Method for preparing biodiesel by utilizing food waste recycling oil

A technology for biodiesel and kitchen waste, applied in the fields of biofuel, fat oil/fat refining, petroleum industry, etc., can solve the problems of inability to form industrial applications, discharge of waste lye or waste acid, and difficult recovery of esterification products. , to alleviate the energy and environmental crisis, reduce pollution, reduce food safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

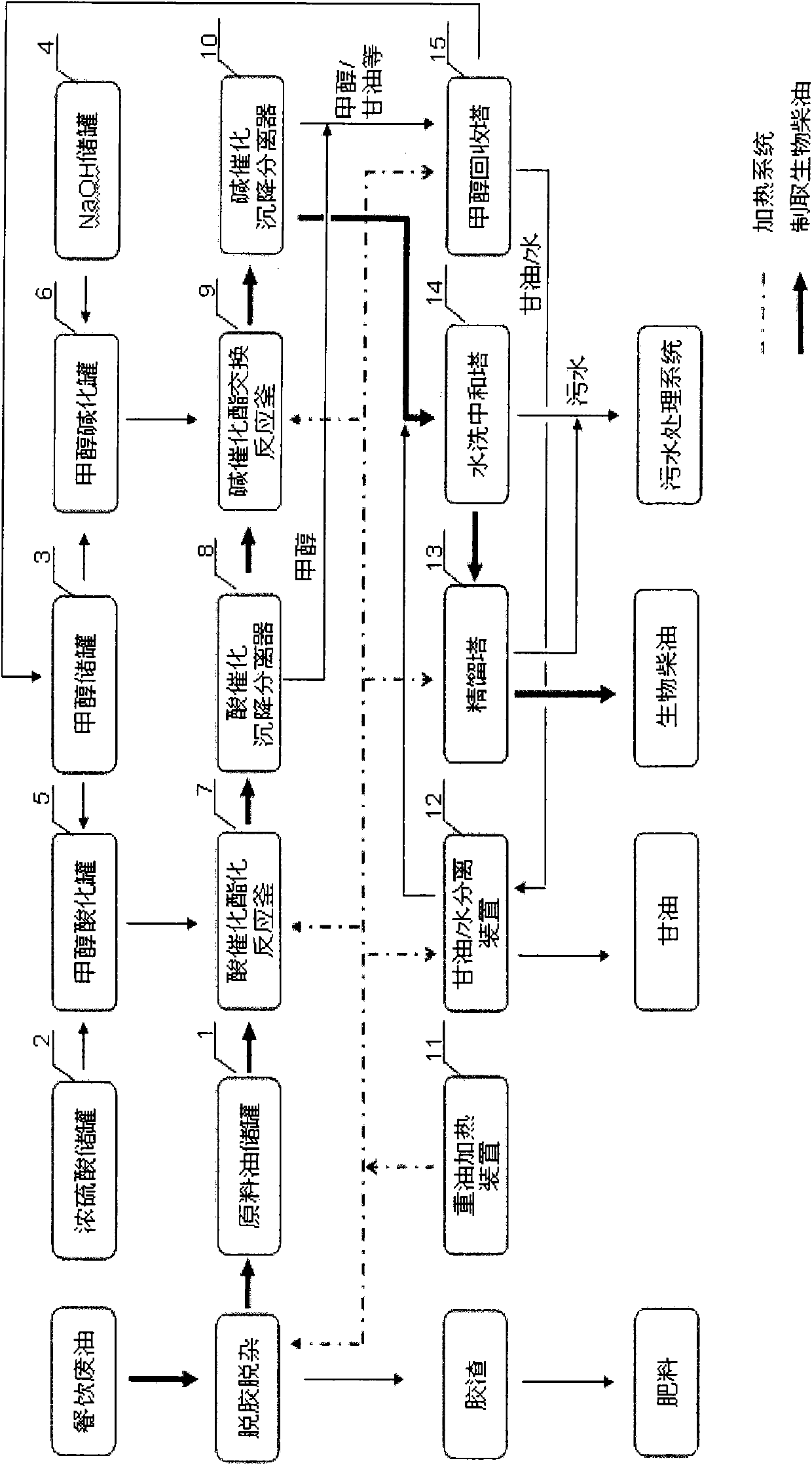

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] Step 1, pretreatment: The colloids and impurities in the waste catering oil produced after the kitchen waste is processed by the oil-water separator will affect the efficiency of the subsequent acid-catalyzed esterification and alkali-catalyzed transesterification reactions, so the waste catering oil must be treated first Degumming and impurity removal treatment. The present invention adopts the hydration degumming and impurity removal method, and the specific operation process is as follows: 3% tap water of its volume is added to the waste catering oil and heated to 90-100°C. And slowly add 1.5% of waste catering oil weight, the concentrated sulfuric acid of mass concentration 98% in above-mentioned mixed solution, leave standstill 30 minutes after stirring for 10 minutes, oil and glue, impurity can be separated, and the upper layer is oil (hereinafter referred to as raw material Oil), the lower layer is colloid and impurities. The raw material oil in the upper layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com