Full-biomass resource utilization method for kitchen waste

A kitchen waste and full biomass technology, which is applied in the field of waste resource recycling, can solve the problems of increased processing cost of kitchen waste, incomplete utilization of raw material components, low added value of products, etc., so as to shorten the fermentation time and reduce the processing time. Cost, mild effect of operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

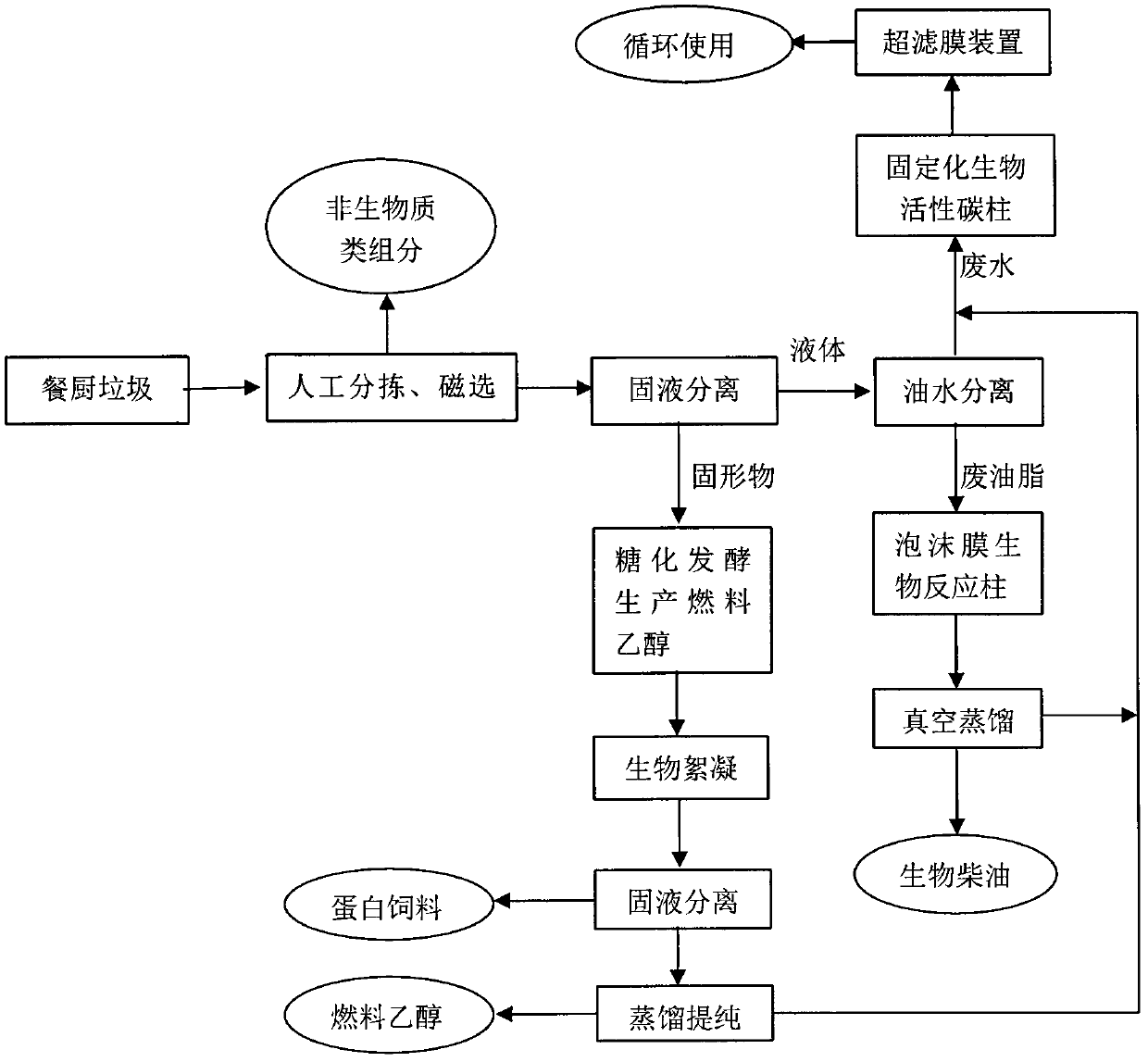

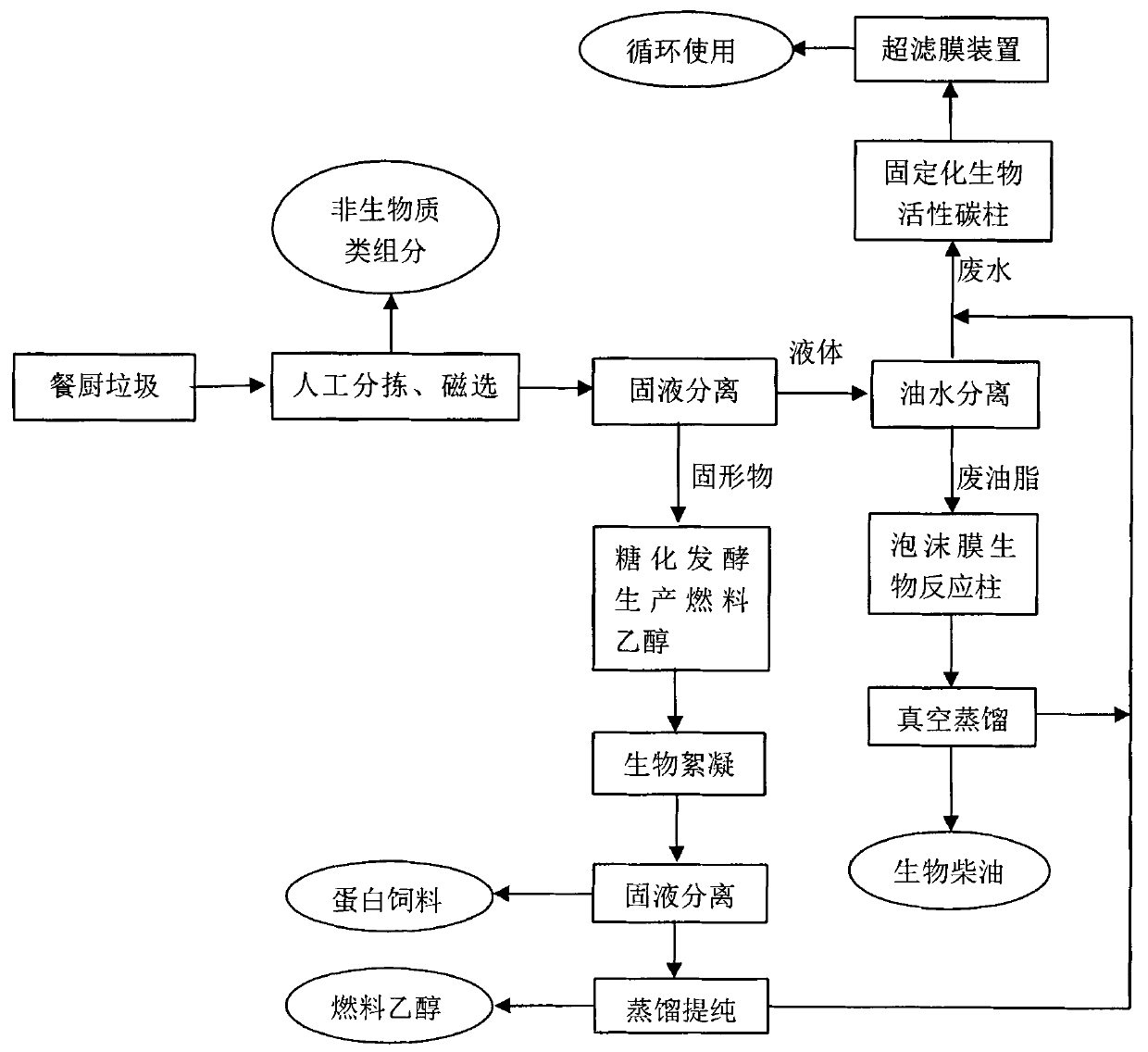

[0024] Example 1: Preparation of fuel ethanol, biodiesel and protein feed from food waste collected from restaurants

[0025] The collected food waste is manually sorted out of non-biomass components, and the metal debris mixed in is selected by a movable magnetic separation device; then it is sent to a filter press for solid-liquid separation, and a large amount of oil-water components are removed Enter the oil-water separator for oil extraction, and the waste water enters the sewage treatment system; the water content of the solid component after dehydration and deoiling is 70%, and it is sent to the pulverizer, and the particle size after pulverization is ≤1cm. Put 1000g of pulverized material into an ethanol fermenter, add 5g of liquefaction enzyme, and liquefy at 85°C for 30 minutes; cool the temperature of the fermenter to 45°C, adjust the pH of the material to 4.5-5.0 with sulfuric acid or sodium hydroxide, and add glucoamylase and pectinase, enzymatic hydrolysis for 4 ...

Embodiment 2

[0026] Example 2: Preparation of fuel ethanol, biodiesel and protein feed from food waste collected from canteens

[0027] The non-biomass components are manually sorted from the food waste collected in the canteen, and the metal debris mixed in is selected by a movable magnetic separation device; then it is sent to a filter press for solid-liquid separation, and the oil-water components removed Enter the oil-water separator for oil extraction, and the waste water enters the sewage treatment system; the water content of the solid component after dehydration and deoiling is 70%, and it is sent to the pulverizer, and the particle size after pulverization is ≤1cm. Put 1000g of pulverized material into an ethanol fermenter, add 5g of liquefaction enzyme, and liquefy at 85°C for 30 minutes; cool the temperature of the fermenter to 45°C, adjust the pH of the material to 4.5-5.0 with sulfuric acid or sodium hydroxide, and add glucoamylase and pectinase, enzymatic hydrolysis for 4 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com