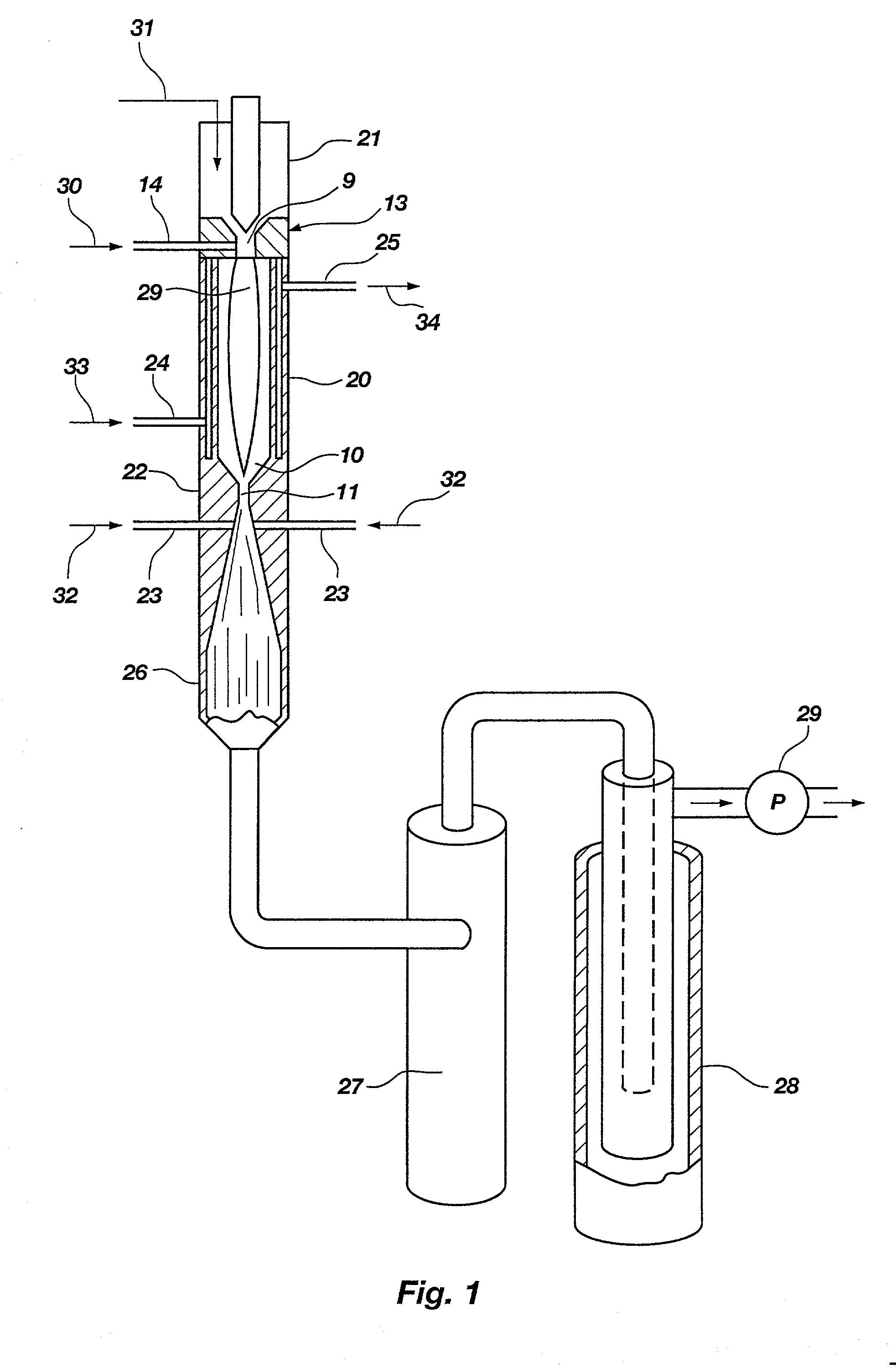

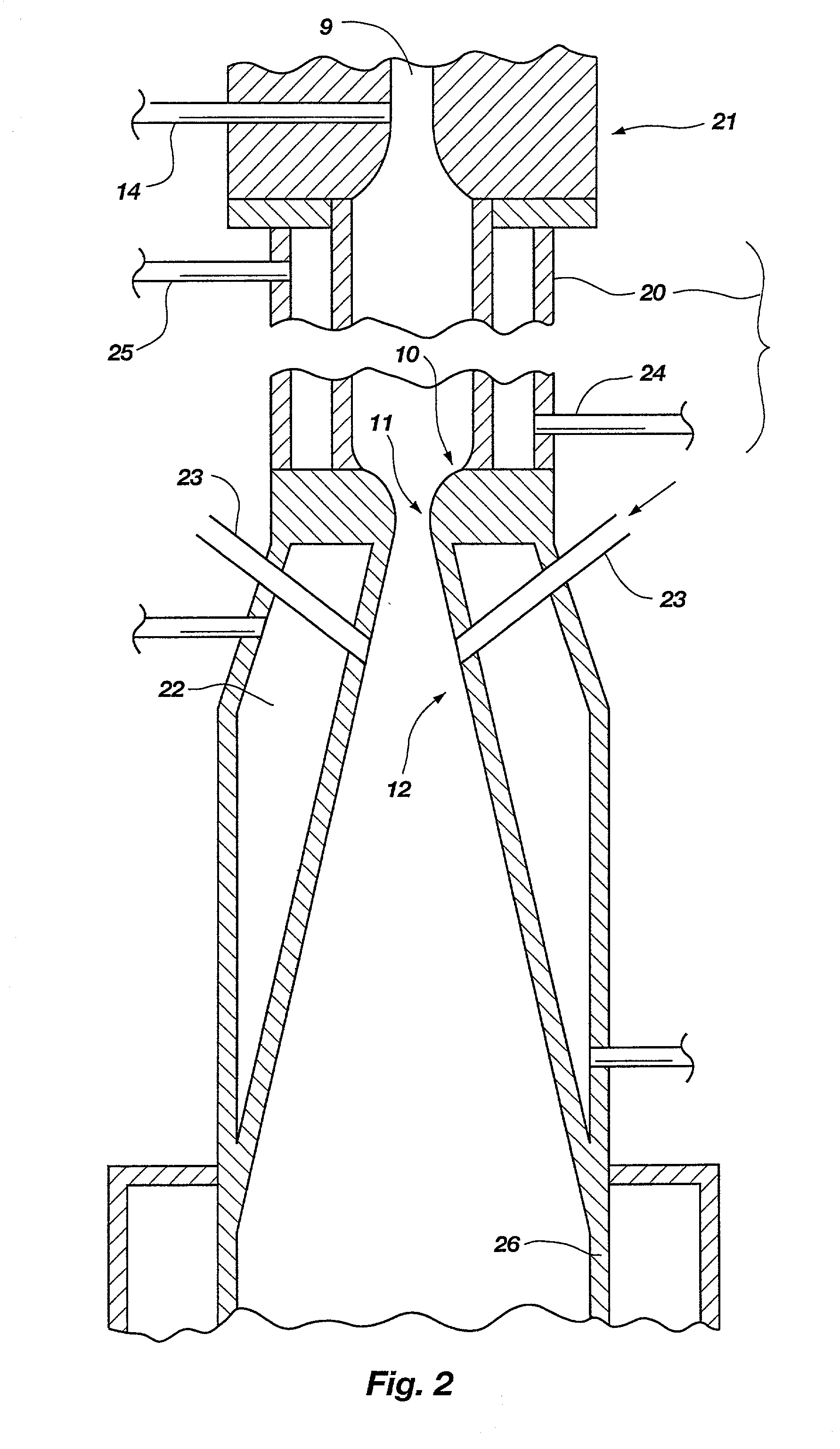

Hydrogen and elemental carbon production from natural gas and other hydrocarbons

InactiveUS6395197B1High quench rateAddressing slow performanceHydrocarbon from carbon oxidesEnergy inputUnsaturated hydrocarbonHydrogen fuel

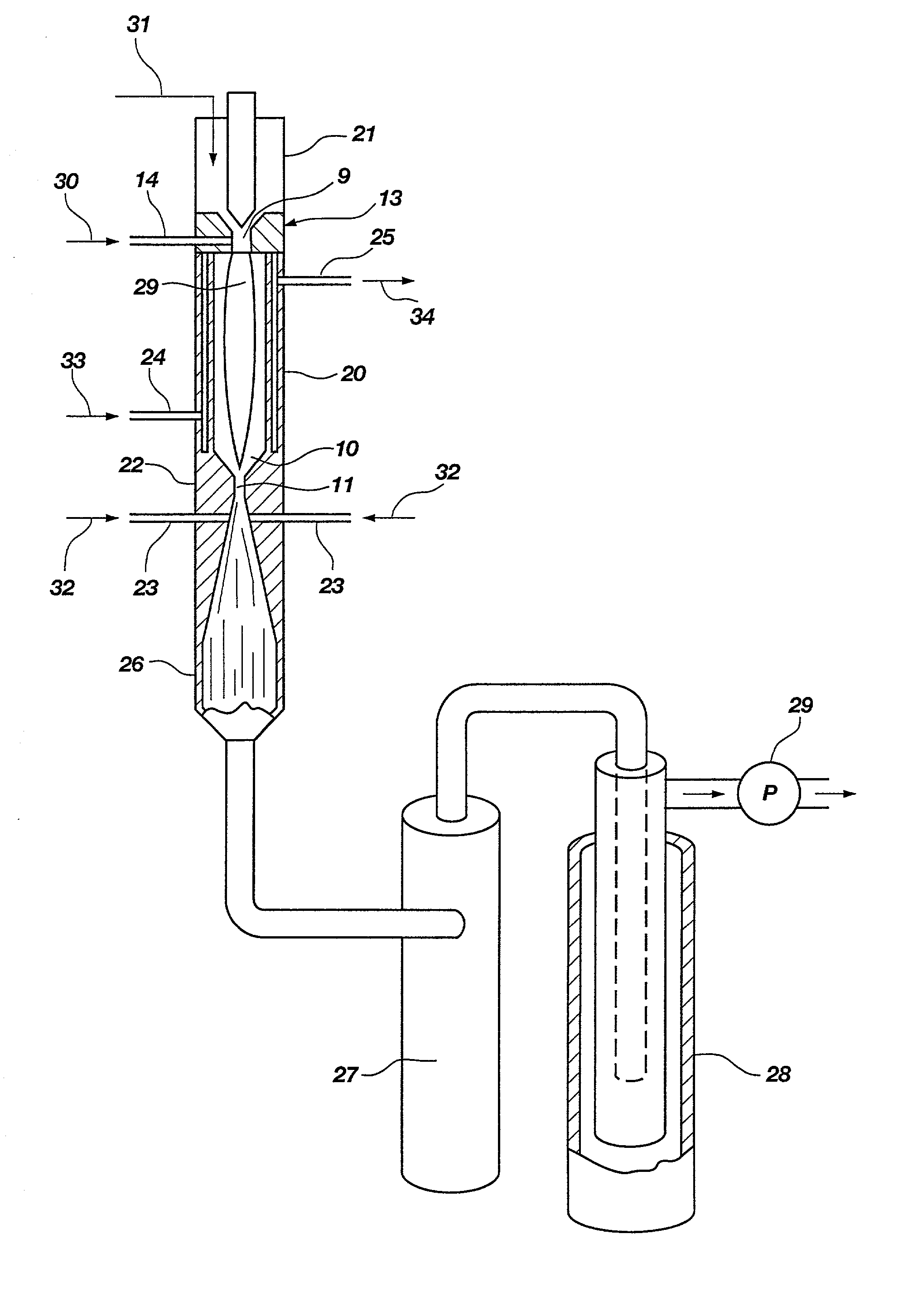

Diatomic hydrogen and unsaturated hydrocarbons are produced as reactor gases in a fast quench reactor. During the fast quench, the unsaturated hydrocarbons are further decomposed by reheating the reactor gases. More diatomic hydrogen is produced, along with elemental carbon. Other gas may be added at different stages in the process to form a desired end product and prevent back reactions. The product is a substantially clean-burning hydrogen fuel that leaves no greenhouse gas emissions, and elemental carbon that may be used in powder form as a commodity for several processes.

Owner:BATTELLE ENERGY ALLIANCE LLC

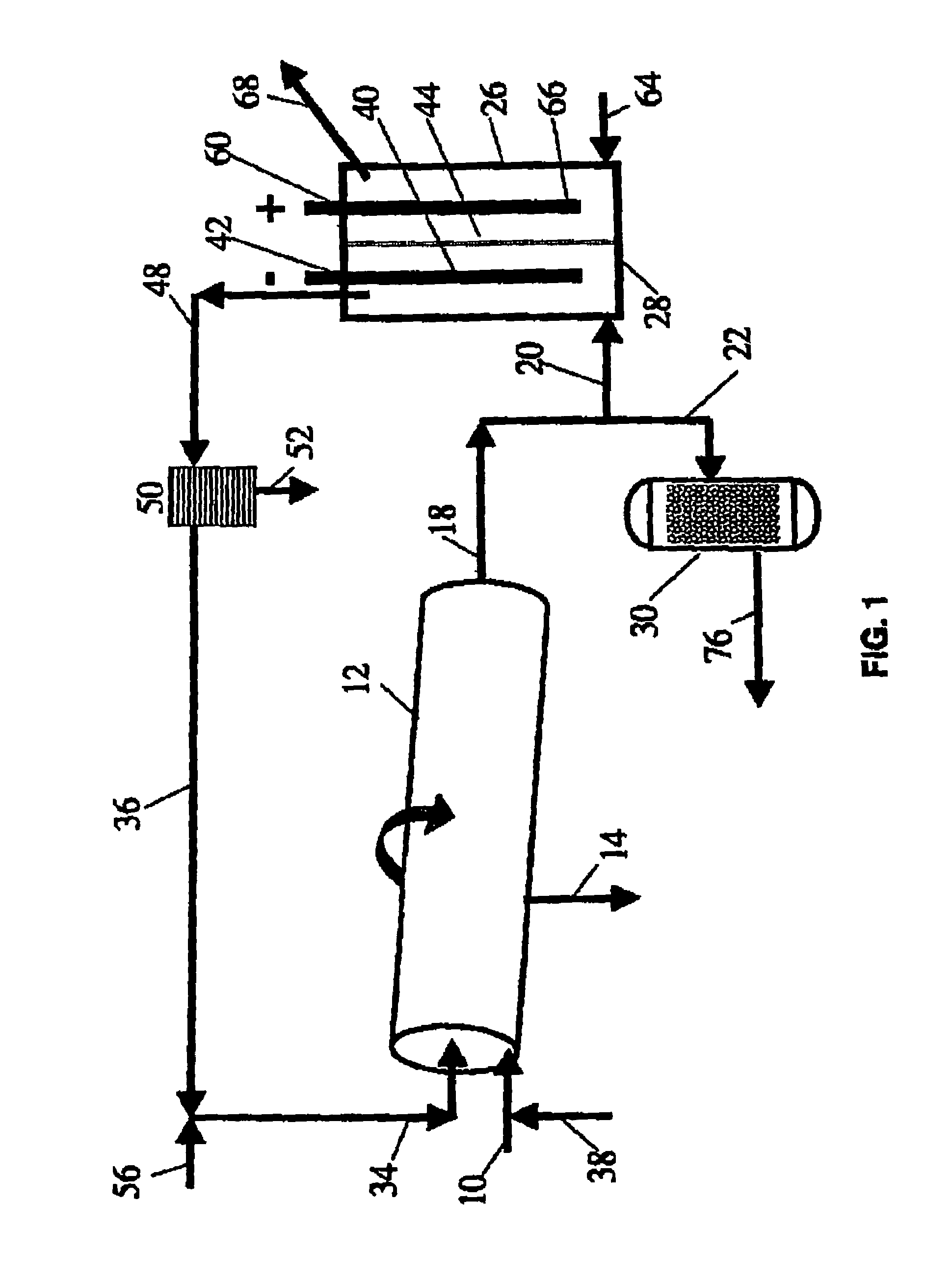

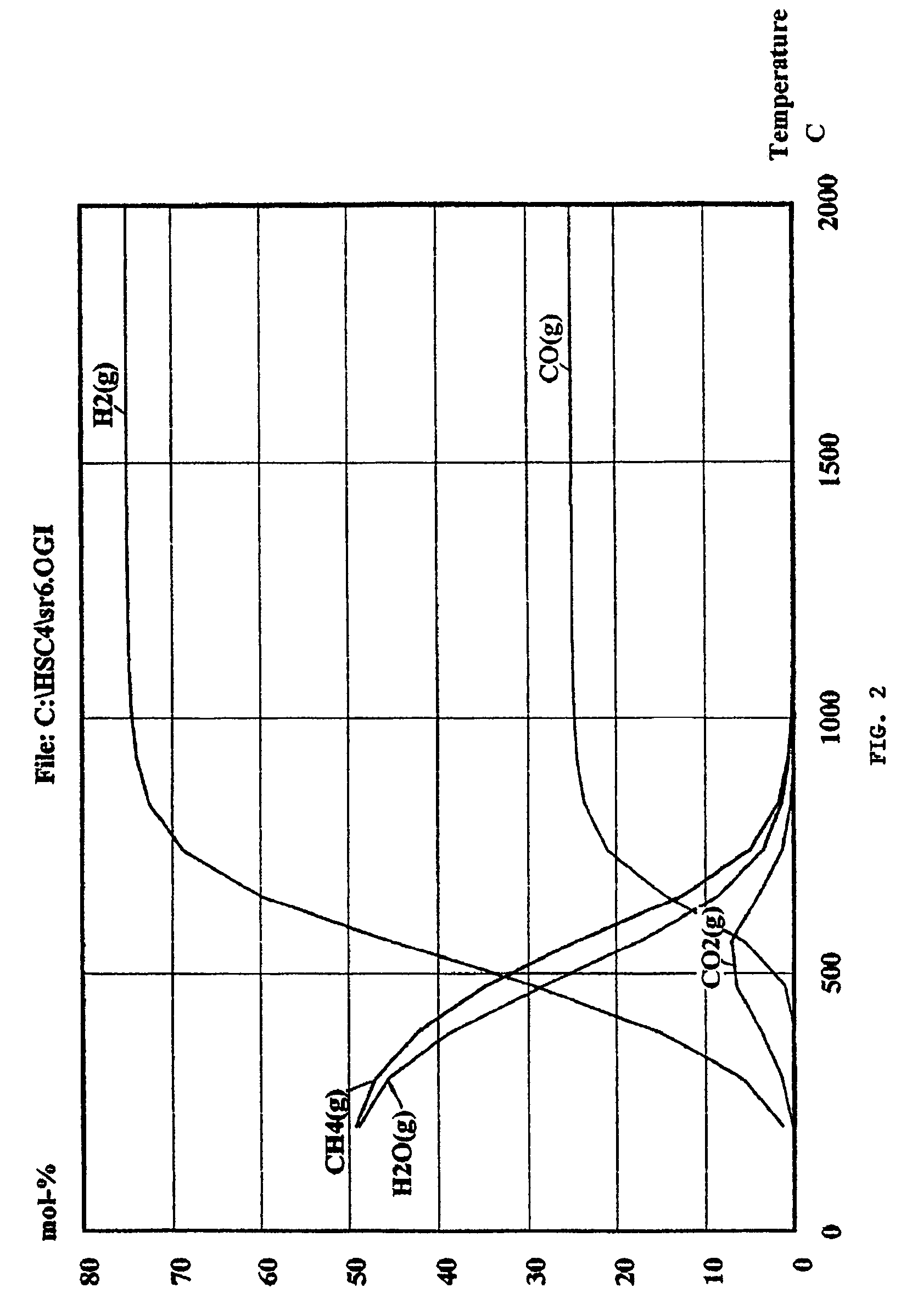

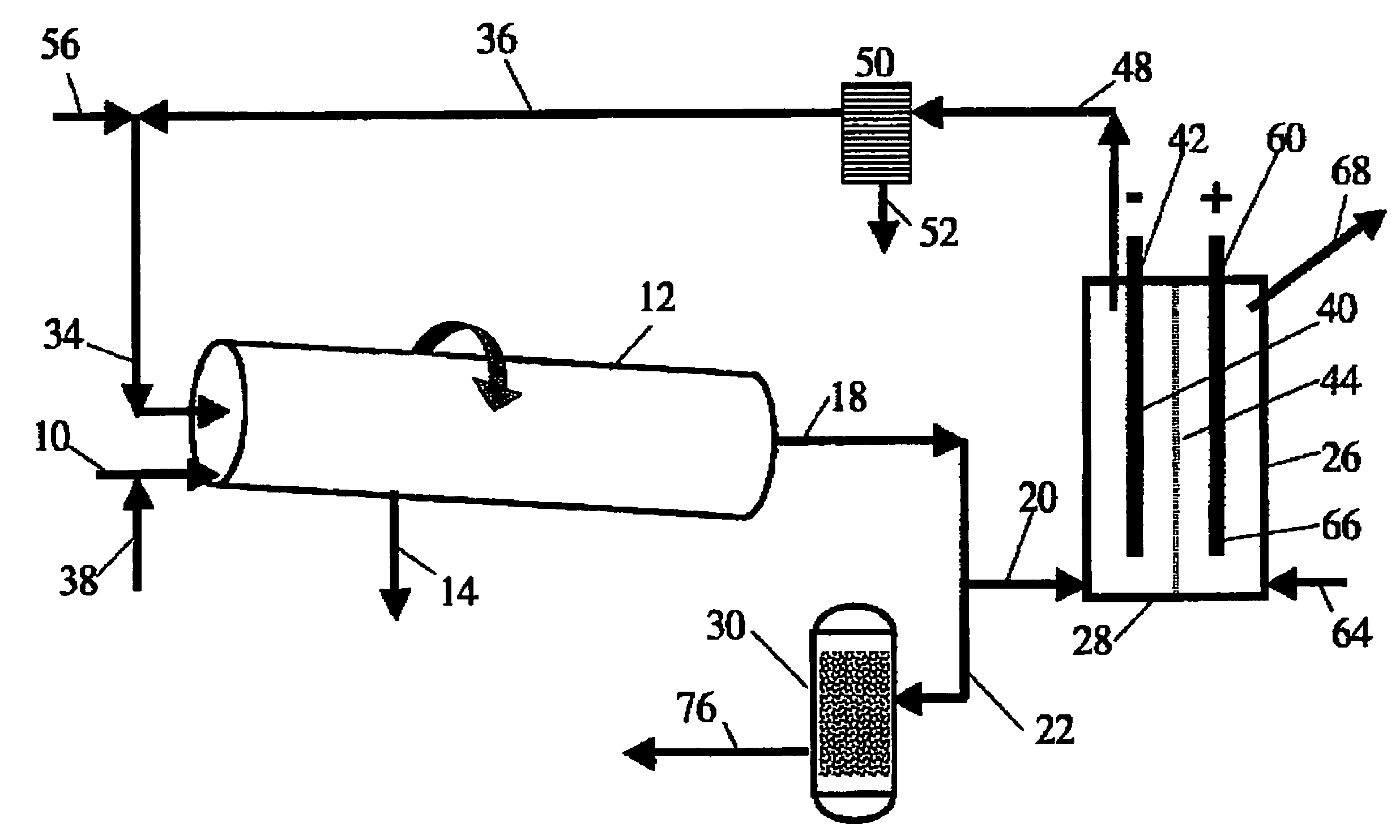

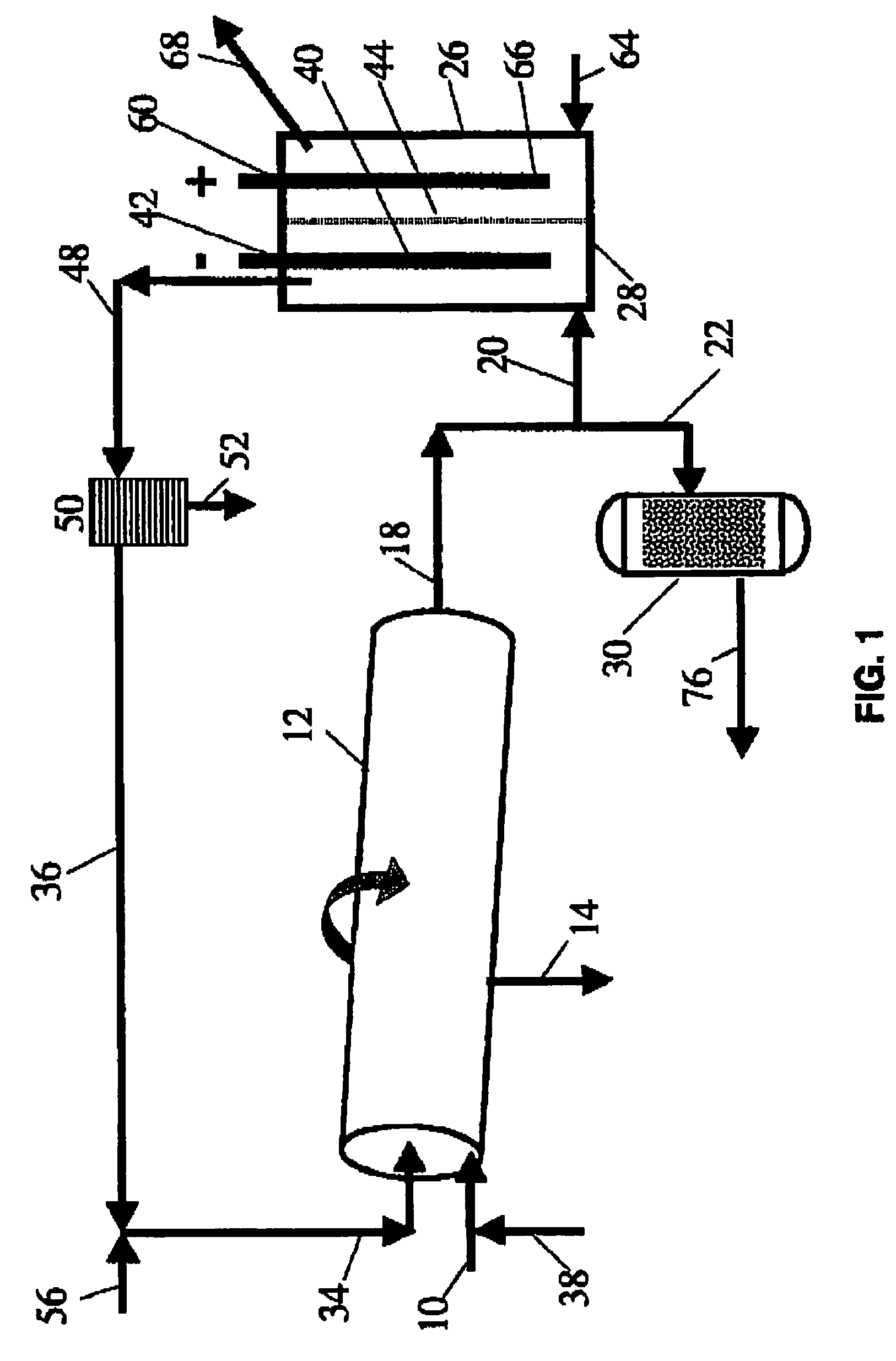

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

InactiveUS7220502B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesWaste based fuelPetroleum cokeToxic industrial waste

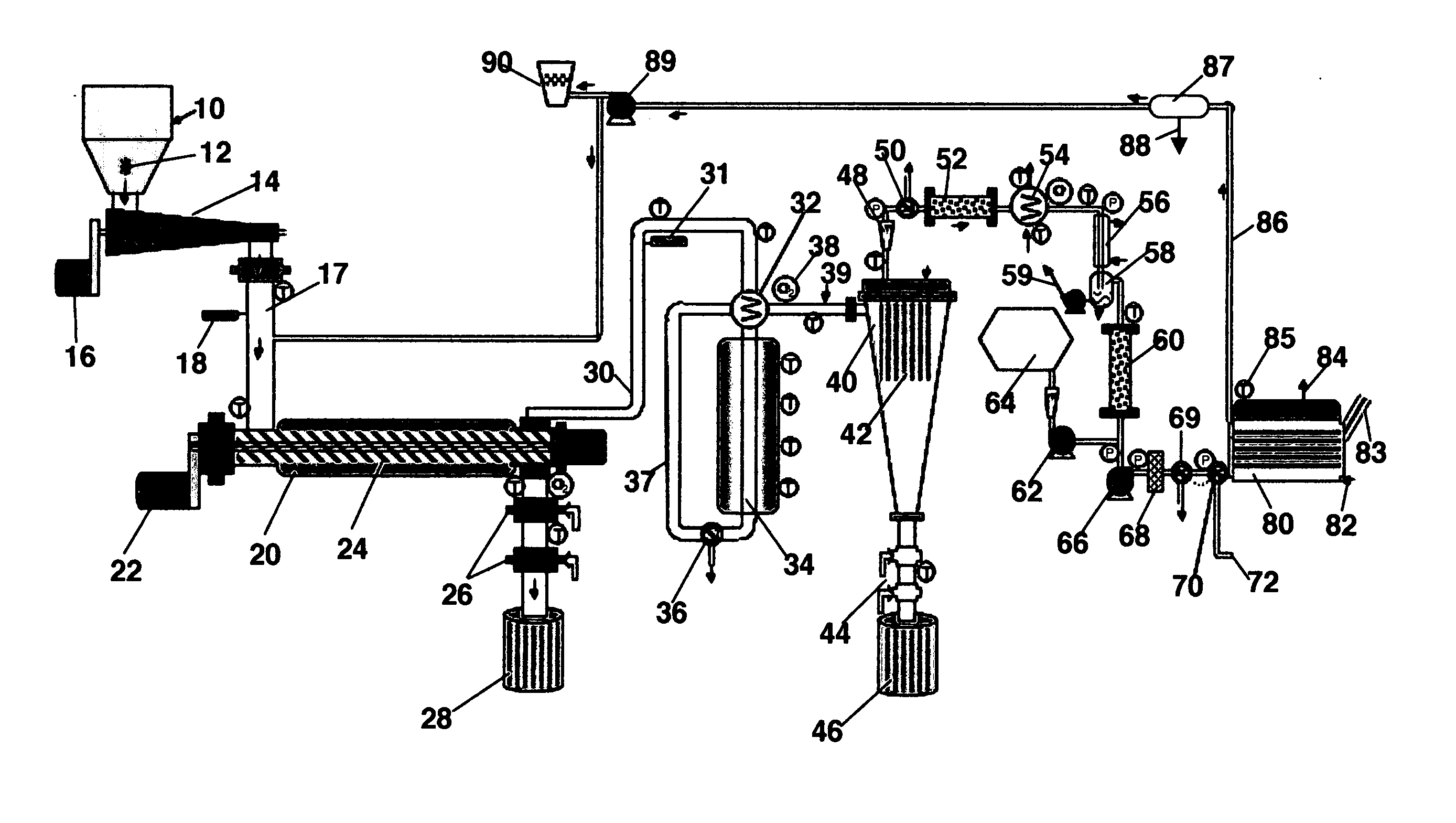

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300-2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

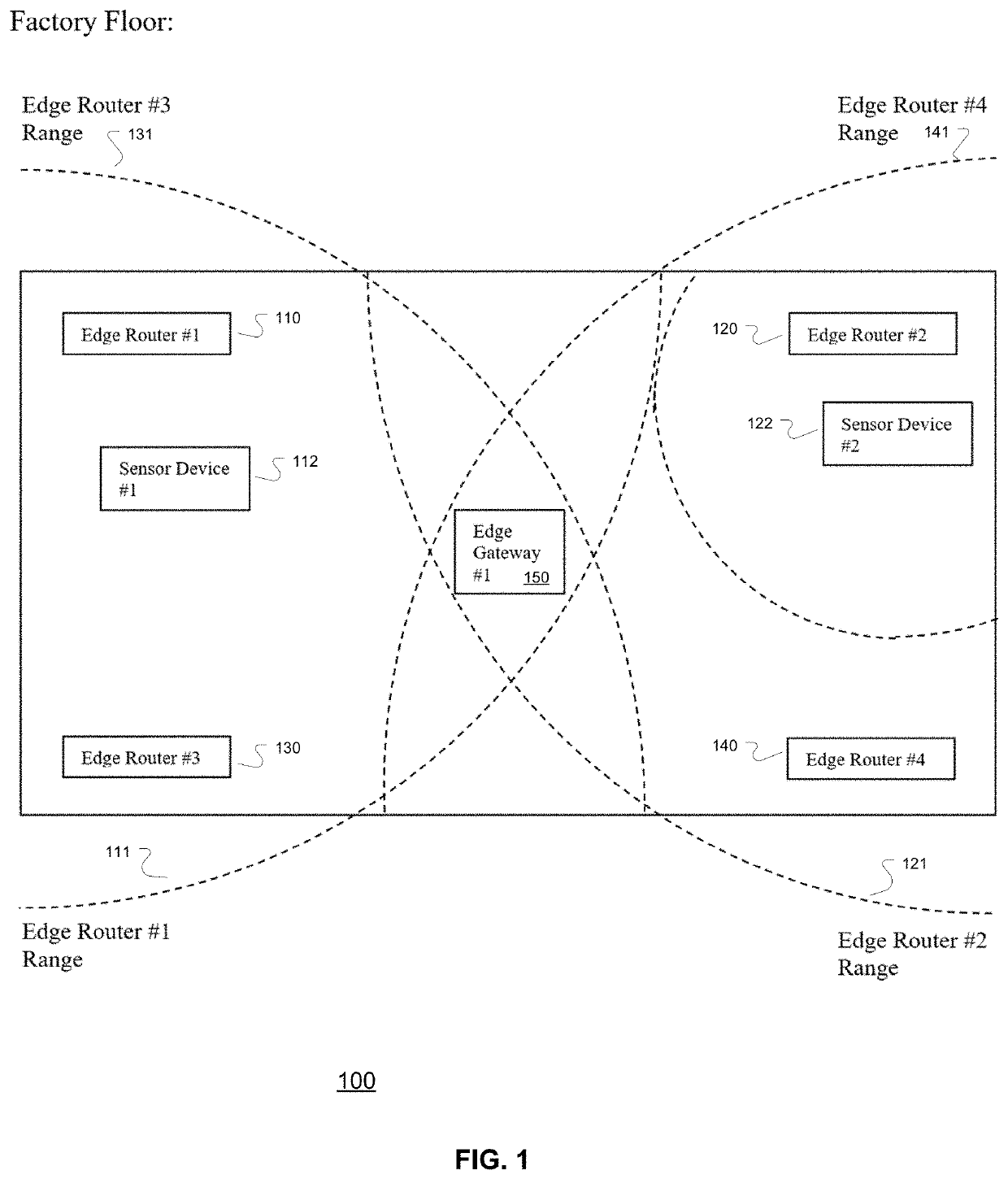

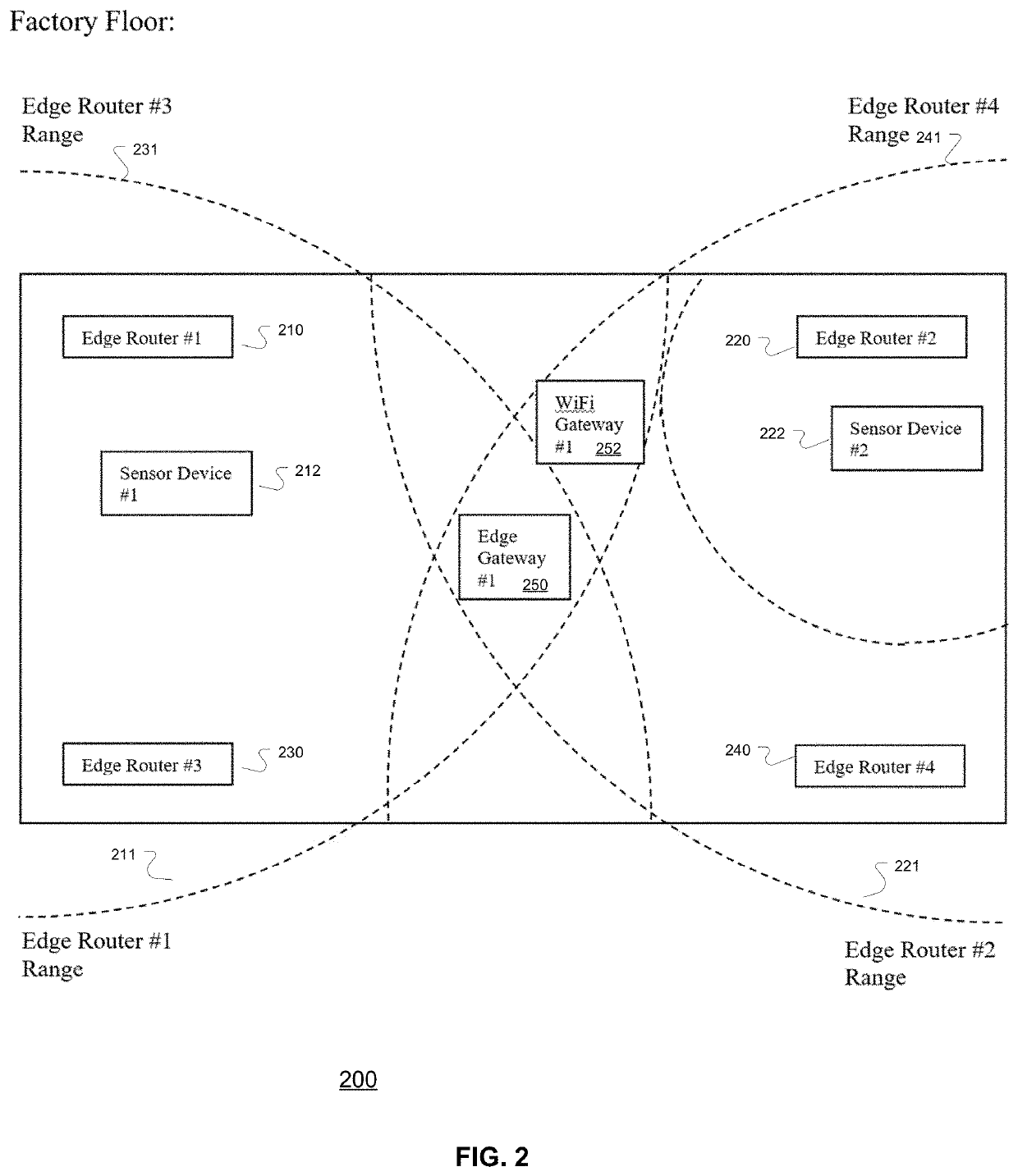

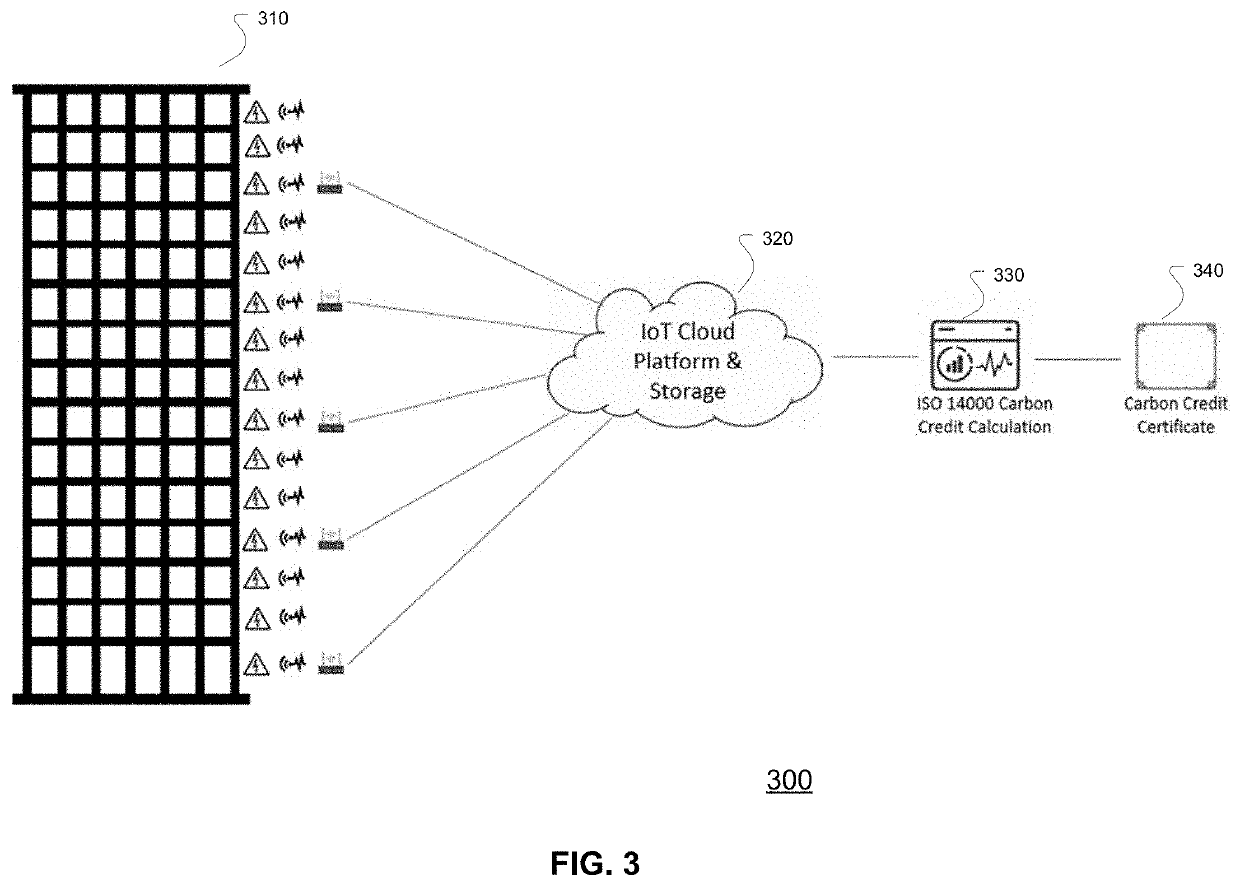

System, business and technical methods, and article of manufacture for utilizing internet of things technology in energy management systems designed to automate the process of generating and/or monetizing carbon credits

InactiveUS20200027096A1Improve operator safetyImprove user experienceFinancePayment protocolsEnvironmental resource managementCarbon dioxide equivalent

A carbon credit is a generic term for any tradable certificate or permit representing the right to emit one ton of carbon dioxide or the mass of another greenhouse gas with a carbon dioxide equivalent (tCO2e) equivalent to one ton of carbon dioxide.Carbon credits and carbon markets are a component of national and international attempts to mitigate the growth in concentrations of greenhouse gases (GHGs). One carbon credit is equal to one ton of carbon dioxide, or in some markets, carbon dioxide equivalent gases. Carbon trading is an application of an emissions trading approach. Greenhouse gas emissions are capped and then markets are used to allocate the emissions among the group of regulated sources.Carbon credits can be generated by any process that conforms to ISO 14064-66 standards. Once generated, carbon credits can be stored in a distributed, Cloud-based ledger. The ledger entries can serve as a registry for carbon credits as well as the data source for an Internet-enabled trading system or financial exchange that allows the carbon credits to be sold and bought as part of the same system. The distributed ledger can provide records that combine the details of the carbon credits' origin, transaction history, and financial instructions associated with trading of the carbon credits via a distributed ledger system.

Owner:COONER JASON RYAN

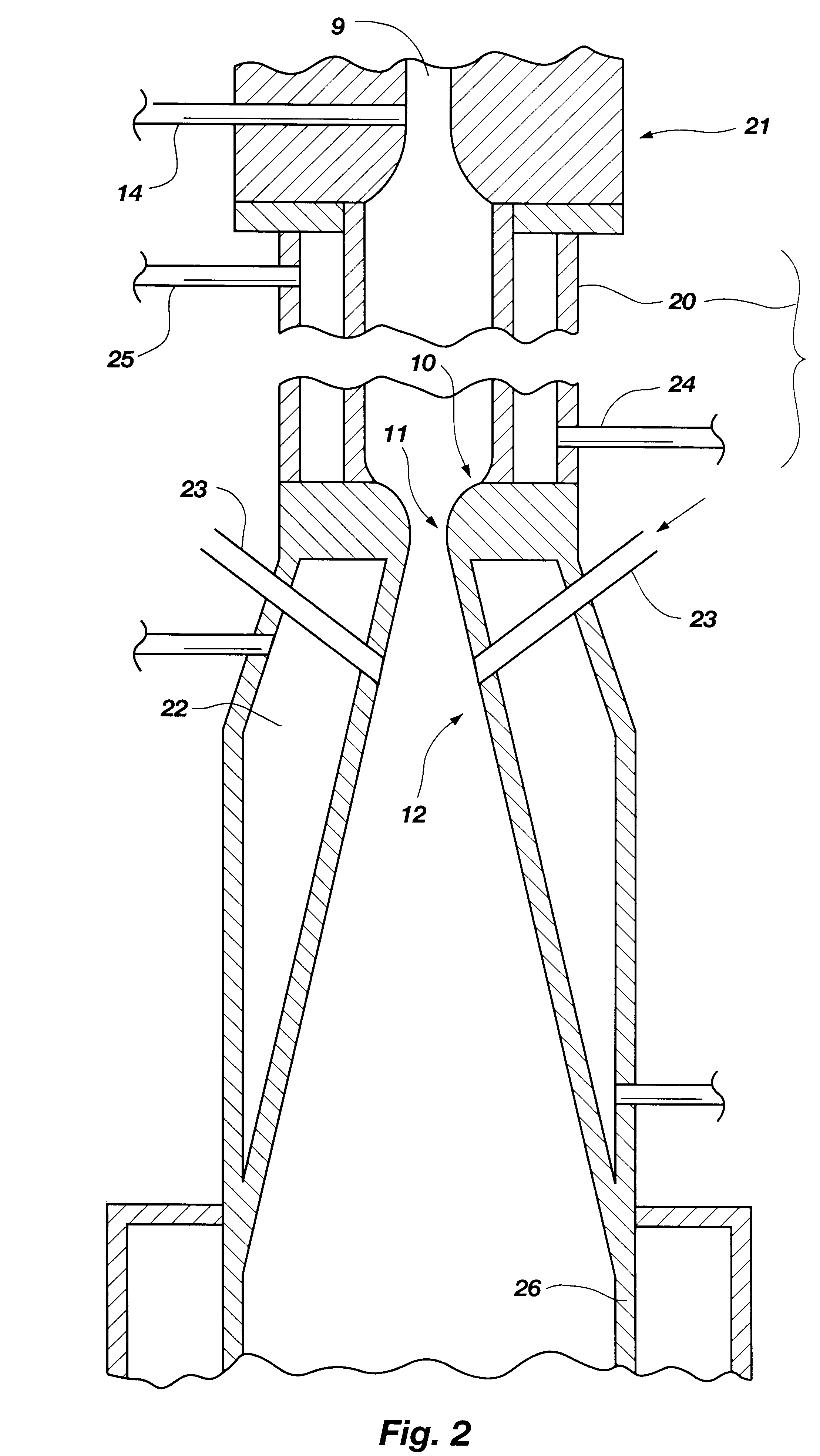

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS7132183B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesGasification processes detailsWaste oilHigh pressure

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing hazardous waste, carbonaceous-containing medical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300–2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

Gas-energy observatory

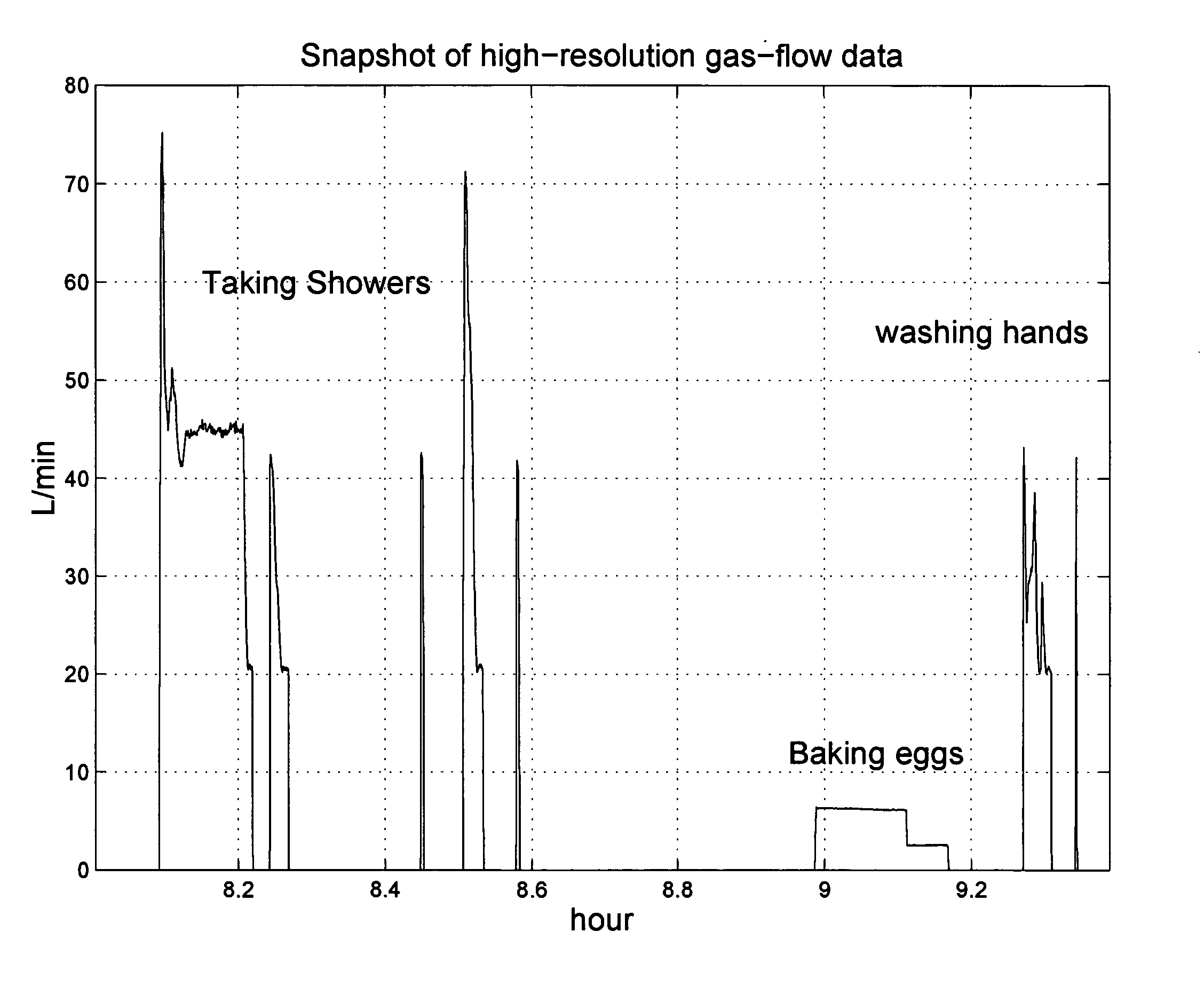

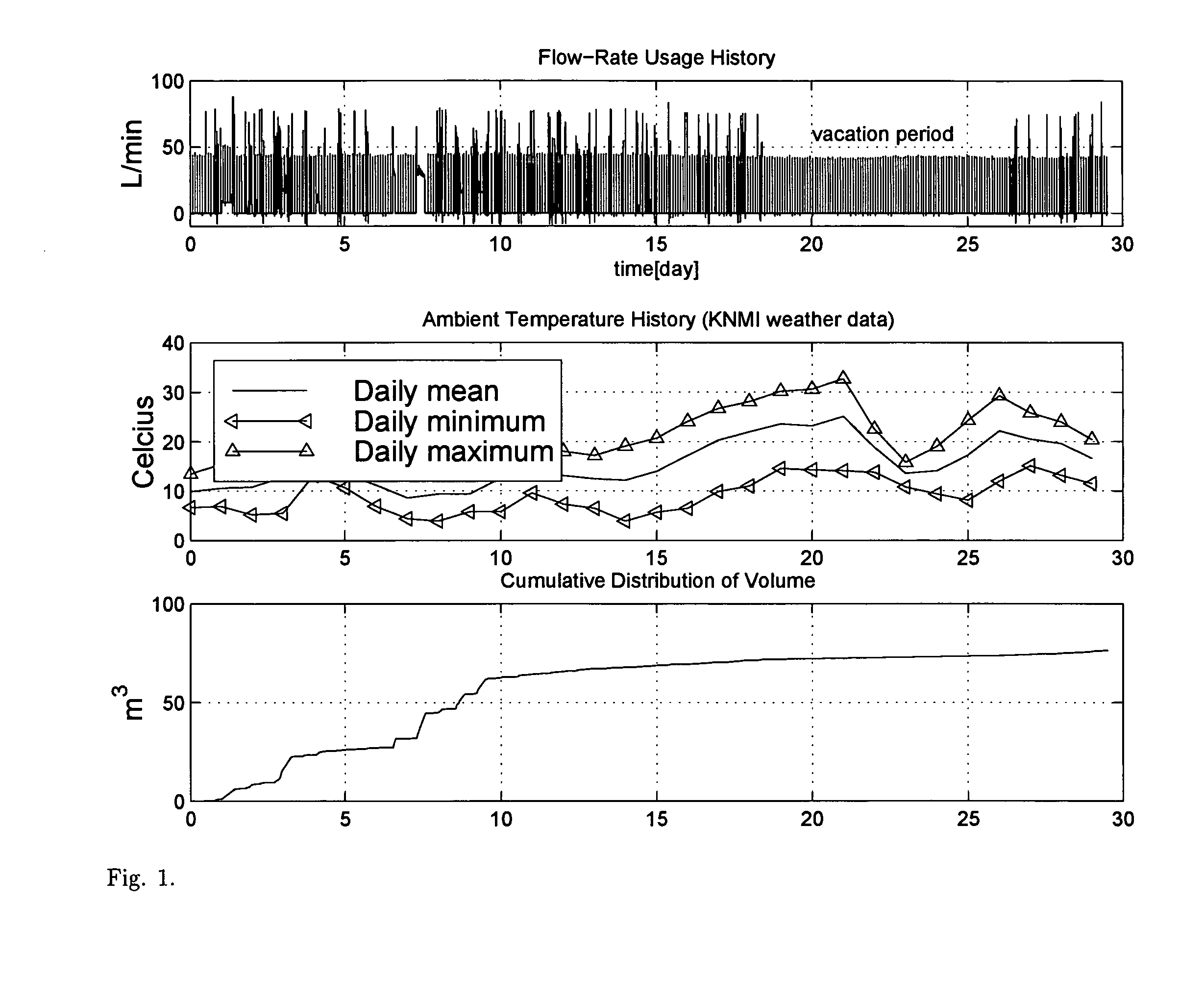

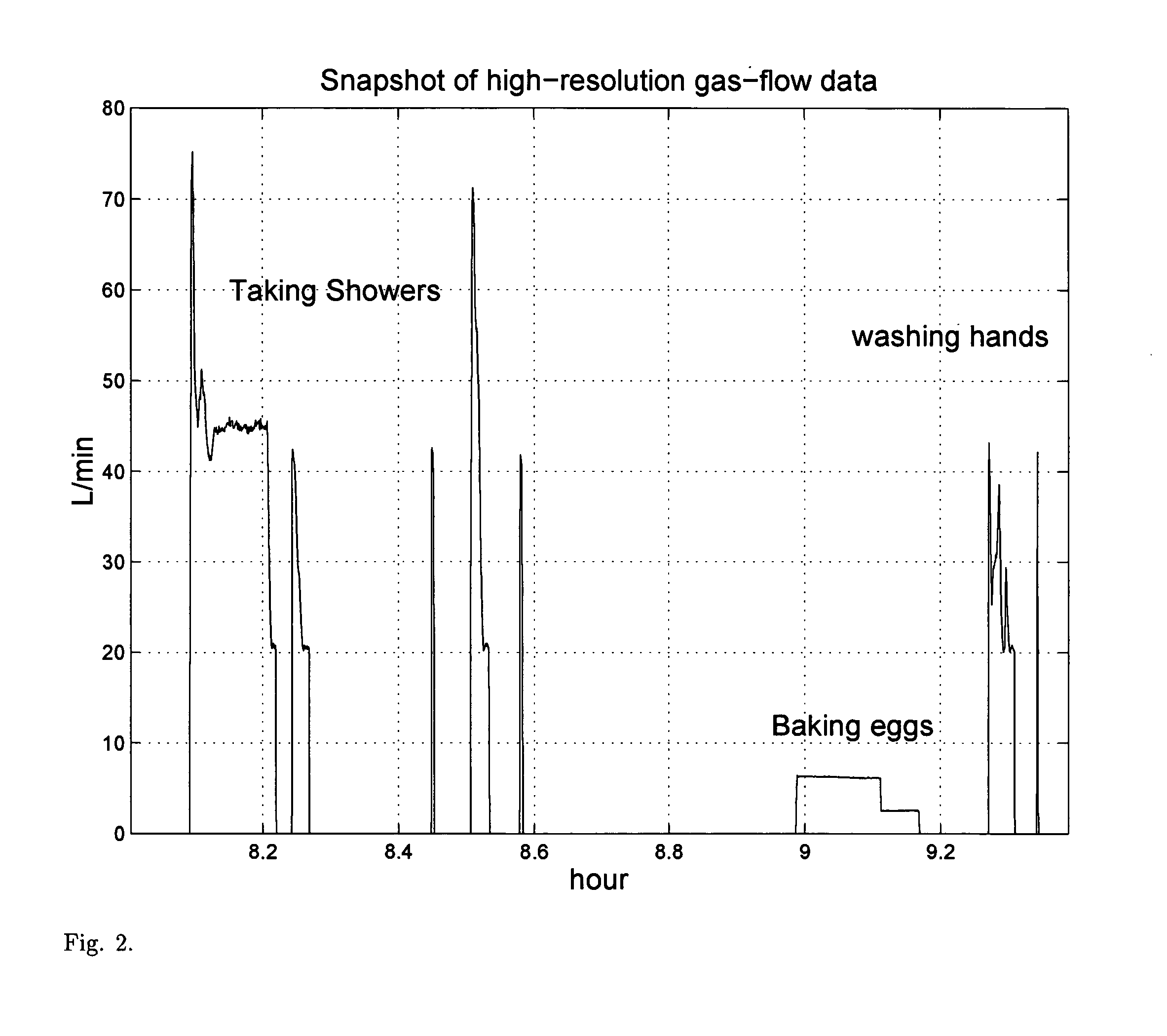

Heating is a significant factor in residential gas-energy usage. Saving energy on heating is receiving increasing attention with rising energy prices and the Kyoto Protocol on reducing greenhouse gas emissions. Energy awareness and energy efficiency hereby become important qualifications for human behavior and residential building codes, and become a factor in the evolution of the global climate. Here, we describe a novel measurement and validation system for domestic gas-energy usage in combination with primary weather data. We disclose a gas-energy observatory which visualizes human behavior in gas-energy consumption associated with domestic facilities, and measures home energy efficiency by calorimetry. Weather-sensitivity analysis quantifies energy-usage as a function of small variations in room temperature and home energy efficiency. Weather-sensitivity data can be used to calculate changes in room-temperature settings or improvements in home insulation for a desired reduction in CO2-output. By public dissemination of its primary weather data, it creates in dual-use at no additional cost a novel in-situ climate observational systems with unprecedented wide-area coverage and spatial resolution.

Owner:VAN PUTTEN MAURITIUS H P M +3

Hydrogen and elemental carbon production from natural gas and other hydrocarbons

InactiveUS20020151604A1Addressing slow performanceReduce momentumHydrogenOrganic compound preparationUnsaturated hydrocarbonHydrogen fuel

Owner:BATTELLE ENERGY ALLIANCE LLC

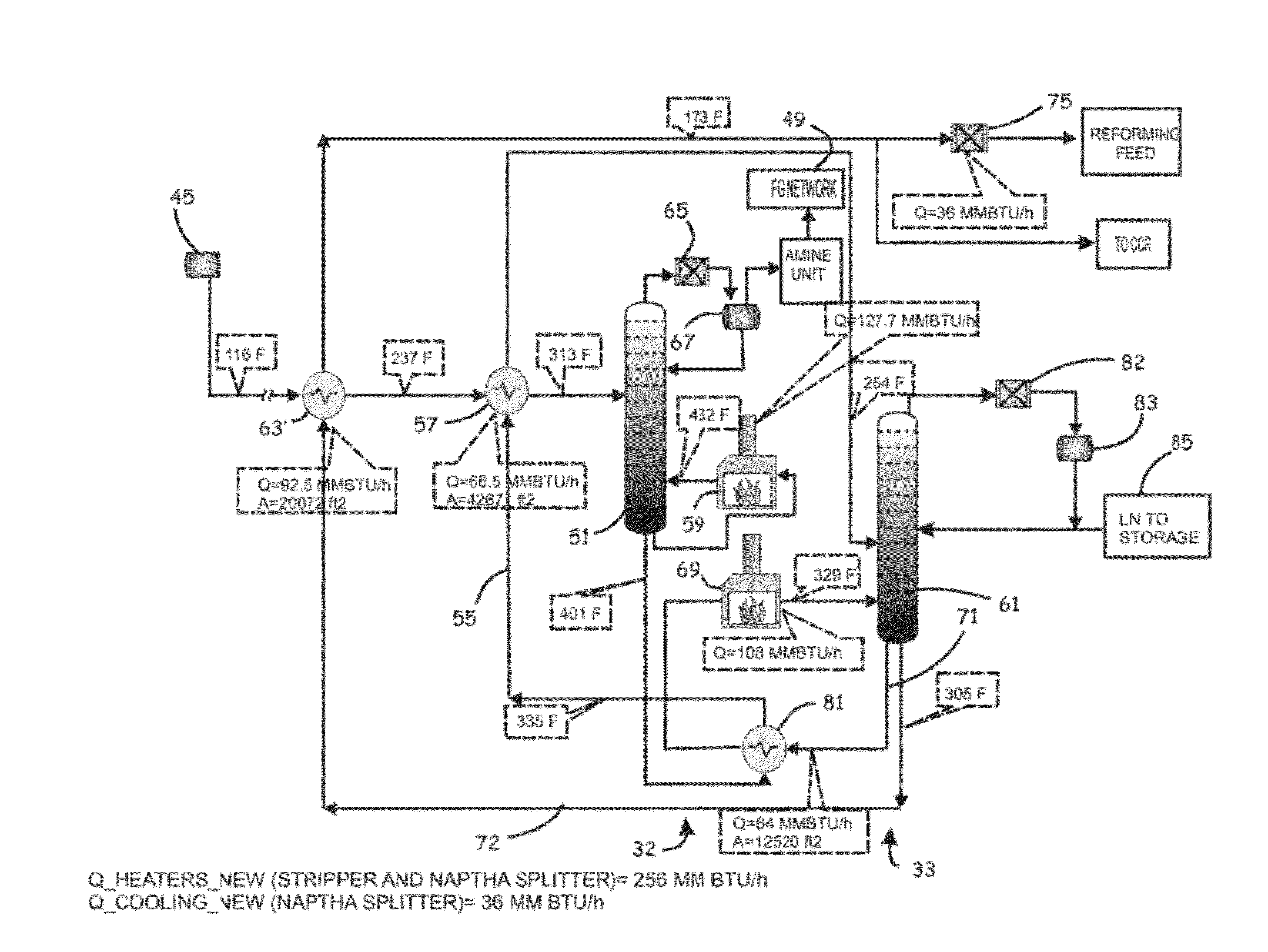

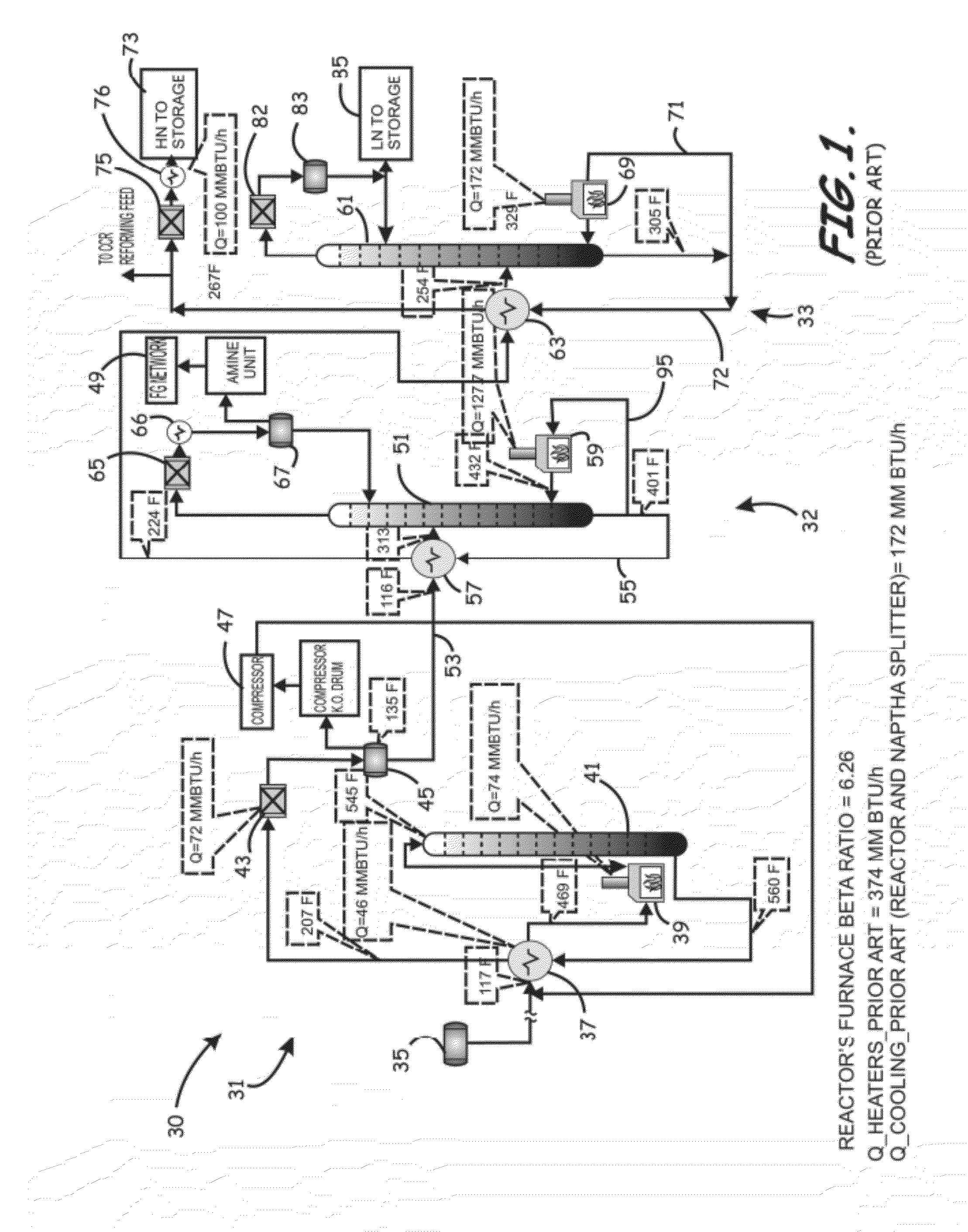

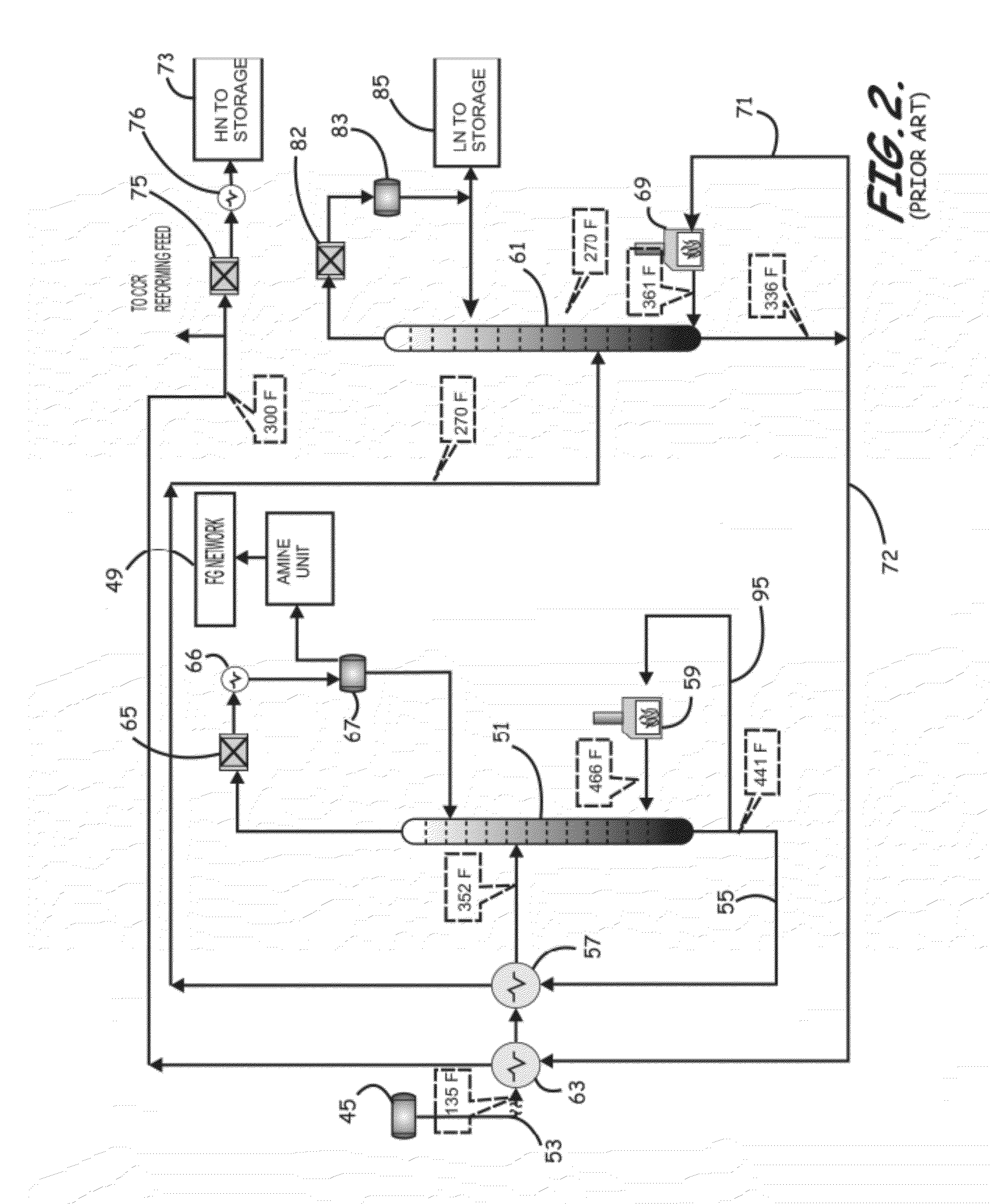

Energy-Efficient and Environmentally Advanced Configurations For Naptha Hydrotreating Process

ActiveUS20120279900A1Less emissionsLower ratioRecuperative heat exchangersThermal naphtha reformingProcess systemsNaphtha

Systems and methods of hydrotreating different naphtha feed stocks destined for a refining reforming unit and other applications with less energy consumption than conventionally possible, while producing less greenhouse gas emissions, and / or using a lesser number of heaters and correspondingly less capital investment in such heaters, air coolers, and water coolers, are provided. According to the more examples of such systems and methods, such reductions are accomplished by directly integrating a naphtha stripping process section with a naphtha splitting process section. Additional reductions can also be accomplished through directly integrating a naphtha hydrotreat reaction process section with the naphtha stripping process section.

Owner:SAUDI ARABIAN OIL CO

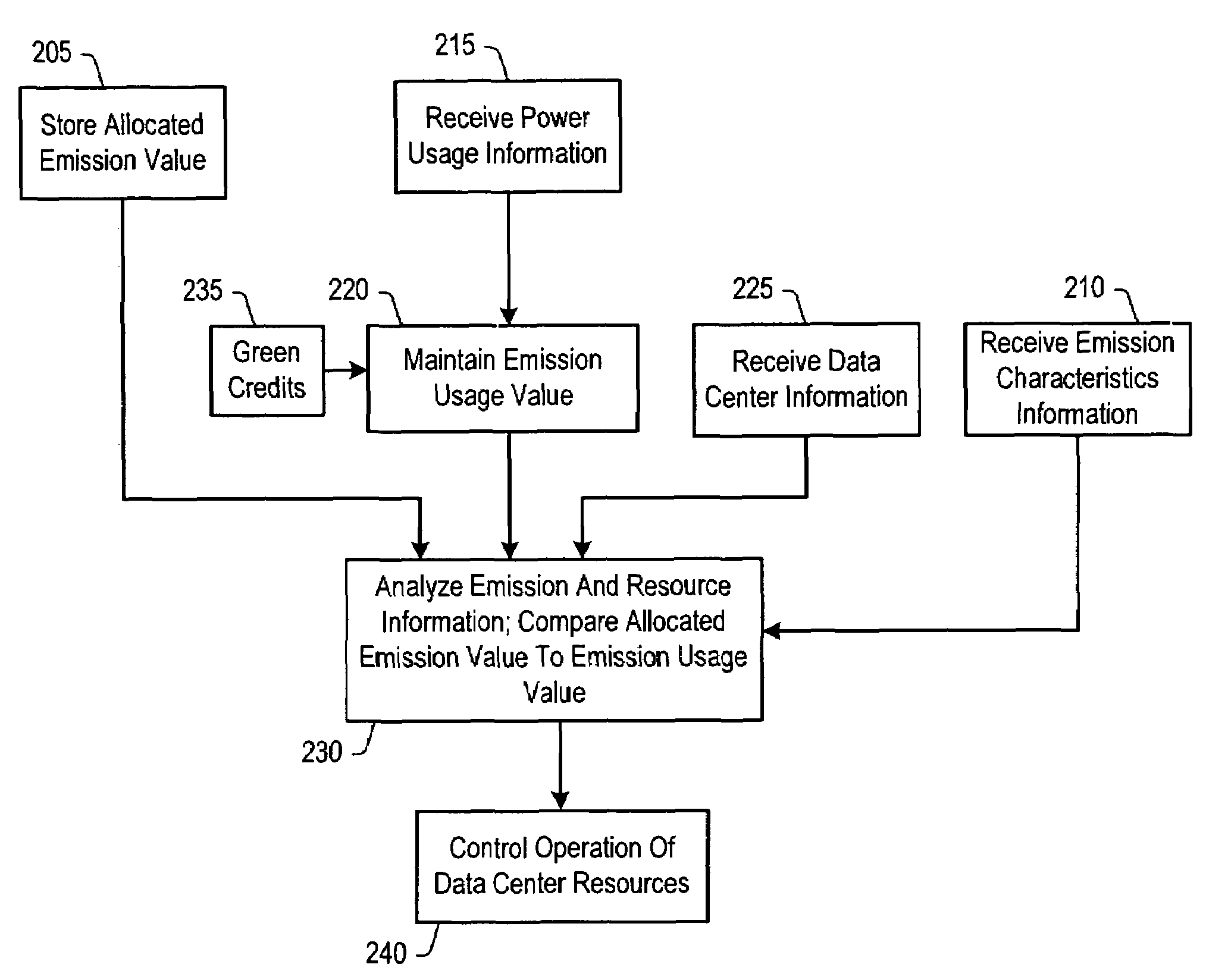

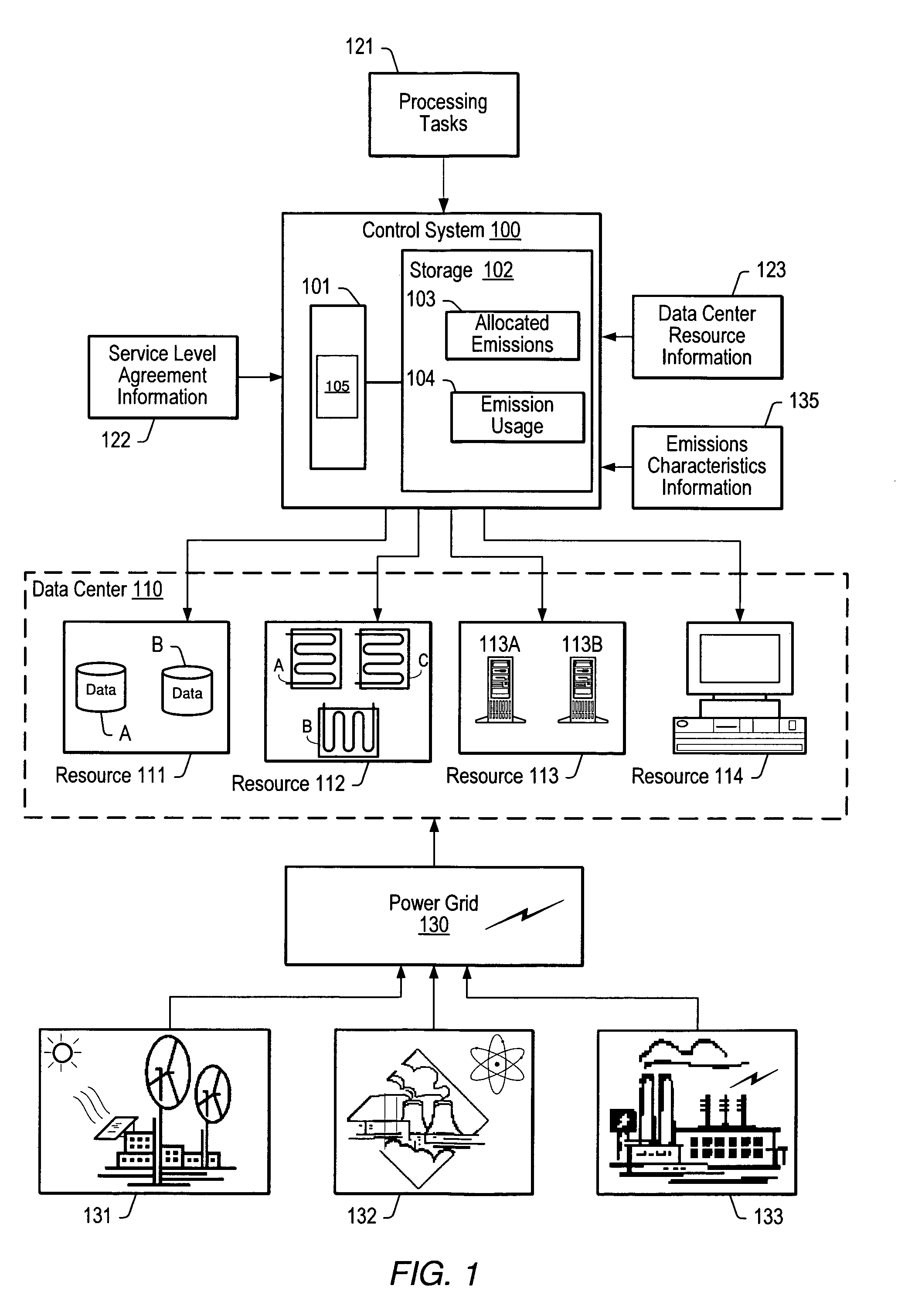

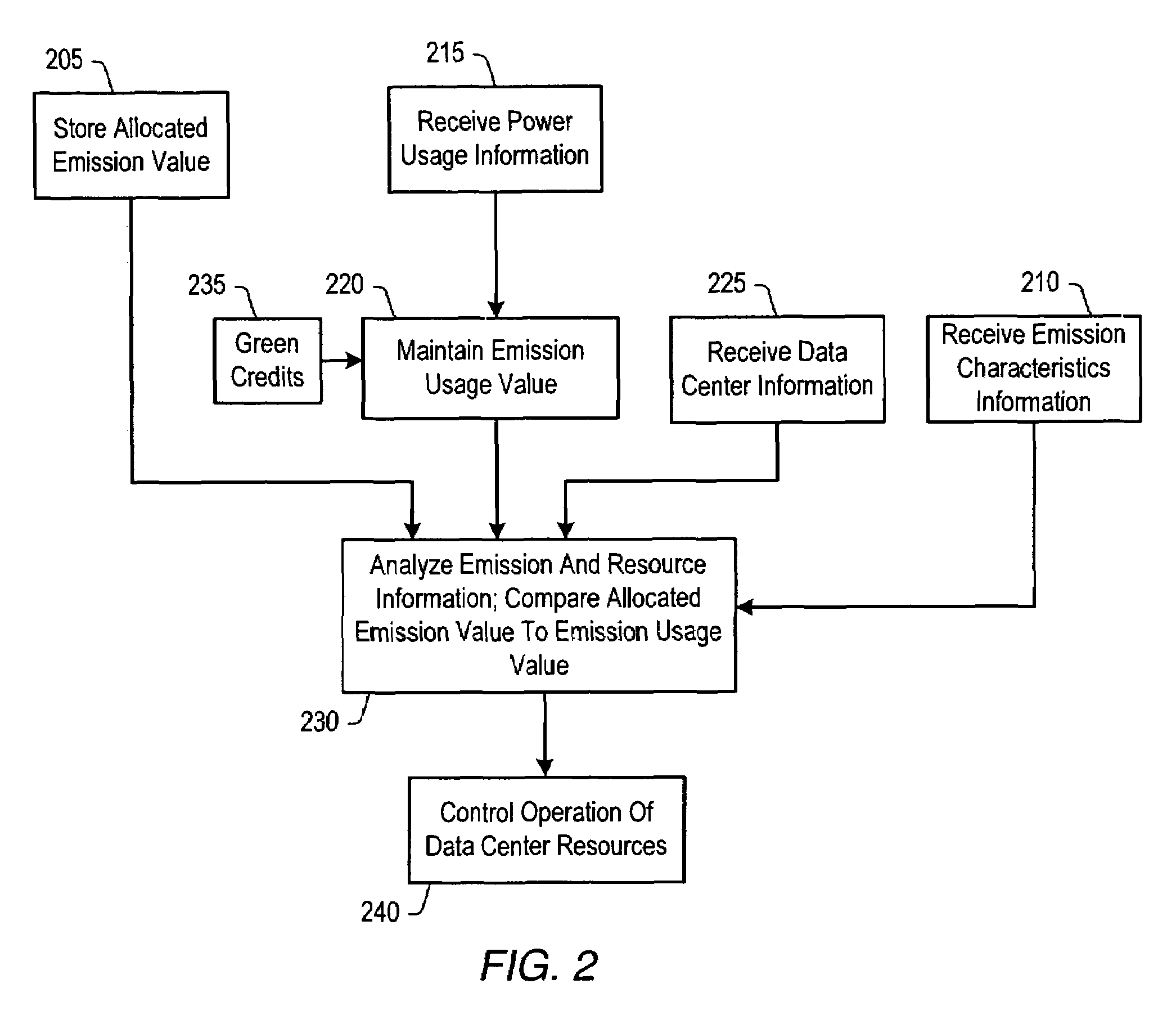

System and method of controlling data center resources for management of greenhouse gas emission

A data center control system includes a storage configured to maintain an emission usage value indicative of an estimated amount of greenhouse gas emission caused by consumption of power by resources within one or more data centers. The control system also includes a controller that may provide a signal to control an operation of at least one of the resources depending upon the indication of the estimated amount of greenhouse gas emission.

Owner:CA TECH INC

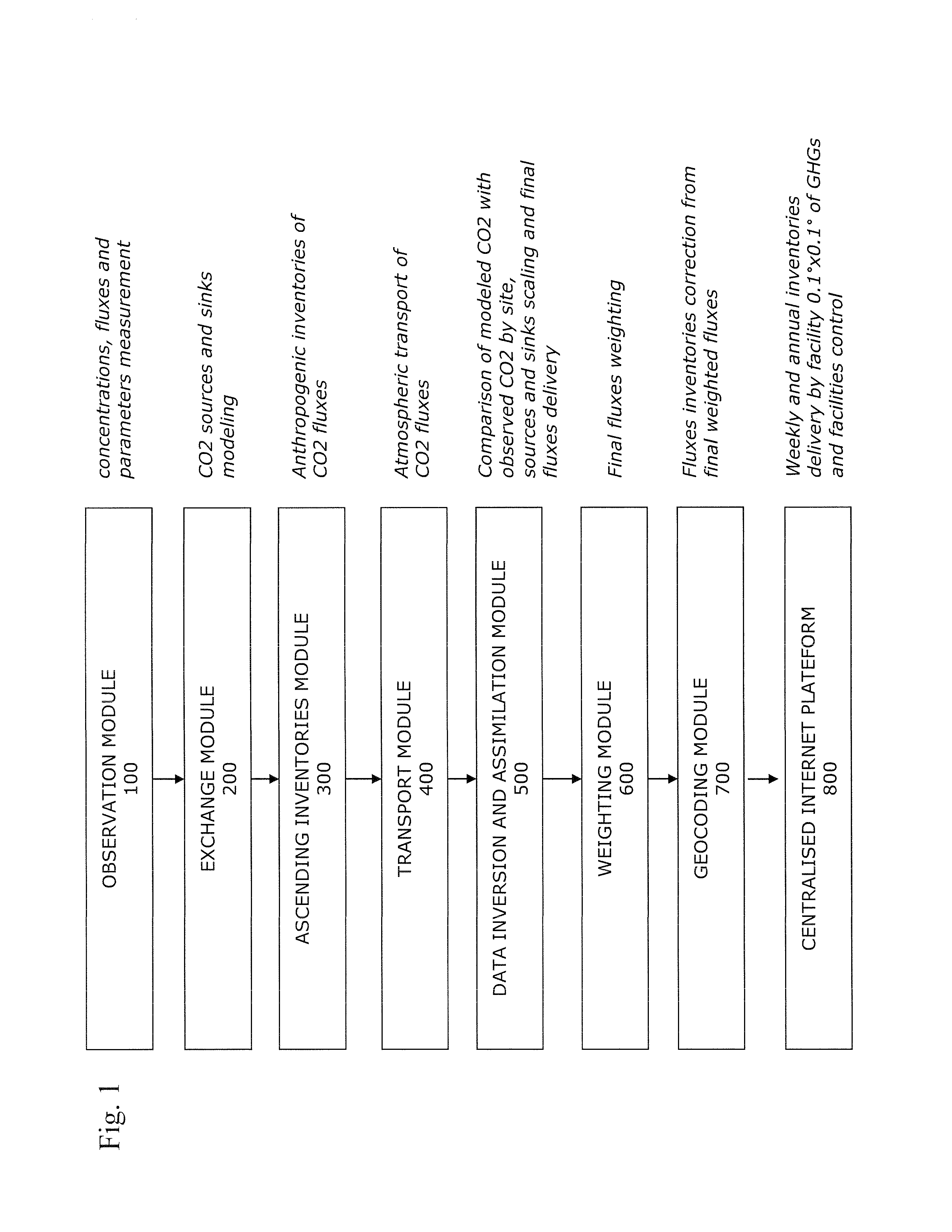

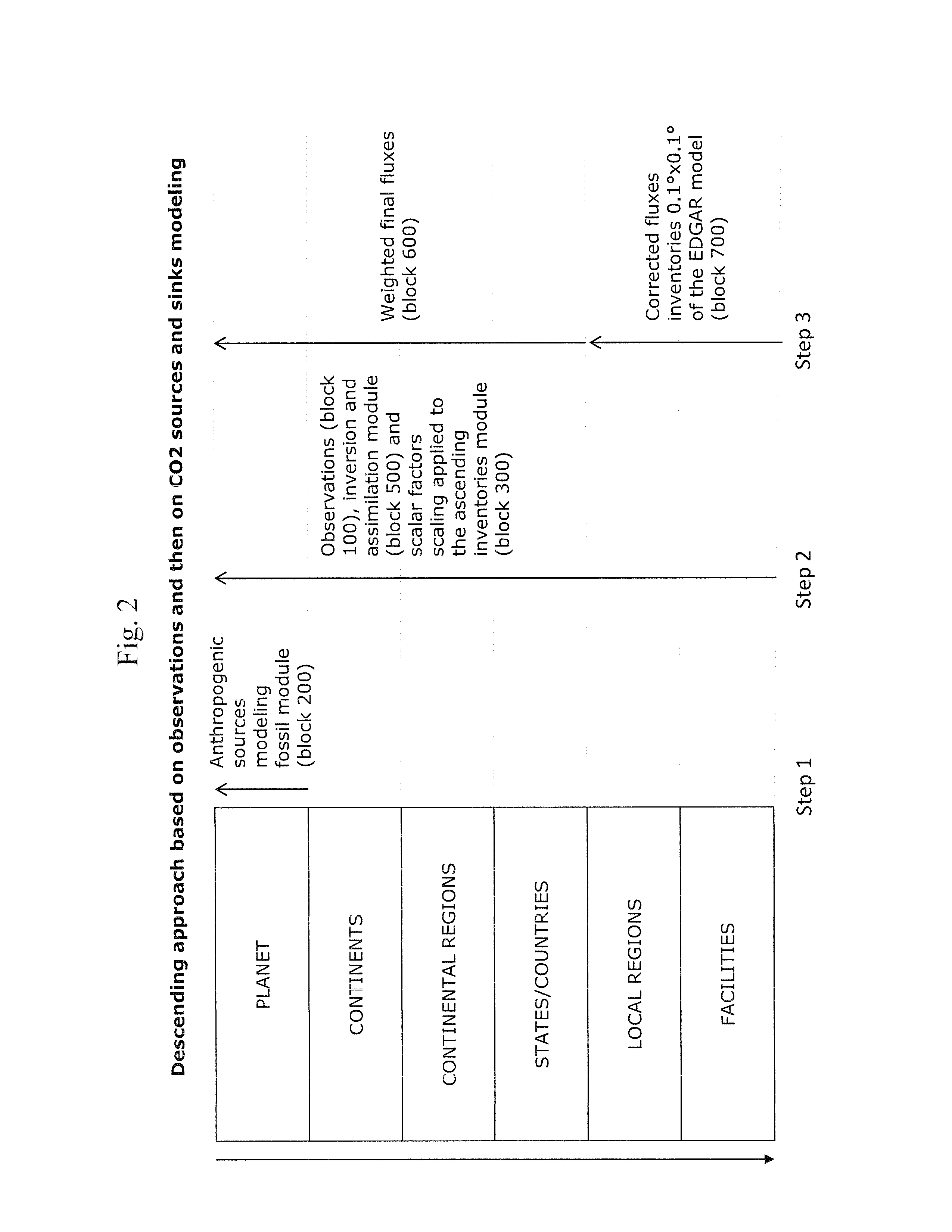

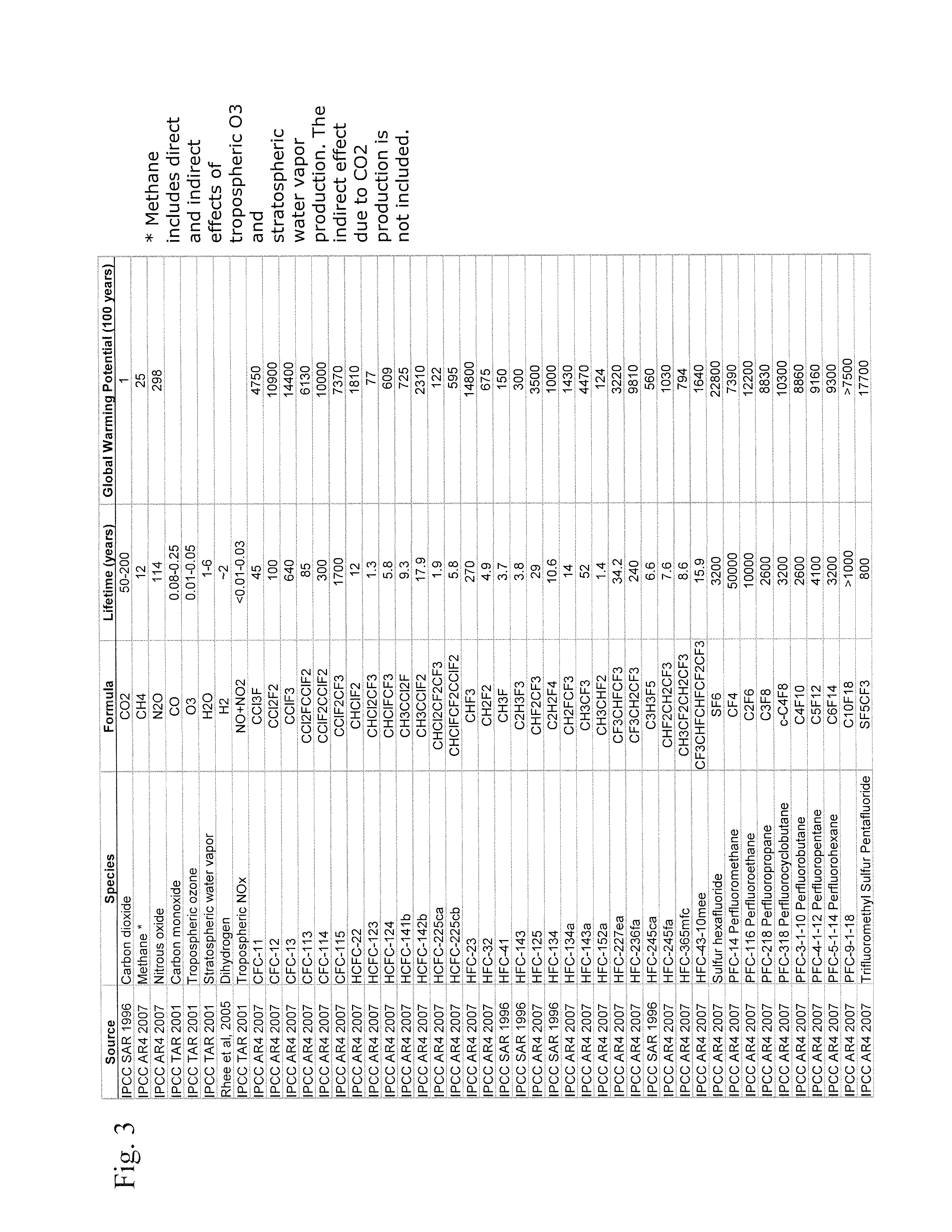

Method for measuring weekly and annual emissions of a greenhouse gas over a given surface area

InactiveUS20130179078A1Avoid source omissionReduce uncertaintyData processing applicationsWeather condition predictionAtmospheric sciencesGreen house gas emission

Method for measuring weekly and annual emissions of a greenhouse gas generated over a determined geographical area and measuring system implementing the method.

Owner:GRIFFON SA

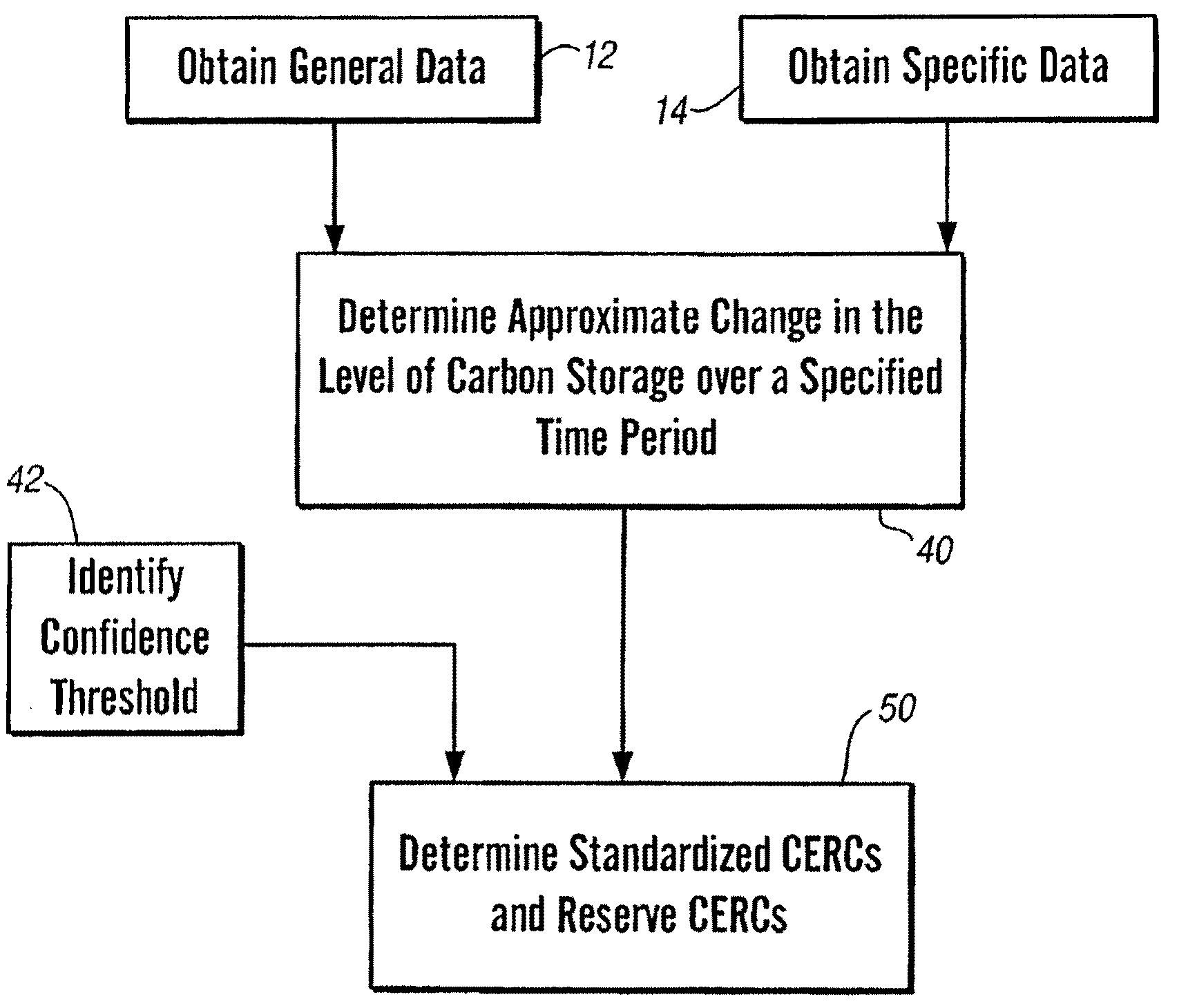

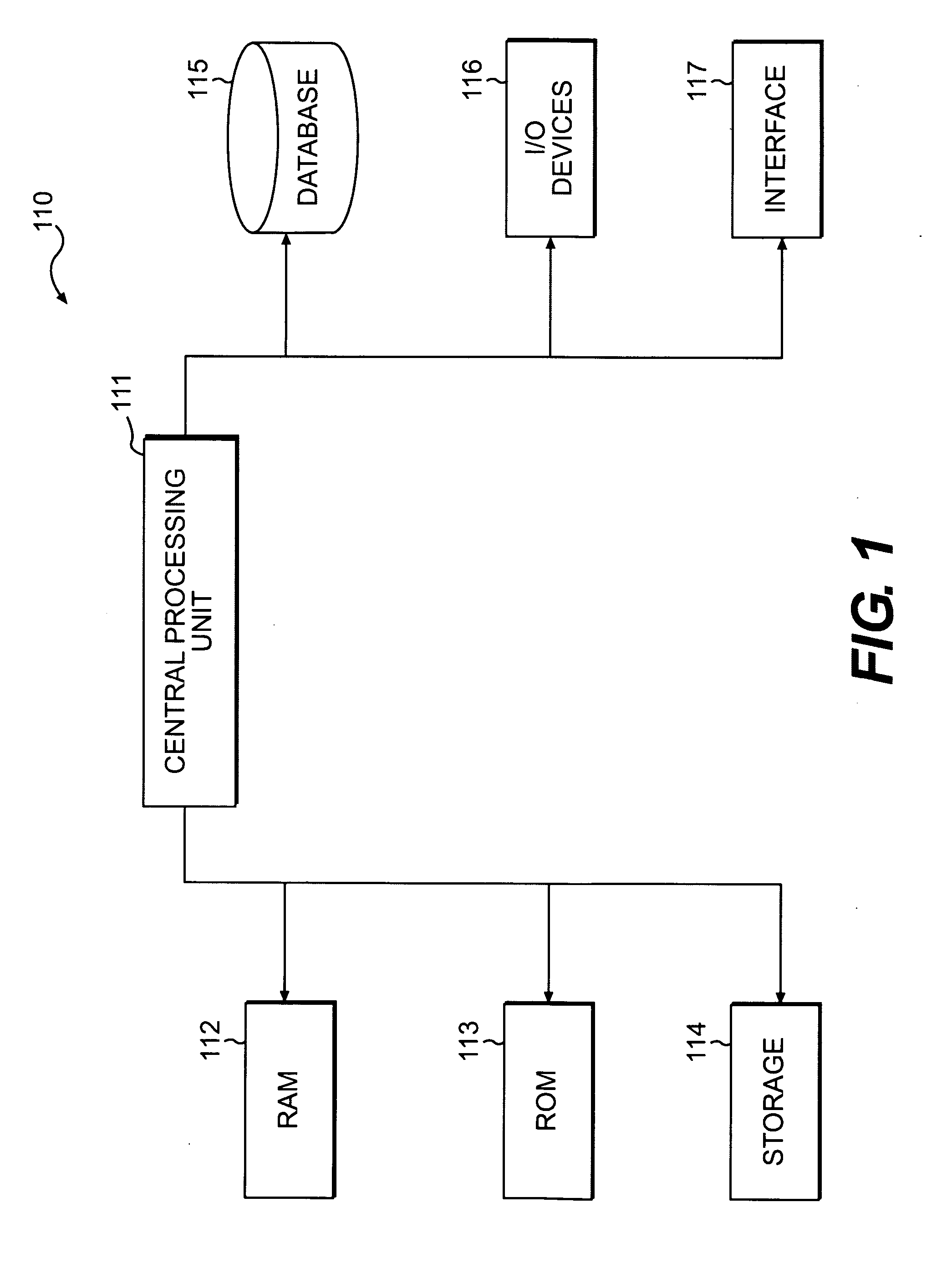

Technique for determining and reporting reduction in emissions of greenhouse gases at a site

A system for generating standardized greenhouse gas emission reduction credits based on mitigation of greenhouse gas emissions at a site resulting from use of renewable carbon as a fuel at the site to produce energy in substitution for previous use of a fossil fuel at the site, includes a computer, at least one database accessible by the computer and containing past site-specific data and subsequent site-specific data regarding the at least one variable impacting emissions of the greenhouse gas generated from the use of the renewable carbon as a fuel for generating energy at the site, a greenhouse gas emissions modeling module, and at least one interface to the computer, for outputting a report of the identified quantity of the standardized greenhouse gas emission reduction credits.

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

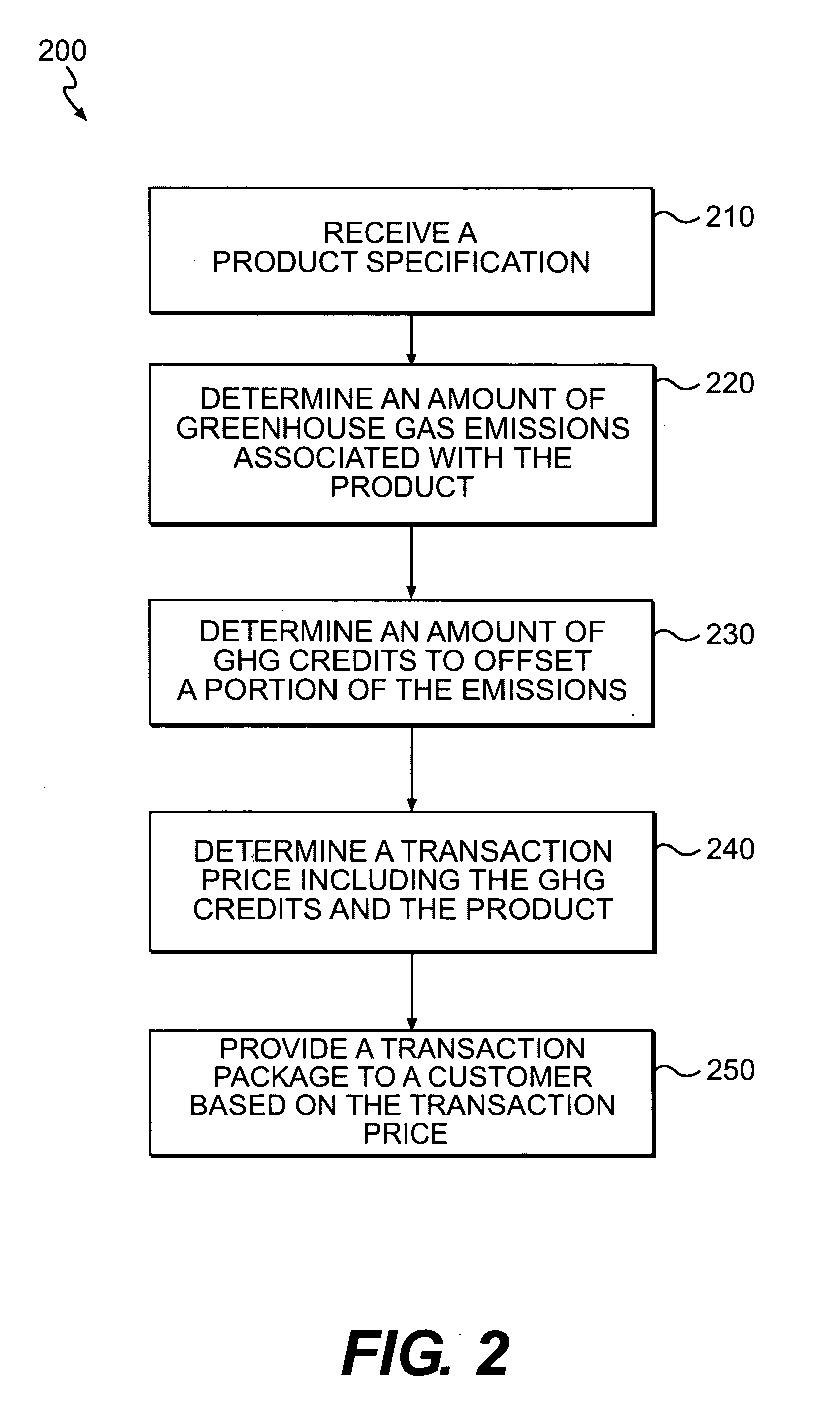

Method for packaging greenhouse gas credits with a product transaction

A method for packaging greenhouse gas credits with a product transaction includes determining an amount of greenhouse gas emissions associated with one or more products. The method also includes determining a quantity of greenhouse gas credits required to offset at least a portion of the greenhouse gas emissions of the one or more products. The method further includes determining a transaction price associated with the quantity of greenhouse gas credits. The method also includes providing a transaction package based on the determined purchase price associated with the greenhouse gas credits to a prospective customer.

Owner:CATERPILLAR INC

Paddy hull burned gas and waste residue comprehensive utilization method

The invention discloses a comprehensive utilization method for rice hull combustion emissions and waste residue, in particular a method for preparing superfine silicon dioxide and active carbon with high specific surface area by using the emissions and waste residue generated by the pyrolysis and combustion of the rice hull, which comprises the following steps: the main raw material sodium carbonate (or potassium carbonate) is heated and hydrolyzed to be sodium bicarbonate (or potassium bicarbonate), OH<-> is released, the silicon dioxide in the rice hull ashes is dissolved, the sodium bicarbonate (or the potassium bicarbonate) is reduced to sodium carbonate (or potassium carbonate) after temperature reduction, and then the silicon dioxide precipitate is separated out. The method has the advantages that the silicon dioxide which only plays the role of catalyst in the process can be used circularly without consumption, the cost is reduced; the purified combusted tail gas can be used for preparing a precipitator of the silicon dioxide, thus avoiding the pollution brought by acid neutralization and precipitation in the traditional technology, reducing the cost, making full use of carbon dioxide and reducing green house gas emission; and the activating agent for preparing the active carbon can be recovered, which can be returned to the hydrolyzation process to be reused after adjusting the concentration of the sodium carbonate (or the potassium carbonate), thus reducing the cost.

Owner:JILIN UNIV

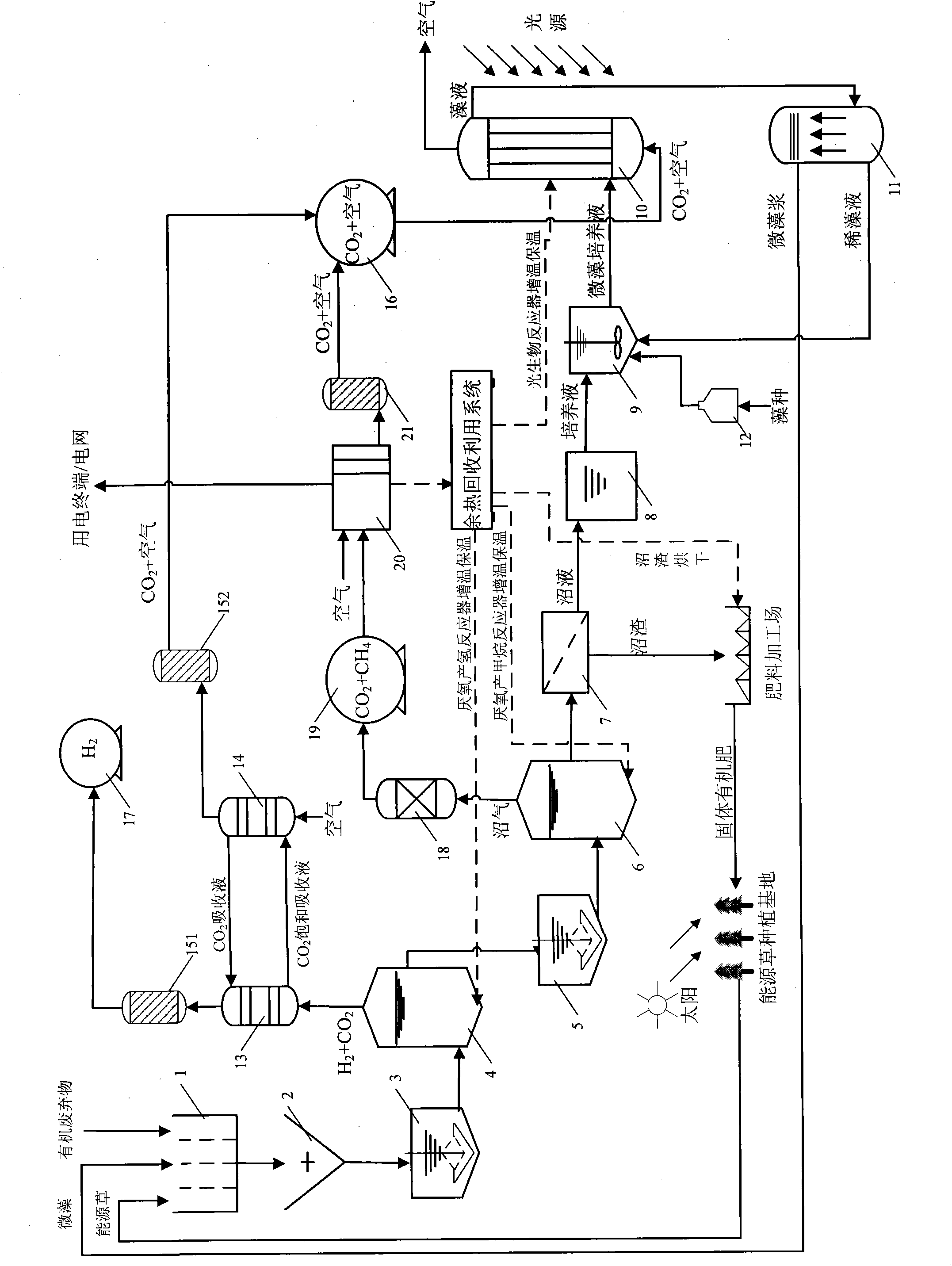

Energy utilization method of carbon dioxide zero-emission type organic waste

ActiveCN101914572AReduce the cost of trainingAvoid emissionsBio-organic fraction processingInternal combustion piston enginesNew energySludge

The invention provides an energy utilization method of carbon dioxide zero-emission type organic wastes, comprising the following steps of: (1) collecting and pretreating raw materials; (2) preparing hydrogen by anaerobic fermentation and purifying hydrogen; (3) fermenting methane and generating power by the methane; (4) treating biogas slurry and fixing carbon dioxide with microalgae; (5) processing biogas residues and planting energy grass; and (6) recycling afterheat. The method is suitable for treating various types of organic wastes, can be used for treating agricultural organic wastes, industrial organic wastes, domestic organic garbage, mud, and the like and the industries of developing new energy, and the like. The method can carry out a concrete application example of cyclic economy, eliminates environmental pollution, obtains clean energy at the same time, has no greenhouse gas emission in the process and can realize three effects of treating wastes, generating renewable clean energy and reducing carbon dioxide emission.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Poly-generation technique for using coal gas and coke oven gas as raw materials

ActiveCN101538483ANo conversionNo transform operationUrea derivatives preparationOrganic compound preparationHydrocarbon mixturesDesorption

The invention relates to a poly-generation technique for using coal gas and coke oven gas as raw materials. The poly-generation technique comprises the following steps of: carrying out mixing on part of H2 prepared by purified water gas and coke oven gas through pressure swing adsorption and tail gas obtained by Fischer-Tropsch synthesis, carrying out Fischer-Tropsch synthesis and obtaining hydrocarbon mixture and tail gas. The CO2 separated from tail gas separate by first pressure swing adsorption enters a urea synthesis unit for reaction, the CO and the hydrogen respectively obtained by separation of second pressure swing adsorption and third pressure swing adsorption of the residual tail gas are circulated back to a Fischer-Tropsch synthesis unit for reaction; and the residual gases can be used for generating power or obtaining SNG by secondary condensation. The coke oven gas enters pressure swing adsorption after being purified and desulphurized so as to separate H2; wherein one part of H2 is used as supplementation of H2 needed by Fischer-Tropsch synthesis and the other part of H2 is mixed with N2 for ammonia synthesis so as to obtain synthetic ammonia; and the synthetic ammonia is mixed with CO2 obtained by the first condensation and CO2 separated from the Fischer-Tropsch synthesis for urea synthesis so as to obtain urea. The CO2 separated from the first condensation of desorption gas by pressure swing adsorption of the coke oven gas is used for urea synthesis; and the residual gases is treated by the second condensation to obtain SNG and mixed gas of CO and N2. The invention has no emission of greenhouse gases, uses richness in carbon and deficiency in hydrogen of the coal gas and the richness in hydrogen and deficiency in carbon of the coke oven gas to carry out complementation, realizes modulation of product structure by Fischer-Tropsch synthesis and improves the economical efficiency of the process of Fischer-Tropsch synthesis.

Owner:中科潞安能源技术有限公司

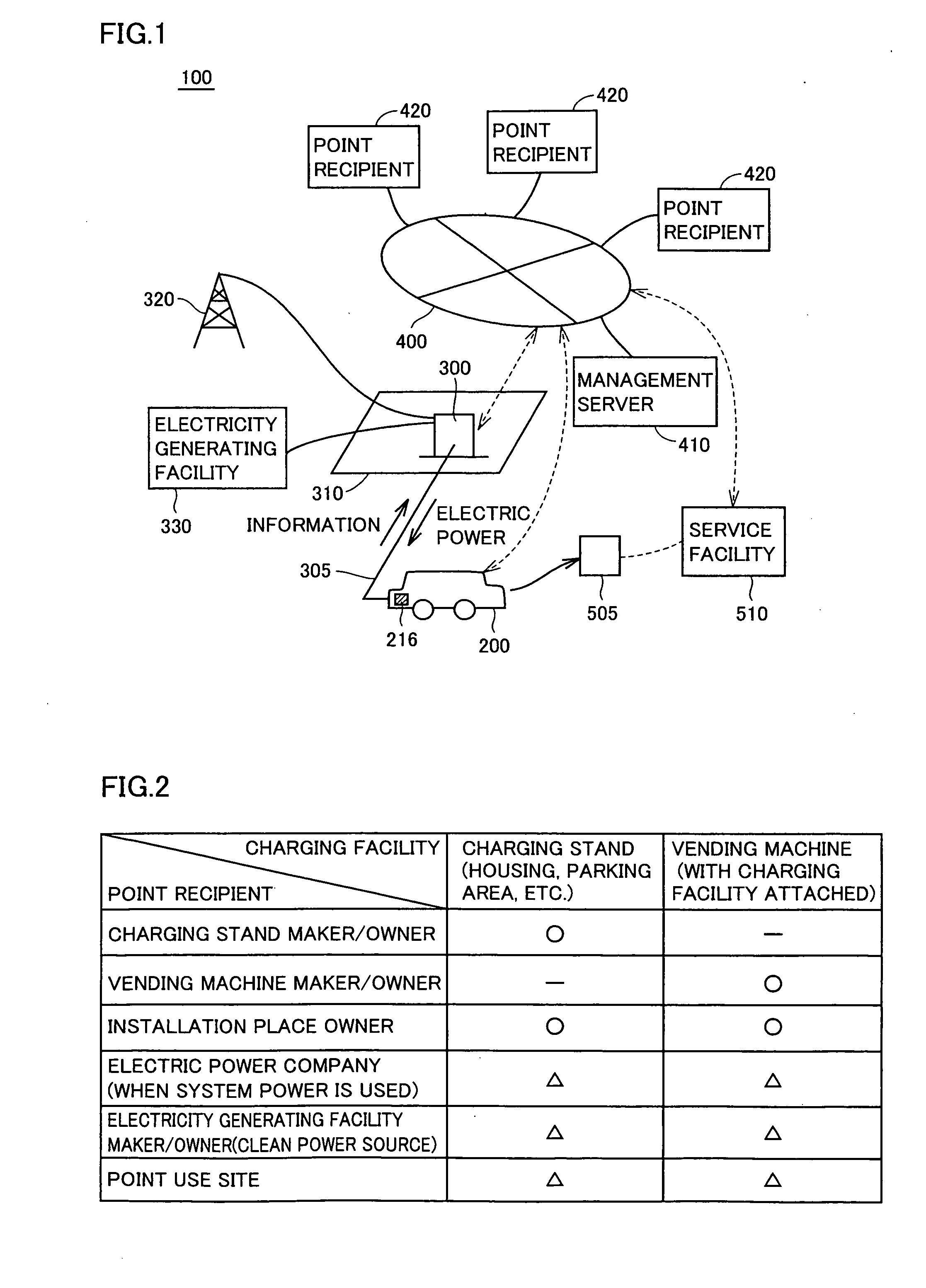

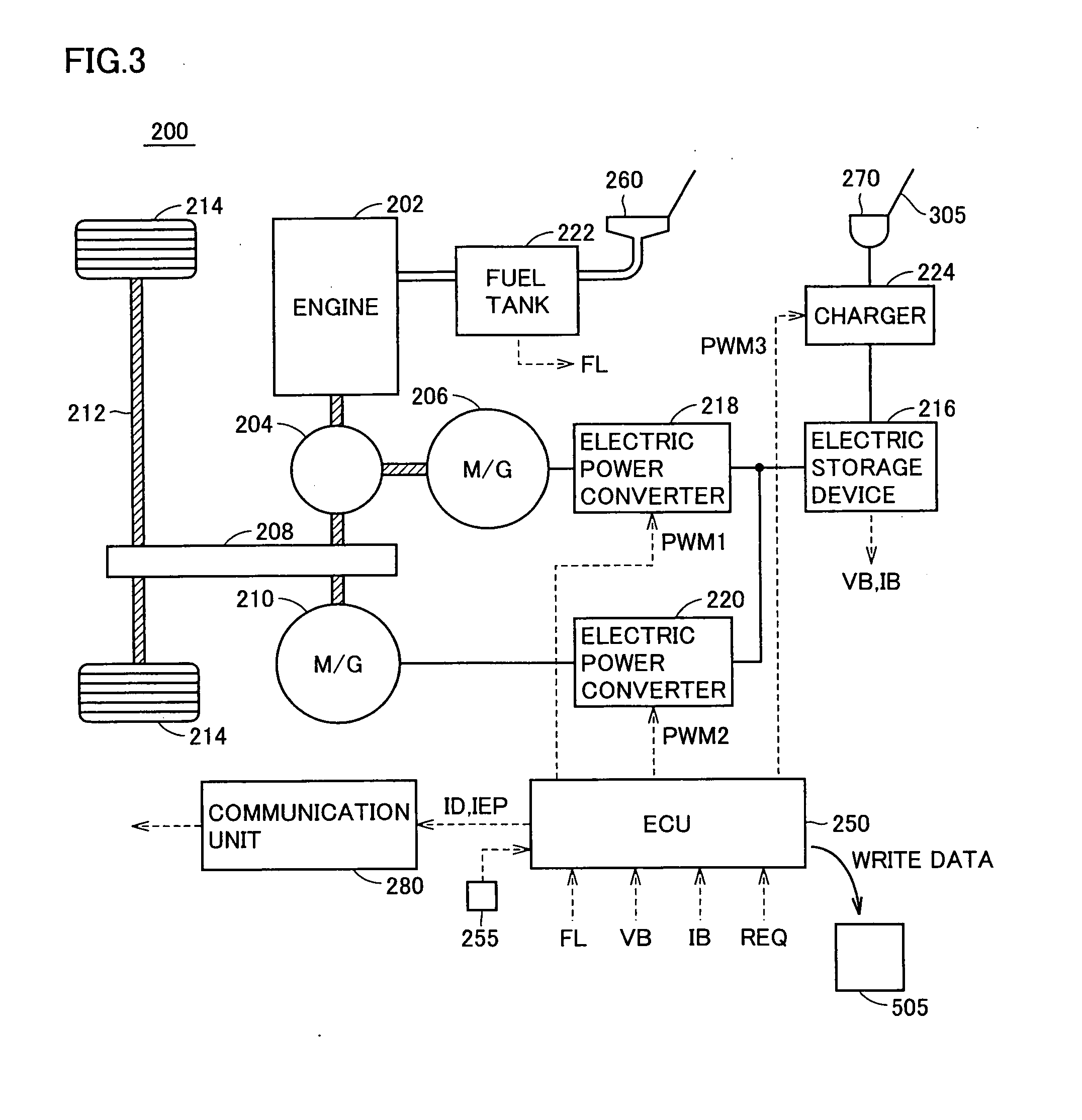

Ecological-point management system

InactiveUS20090144149A1Reducing greenhouse gas emissionEasy to useDigital data processing detailsCoin-freed apparatusDriver/operatorEngineering

An ecological-point management system includes an electric powered vehicle, a charging facility, a communication network, a management server, point recipients each having a device capable of accessing the communication network. The electric storage device of the electric powered vehicle is configured to be chargeable by the charging facility. In the ecological-point management system, an ecological point in accordance with an amount of greenhouse gas emission that can be reduced by traveling using electric power by the electric powered vehicle is given to the point recipients. The point recipients can include an owner or a driver of the electric powered vehicle, and a manufacture, an installation personnel, an owner of the charging facility, and an owner of an installation place, and further a provider of the charging power.

Owner:TOYOTA JIDOSHA KK

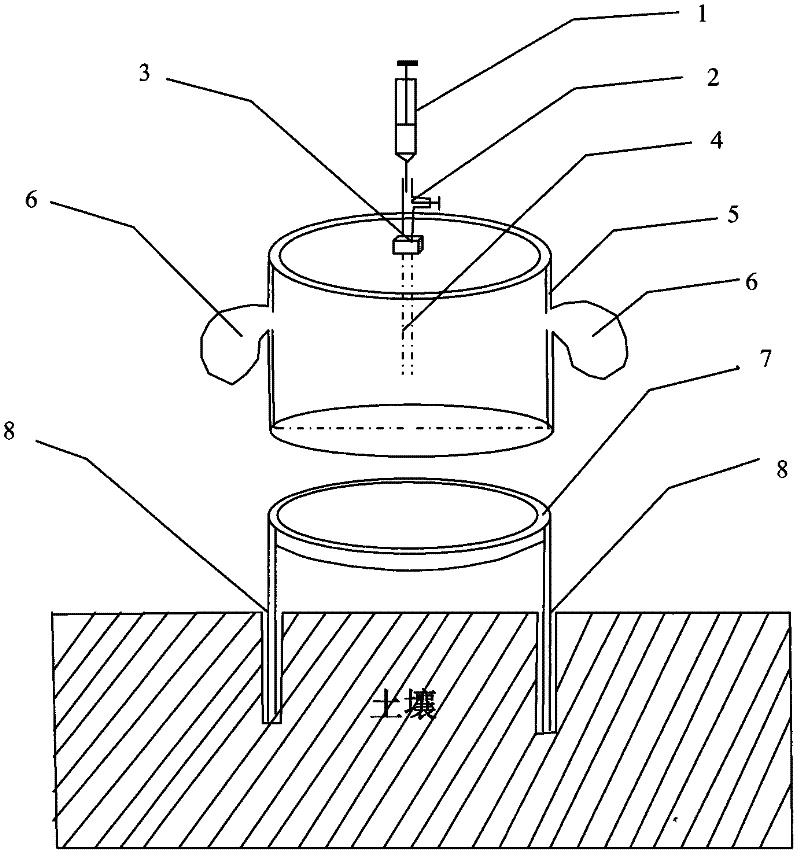

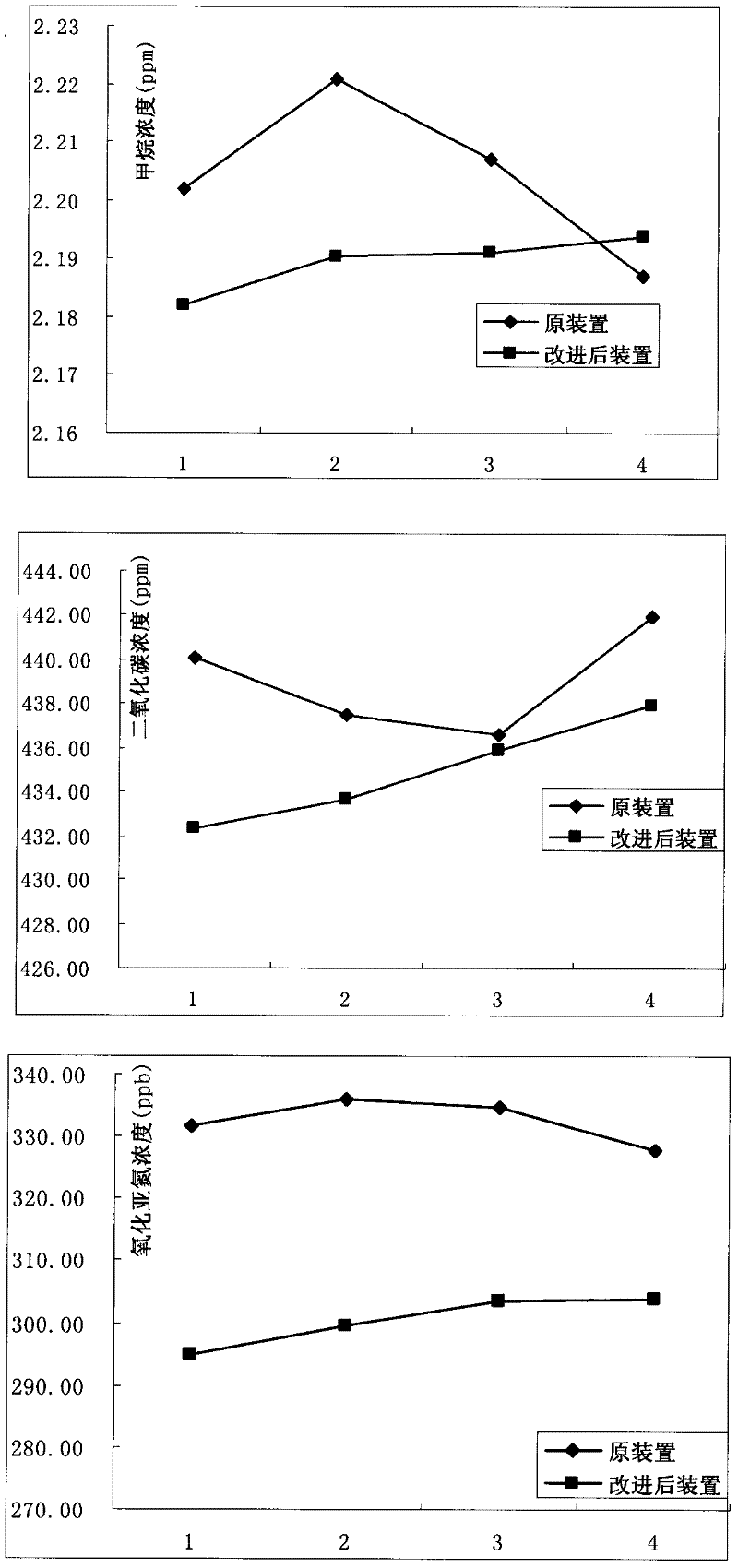

Buffer type soil gas sampling device

InactiveCN102252876APrevent air leakageGuaranteed reliabilityWithdrawing sample devicesGrasslandEngineering

The invention discloses a buffer type soil gas sampling device, belonging to the technical field of soil experimental facilities. The device consists of an injector, a valve, a gas-exhausting hole, a gas-exhausting conduit, a box body, gasbags, a water seal tank and a base. As the gasbags are additionally arranged on the box body, gas pressure inside / outside the box body during a whole storing and sampling process is always maintained in a balance state after the buffer adjustment of the gasbags, the box body is prevented from outward or inward gas leakage, and the quality of gas stored in the box body is maintained; meanwhile, the difficulty that natural release of soil gas is subjected to inhibition is also overcome, the reliability of measured data for gas released by soil is enhanced.The device has the advantages of reasonable design, simplicity for operating and low cost, and can be widely applied to gathering work for greenhouse gas emission in farmland, nudation, grassland andthe like.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

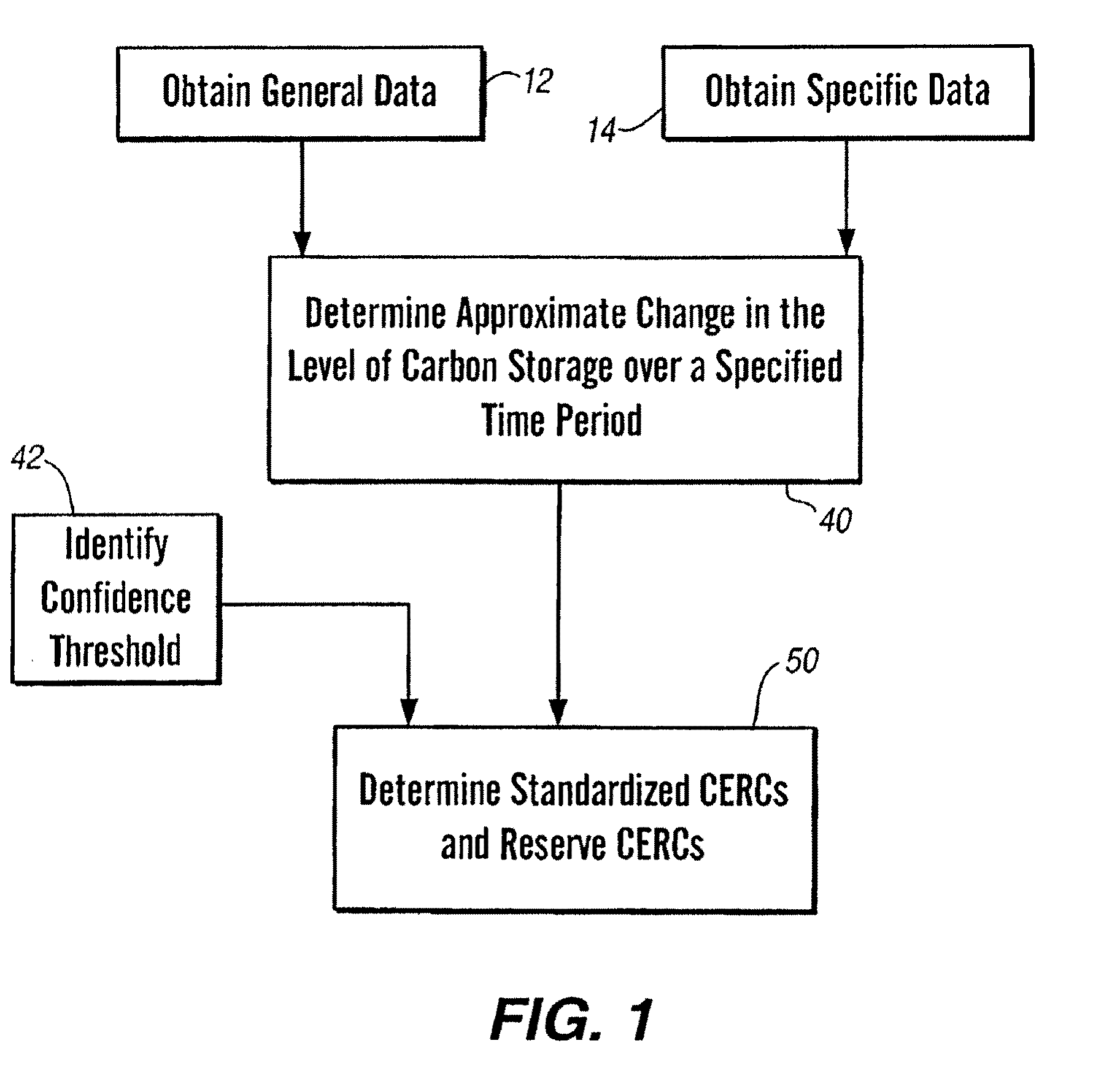

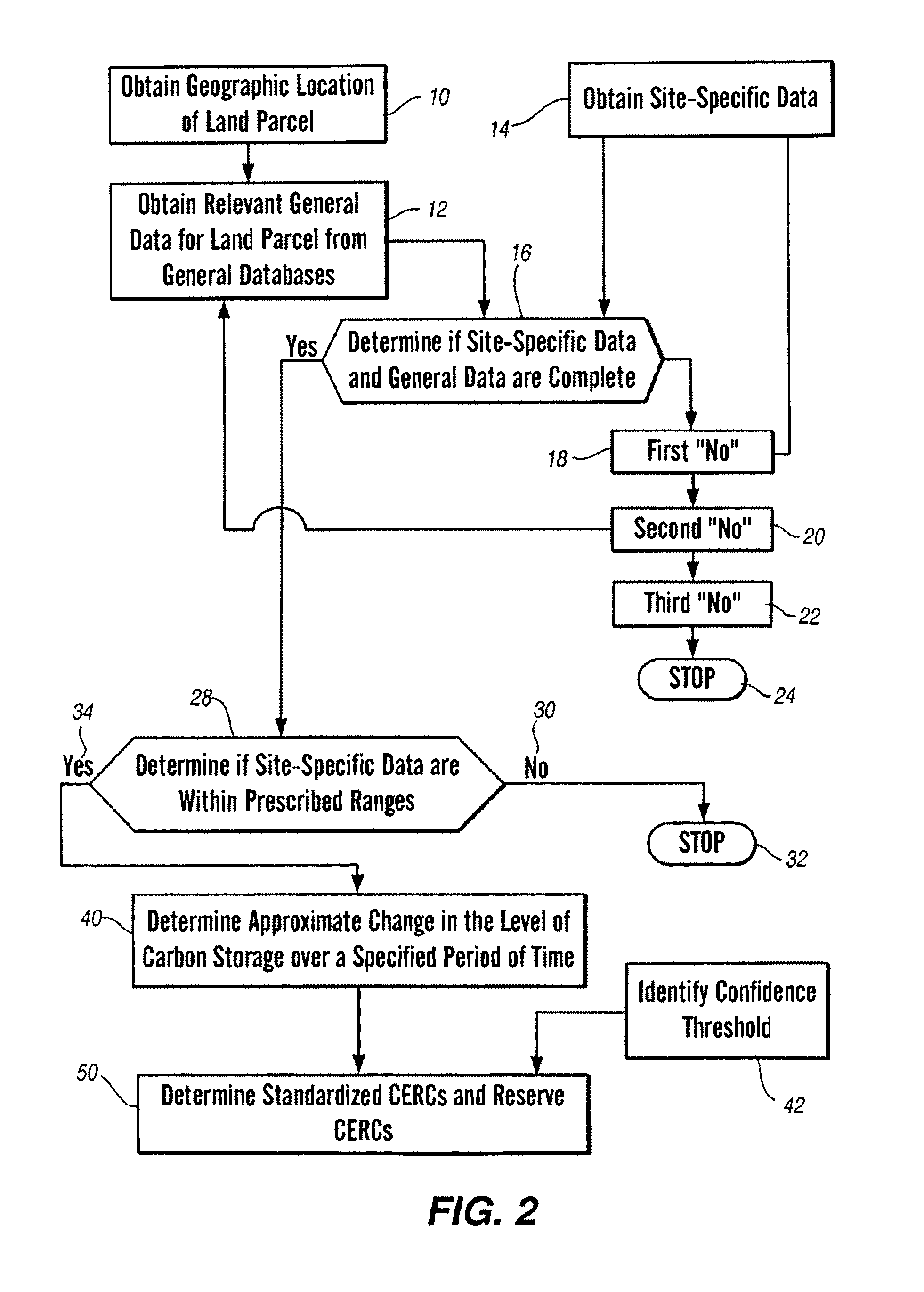

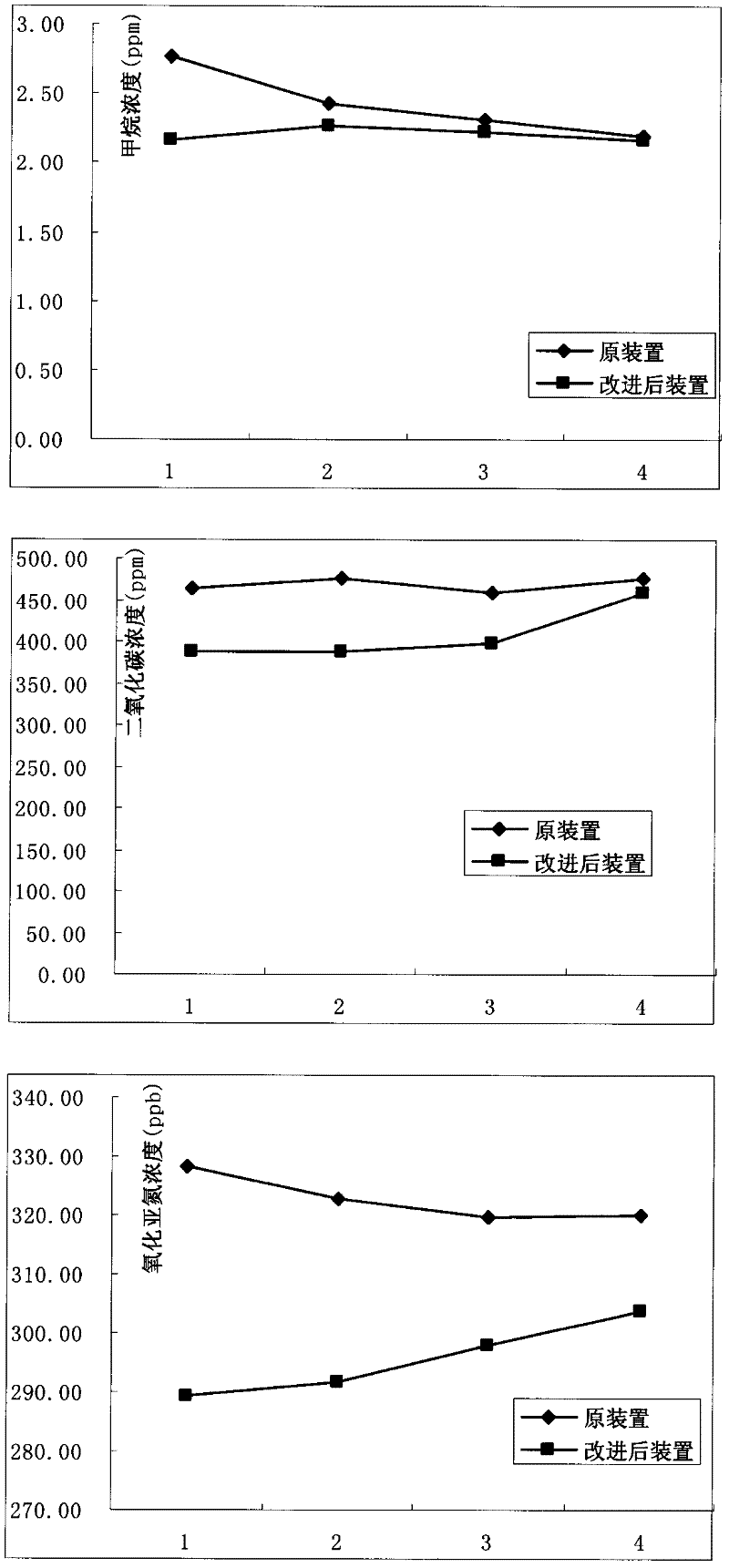

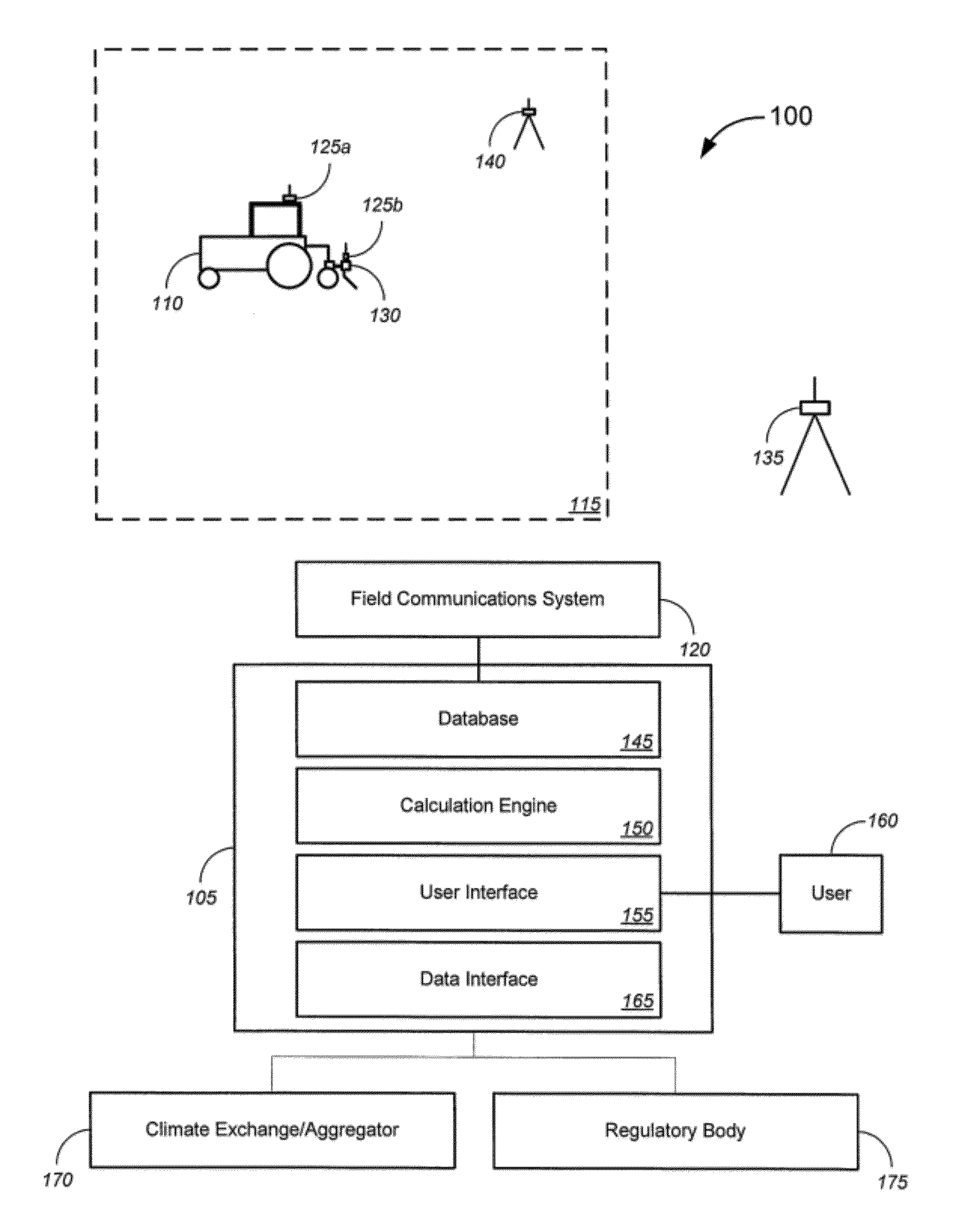

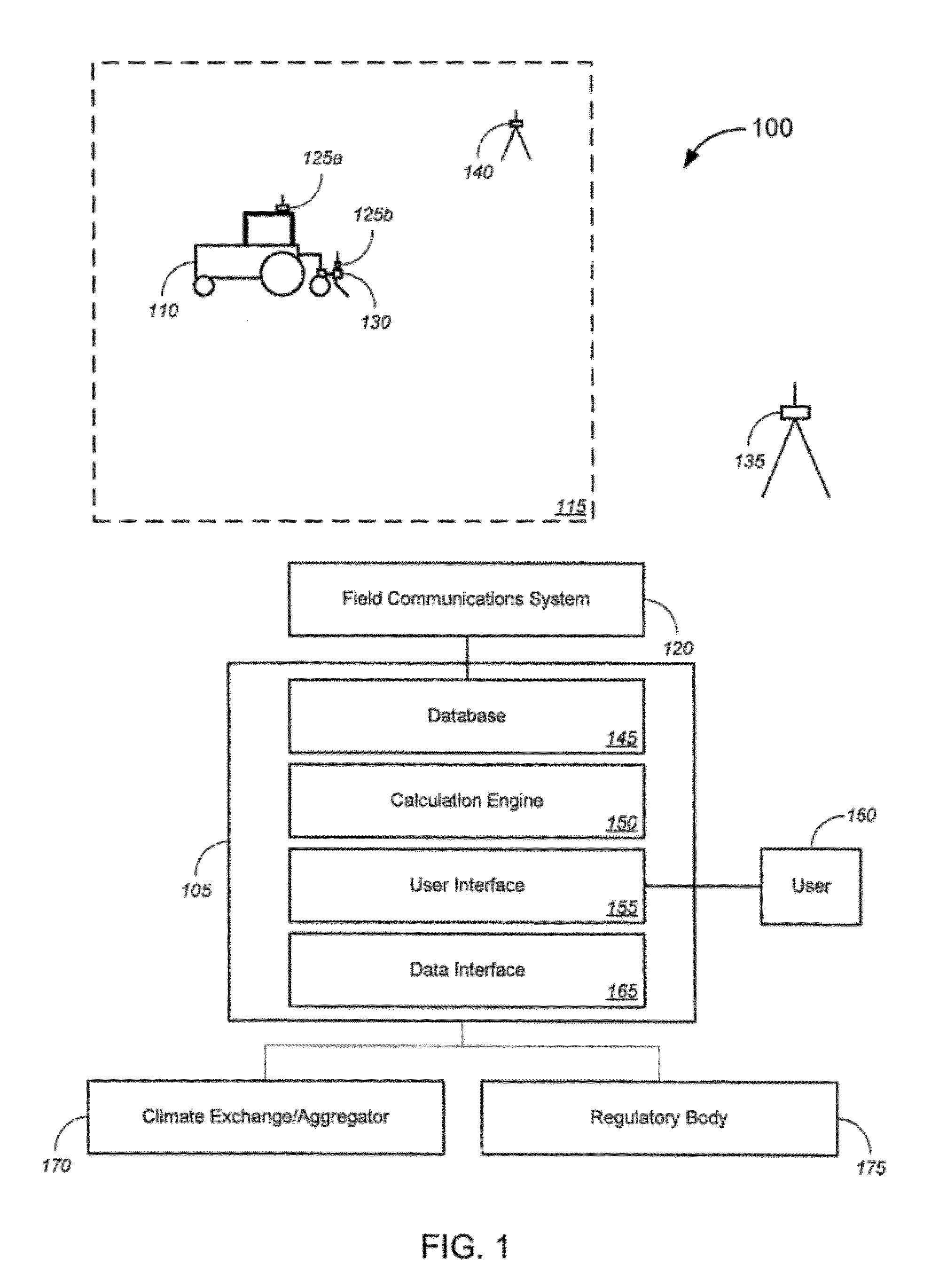

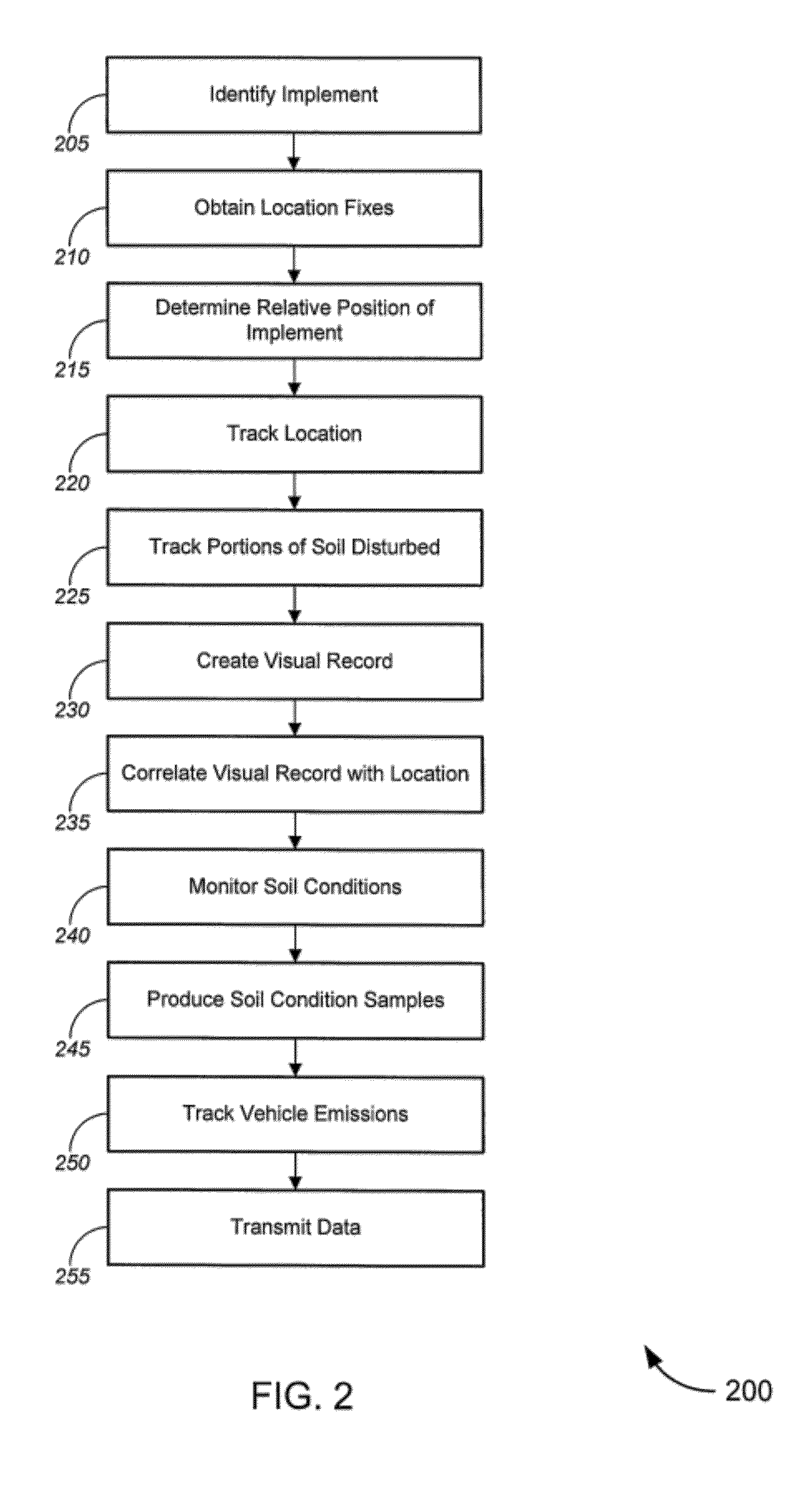

Tracking Carbon Output in Agricultural Applications

ActiveUS20120089304A1Enhance and facilitate collectionEnhance and facilitate and and verificationData processing applicationsAnalogue computers for trafficCarbon creditAgricultural engineering

Novel tools and techniques to enhance and / or facilitate the collection, tracking, and / or verification of greenhouse gas emissions and / or savings, particularly (but not exclusively) in agricultural applications. Some tools, for example, can assist in the verification of carbon credits that may result from conservation tilling activities. Other embodiments can track greenhouse gas emissions that result from agricultural activities, including without limitation the application of pesticides, fertilizers, and / or other agricultural chemicals.

Owner:TRIMBLE NAVIGATION LTD

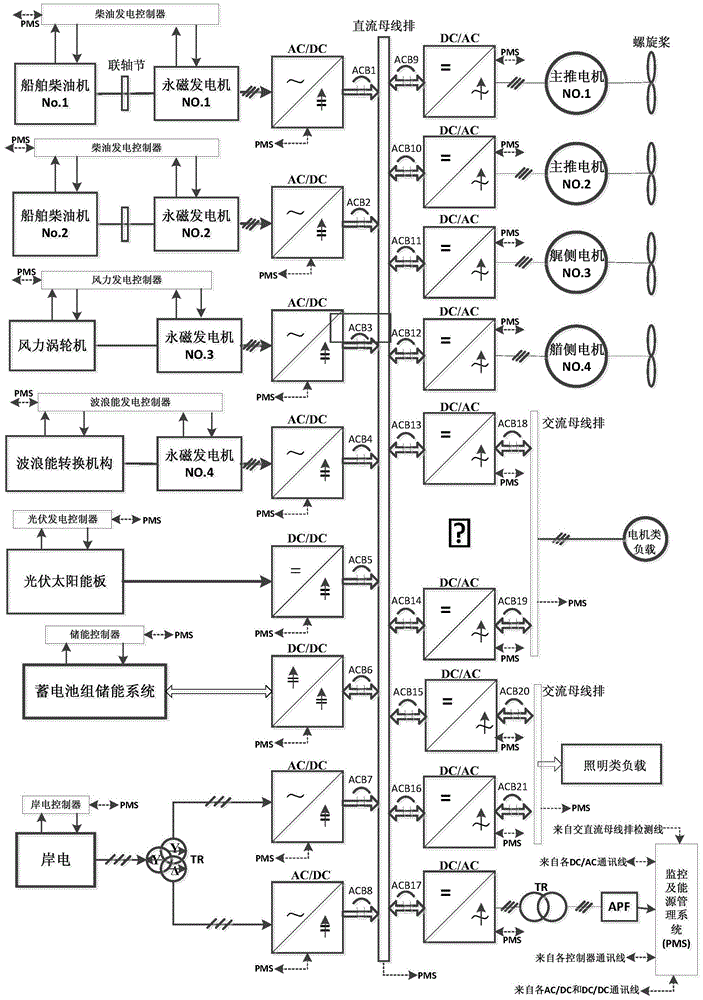

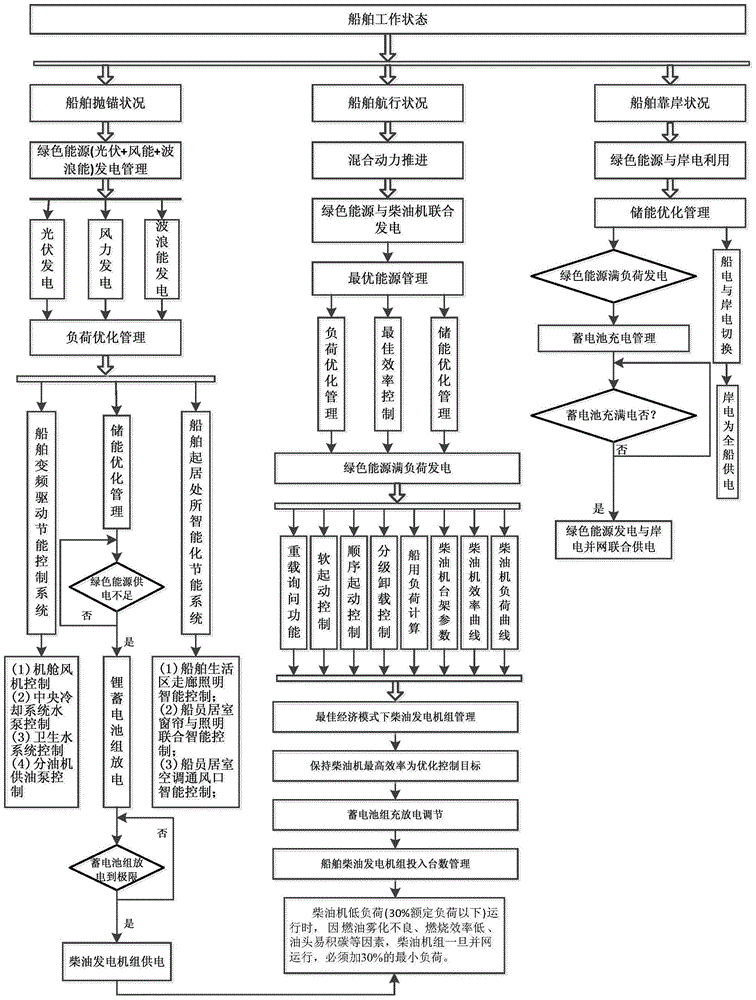

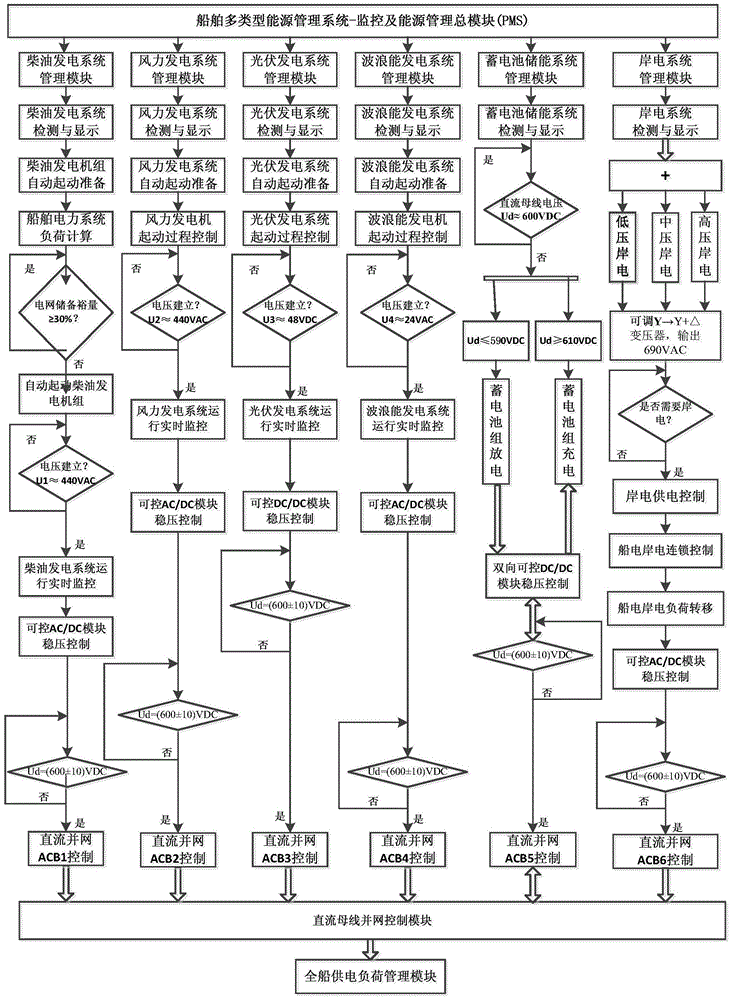

Ship multi-type energy source management system and energy source management method

InactiveCN106809363AControlled emissionsPromote sustainable developmentPropulsion based emission reductionAuxillariesThermal energyShore

The invention provides a ship multi-type energy source management system and an energy source management method. The ship multi-type energy source management system comprises a monitoring and energy source management master module, a diesel power generation system, a wind power generation system, a photovoltaic power generation system, a wave energy power generation system, a storage battery energy storage system, a shore power system, a direct current bus bar and a plurality of paths of power transmission systems. The ship multi-type energy source management system and the energy source management method have the advantages that the ship multi-type energy source management system provided by the invention fills the technological blank of integrating various types of green energy source power generation into ship heat energy power generation systems; the energy conservation and emission reduction are met; the global warming is responded; the greenhouse gas emission is controlled; the atmospheric environment is protected and the sustainable development of low-carbon economy is promoted.

Owner:SHANGHAI GUANTU ELECTRICAL TECH CO LTD

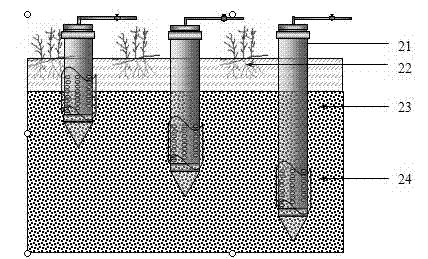

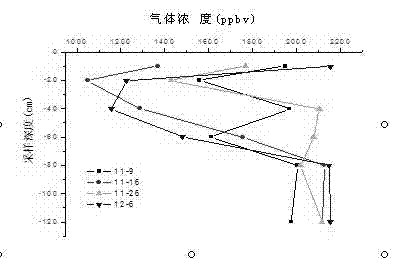

Greenhouse gas collection device for soil at different depths, and in-situ observation method

InactiveCN102879231ASimple structureFew influencing factorsWithdrawing sample devicesGreenhouseEnvironmental engineering

The invention provides a greenhouse gas discharging and collection device for soil at different depths. The device comprises more than two gas collectors with different lengths of circular gas storage tubes. The device is simple in structure, convenient to use and suitable for collecting greenhouse gas at different depths of soil with non-saturated water and soil with saturated water in a non-growth season and can continuously collect gas such as CO2, N2O and CH4; when the gas is collected, the environment interference is small, so that the influence factor in a gas collection process is reduced; the device is easy to operate; the collected greenhouse gas has representativeness in discharging intensity in a unit area; and the device can continuously observe discharging of the greenhouse gas of the soil for many years and can observe the accumulation situation of the greenhouse gas in a freezing process and the discharging situation in a soil melting process. The device can be widely applied to observation and research on discharging of the greenhouse gas of various types of soil at different depths in a farmland, a grassland, a wet land and the like.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

Energy utilization system of organic wastes with zero emission of carbon dioxide

ActiveCN101920258ARealize processingEliminate pollutionWaste processingSolid waste disposalSludgeCo2 absorption

The invention provides an energy utilization system of organic wastes with zero emission of carbon dioxide, which organically combines anaerobic fermentation hydrogen production, methane fermentation, CO2 absorption, microalgae fixation CO2, biogas liquid treatment and energy grass planting. The system is suitable for treating various types of organic wastes, can be applied to the treatment of agricultural organic wastes, industrial organic wastes, domestic organic wastes, slurry and the like, and the industries, such as new energy development. Through the application of the invention, the specific application demonstration of recycling economy can be carried out, clean energy is obtained while eliminating environmental pollution, no greenhouse gas emits in the process, and the triple effects of wastes treatment, production of clean and renewable energy sources and reduction of carbon dioxide emission can be realized.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

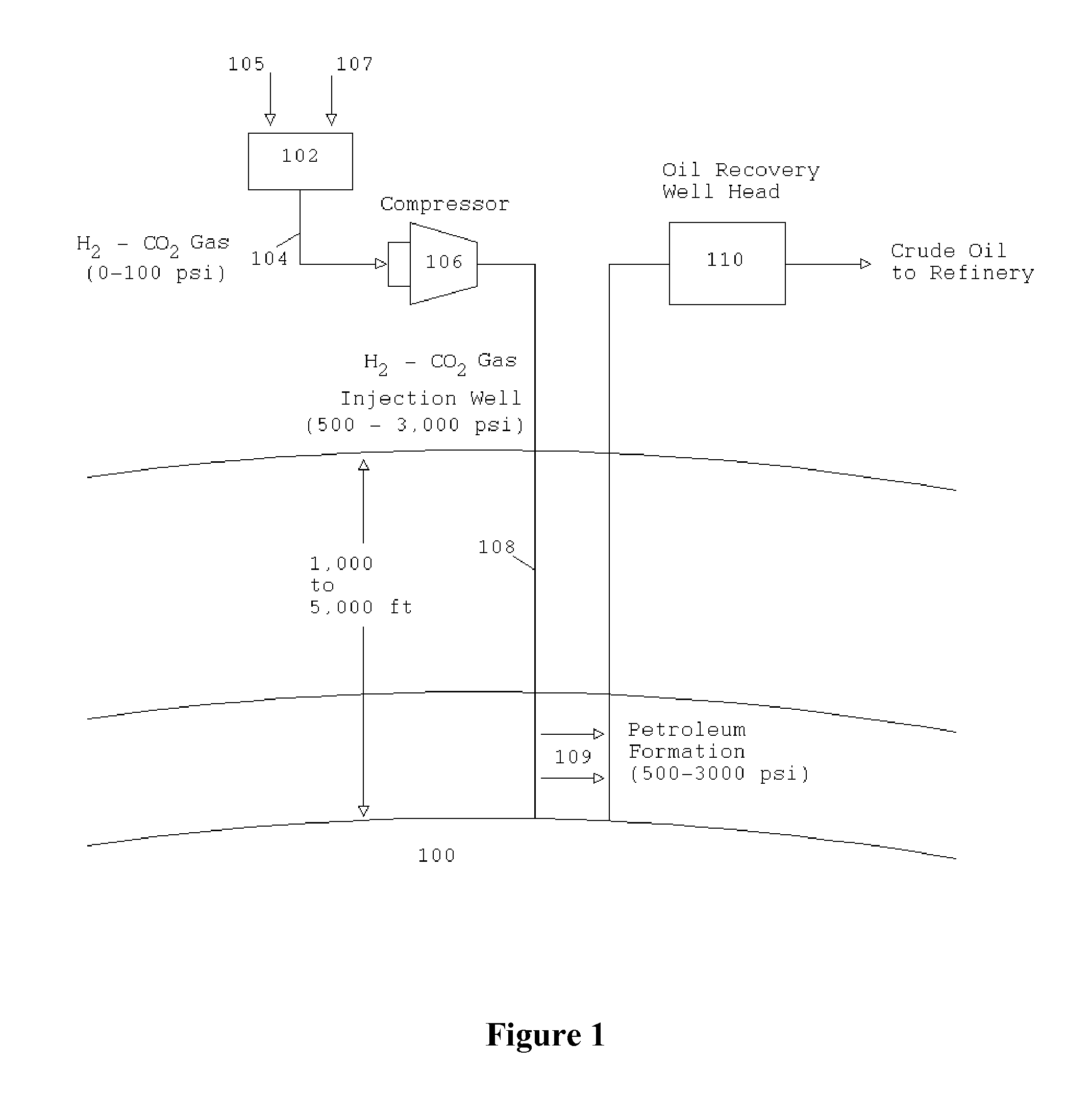

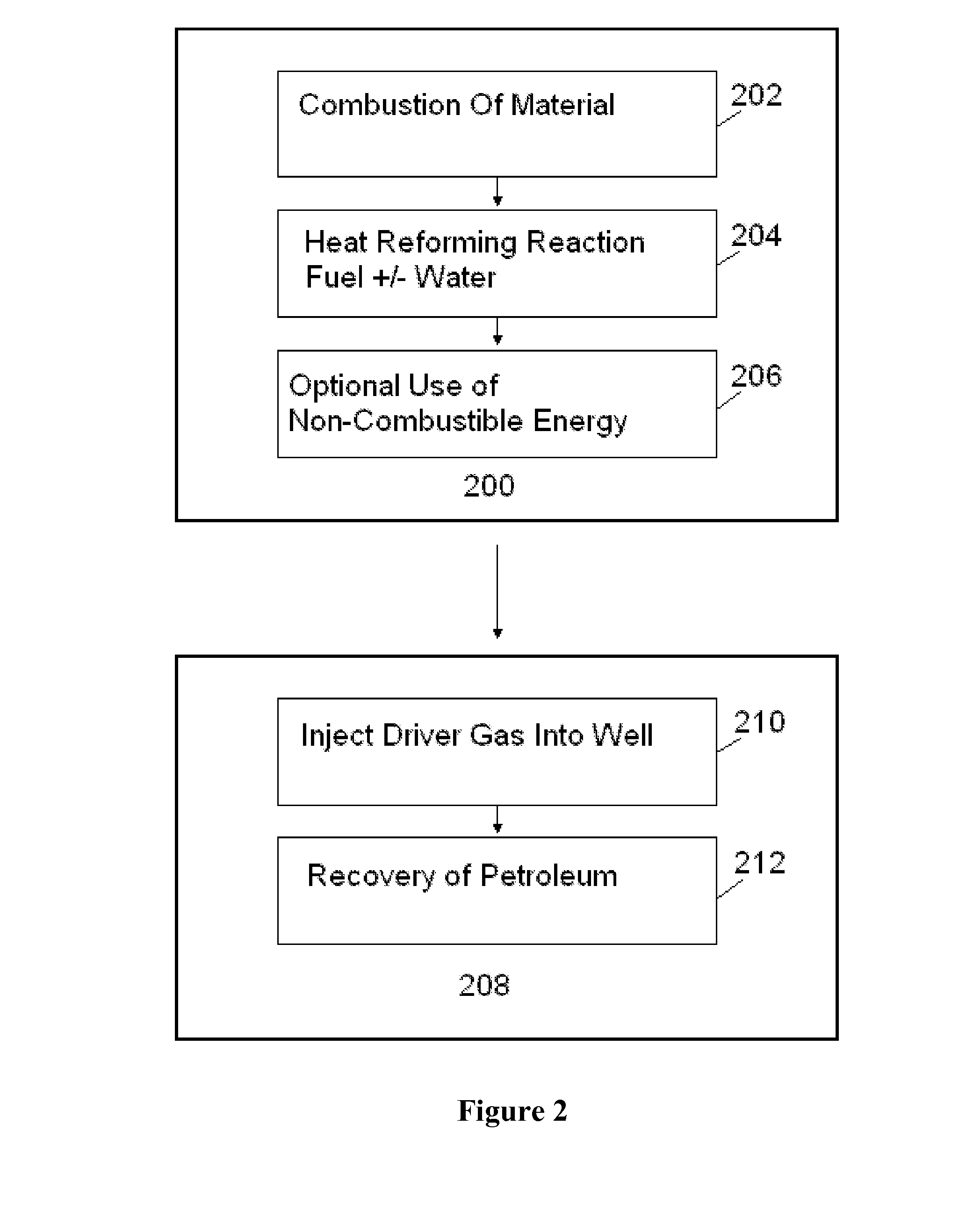

Systems for extracting fluids from the earth's subsurface and for generating electricity without greenhouse gas emissions

InactiveUS20090014170A1Improve thermal efficiencyEnhanced overall recoveryDrilling rodsInsulationElectricityHydrogen

An embodiment is an apparatus for generating a driver gas, for recovering fluid from the Earth's subsurface. The apparatus includes a fuel reformer, adapted to react a fuel with water to produce carbon dioxide gas and hydrogen gas; a compressor, adapted to compress a portion of the carbon dioxide gas and a portion of the hydrogen gas; a gas injection unit, adapted to inject the portion of the carbon dioxide gas and the portion of the hydrogen gas compressed by the compressor, into a subsurface reservoir; a gas capture unit, adapted to capture a portion of the carbon dioxide gas and the hydrogen gas, that emerges from the subsurface reservoir; and a control module capable of using subsurface data to regulate operation of the gas injection unit. The apparatus may also include a power generator adapted to utilize a portion of the hydrogen gas to generate power, hence producing electricity without greenhouse gas emissions.

Owner:PIONEER ENERGY

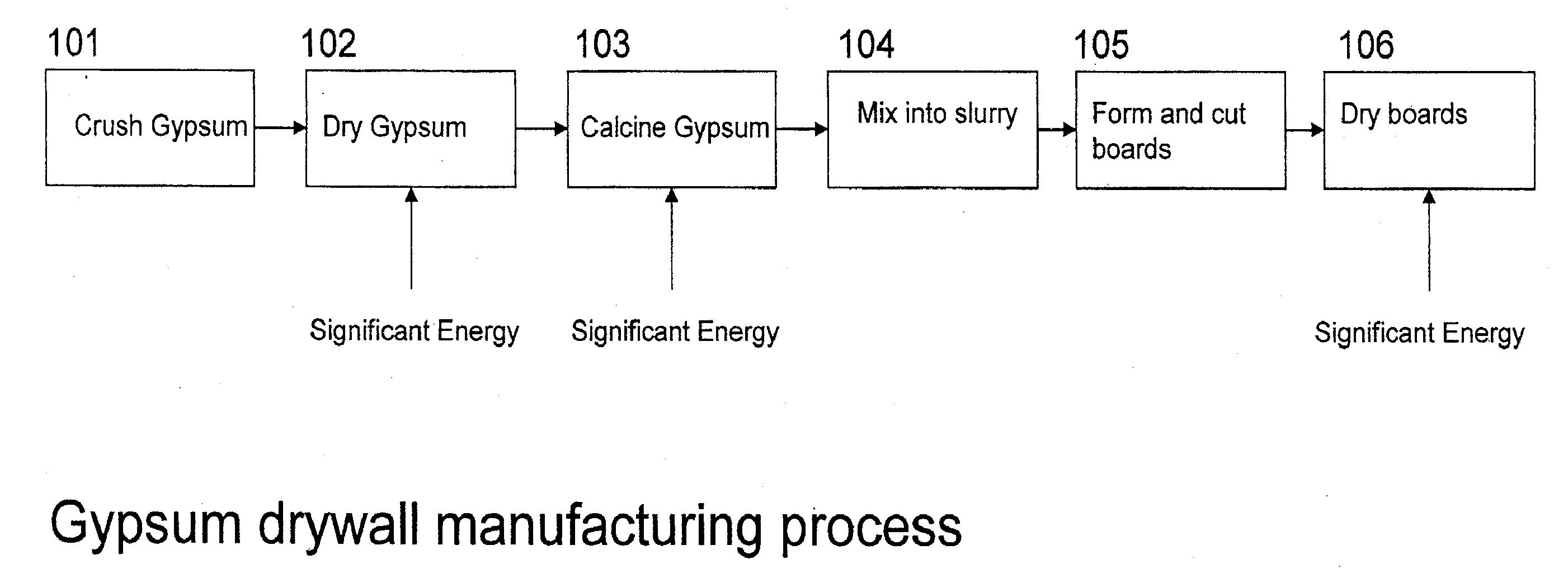

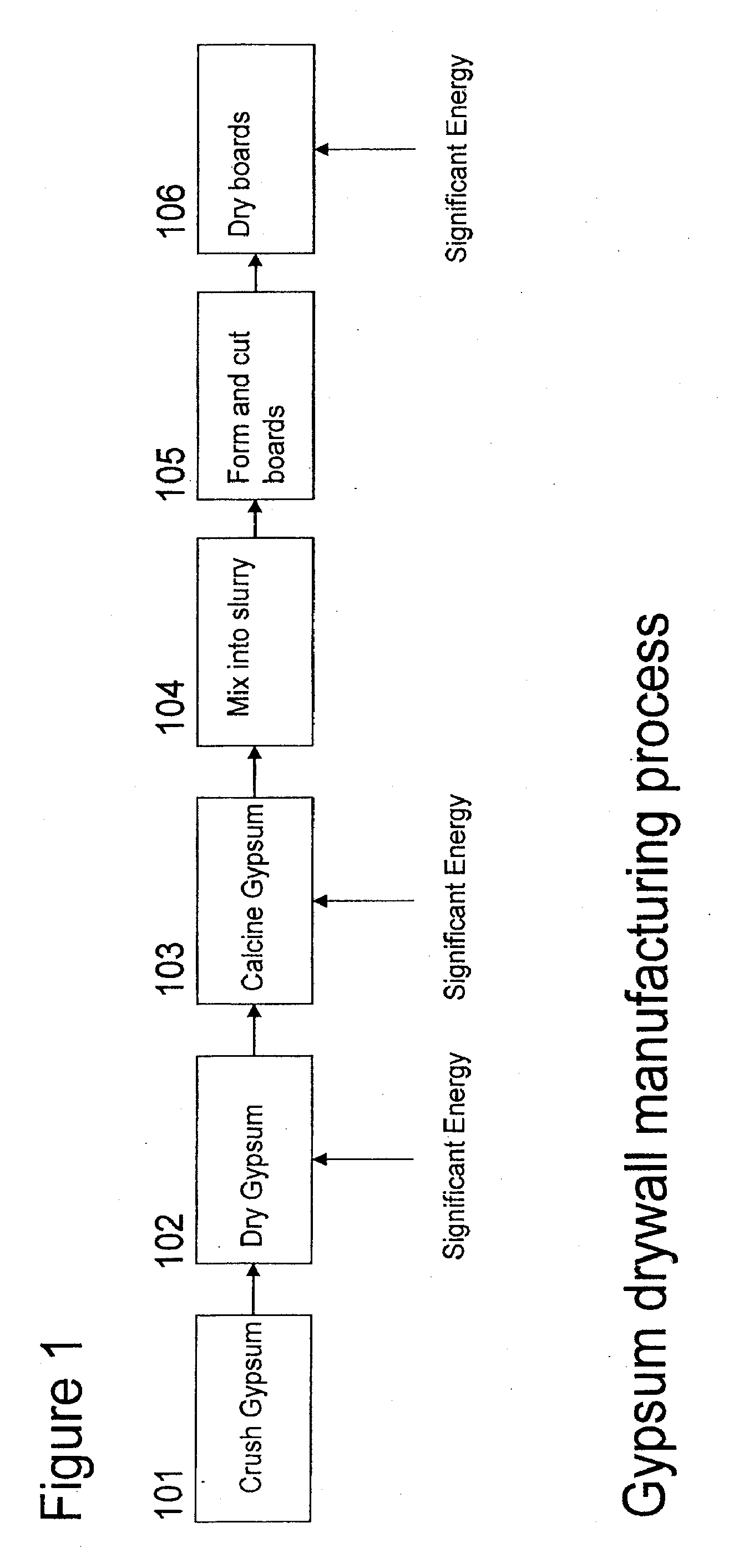

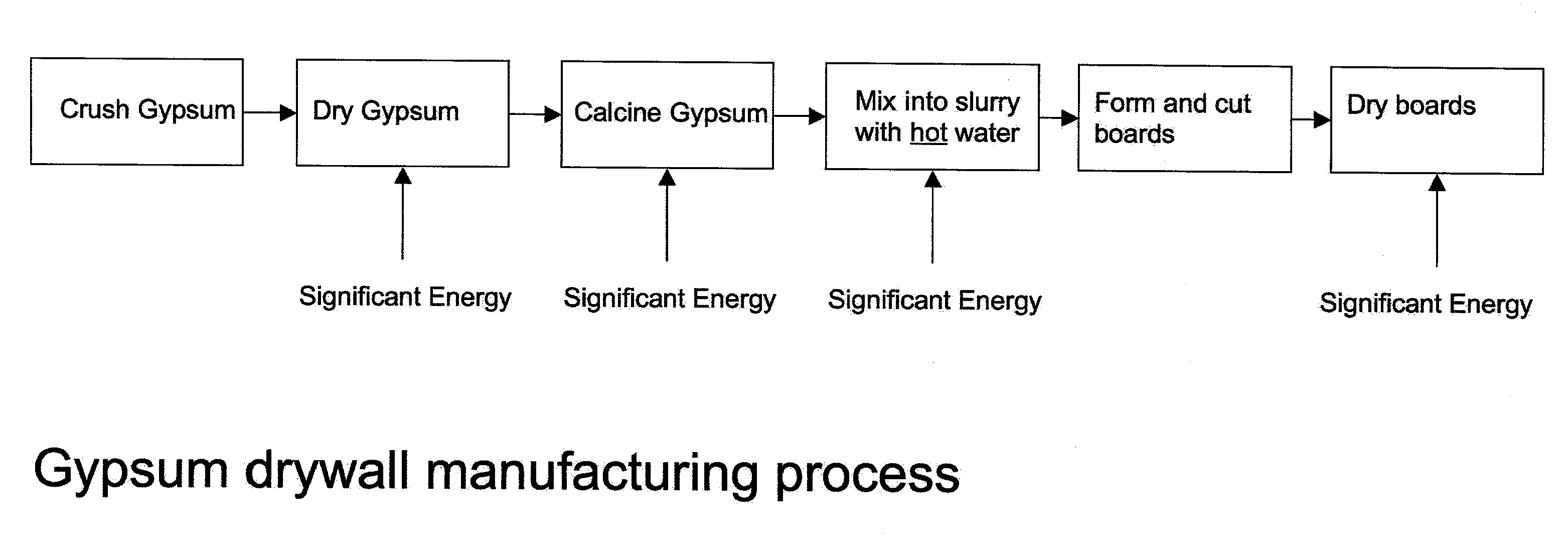

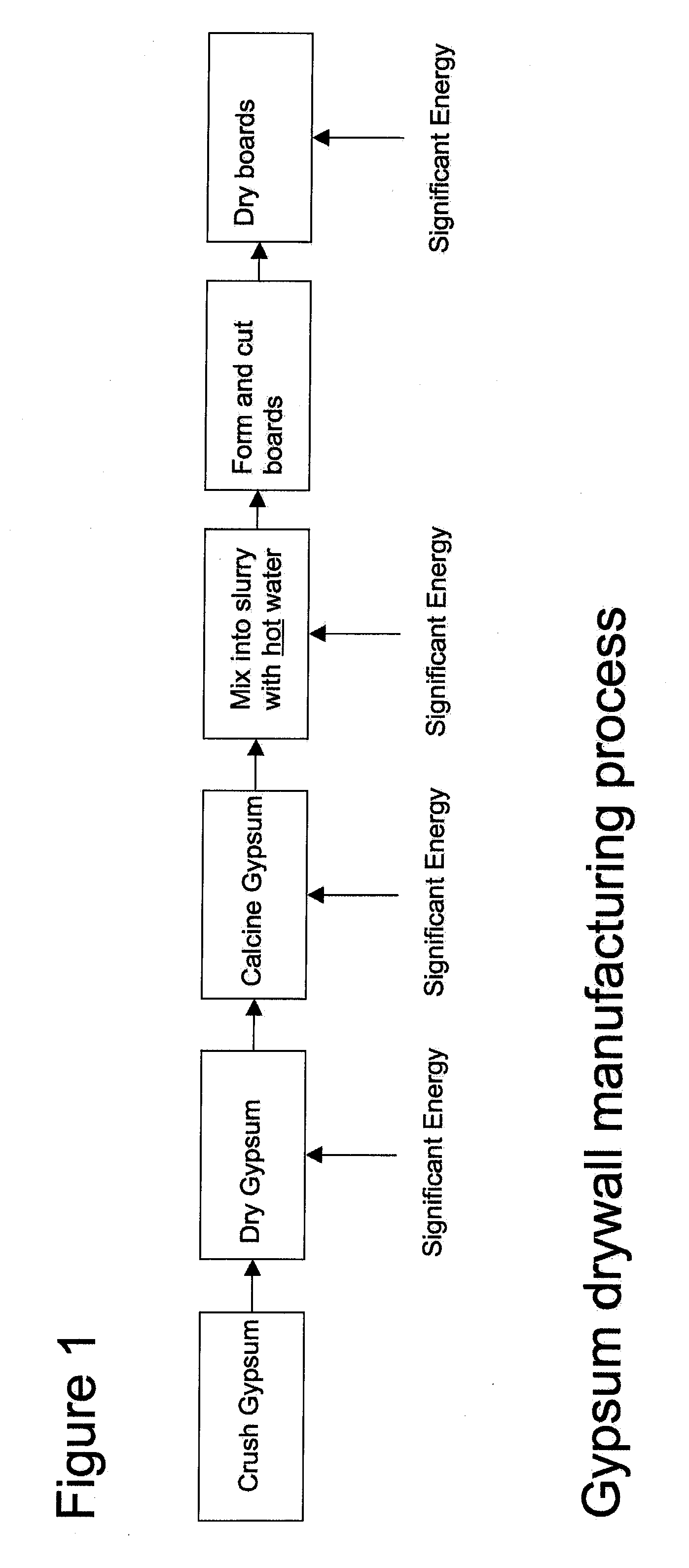

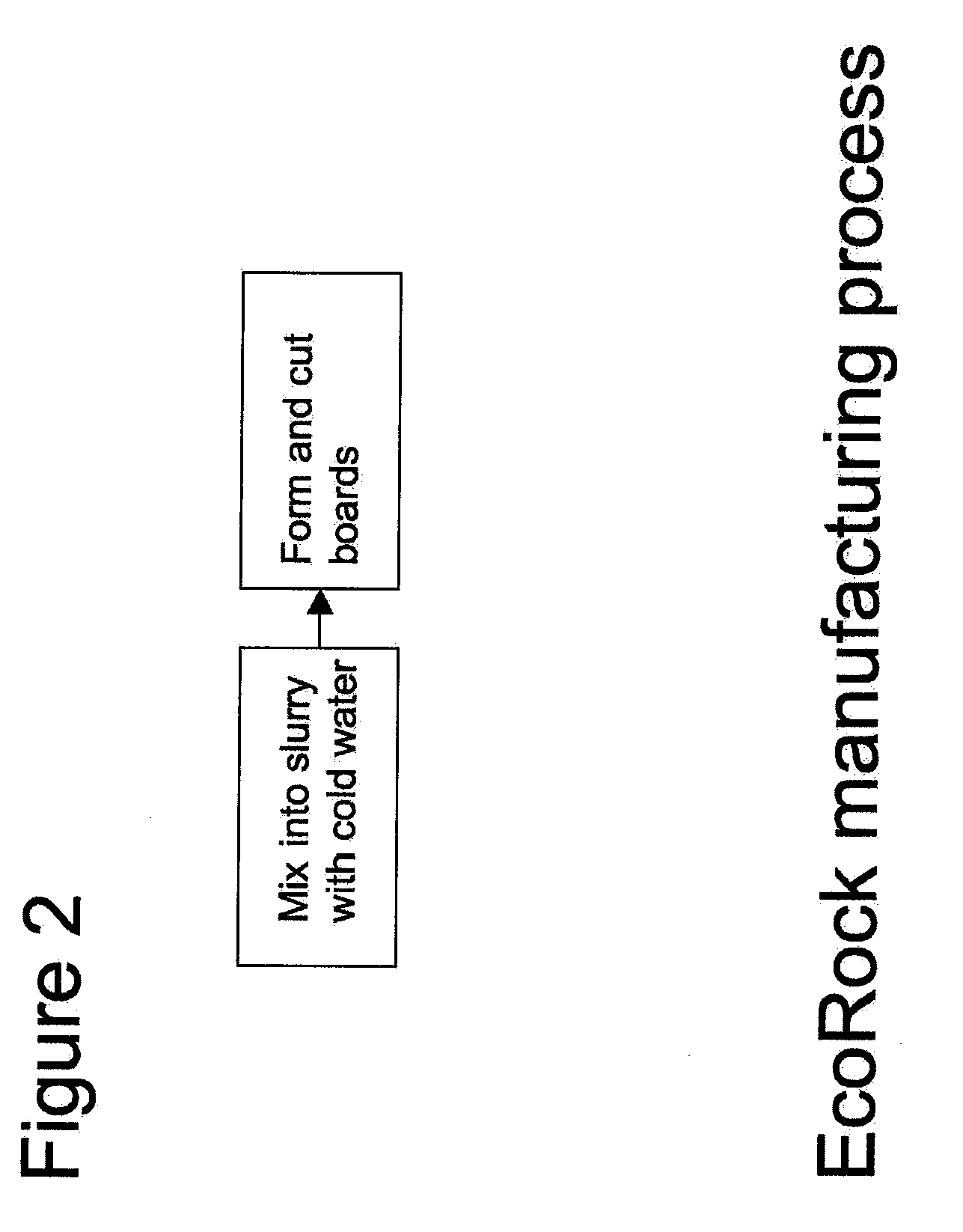

Low Embodied Energy Wallboards and Methods of Making Same

ActiveUS20090130452A1Weaken energyEmission reductionSolid waste managementLayered productsSlagToxic industrial waste

Wallboards, as well as other building materials, are produced by methods which use significantly reduced embodied energy, generating far less greenhouse gases when compared with the energy used to fabricate gypsum wallboard. A novel cementitious core, consisting in one embodiment of post-industrial waste such as slag and combined with pH modifiers, provides a controlled exothermic reaction to create a gypsum-wallboard-like core which can be wrapped in a selected material such as recycled paper and manufactured on a conveyor system to appear, weigh and handle similar to gypsum wallboard, but without the large amounts of energy required to make gypsum wallboard. The manufacturing process results in lower greenhouse gas emissions than the processes used to make gypsum wallboard.

Owner:ASHTECH IND LLC

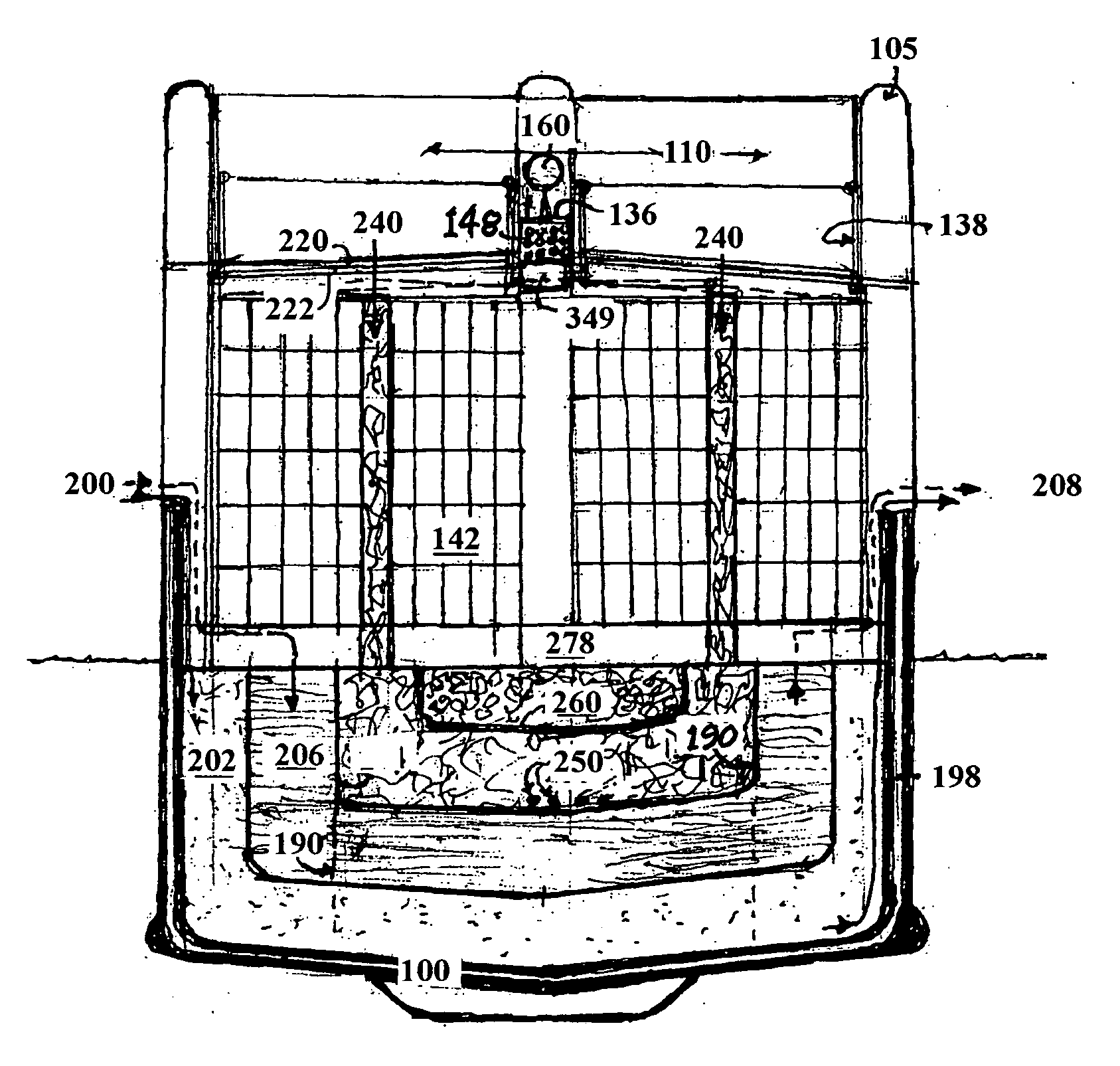

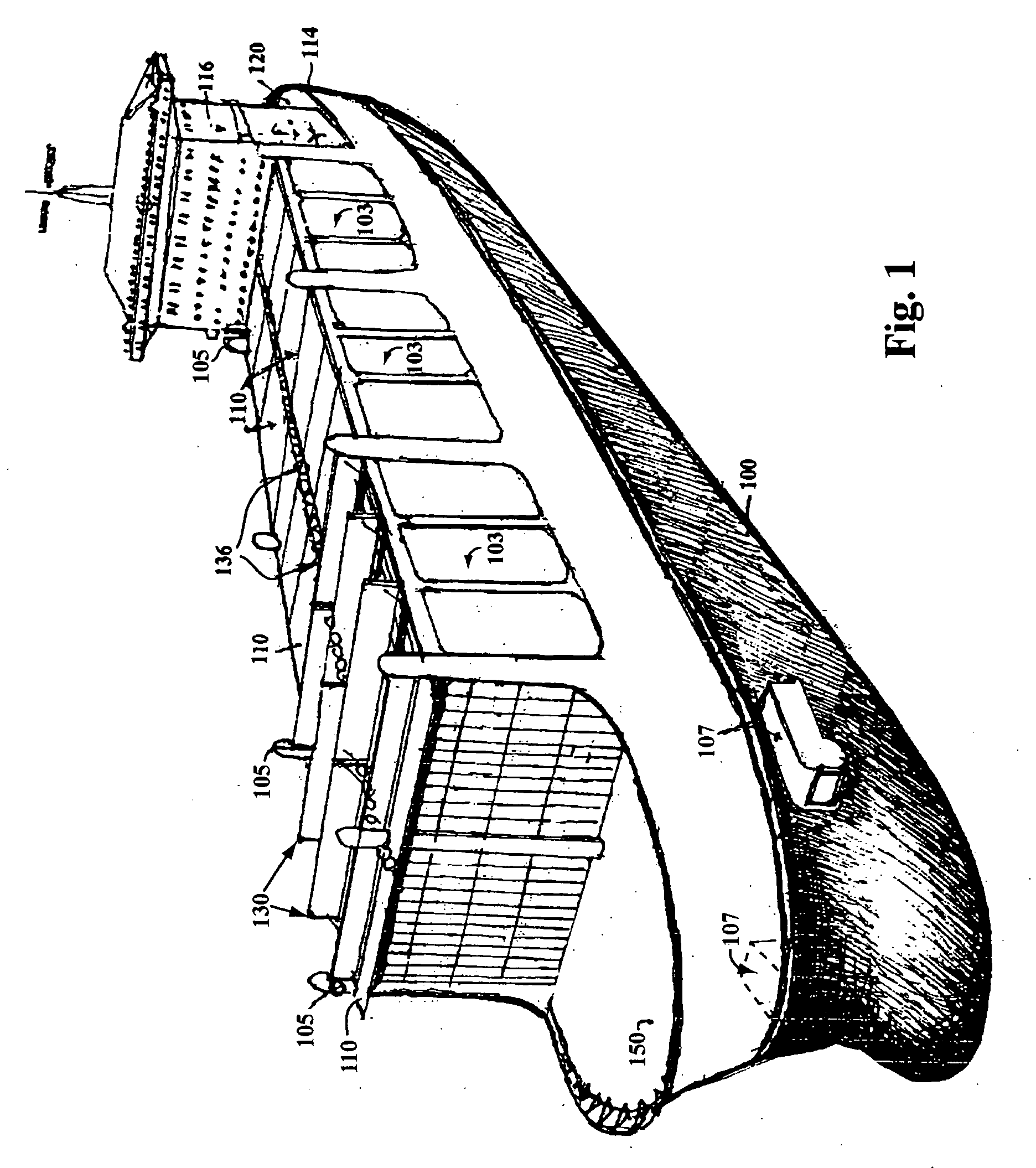

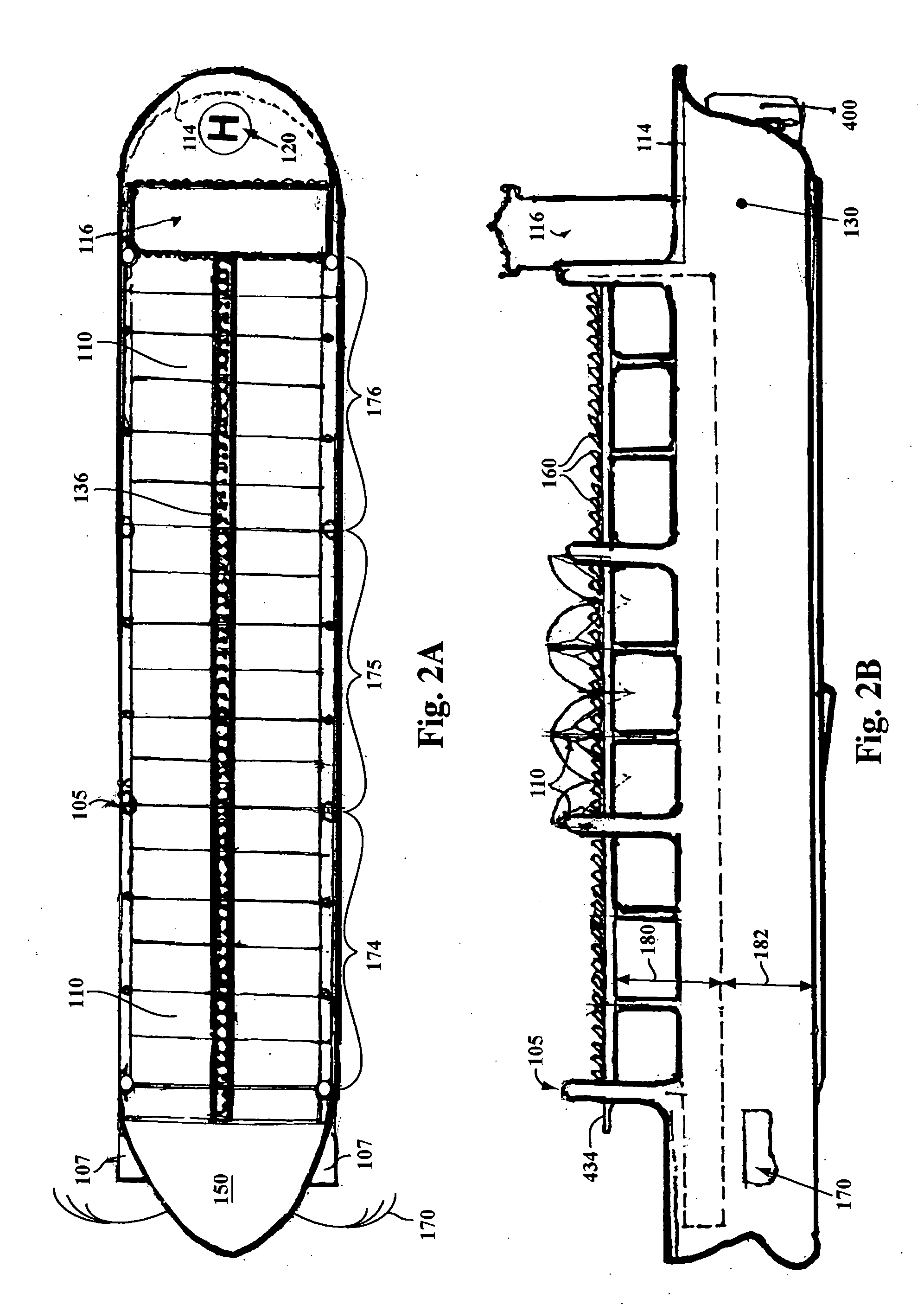

Process and system for converting biomass materials into energy to power marine vessels

ActiveUS20070017864A1Gasifier mechanical detailsCombustible gas catalytic treatmentFuel cellsOn board

The process and system of the invention converts biomass materials into energy to power a large marine vessel without the problematic environmental releases of either liquids to the sea or greenhouse gases to the atmosphere. The biomass is conveyed to an on-board biomass storage facility and converted to synthesis gas in an on-board gasification unit to synthesis gas that is used as fuel for fuel cells to power the marine vessel. A portion of the biomass is sea biomass harvested from the sea and removed from the sea by on-board biomass removal means that strains the biomass from the sea water and flips the biomass into a holding bin before being conveyed to the biomass storage facility. A portion of the synthesis gas is converted to useful products. These products are partially used as fuel for the fuel cells. The remaining products are off-loaded at port facilities where biomass waste materials are loaded on-board and conveyed to the biomass storage to serve as the remaining portion of biomass.

Owner:PRICE LESLIE DEAN +2

Method for Biofuel Life Cycle Assessment

InactiveUS20090326715A1Easy to optimizeAccurate representationSampled-variable control systemsTechnology managementNatural resourceEmission inventory

A method for calculating the greenhouse gas (GHG) emissions, energy efficiency, and natural resource requirements of a biofuel production system, using a life cycle assessment of biofuel production from the creation of material inputs to finished products, and producing a GHG emissions inventory from fossil fuels and a few key non-fossil fuel GHG emissions in the production life cycle.

Owner:BOARD OF RGT UNIV OF NEBRASKA

Method for preparing environment-friendly high-modulus glass fiber

The invention relates to an environment-friendly high-modulus glass fiber composition, and discloses a glass component combination used for preparing the high-modulus glass fiber. The glass fiber prepared by glass components is particularly applied to preparing glass fiber reinforced plastic composite material with higher rigidity requirement. The glass composition has no emission of harmful gas, greatly reduces the emission of greenhouse gas, and is an environment-friendly glass fiber formula. The environment-friendly high-modulus glass fiber composition is characterized in that: a blast furnace slag preferably serves as one of major raw materials for reducing the operational difficulty and prepares the high-modulus glass fiber, and the high-modulus glass fiber can be produced and wiredrawn on a tank furnace having an electro-boost structure on a large scale by adopting a direct method. The fiber mainly comprises the following main components: 57 to 62.5 weight percent of SiO2, 14.5 to 19.5 weight percent of Al2O3, 16 to 23.5 weight percent of RO (wherein RO is the sum of CaO, MgO, SrO and BaO), and less than and equal to 1.5 percent of alkali metal oxide. The glass composition and the adopted raw material mode are suitable for the mass production under the production technological condition of the electro-boost tank furnace, and the glass composition has low production cost.

Owner:TAISHAN FIBERGLASS INC

Low embodied energy wallboards and methods of making same

InactiveUS20080286609A1Reducing greenhouse gas emissionReduction in embodied energyConstruction materialCovering/liningsCalcium silicatePhosphoric acid

Wallboards, as well as cement boards, are produced by methods which use significantly reduced Embodied Energy when compared with the energy used to fabricate gypsum wallboard. A novel binder, consisting in one embodiment of phosphoric acid and calcium silicate, and combined with various fillers, is used to provide a controlled exothermic reaction to create a gypsum-board-like core which can be wrapped in a selected material such as recycled paper and manufactured on a conveyor system to appear and handle like gypsum wallboard, but without the large amounts of energy required to make gypsum wallboard. The resulting product may be used in interior or exterior applications and may possess fire resistance, sound ratings and other important properties of gypsum wallboard. As energy costs increase, the novel wallboards of this invention can become less expensive to manufacture than traditional wallboard. The manufacturing process results in much lower greenhouse gas emissions than the processes used to make gypsum wallboard.

Owner:PACIFIC COAST BUILDING PRODS

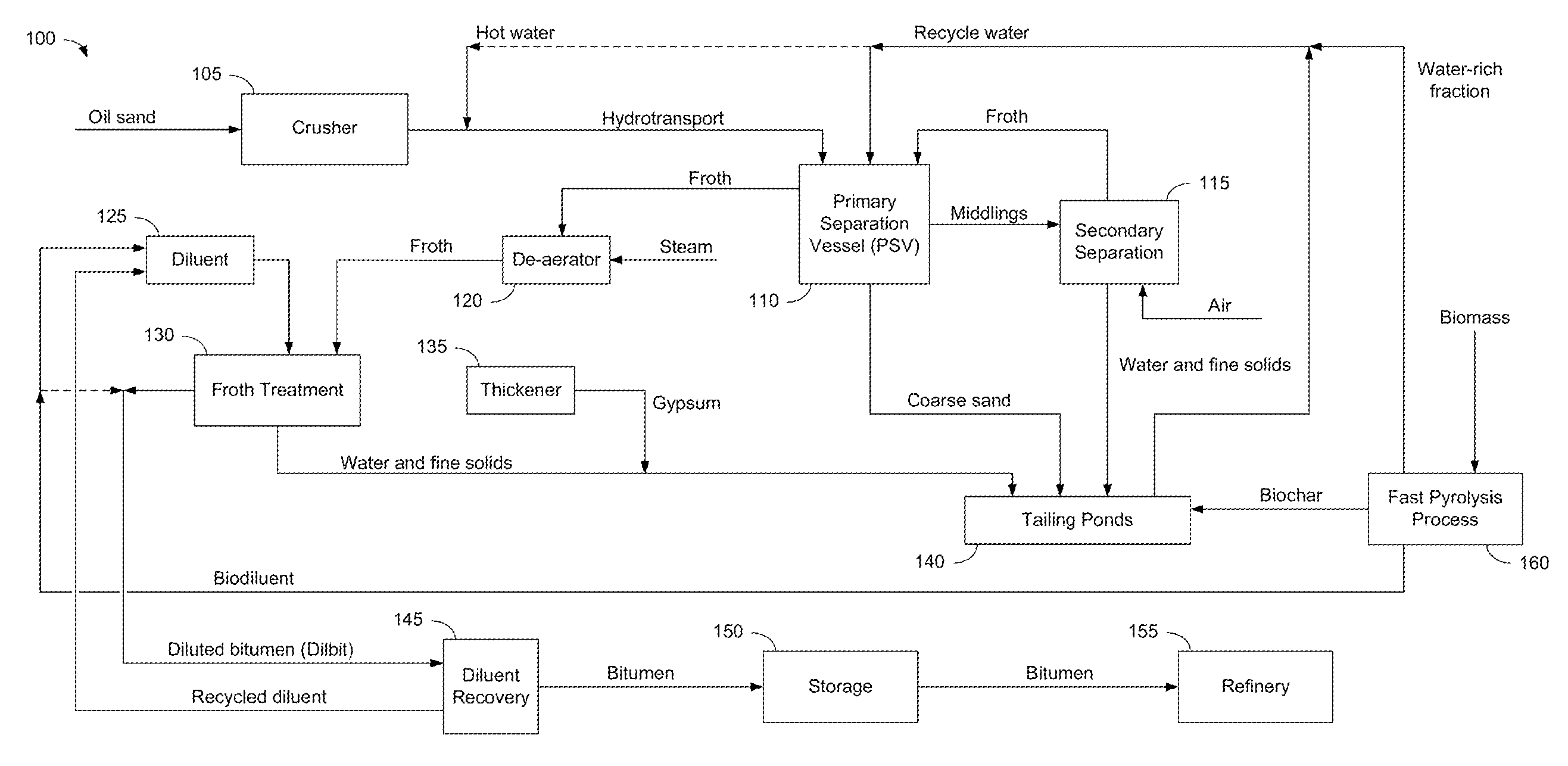

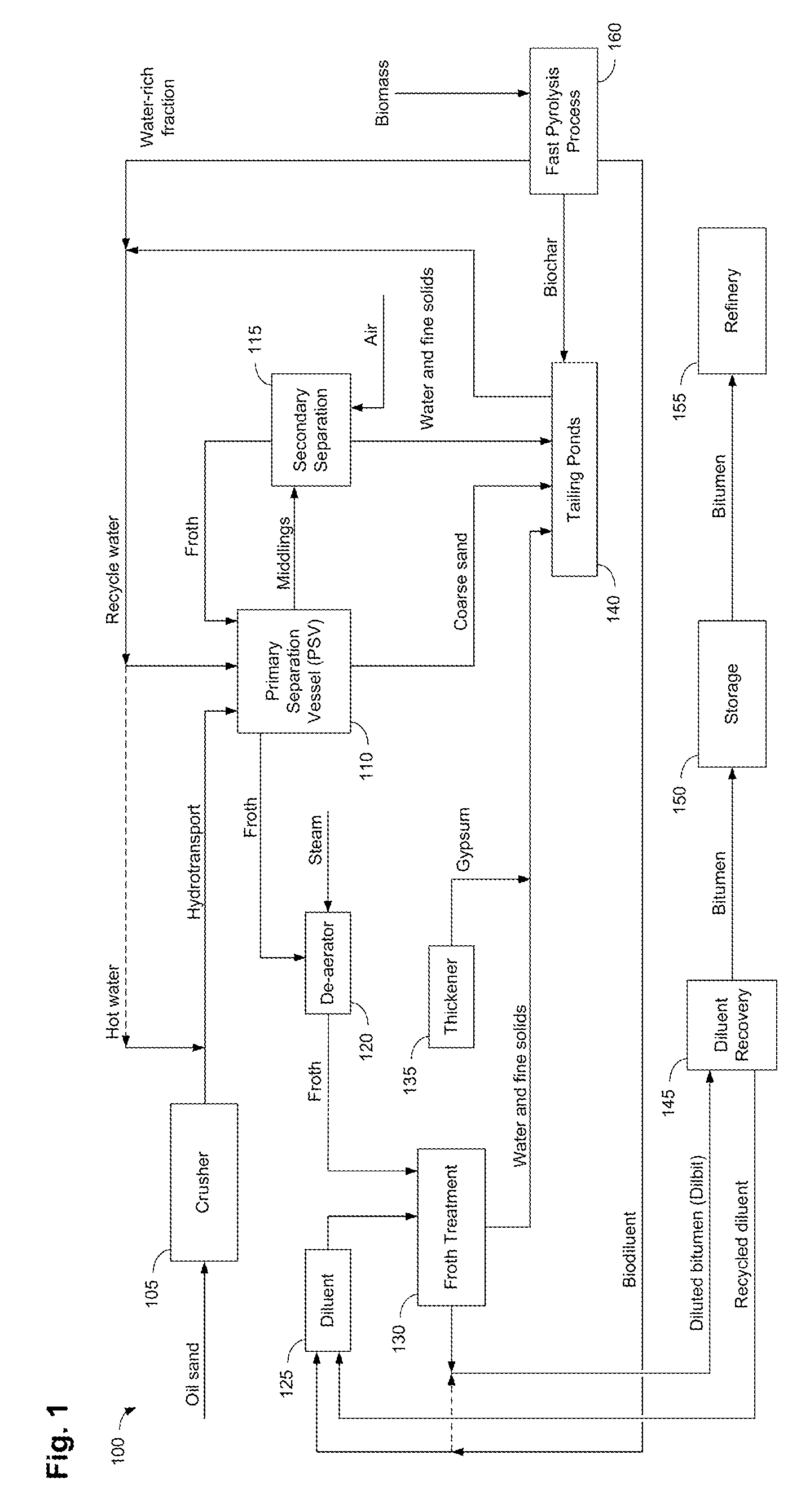

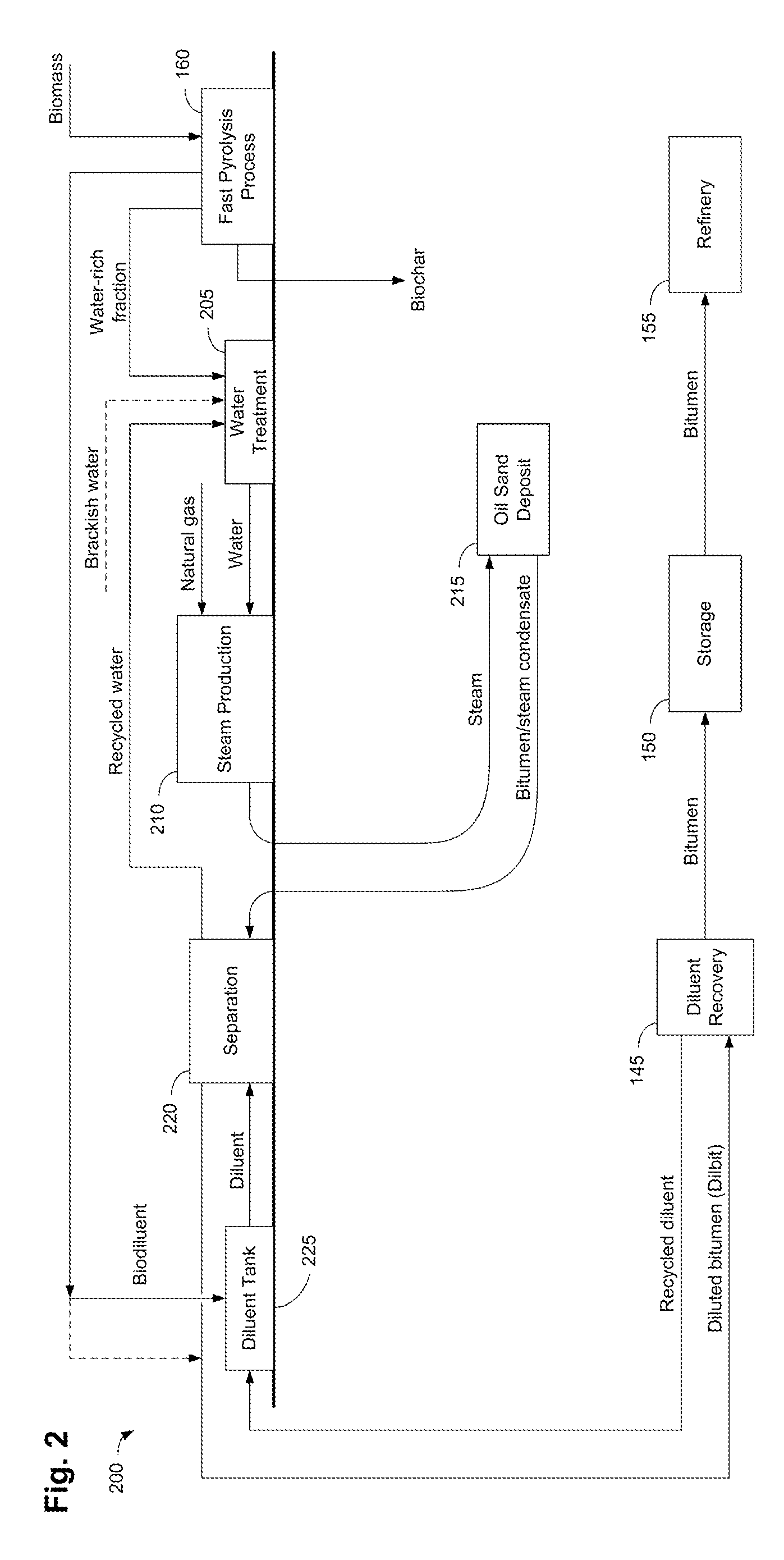

Methods, apparatus, and systems for incorporating bio-derived materials into oil sands processing

ActiveUS20120289440A1Reduce GHG emission profileImprove propertiesBiofuelsFluid removalWater useOil sands tailings ponds

Methods, processes, apparatus, systems, and compositions are disclosed for improving the sustainability of oil sands processing. In some embodiments, bitumen is combined with biodiluent comprising one or more liquid pyrolysis fractions obtained from pyrolyzing biomass and collecting multiple liquid fractions. The bitumen may be any source of bitumen, such as bitumen obtained from oil sands. In some embodiments, a water-rich pyrolysis liquid displaces water use in an oil sands process. The water-rich pyrolysis liquid may be used for primary separation of bitumen from oil sands or for hydrotransport, for example. Also, biochar produced from biomass pyrolysis may be introduced to an oil sands tailing pond with various benefits. Water may be recycled from a tailing pond. Integration of a pyrolysis and separation process into an oil sands refining process reduces the overall greenhouse-gas emissions on a well-to-refined product basis by 10-70% or more. Various compositions and products are also disclosed.

Owner:AVELLO BIOENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com