Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104 results about "Short path distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

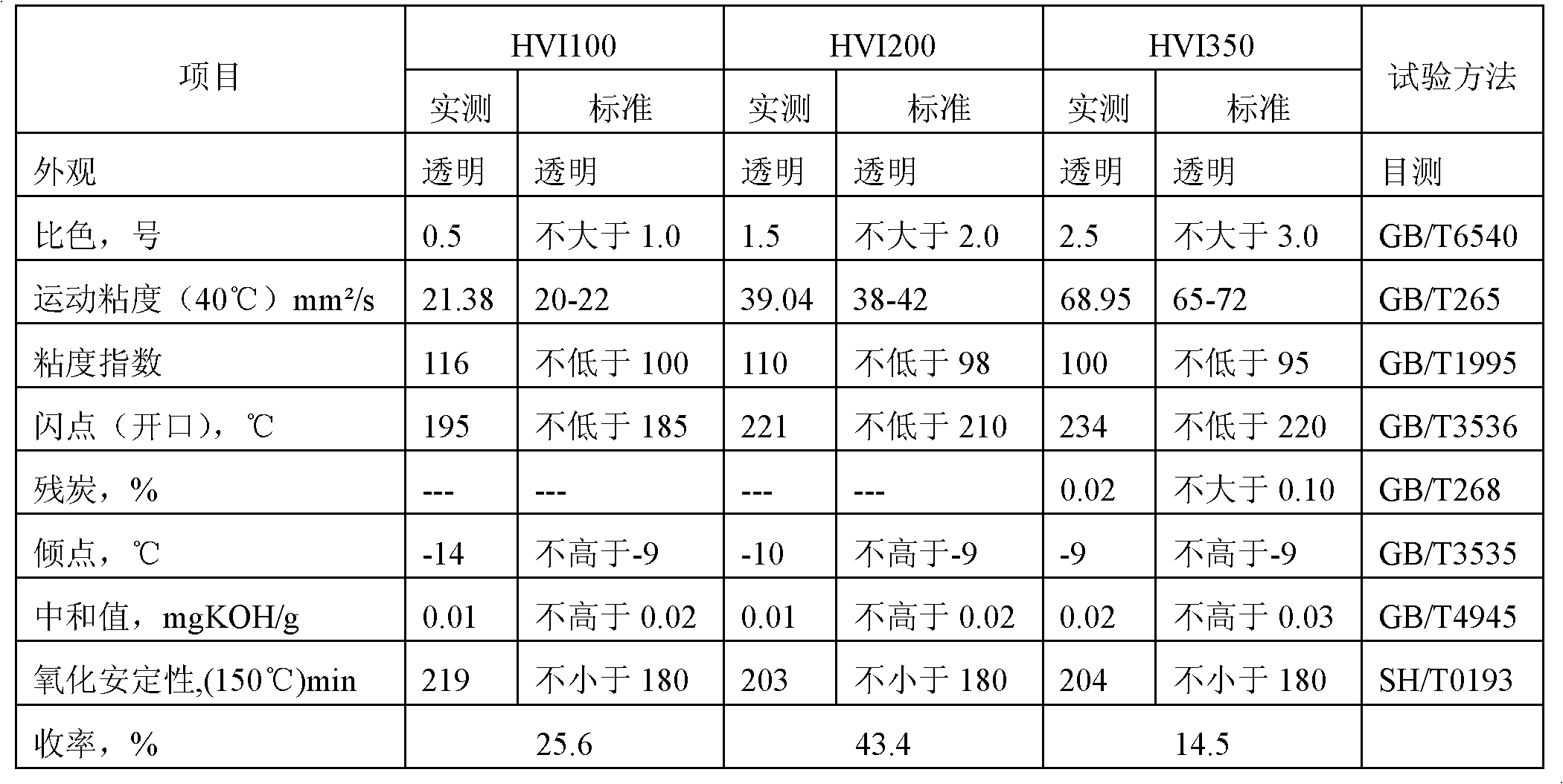

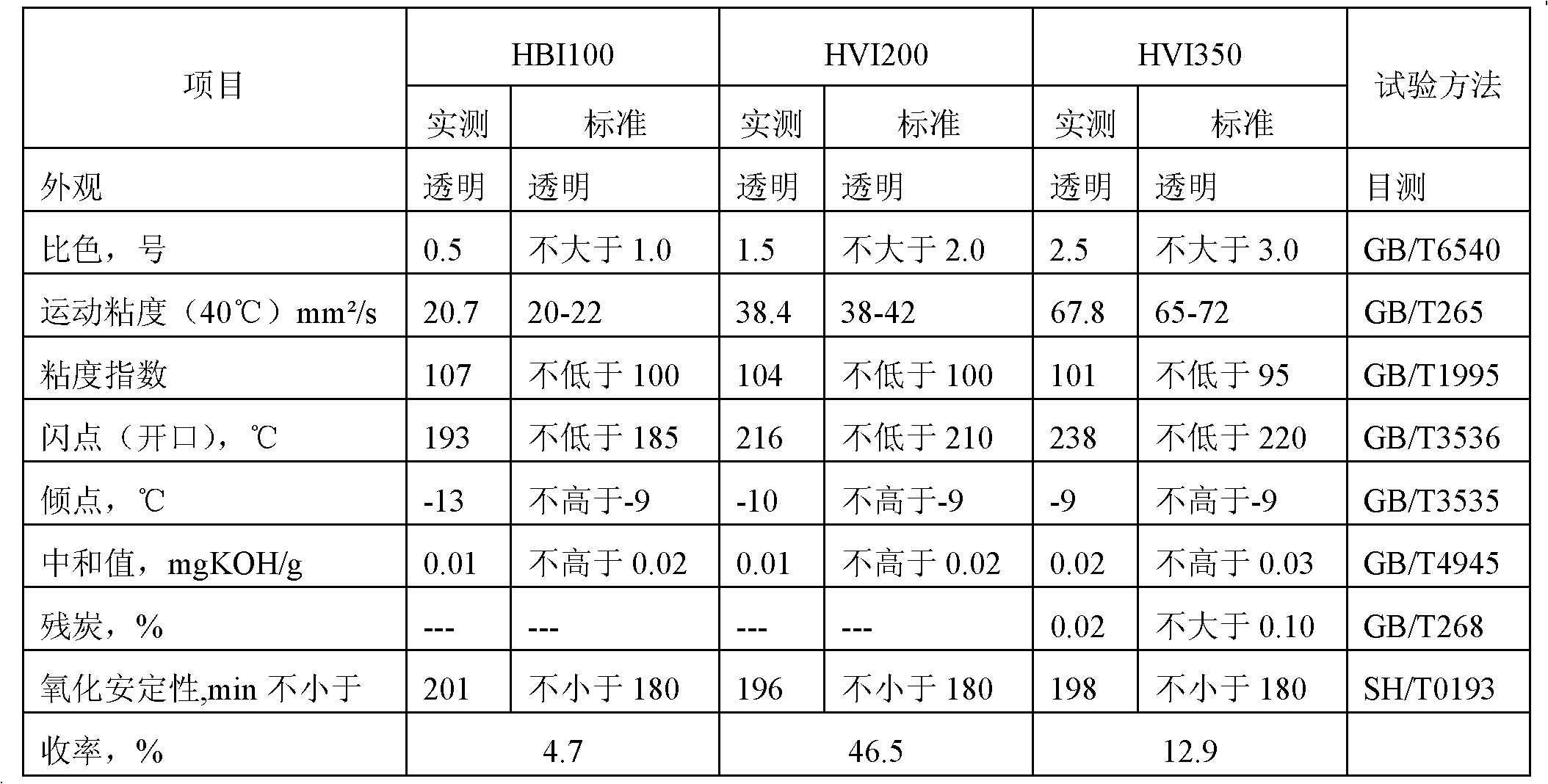

Regeneration method of waste lubricating oil

InactiveCN102504933ASimple methodFlexible operationTreatment with hydrotreatment processesLubricant compositionWaste oilPre treatment

The invention provides a regeneration method of waste lubricating oil which at least comprises the steps of waste oil pretreatment, short path distillation and hydrofining. Compared with the prior art, the invention has the advantages that the technology is simple, the operation is flexible, no pollution is caused, all the quality indexes of produced lube base oil meet the standard requirements of universal base oil of lubricating oil, and the produced lube base oil can be used for preparing various lubricating oil products. Therefore, the regeneration method of the waste lubricating oil has a wider application range and is more environment-friendly.

Owner:北京耀锋技术开发中心

Process for the production of diglyceride using holoenzyme

InactiveCN1884564AFlexible adjustment of distillation temperaturePromote generationMicroorganism based processesFermentationMonoglycerideEnzymatic hydrolysis

This invention is associated with the producing method of diglyceride with enzyme. The steps include: hydrolyze fat or oil using 1, 3 special lipase, the hydrolysis degree is 20 - 55%. After molecular distillation or short path distillation the obtained hydrolysis products can generate the high temperature fractions with the main contents of diglyceride and triglyceride as well as the low temperature fractions with the main contents of fatty acid and monoglycerides. This invention gets the fat or oil catalyzed by specific lipase, and then appropriately hydrolyzes it. The hydrolyzed products contain a lot of diglycerides, but the contents of by-product monoglycerides are very low. This invention also combined the enzymatic hydrolysis and enzymatic deacidification so to increase the output of diglyceride.

Owner:广东润隆再生资源股份有限公司

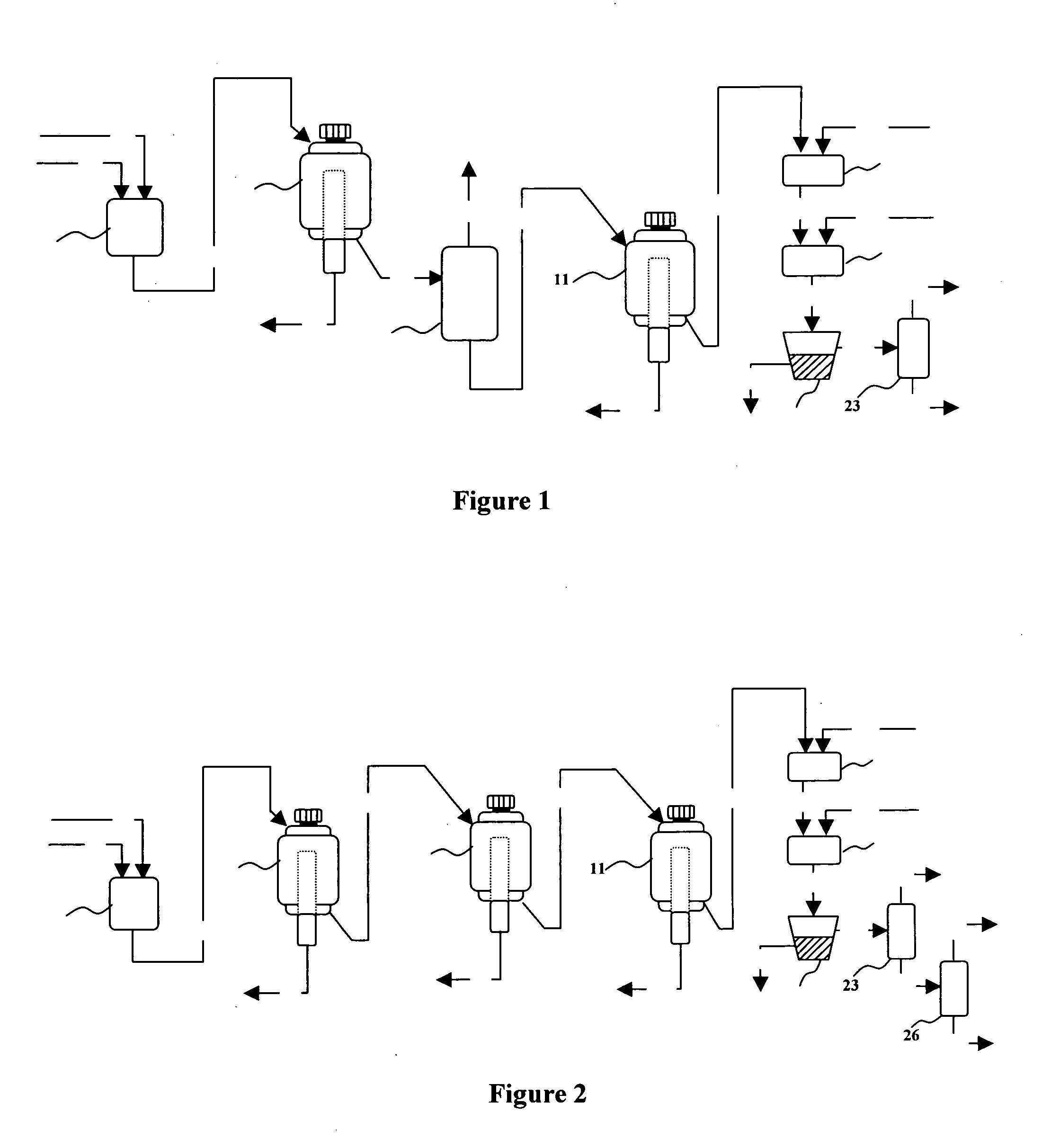

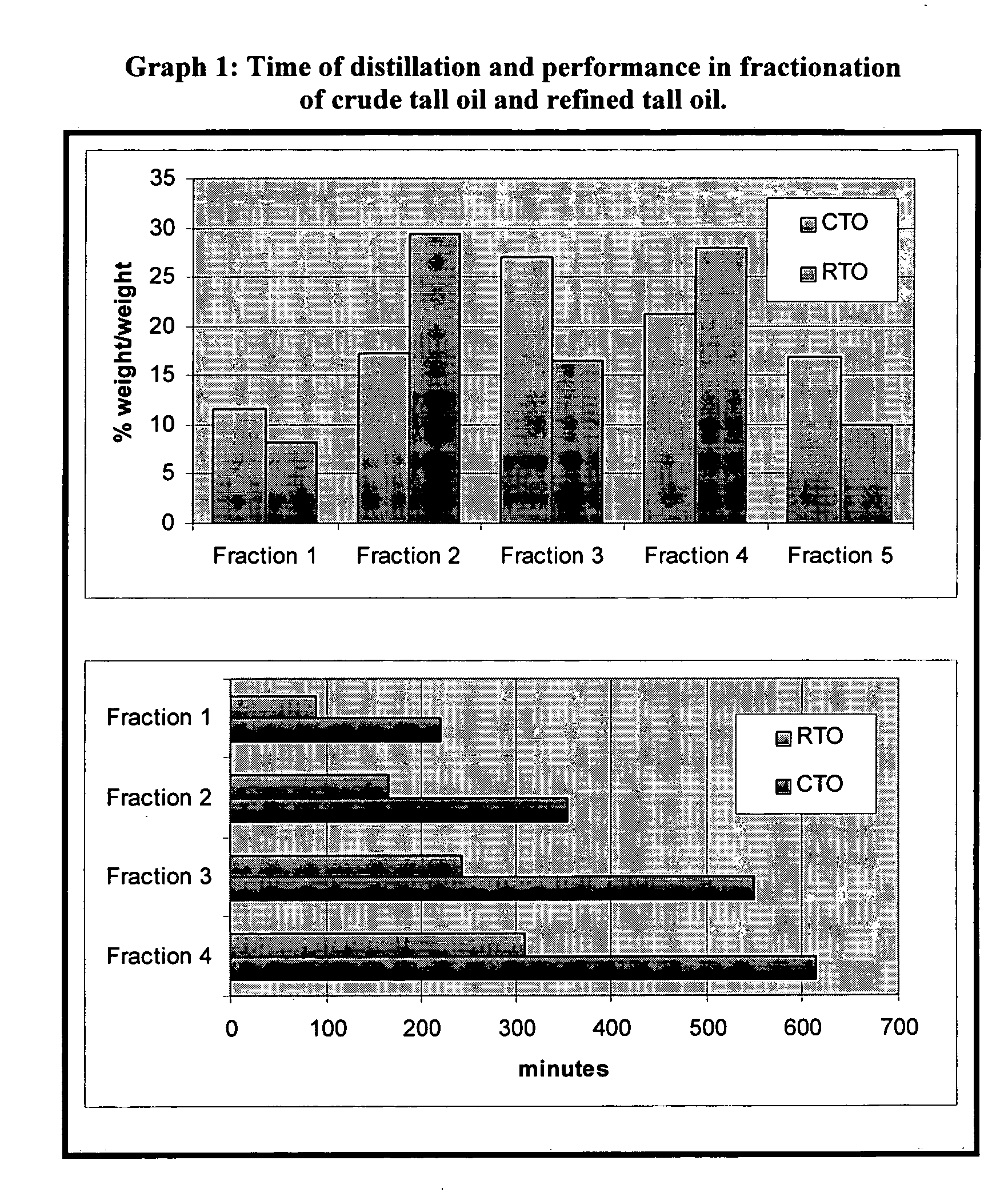

Process of refinement of crude tall oil using short path distillation

InactiveUS20050203279A1Avoid problemsEfficient ConcentrationFatty oils/acids recovery from wasteNatural resin processFractionationFatty acid

The present invention is related to a process for the production of high quality fatty acids and rosin acids and their mixtures from crude tall oil by means of short path distillation of saponified crude tall oil, acidulation and fractionation by distillation.

Owner:GLADE THOMAS FRANCIS HARTING

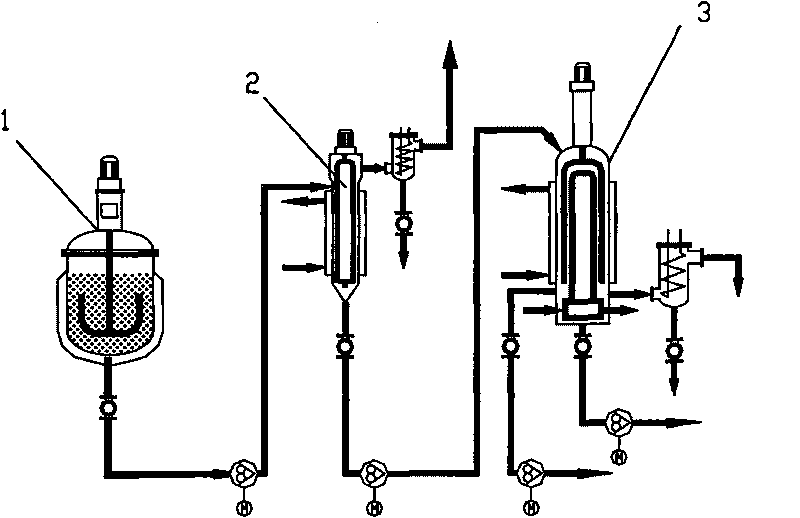

Method for separating and recovering product oil from waste lubricating oil and device thereof

ActiveCN101831348AImprove heating efficiencyShort heating timeLubricant compositionEvaporationEngineering

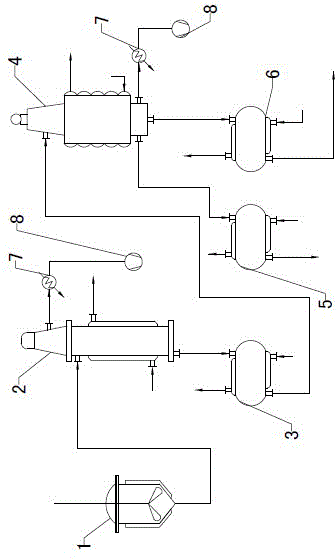

The invention relates to a method for separating and recovering product oil from waste lubricating oil and a device thereof, which relates to chemical production methods and devices. The method adopts the process that after preliminary treatment of dewatering, degassing and mechanical purity removal, multi-time intermittent rectification or multistage continuous rectification is carried out on the waste lubricating oil by thin-film evaporation and hypergravity revolving field. The device is a 1-4 time intermittent rectifying device or a 1-4 stage multistage continuous rectifying device comprising a raw material tank, a material pump and one to four thin-film evaporators, hypergravity revolving beds, condensers, coolers, finished product tanks, discharging pumps, heavy constituent receiving tanks, material pumps and reflux regulating valves. The method has high rectification speed, good product quality and high recovery rate, and meets the requirements of environmental protection; compared with short path distillation technology, the invention has smaller device volume and higher rectification efficiency and can further refine materials; the device for treating the materials with the same scale has lower requirements for field, less investment and relatively lower vacuum degree requirement.

Owner:HANDWAY TECH FOSHAN

Method for extracting cholesterol from lanoline

This invention discloses a method for extracting high-purity cholesterol from lanolin. The method comprises: (1) dissociating cholesterol from lanolin by transesterification reaction; (2) performing short-path distillation to obtain cholesterol crude product; (3) purifying by silica gel column chromatography; (4) crystallizing to obtain refined cholesterol with purity higher than 95% and yield higher than 70%. The method has such advantages as high product consumption, little pollution, simple process and easy operation, thus is suitable for mass production.

Owner:ZHEJIANG UNIV

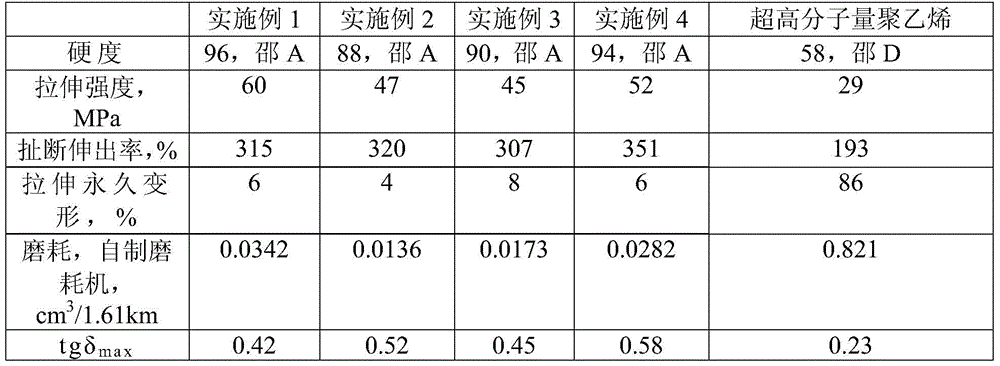

Polyurethane elastomer used as counterweight guide shoe lining and preparation method and application of polyurethane elastomer

The invention discloses polyurethane elastomer used as a counterweight guide shoe lining and a preparation method and application of the polyurethane elastomer.The preparation method includes: dispersing methyl silicone oil and nano white carbon black into oligomer polyol, keeping the temperature for 2 hours, dripping into 2, 4-toluene diisocyanate, and reacting for 2 hours; performing short-path distillation on the reaction mixture until the percentage content of free isocyanate monomer is lower than 0.5% to obtain polyurethane prepolymer; regulating the proportion of the polyurethane prepolymer to chain extender according to chain extender use amount coefficient of 0.92-1.05, and starting a pouring machine to pour the mixed material into a die for casting molding, wherein a guide shoe framework is placed in the die, and the die is preheated to 115-130 DEG C.Compared with an existing engineering plastic shoe lining, the polyurethane elastomer used as the counterweight guide shoe lining of a high-speed elevator has the advantages that good shock absorption performance is achieved, the elevator is comfortable to ride, good wear resistance is achieved, and the shoe lining is long in service life.

Owner:SOUTH CHINA UNIV OF TECH

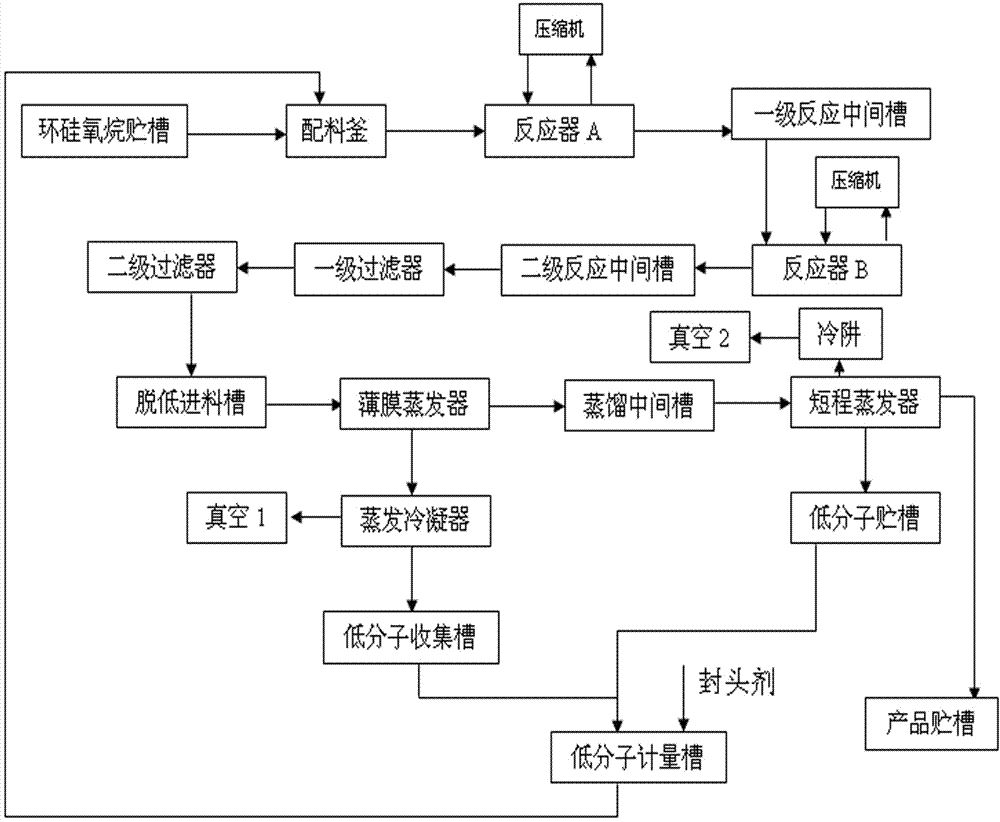

Continuous production process for silicone oil

The present invention discloses a continuous production process for silicone oil. The continuous production process comprises: (1) measuring raw materials through a measurement tank, and uniformly mixing the raw materials in a material preparation kettle to obtain a mixed raw material, wherein the raw materials comprise an organosilicon capping agent and cyclic siloxane; (2) adding a catalyst to an equilibrium polymerization reactor I with nitrogen compression cycle stirring and a reactor II, adding 1500-2000 kg of the mixed raw material from the step (1) to the reactor I in one time, opening a compressor to carry out nitrogen bubbling stirring, and continuously conveying the mixed raw material to the reactor I to carry out a primary reaction; (3) conveying the reactant from the primary reaction to the reactor II through an overflow manner to carry out continuous reaction; (4) carrying out two-stage filtration on the product from the reactor II through a primary coarse filter and a secondary precision filter to remove solid impurities; and (5) conveying the filtered product to a scraper-type thin film evaporator and a short path distiller to carry out a two-stage low removing treatment to obtain the silicone oil product.

Owner:江苏梅兰化工有限公司

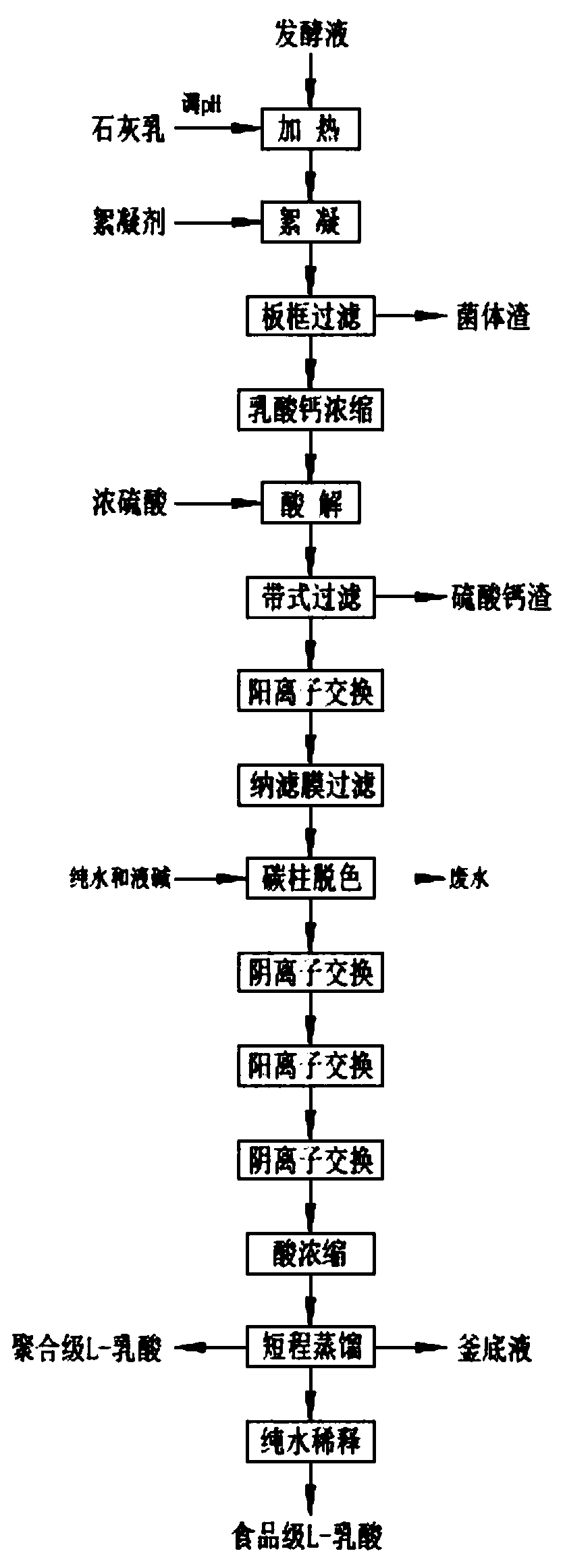

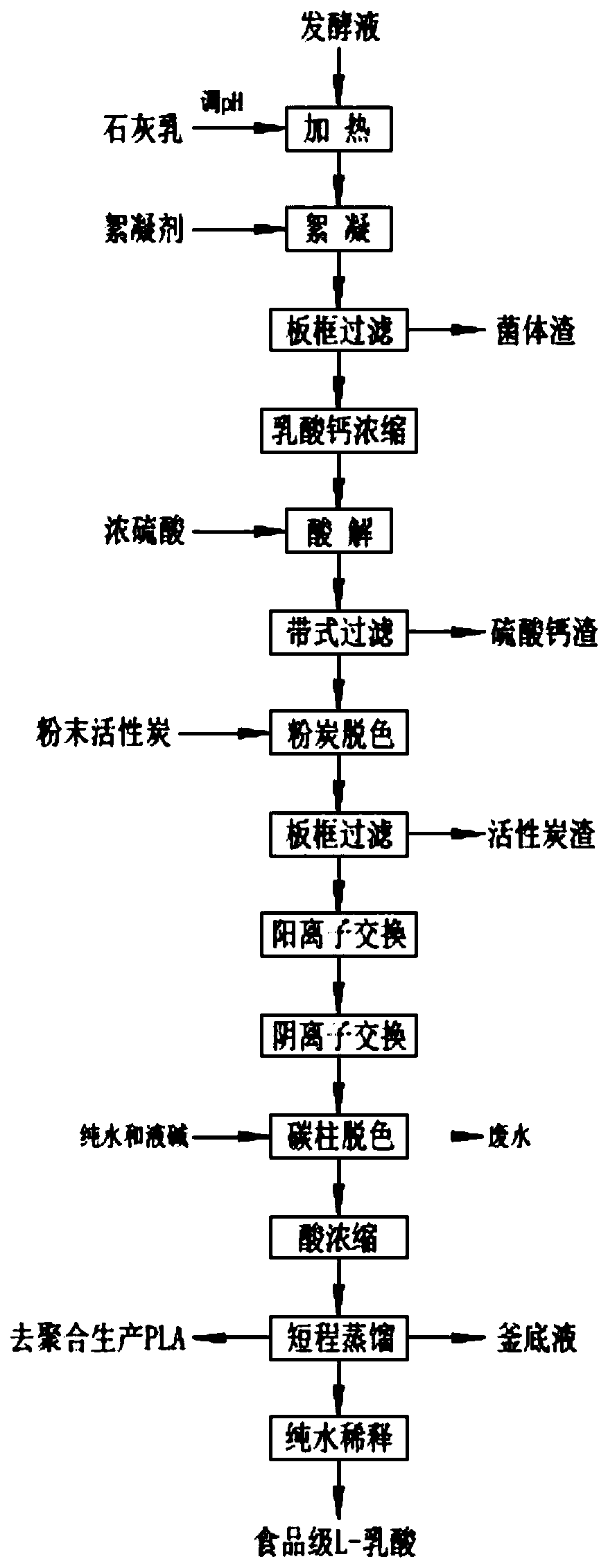

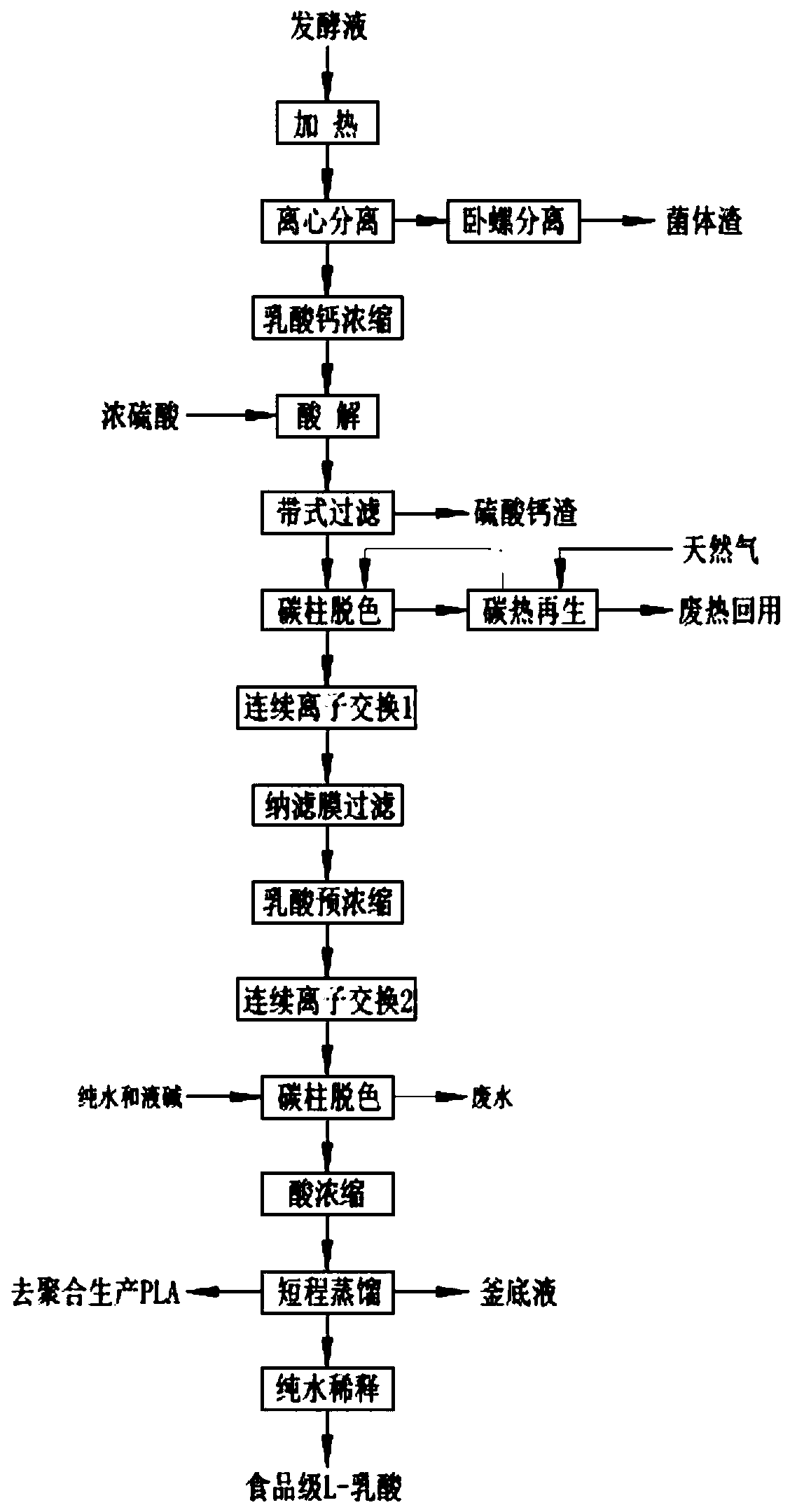

Method for purifying and refining L-lactic acid

ActiveCN111269107AOffset production costsReduce consumptionPreparation from carboxylic acid saltsCalcium/strontium/barium sulfatesBiotechnologyActivated carbon

The invention belongs to the technical field of L-lactic acid production, and particularly discloses a method for purifying and refining L-lactic acid. The method for purifying and refining L-lactic acid comprises the following steps: removing thalli in a fermentation liquor through separation to obtain thallus residues which can be used as a feed raw material; decolorizing an acidolysis filteredclear liquid by using activated carbon, feeding the decolorized acidolysis filtered clear liquid into a first ion exchange column, carrying out cation and anion exchange to obtain a primary ion exchange liquid, filtering the primary ion exchange liquid by using a nanofiltration membrane, carrying out pre-concentration, and sequentially carrying out cation and anion exchange to obtain a secondary ion exchange liquid; decolorizing the secondary ion exchange solution by adopting an activated carbon decolorizing column, and then concentrating to obtain a lactic acid concentrate with the L-lactic acid content of 80-90%; and carrying out short-path distillation and purification on the lactic acid concentrate to obtain high-purity food-grade lactic acid or produce polylactic acid. According to the L-lactic acid purification and refining method provided by the invention, the finished product quality of the L-lactic acid is improved, and the finally obtained L-lactic acid is good in quality andhigh in yield and particularly meets the quality requirement of the L-lactic acid serving as a PLA raw material.

Owner:安徽固德生物工程有限公司

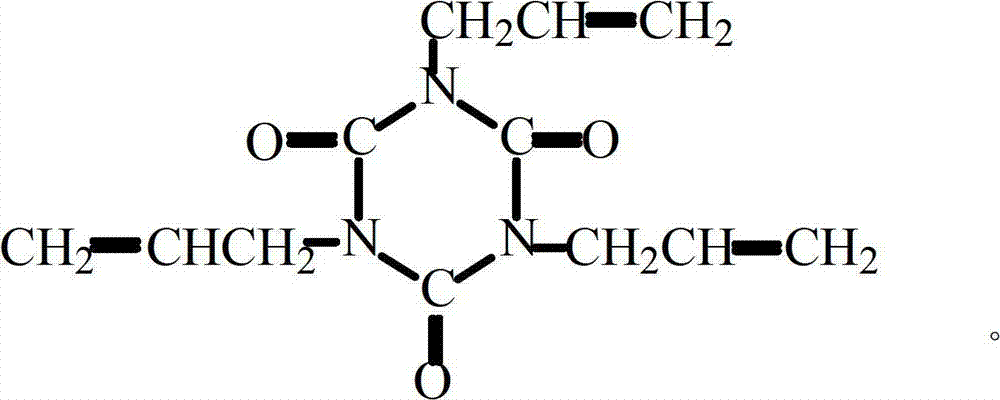

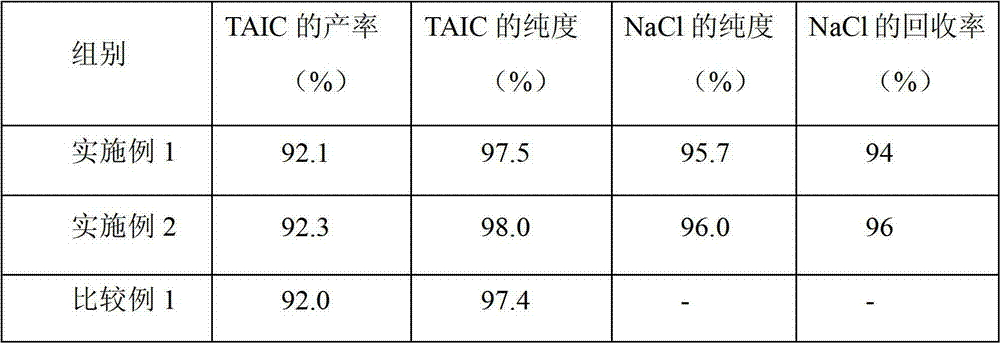

Preparation method of cross linking agent triallyl isocyanurate

The invention discloses a preparation method of cross linking agent triallyl isocyanurate. In the reaction process of synthesizing triallyl isocyanurate by chloropropene and alkali cyanate, the thick powdered sodium chloride precipitated during the reaction process is transformed into crystallized sodium chloride with large particles by adding a crystallizing agent and controlling reaction temperature and reaction time, and the crystallized sodium chloride can be separated by simple filter operation, then is subjected to washing and vacuum drying to recover solvent, so as to obtain sodium chloride byproduct with industrial application value and purity of about 95%. According to the invention, the method of dissolving and separating sodium chloride by water phase in TAIC (triallyl isocyanurate) production technique is changed into the filter separation method, in this way, the problem of discharge and high treatment cost of the salt-containing waste water is avoided, and the TAIC (triallyl isocyanurate) crude product with brown appearance is purified by molecular short-path distillation, so as to obtain colourless TAIC (triallyl isocyanurate) product.

Owner:HEFEI UNIV OF TECH +1

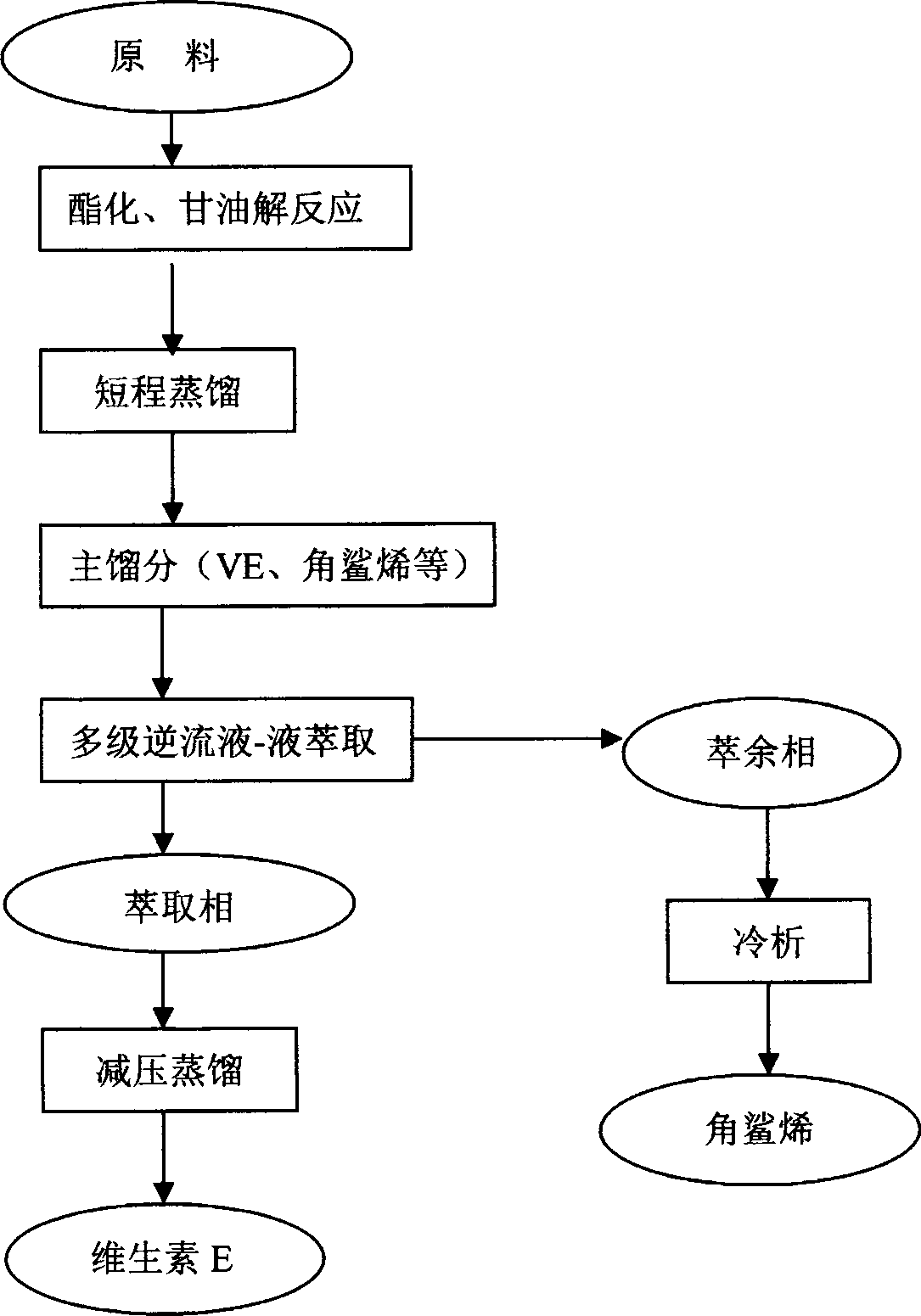

Novel technology for extracting vitamin E and squalene by employing multi-stage counter-current liquid-liquid extraction method

The invention discloses a novel technology for extracting vitamin E and plant squalene from a deodorizer distillate (DD oil) of vegetable oil by employing a multi-stage counter-current liquid-liquid extraction method. The technology comprises the following steps: firstly, converting a free fatty acid in the DD oil into fatty acid methyl ester by a common esterification method, then converting the fatty acid methyl ester into glyceride by glycerolysis reaction; distilling out the vitamin E, squalene and the like with relatively low boiling point by using short-path distillation, and reserving the glyceride, steryl ester and the like with high boiling points at the kettle bottom; and finally, separating out the vitamin E and the squalene by using the multi-stage counter-current liquid-liquid extraction method.

Owner:TIANJIN V HEALTECH CO LTD

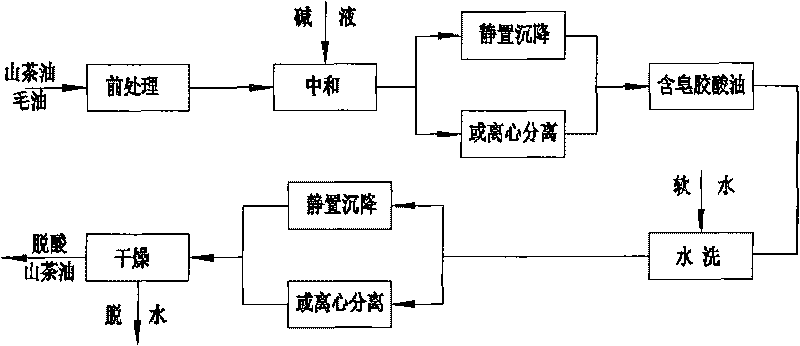

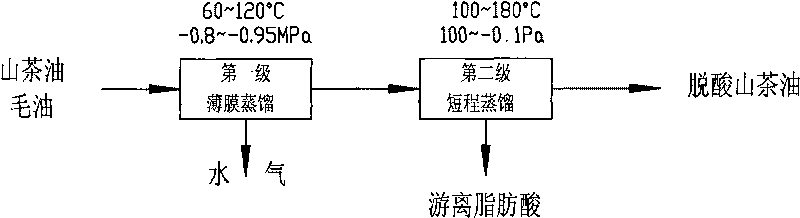

Method for refining camellia oil by adopting short-path distillation

InactiveCN101717690ANo effectNo pollution in the processFatty-oils/fats refiningOleic Acid TriglycerideChemical process

The invention discloses a method for refining camellia oil by adopting short-path distillation, comprising two-stage distillation. During first-stage distillation, firstly the crude camellia oil is directly poured into a buffer tank, then the crude camellia oil is introduced into a first-stage film evaporator through a pump to undergo primary dehydration and degasification under the conditions of temperature between 60 DEG C and 120 DEG C and pressure between minus 0.8MPa and minus 0.95MPa. During second-stage distillation, the camellia oil after undergoing dehydration and degasification is introduced into a second-stage short-path distillator through a pump to undergo deacidification under the conditions of temperature controlled between 100 DEG C and 180 DEG C and pressure between 100Pa and 0.1Pa, thus obtaining oleic acid with high acid value and camellia oil with low acid value. The process with high pollution of wastewater drained after soda soap washing and water washing in the chemical processes of alkali refining and neutralizing does not exist during processing the camellia oil. The flow is simple, the oleic acid with high value and the camellia oil with low acid value are separated by distillation, the separation process is a physical process, and the camellia oil is free of loss, thus having very high yield.

Owner:SOUTH CHINA UNIV OF TECH

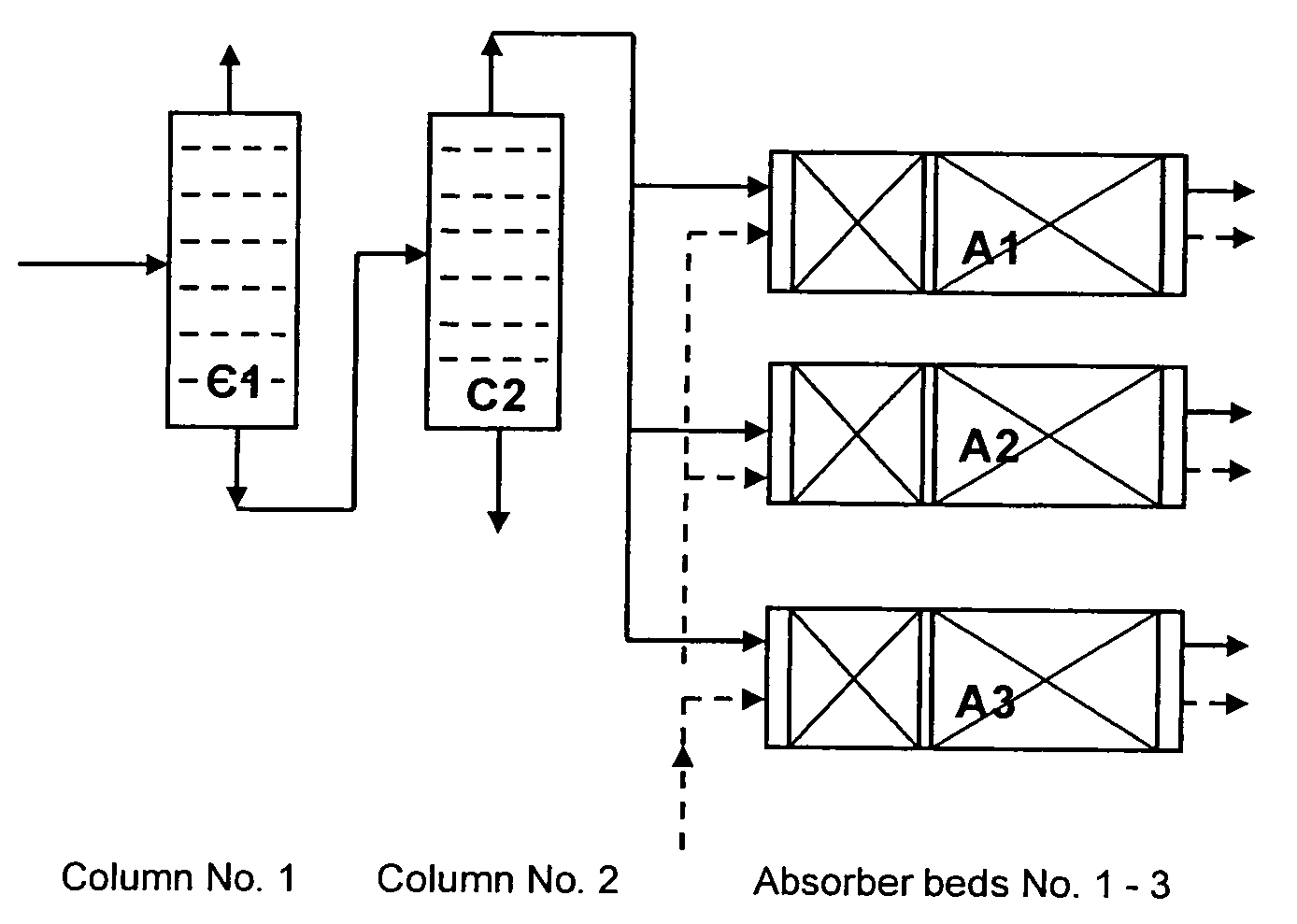

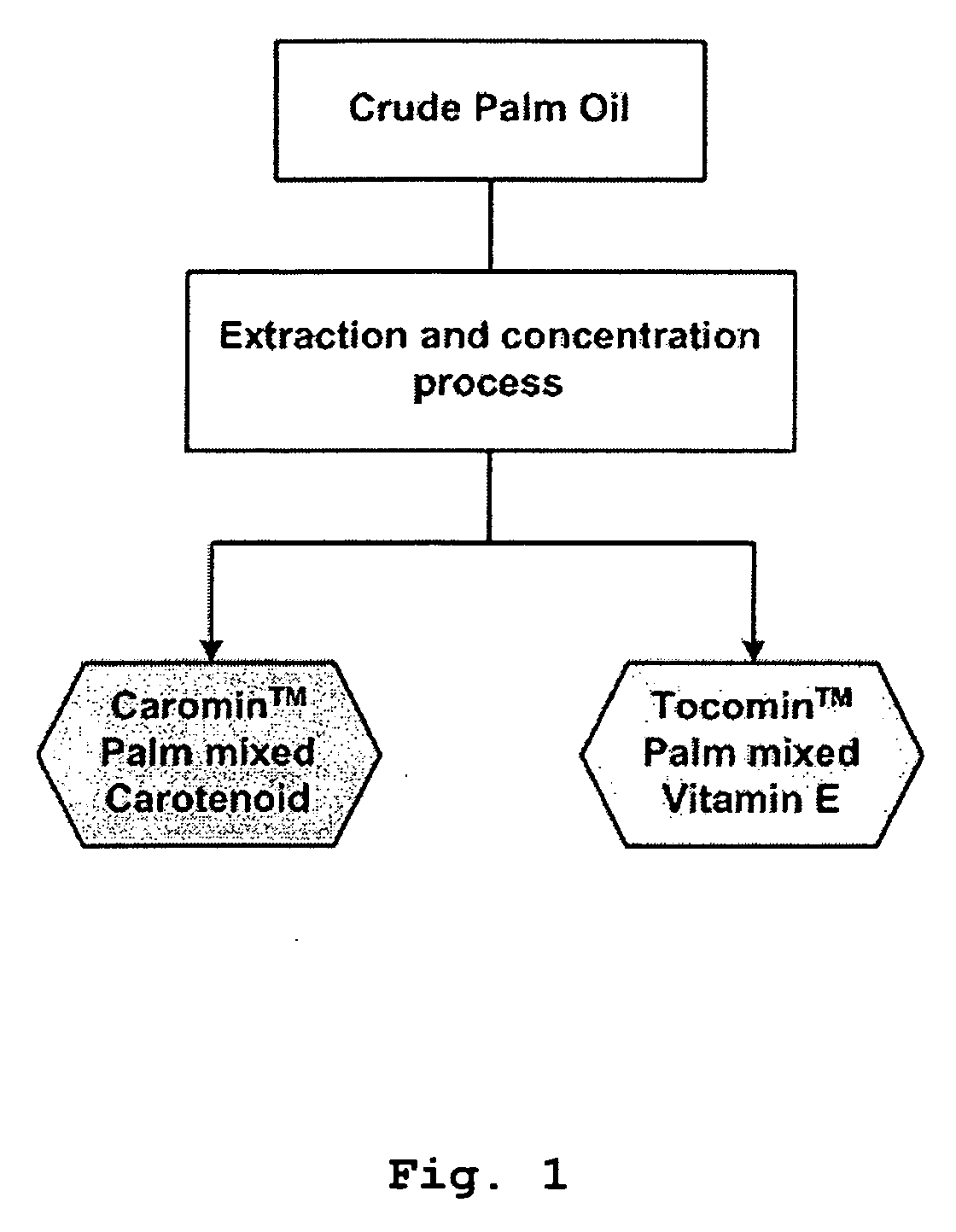

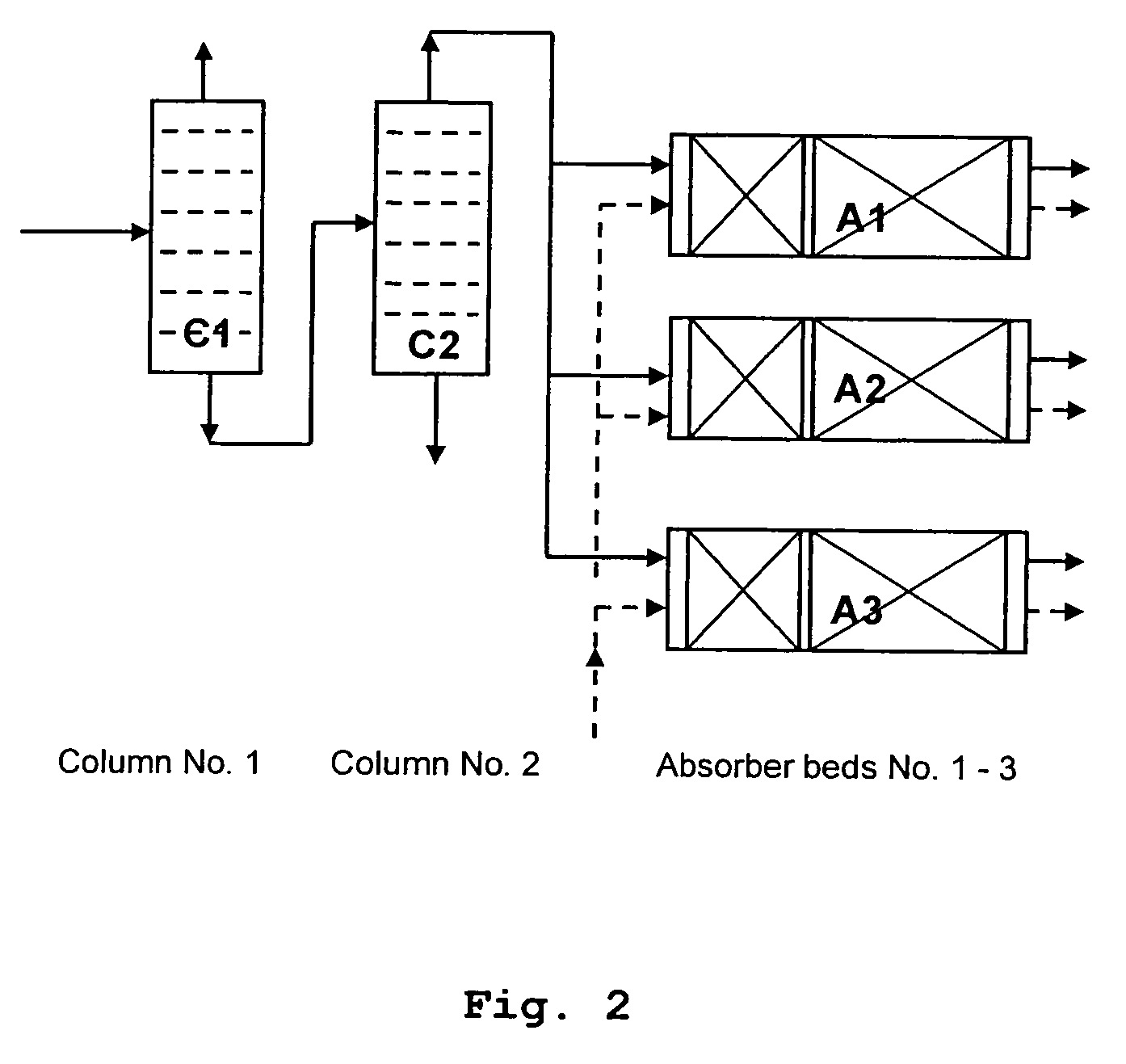

Process for production of highly enriched fractions of natural compounds from palm oil with supercritical and near critical fluids

From palm oil valuable compounds like the tocochromanols, carotenoids, phytosterols, and others can be derived. Enrichment to highly concentrated fractions is hindered by the enormous number of components involved, the very low volatility, the very low solubility of many of the compounds in organic solvents, and the high viscosity of the mixtures to be processed. Starting materials for the new process are enriched fractions of tocochromanols (about 20 to about 50 wt.-%) and / or carotenoids (about 10 to 30 wt.-%) from palm oil obtained by conventional processes, or by counter current multistage processes with supercritical carbon dioxide. These processes, not addressed here, may comprise: Removal of free fatty acids, transesterification of the triglycerides to methyl or ethyl esters, removal of the esters, e.g. by short path distillation, separation of the tocochromanol fraction from the carotenoid fraction by cooling. In the new process, fractions derived from crude palm oil, already enriched to some extent in tocochromanols, carotenoids, phytosterols, and others, are being treated by supercritical fluid technology in a unique combination of counter current separation with selective adsorption and desorption using supercritical fluids. A first enrichment, comprising one or more separation steps by application of a near critical or a supercritical fluid in a single or multistage (counter current) separation process is combined appropriately with a second enrichment step wherein the product of the first enrichment step is directly adsorbed on an adsorbent (silicagel) by passing the product flow over a fixed bed of adsorbent without substantial pressure change, and subsequent desorption with the same (or an other) near critical or supercritical fluid at the same or a different pressure as in the first separation, or by a pre-designed sequence of pressures and temperatures. For the tocochromanol enrichment, carbon dioxide at near critical conditions above the critical temperature of carbon dioxide is used. For the carotenoid enrichment, propane at near critical conditions below the critical temperature of propane is used.

Owner:CAROTECH SD BHD

Process For the Recovery of Sterols From Organic Material

A process for recovering sterols from organic material containing sterols and sterol derivatives. In a first step (a) the organic material is reacted with at least one of polyols, polyamines, alkanolamines or monohydric alcohols to increase the amount of free sterols in the organic material; (b) reacting residual reactants, and their esters or amides with epoxydated components; and (c) separating the free sterols from the mixture by short path distillation, thin film evaporation, or flash evaporation. The recovered sterols can be further purified by a crystallization step.

Owner:COGNIS IP MANAGEMENT GMBH

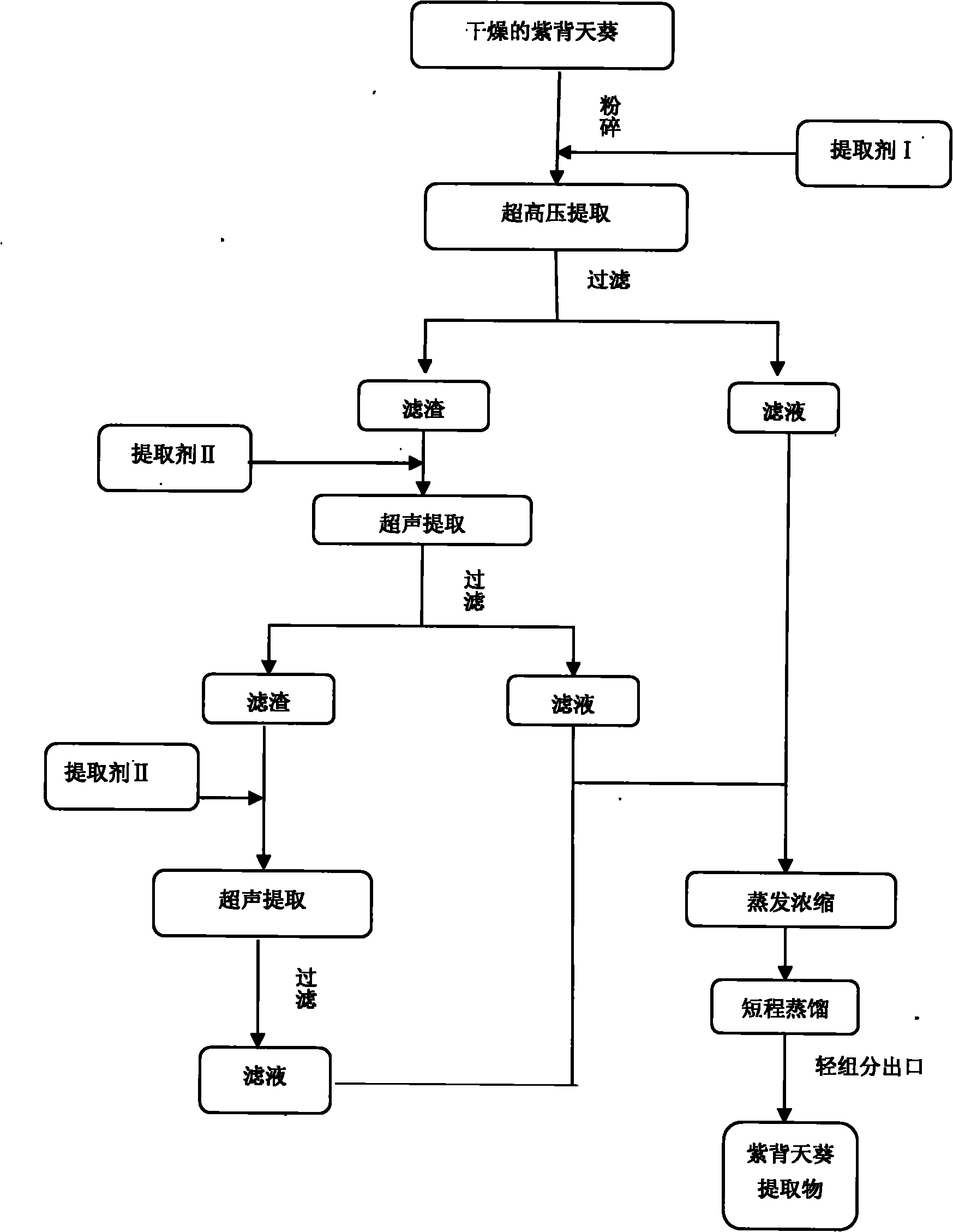

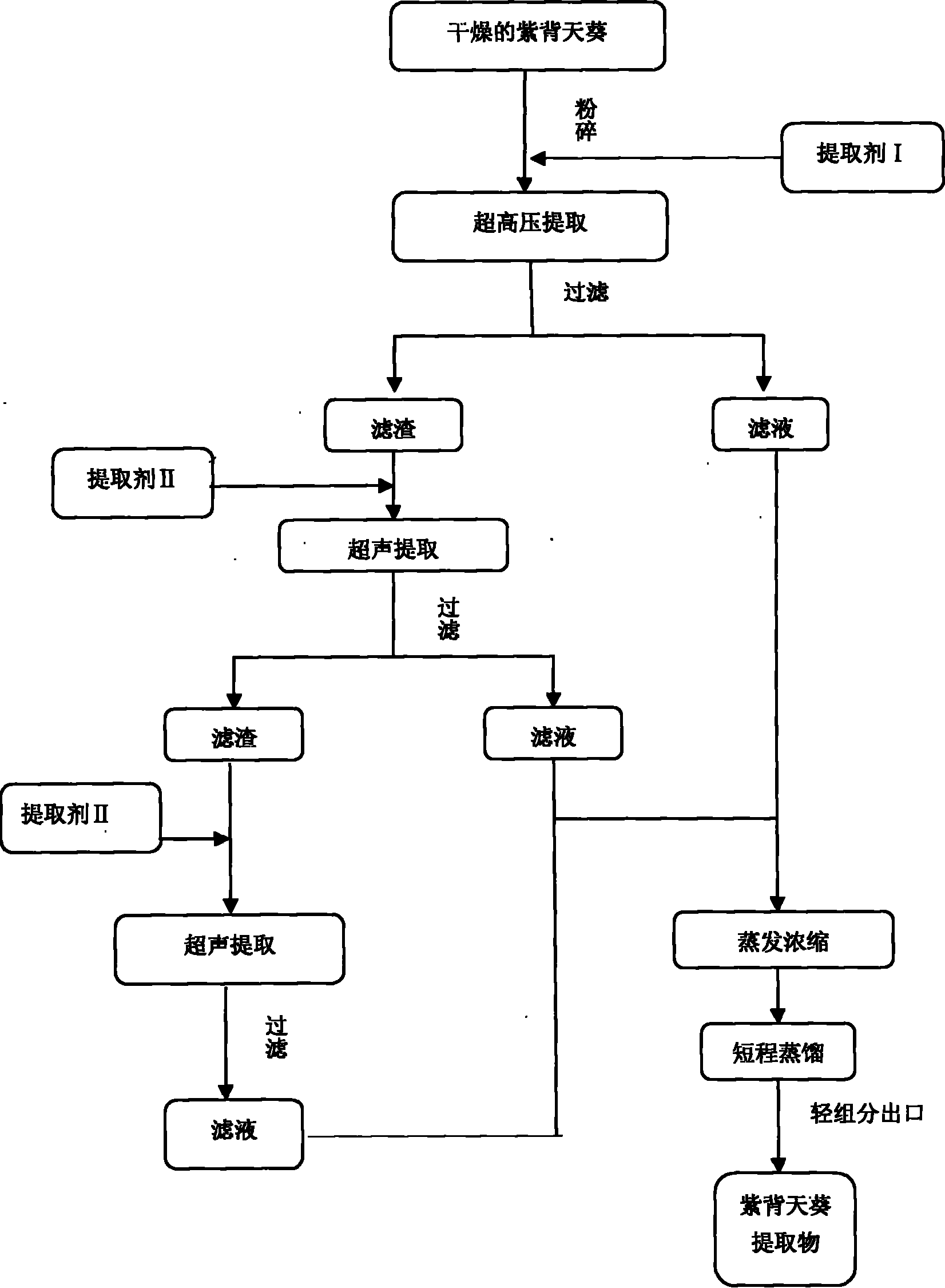

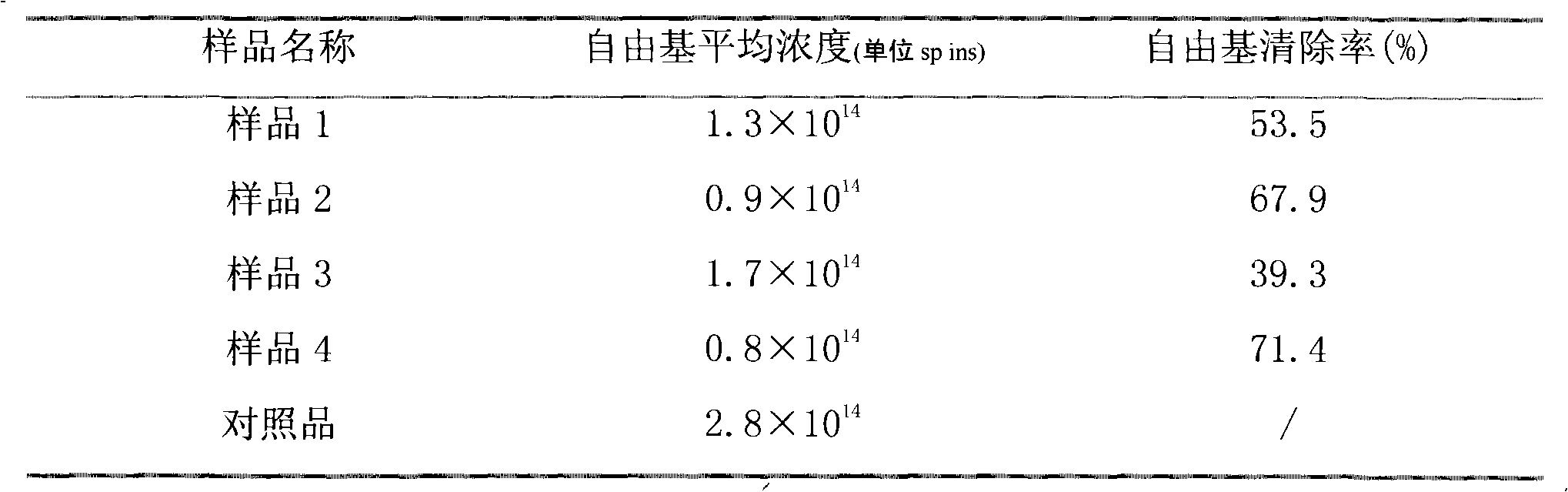

Gynura bicolor extract and usage thereof in removing free radical in cigarette smoke

InactiveCN101828764ADissolution inhibitionAvoid extractingTobacco treatmentGynura bicolorEvaporation

The invention relates to a gynura bicolor extract for removing free radical in cigarette smoke, which is obtained by the following steps of: soaking dry gynura bicolor with an extractant I and extracting at high pressure; extracting the obtained residue by using an extractant II under ultrasonic twice; combining the three filtrates and carrying out evaporation, condensation and short-path distillation sequentially; and taking the fraction at the light component outlet of a short-path distiller. The extract of the invention can be used as an addition material for removing the free radical in the cigarette smoke.

Owner:GUANGZHOU MILLIM VEGETABLE TECH DEV CO LTD

Preparation of high content mixed tocopherols

The invention discloses a method for extracting mixed tocopherols with high content form raw materials with low content of tocopherols. In the existing methods, the amount of some used solvents is too large, some methods have excessive requirements on equipment and some methods are too small in yield, thus being inapplicable to industrialized production. In the invention, deodorizing distillate of fatty acid oil is subjected to esterification and alcoholysis firstly and then freezing and crystallization are carried out to separate out phytosterol; then, after aliphatic ester in a filtrate is reclaimed by short-path distillation, a tocopherol concentrate is obtained and separated by silica gel column chromatography, and eluted with three organic solvents of different polarity so as to obtain the aliphatic ester, the mixed tocopherols with high content and phytosterol crude product. The method of the invention has low requirements on raw materials, is easy for large-scale industrialized production, and can obtain high content of mixed tocopherols and obtain fatty acid methyl ester and phytosterol.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

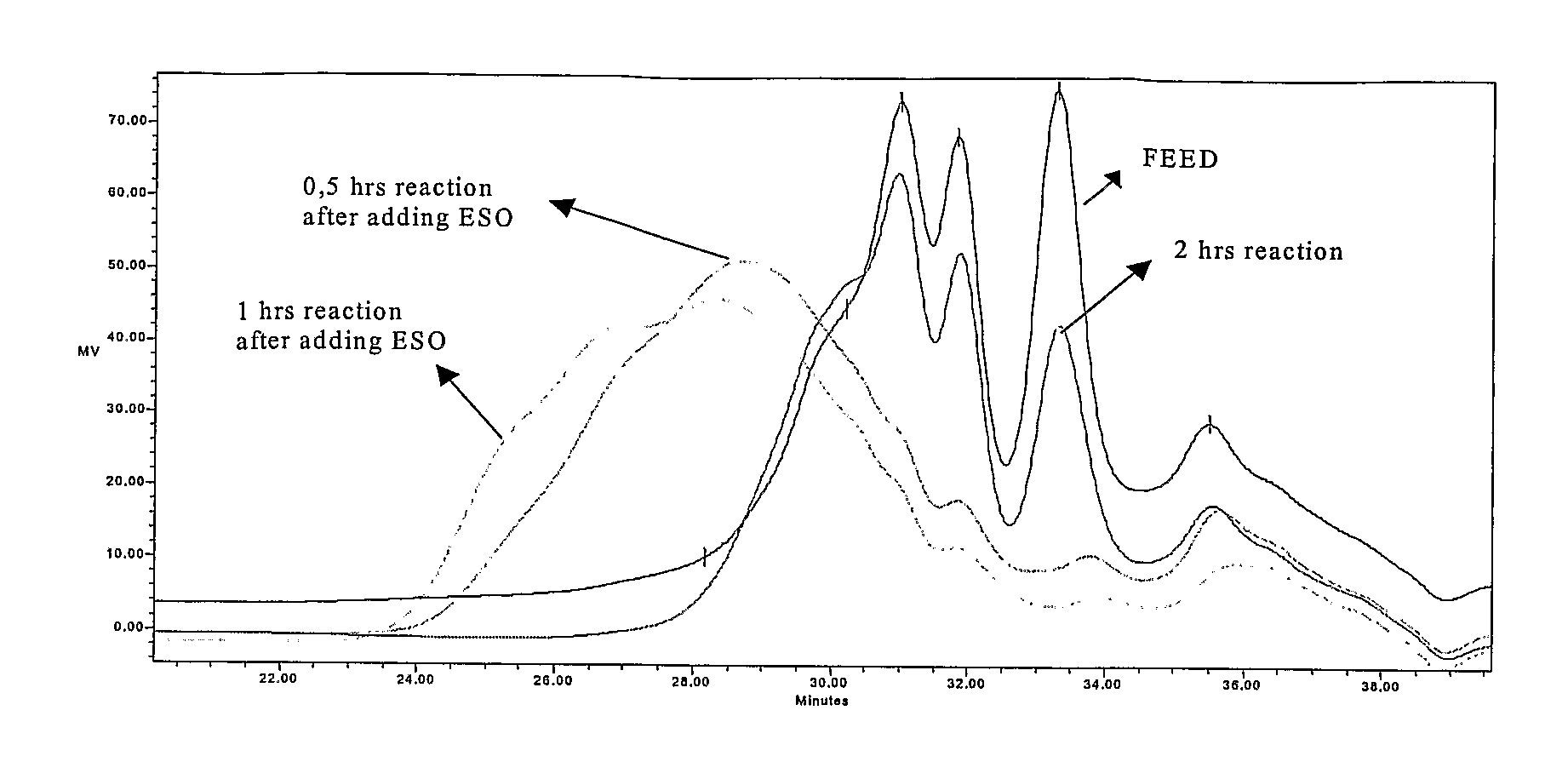

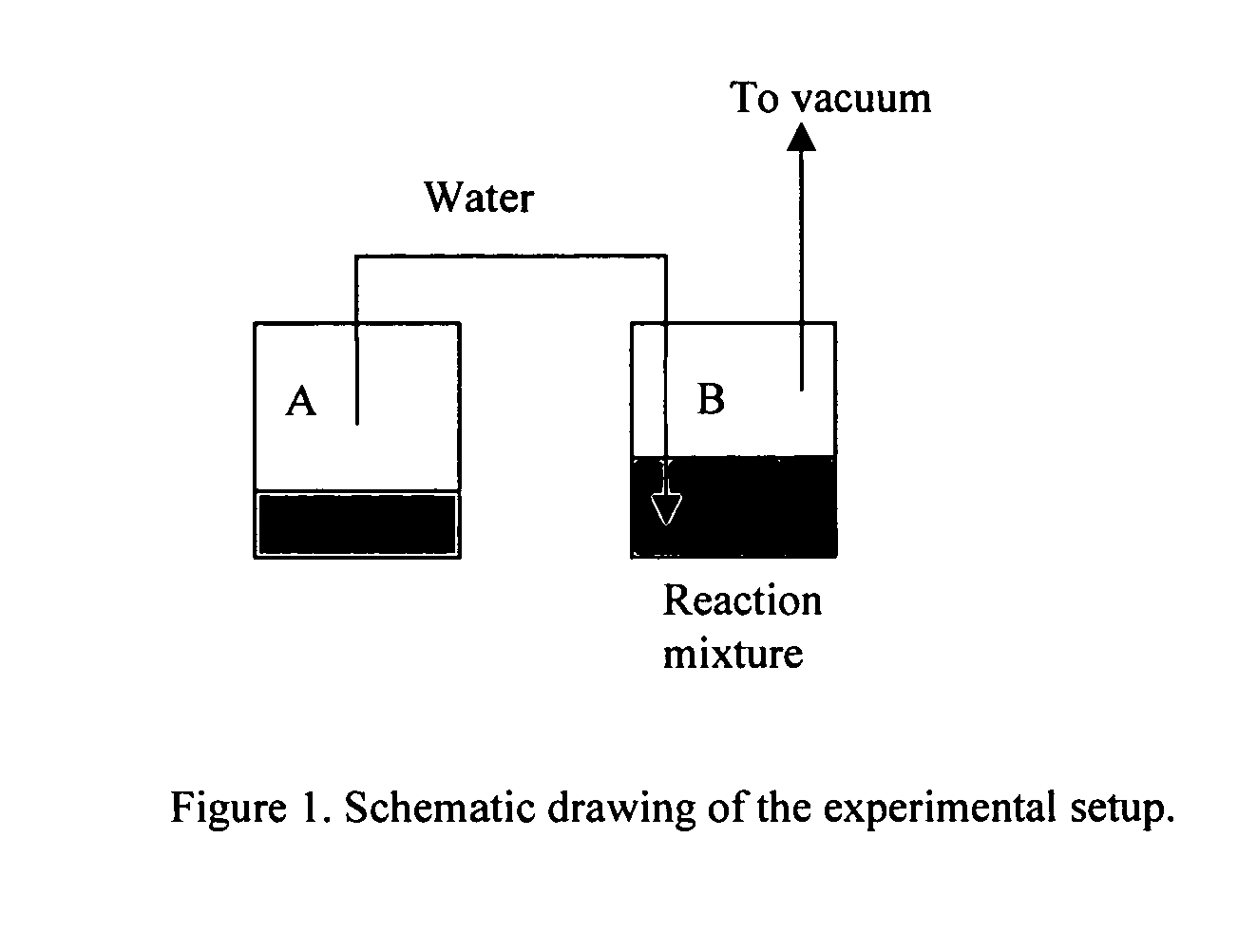

Concentration of fatty acid alkyl esters by enzymatic reactions with glycerol

InactiveUS20060286266A1Food safetyFatty acid esterificationFatty acids production/refiningOrganic solventGlycerol

An enzymatic process for the kinetic separation of alkyl esters under organic solvent free conditions is disclosed. Alkyl esters obtained from e.g. fish oil are reacted with glycerol, in the presence of water, at different rates in an evacuated chamber. The reaction is terminated prior to reaching equilibrium and the enriched alkyl ester fraction is isolated from the reaction mixture by short path distillation.

Owner:EPAX NORWAY

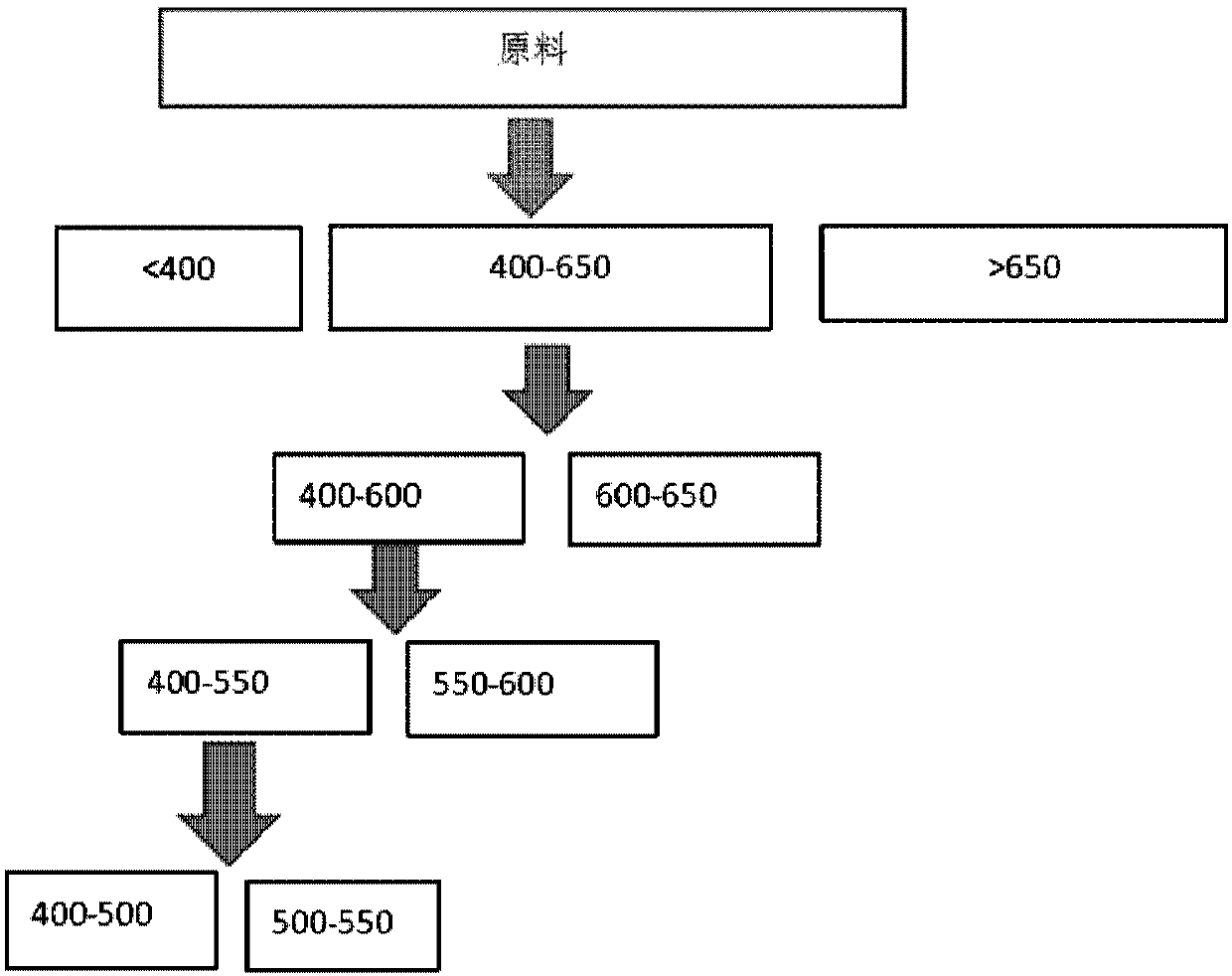

High-temperature phase-change wax and preparation method thereof

The invention discloses high-temperature phase-change wax and a preparation method thereof. The preparation method comprises the following steps: carrying out hydrofining by taking coal-based Fischer-Tropsch wax as a raw material to obtain Fischer-Tropsch refined wax; preheating the refined wax, carrying out pre-short-path distillation cutting, and cutting off light fractions; cutting the residualcomponents obtained in the previous step through multistage short-range distillation cutting, and reducing the temperature and / or the vacuum degree step by step, and enabling light fractions obtainedthrough current-stage short-range distillation to enter a next-stage short-range distillation for separation; and respectively refining a plurality of heavy fractions with boiling points of 500-650 DEG C and a boiling range of 40-60 DEG C remained in each stage of short-range distillation under normal pressure to obtain the high-temperature phase-change wax. The melting point of the high-temperature phase-change wax prepared by the preparation method is 80-100 DEG C, and the enthalpy value is greater than 210 J / g. The production process is simple, the product yield is relatively high, industrial production can be realized, and the high-temperature phase-change wax product can be produced.

Owner:INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

Tea seed oil skin oil and preparation method thereof

ActiveCN102362843AGood for skin careToxic side effectsCosmetic preparationsToilet preparationsNatural resourceSide effect

The invention provides tea seed oil skin oil and a preparation method thereof. The tea skin oil is prepared from the following components in weight proportion: 85-95% of tea seed oil subjected to short path distillation processing, 0.5-1% of flowery essential oil and 4.5-15% of ester; the invention gives full play to natural resources in China and provides a beautifying skin oil which adopts no industrial chemicals, is nutrient to skin of human body and is easy to be absorbed by skin. Main raw materials of a product in the invention are separated by adopting a short path distillation pure physical means, contain pure natural substance, has no toxic or side effect to human body and is applicable to people in various age groups, the product is rich in natural vitamin E and tea polyphenol, no antioxidant is required to be added, the natural vitamin E and the tea polypheonl can realize synergistic antioxidation, and quality guarantee period can be effectively prolonged.

Owner:ZHEJIANG UNIV OF TECH

Special wax for candlelight and preparation method thereof

Owner:INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

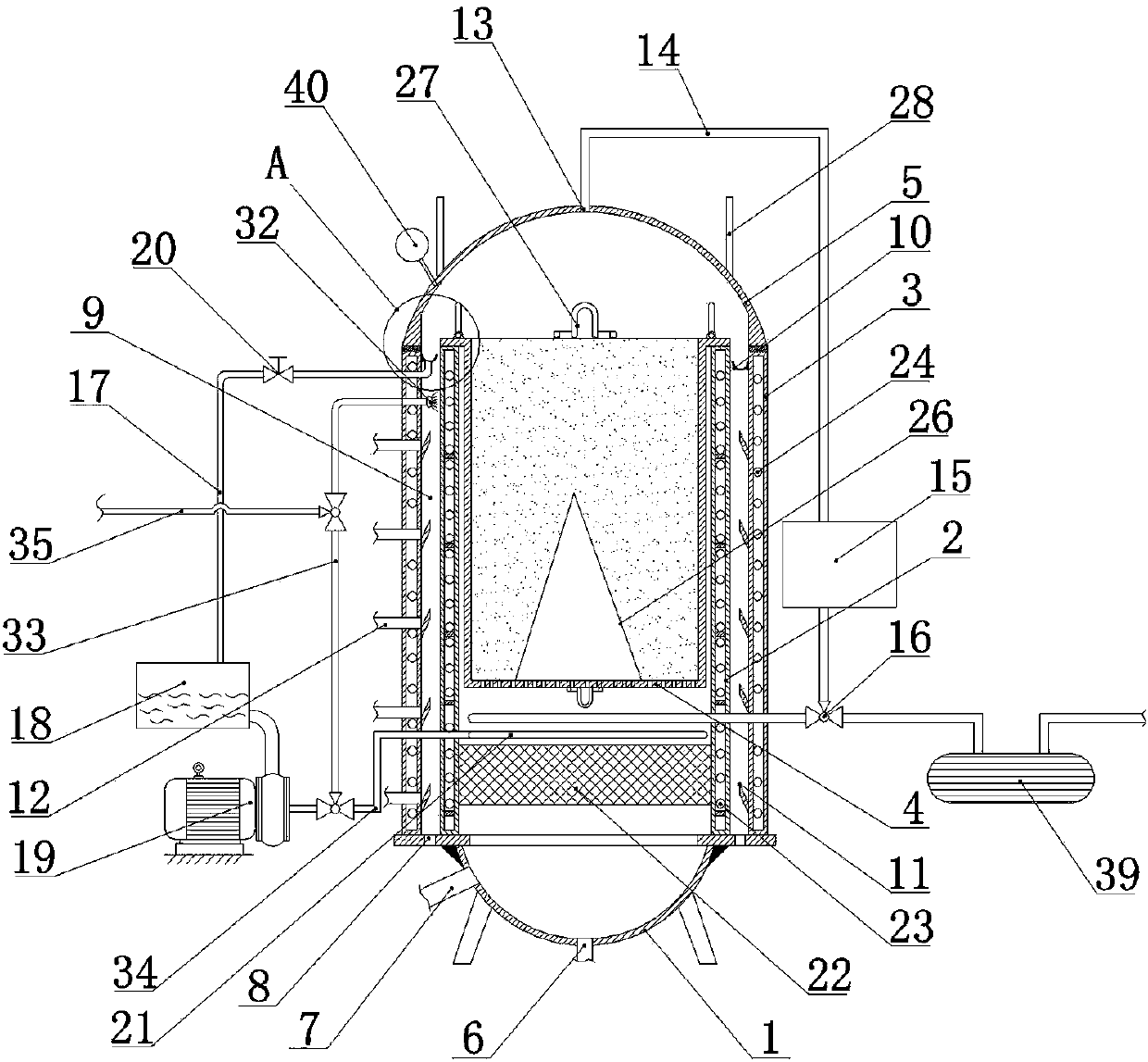

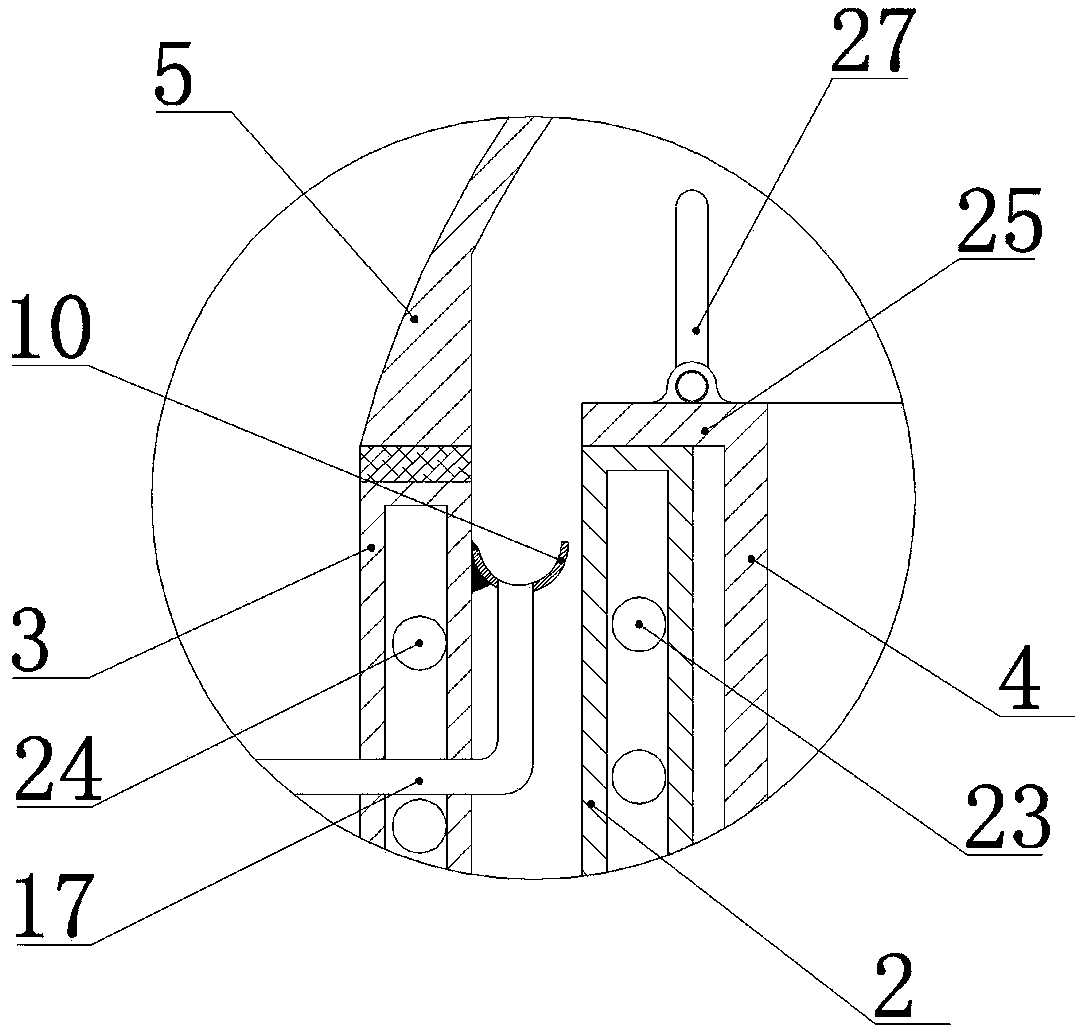

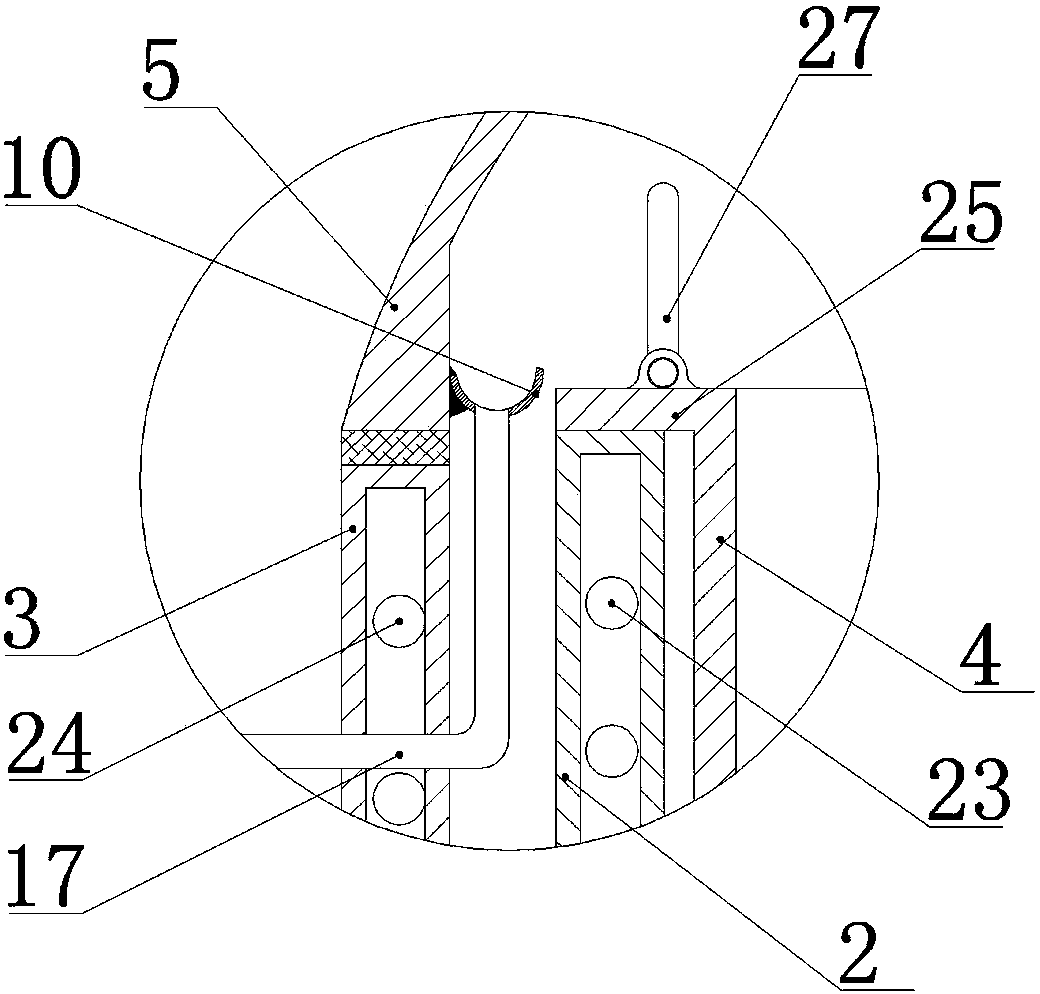

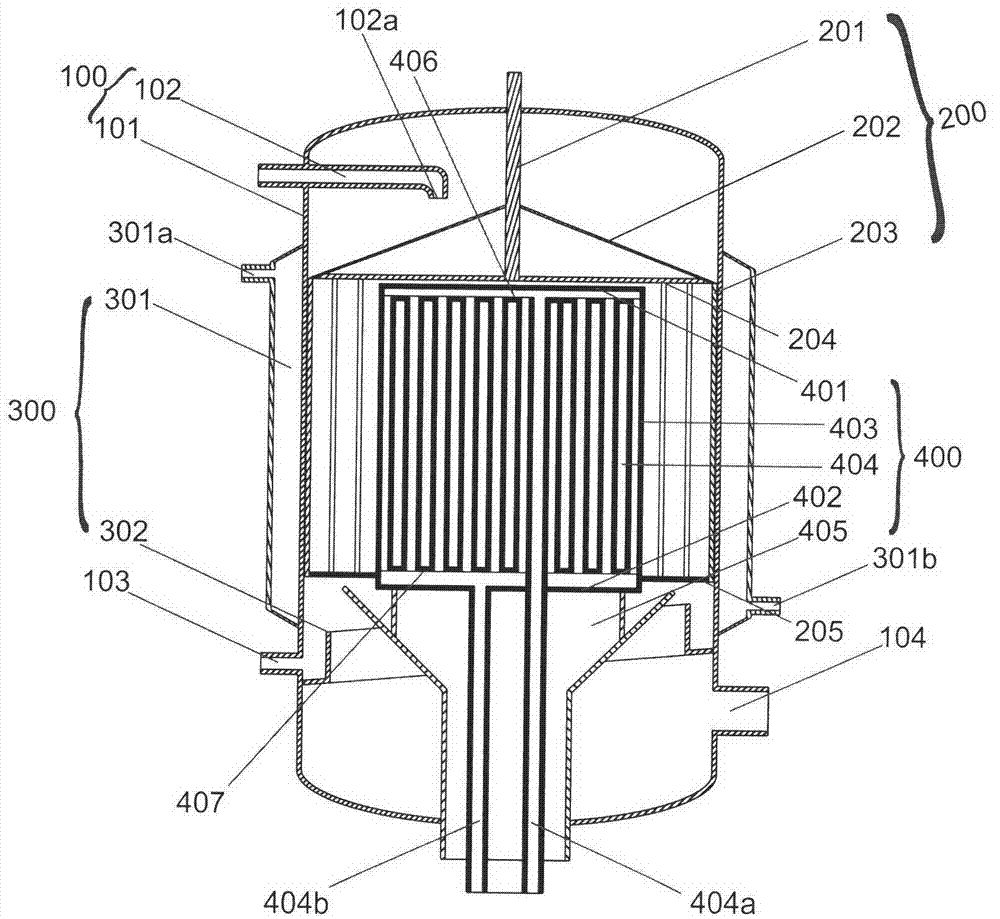

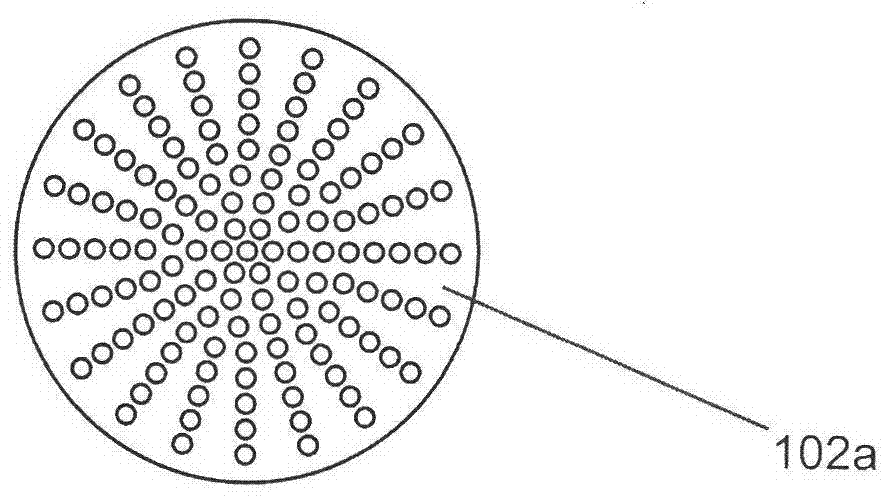

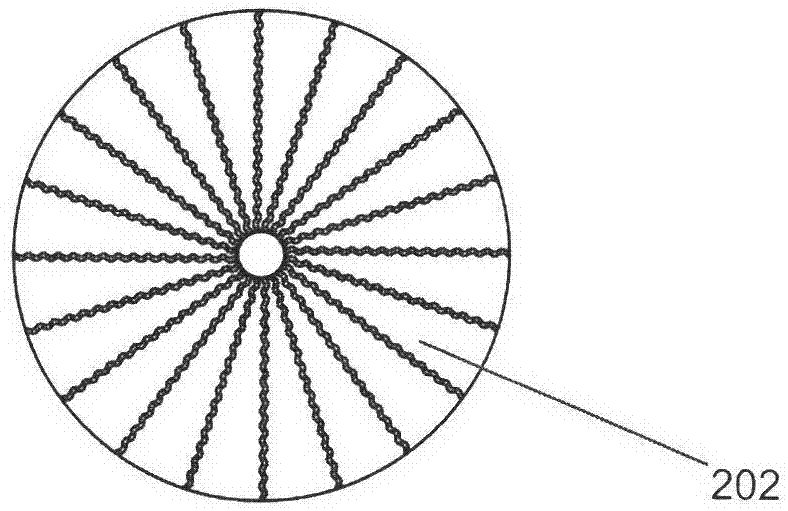

Combined type solid-state distillation device

ActiveCN104195023AQuality improvementScale adjustmentAlcoholic beverage preparationAlcoholFractionation

The invention relates to a distillation device. A combined type solid-state distillation device comprises a base, a vaporization wall barrel and a condensation wall barrel, a boiler barrel and a top cover, wherein the vaporization wall barrel and the condensation wall barrel are arranged on the base and sheathed with each other, the boiler barrel is arranged in the vaporization wall barrel, a liquid outlet and a steam input port are formed in the base, a condensate liquefied layer is arranged on the top cover, the vaporization wall barrel is in seal fit with the condensation wall barrel and the base, the condensation wall barrel is in seal fit with the top cover, an interlayer cavity is formed among the vaporization wall barrel, the condensation wall barrel and the base, a liquid diversion device is arranged at the top of the inner wall of the condensation wall barrel or the inner wall of the top cover, a plurality of circular condensate collecting tanks are arranged on the inner wall of the condensation wall barrel and are respectively communicated with a collection pipeline, and the collection pipeline is used for collecting a fractionation liquid after penetrating through the condensation wall barrel. Low-alcohol wine can be thoroughly eliminated by virtue of molecular short-path distillation, the waste of the low-alcohol can be avoided, and distillation can be adequately conducted.

Owner:孙祯芳

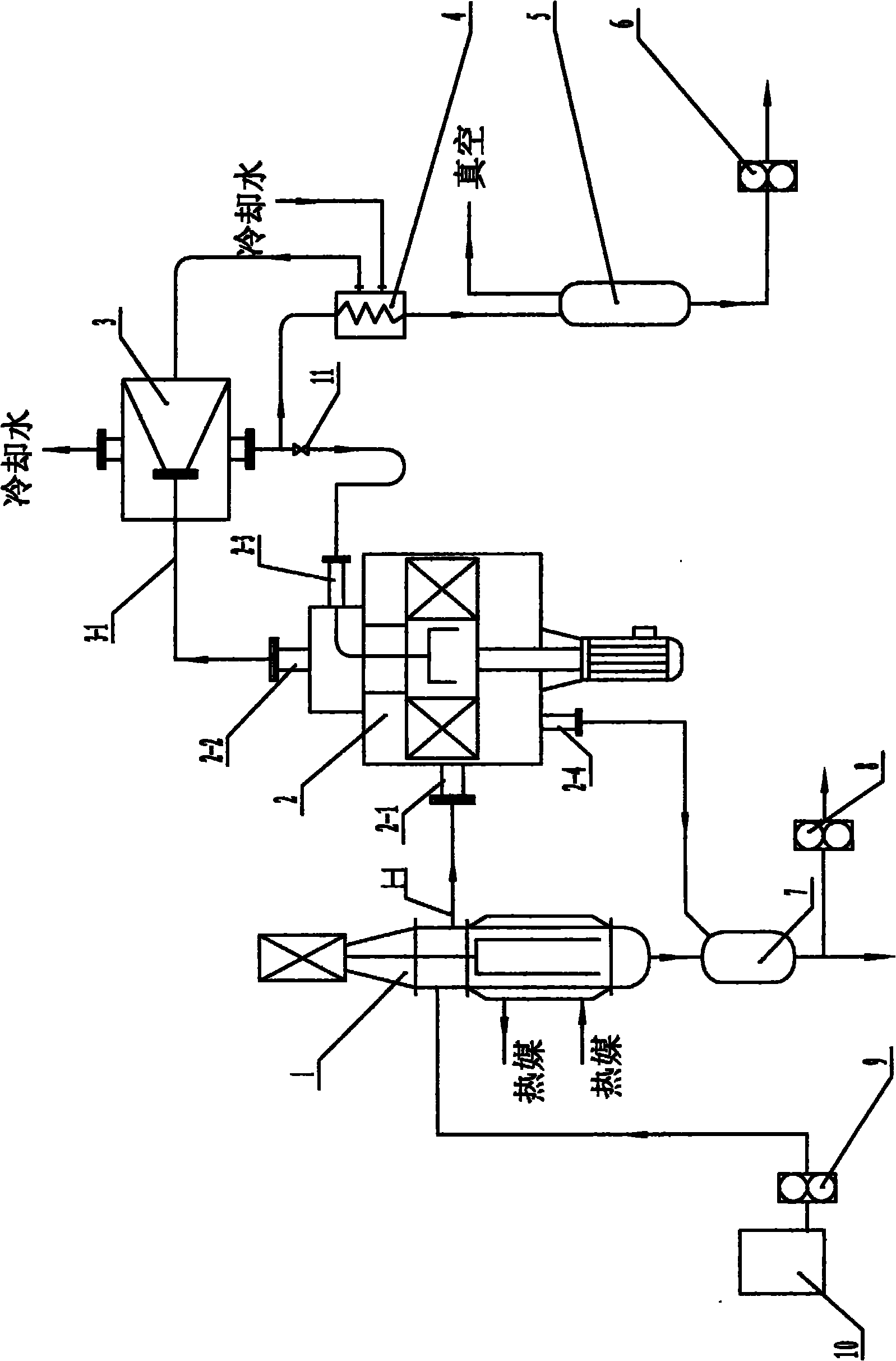

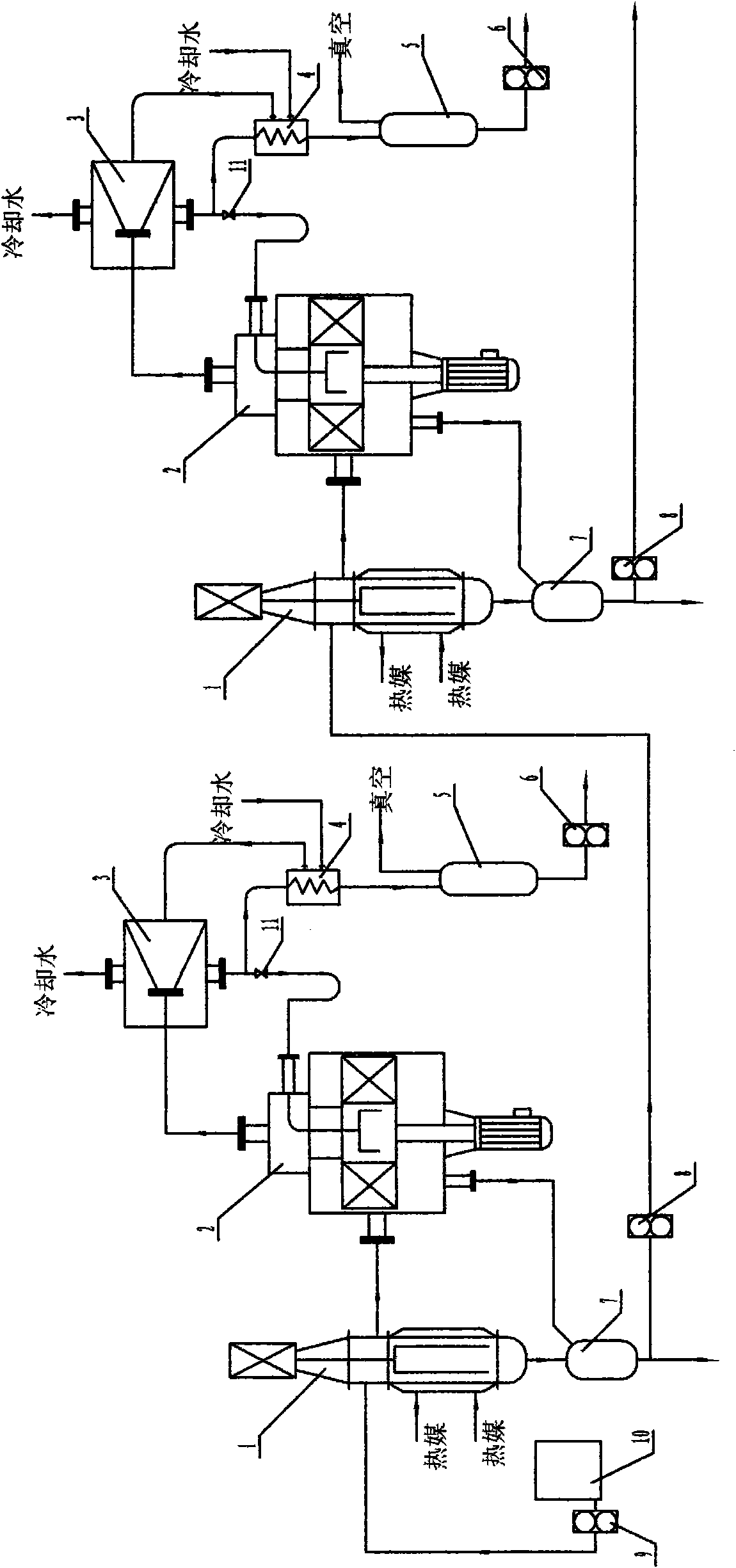

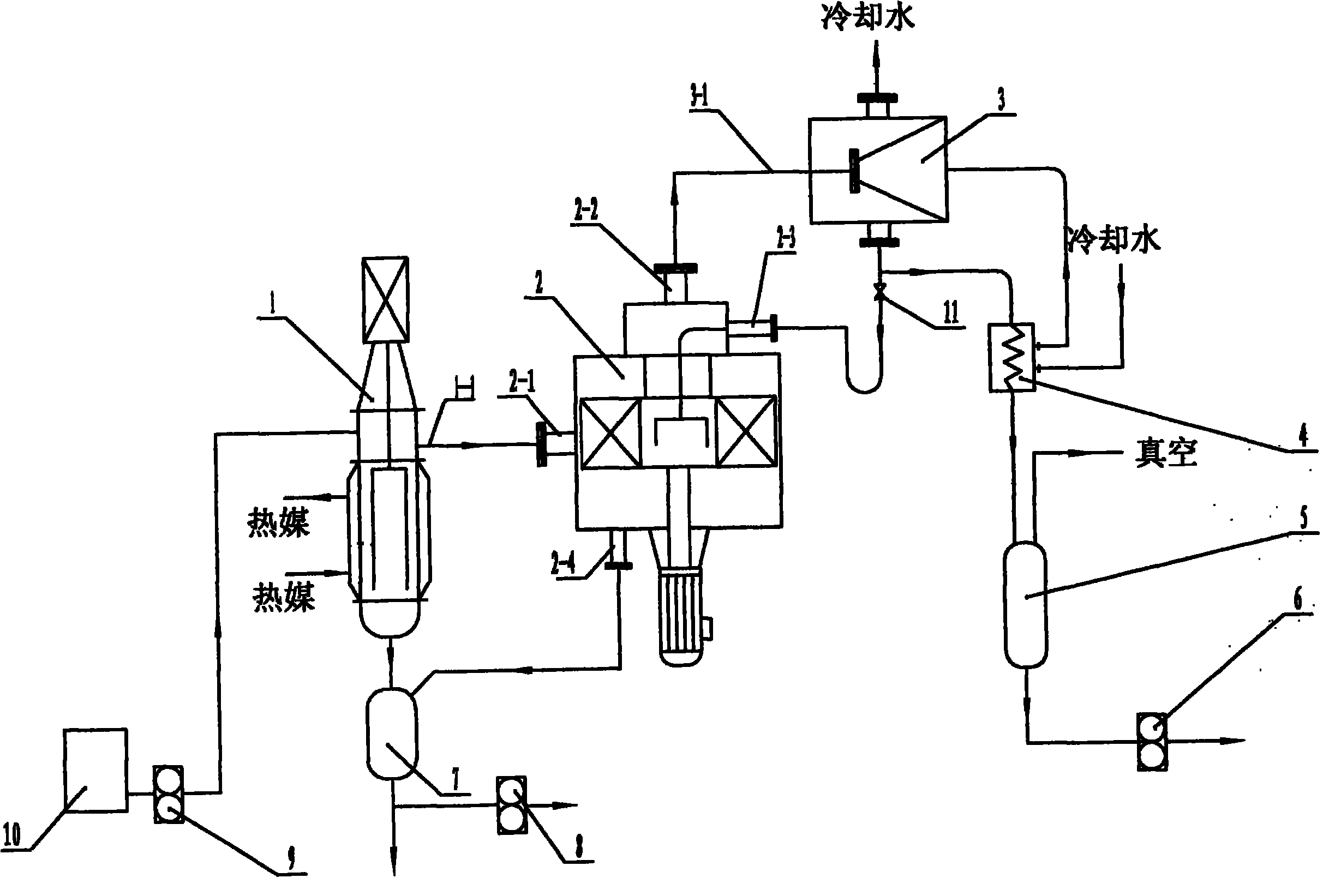

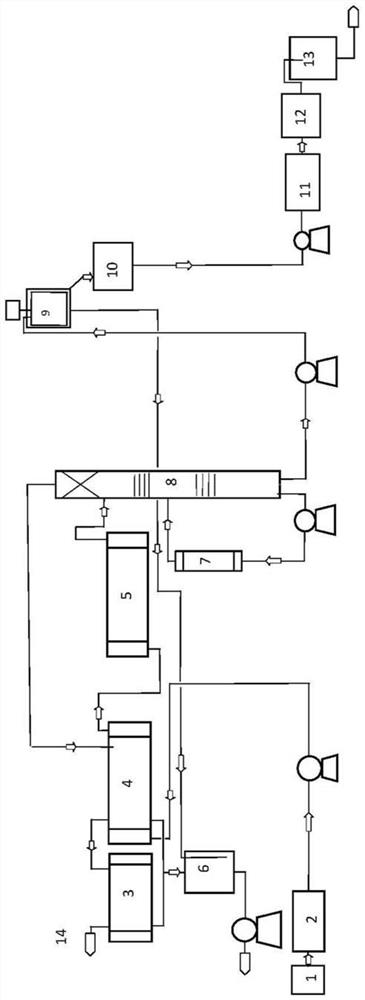

Method and device of preparing needle coke

InactiveCN104479707AControl cut volumeReduce energy consumptionWorking-up pitch/asphalt/bitumen by distillationCoking carbonaceous materialsAsphaltDegasification

The invention discloses a method and a device of preparing a needle coke, and belongs to the technical field of needle coke preparation. The method disclosed by the invention is characterized by comprising the following steps: separating an asphalt raw material by virtue of a degasification column and a molecular distillation column, preheating the asphalt raw material, pumping the asphalt raw material in the degasification column and carrying out degasification treatment at a degasification temperature of 250-330 DEG C under an in-column pressure of 100-1000Pa, then pumping the degasified materials to the molecular distillation column, controlling a distillation temperature in the molecular distillation column to 300-400 DEG C and controlling a pressure to 0.01-100Pa, separating the materials into a light-phase component and a heavy-phase component in the molecular distillation column through a short-path distillation action, carrying out delayed coking on the light-phase component to obtain green coke, and calcining the green coke to obtain the needle coke. The method disclosed by the invention is capable of stably and accurately controlling the cutting amounts of the raw material components, thus flexibly adjusting the product quality, and furthest reserving ideal components. Moreover, the method is low in treatment temperature, rapid in material separation, and free from forming secondary quinoline undissolved substances.

Owner:乔光明

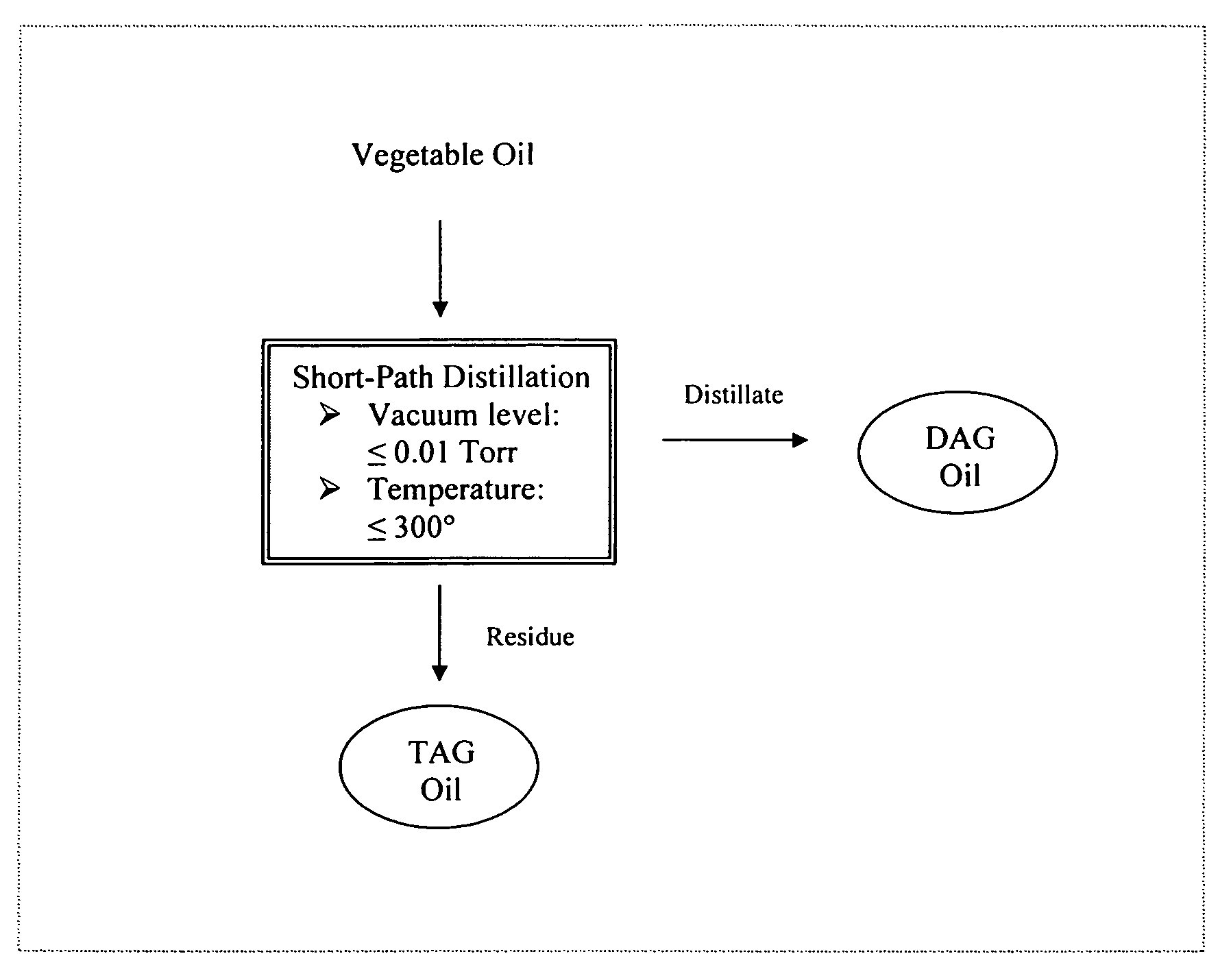

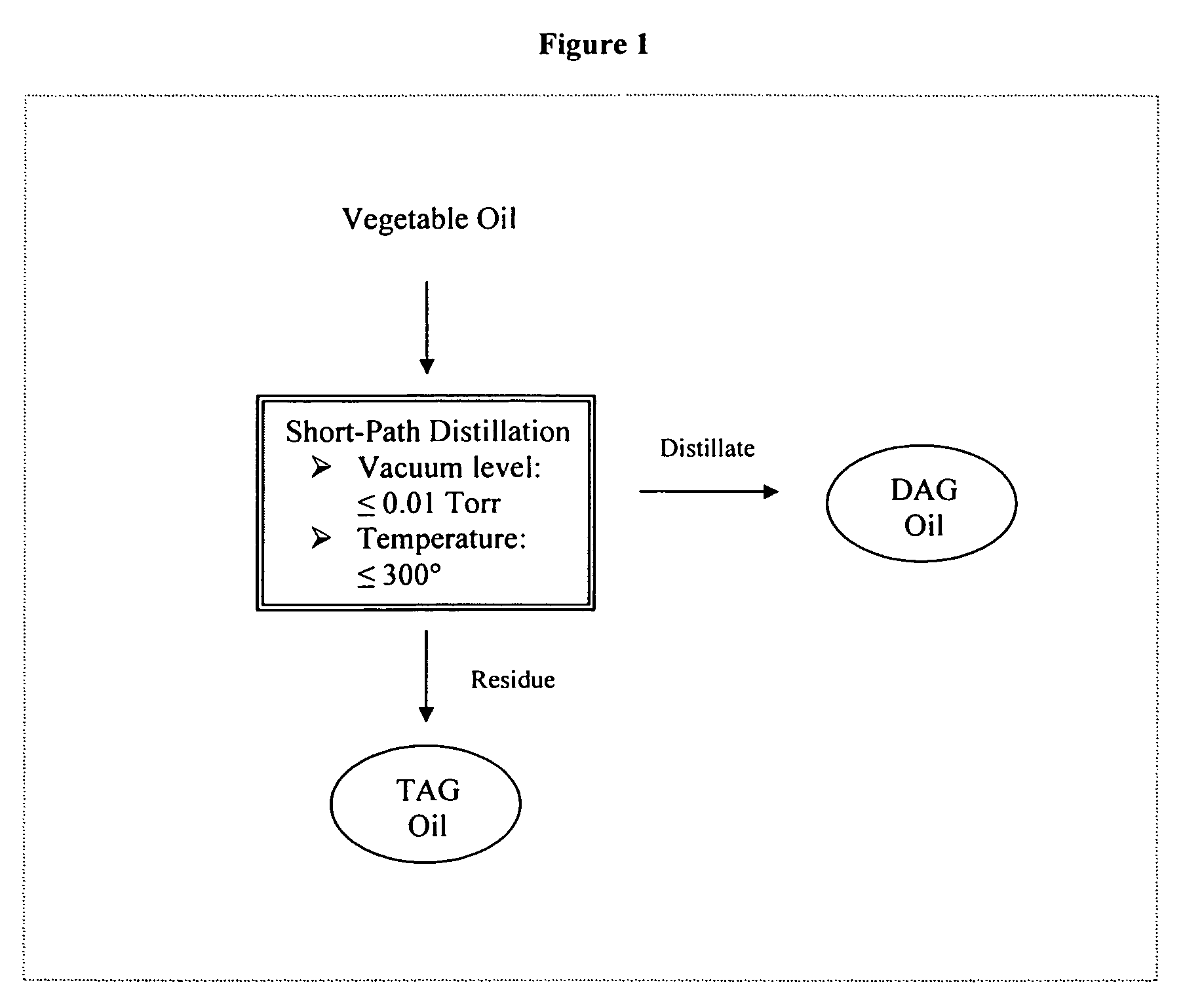

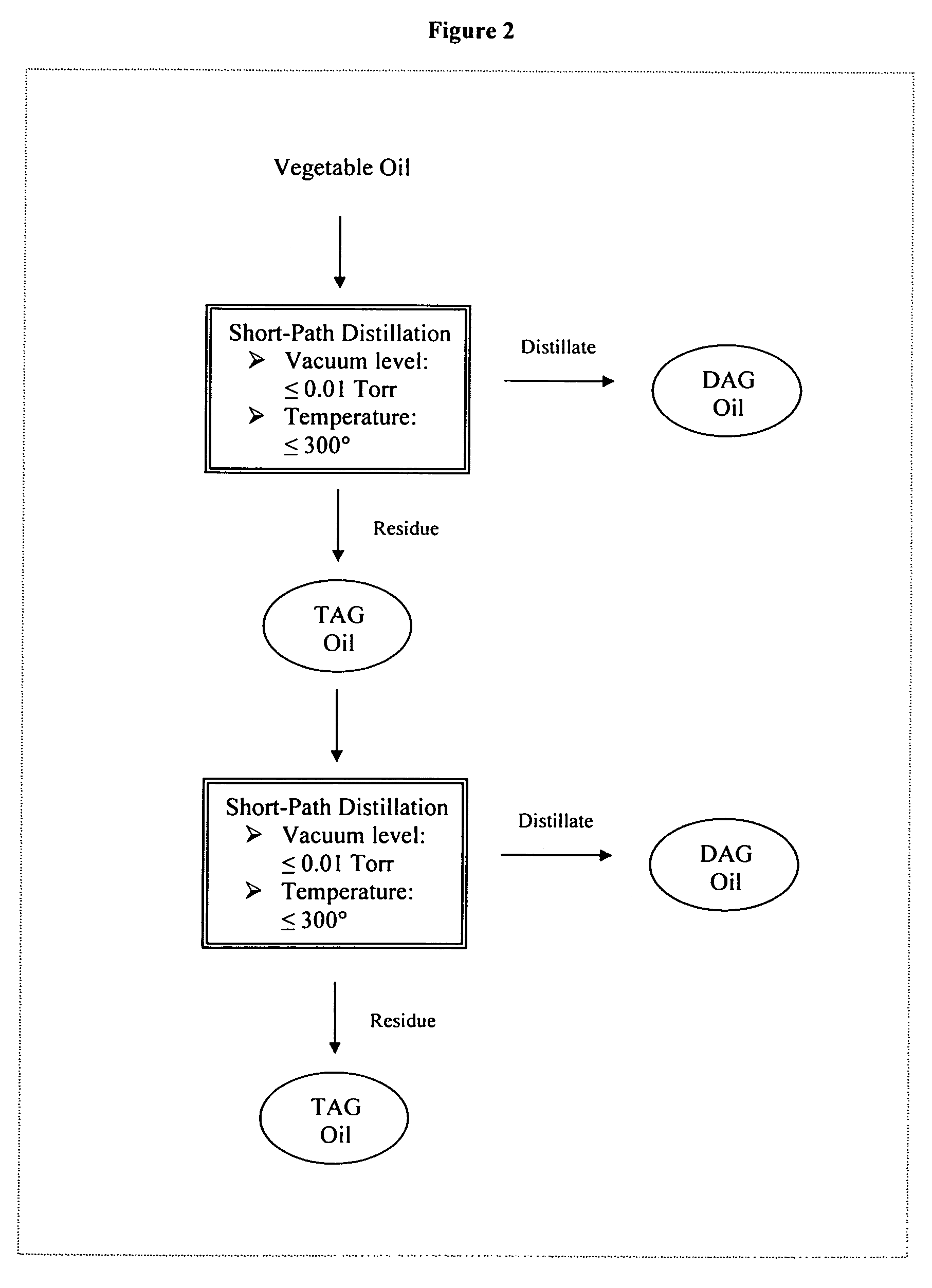

Production of edible oil

ActiveUS7531678B2Fatty oils/acids recovery from wasteOrganic compound preparationVegetable oilVacuum level

The present invention relates to a method for production of two types of edible oils, an oil type with high diacylglycerol content (DAG oil) containing at least 8 wt % diacylglycerol and another oil type with low diacylglycerol content (TAG oil) containing less than 8 wt % diacylglycerol, from a vegetable oil. The method comprises subjecting a vegetable oil to at least one stage of short-path distillation under vacuum level of not more than 0.01 Torr and at temperature of not more than 300° C., wherein DAG oil is obtained as distillate and whereas TAG oil is obtained as residue.

Owner:MALASIAN PALM OIL BOARD

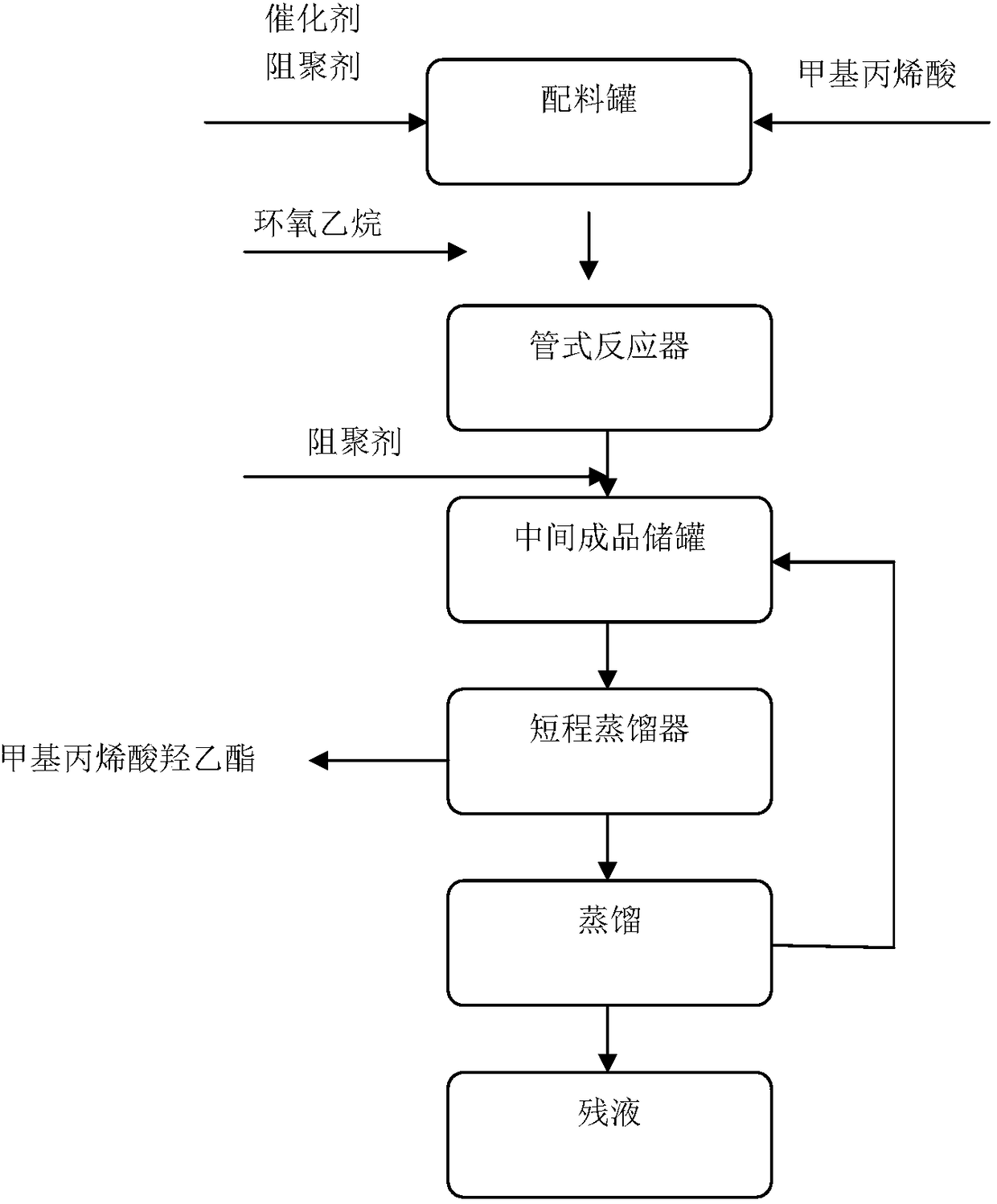

Continuous production method for hydroxyethyl methylacrylate

InactiveCN108383726AReduce lossReduce consumptionOrganic compound preparationCarboxylic acid esters preparation(Hydroxyethyl)methacrylateEthylene oxide

The invention discloses a continuous production method for hydroxyethyl methylacrylate. The continuous production method comprises the following steps: allowing methylacrylic acid, a catalyst and a polymerization inhibitor to enter a tubular reactor, introducing ethylene oxide, carrying out a ring-opening reaction at 60 to 80 DEG C and 0.25 to 0.1 MPa so as to prepare a reaction mixed solution, subjecting the reaction mixed solution to condensation and separation so as to obtain excess ethylene oxide and crude hydroxyethyl methylacrylate, allowing the crude hydroxyethyl methylacrylate to enteran intermediate finished product tank, subjecting the crude hydroxyethyl methylacrylate and the polymerization inhibitor to short-path distillation so as to discharge hydroxyethyl methylacrylate anda first residual solution, subjecting the first residual solution to short-path distillation again so as to discharge hydroxyethyl methylacrylate and a second residual solution, subjecting the secondresidual solution to distillation so as to obtain a distillation product, and subjecting the distillation product to cyclic short-path distillation and distillation so as to realize continuous production of hydroxyethyl methylacrylate. The continuous production method provided by the invention has the following advantages: a reaction temperature is low; side reactions are reduced; the loss of rawmaterials is reduced; the conversion rate of the raw materials is improved; and the quality of a product is improved.

Owner:安徽联化新材料有限公司

Short-path distillation production method and short-path distiller for increasing unsaturated fatty acid content of vegetable oil

ActiveCN103805338AImprove hungerIncrease fatty acid contentFatty-oils/fats refiningMolecular distillationOil and greaseVegetable oil

The invention discloses a short-path distillation production method and a short-path distiller for increasing the unsaturated fatty acid content of vegetable oil. The short-path distillation production method comprises the following steps of preheating an evaporating surface to 170 to 320 DEG C, vacuumizing to 0.1 to 10Pa, cooling a condensing surface to 3 to 45 DEG C, heating degummed vegetable oil to 150 to 190 DEG C by using a heat exchanger, causing the vegetable oil to enter the short-path distiller, causing light components to enter light component collection tanks, and causing heavy components to enter heavy component collection tanks. The short-path distiller and the short-path distillation production method for increasing the unsaturated fatty acid content of the vegetable oil have the advantages that operation in easy; materials are heated only for tens of seconds during short-path distillation, so that the side reaction of oxidation, polymerization and the like of unsaturated fatty acid can be suppressed; the short-path distiller and the method have high application value in the field of fractionation for oil and fat refining.

Owner:陈汉卿

New technique for separating and extracting fatty acid in nigre of vegetable oil

InactiveCN1916141AMild reaction conditionsLower requirementFatty oils/acids recovery from wasteFatty substance recoveryVegetable oilAcid catalyzed

This invention relates to a new technique for separating and purifying fatty acids from soap stock of plant oil. The new technique is aimed to achieving a hydrolysis rate of 98% with mild reaction conditions. The technique comprises: (1) performing short-path distillation on acidified plant oil to separate heavy and light components; (2) performing acid-catalyzed hydrolysis on the heavy components under normal pressure to obtain crude fatty acids; (3) performing short-path distillation to obtain purified fatty acids. The light components are mainly fatty acids, thus can reduce the contents of fatty acids in the acidified plant oil and realize rapid and high-efficiency hydrolysis of grease. The reactions are performed at 120 deg.C under normal pressure, thus can reduce the requirements on the equipment.

Owner:HEFEI UNIV OF TECH

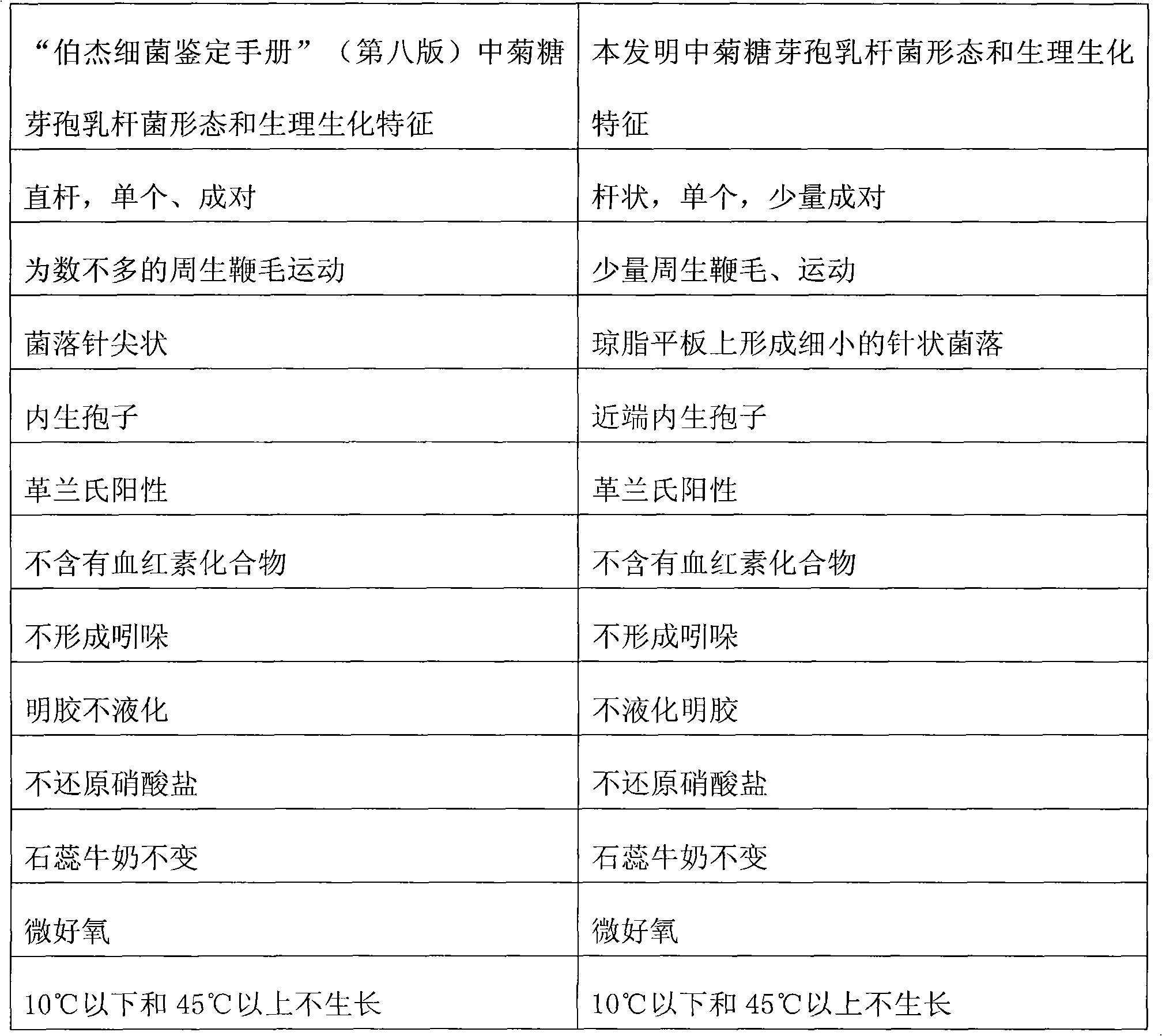

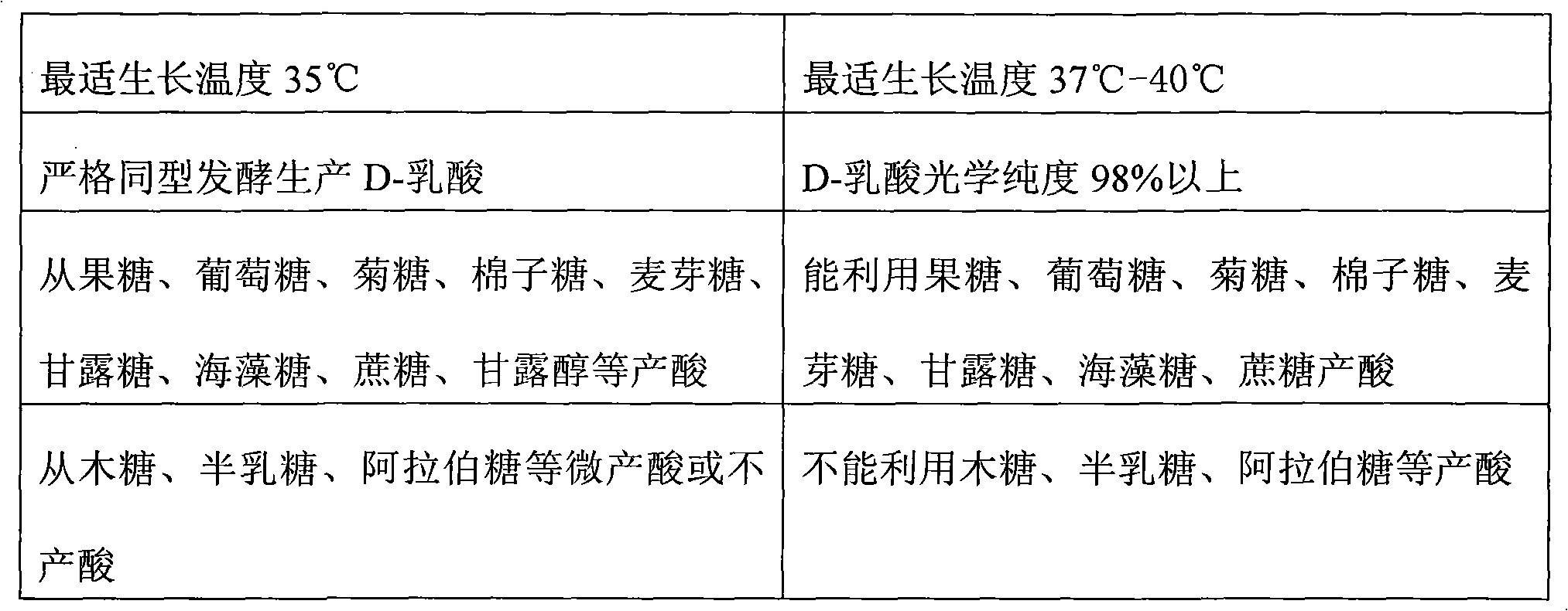

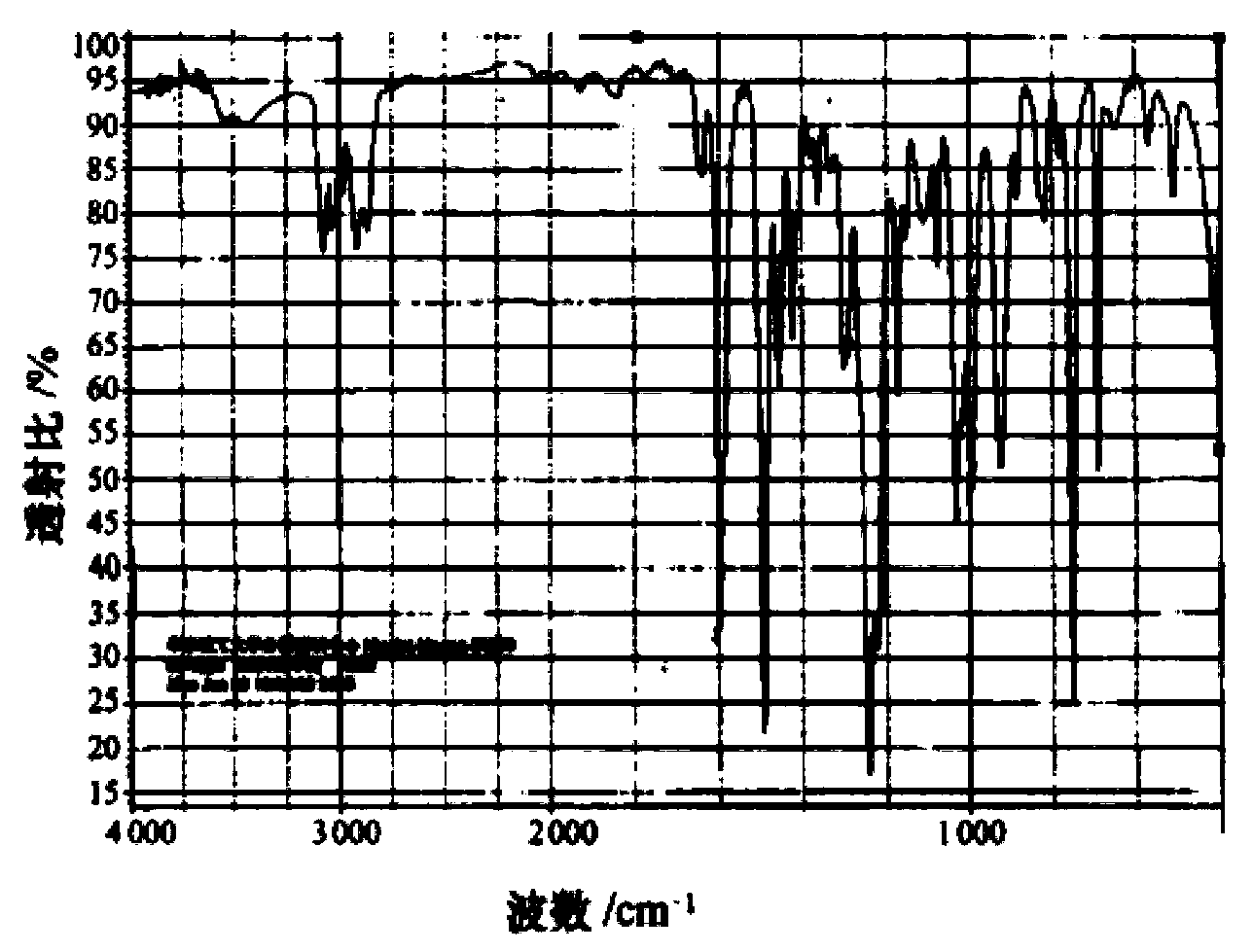

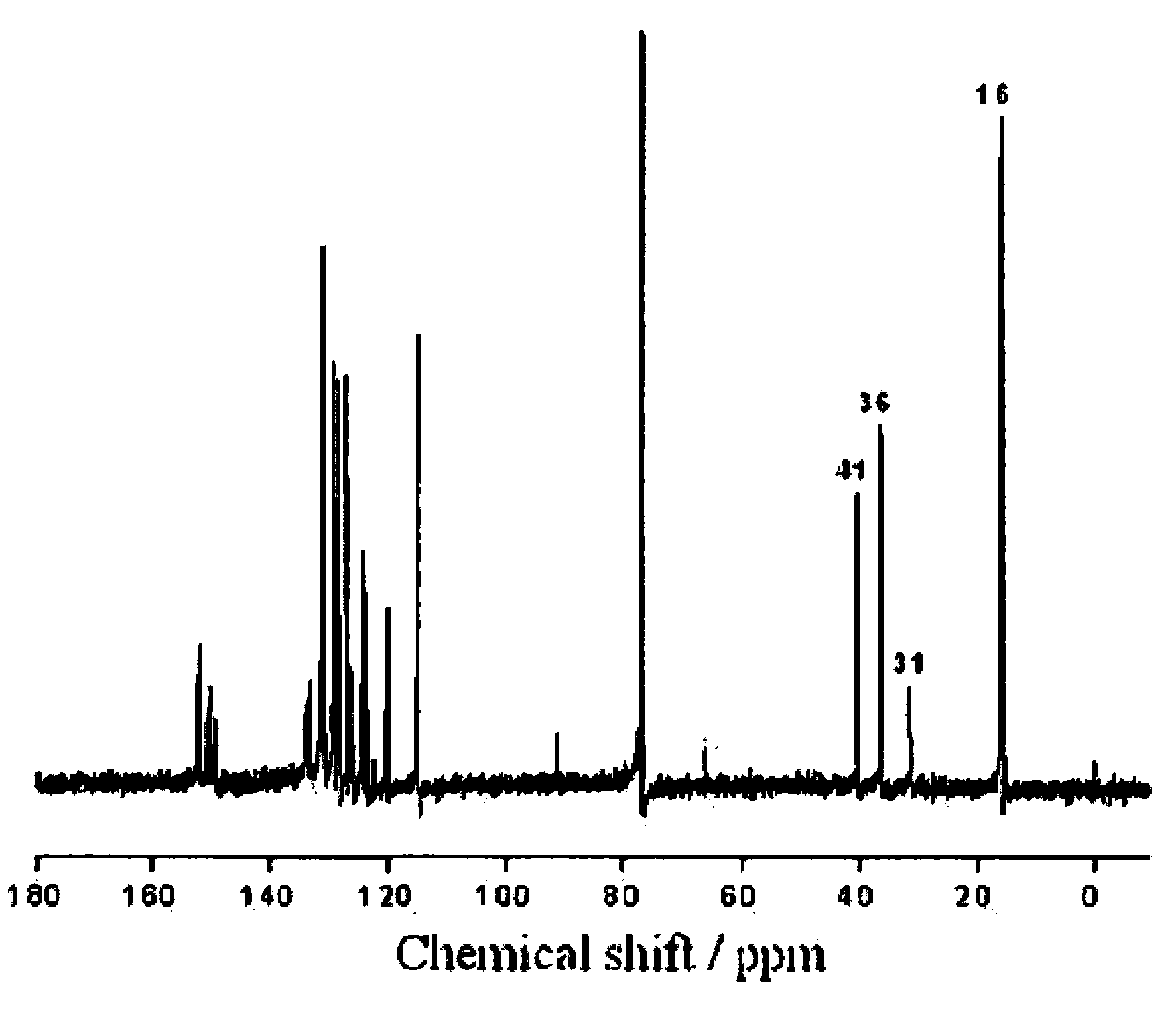

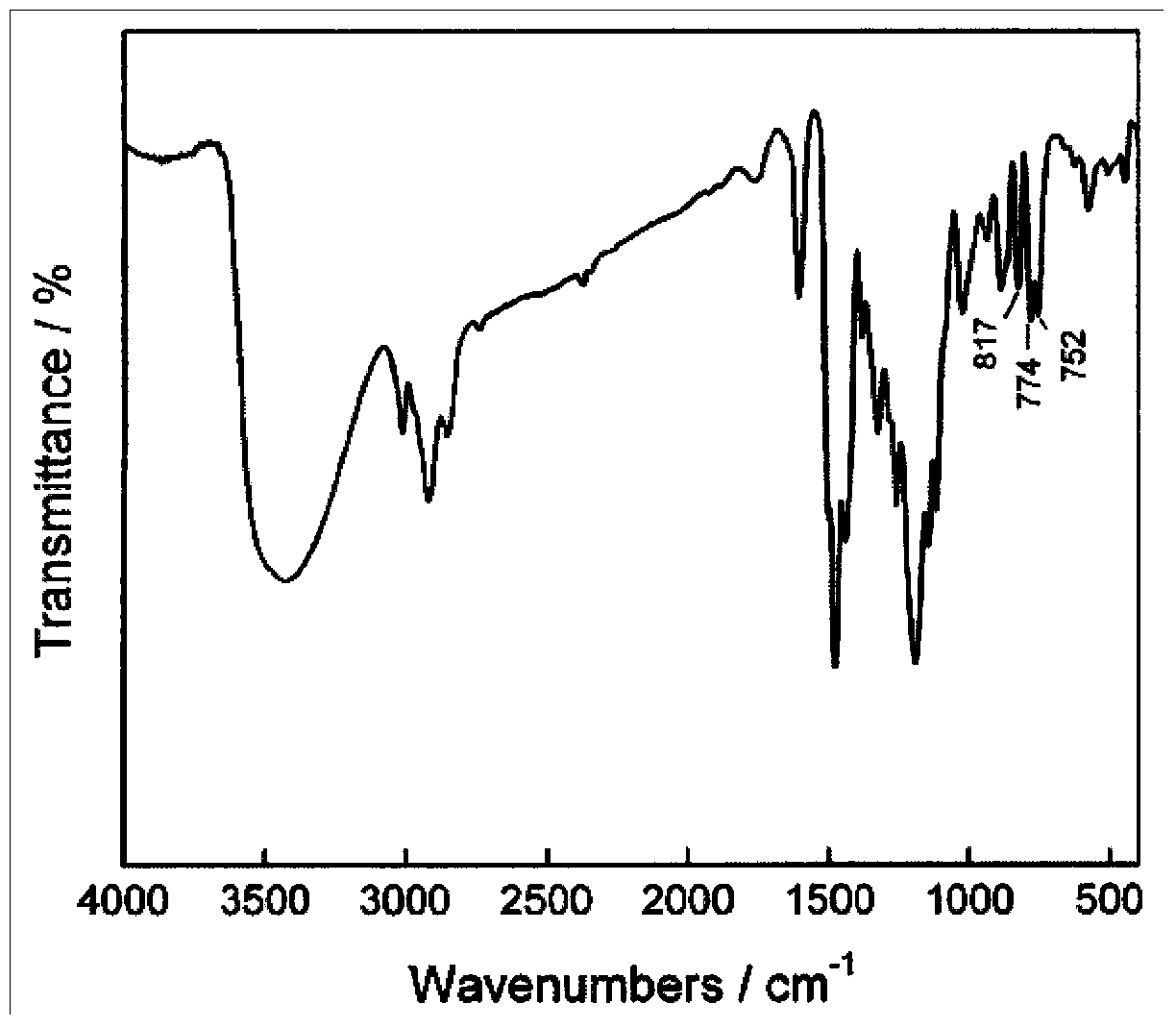

Sporolactobacillus inulinus and method for preparing D-lactic acid by fermenting strains of sporolactobacillus inulinus

ActiveCN101974447AIncrease production capacityHigh optical purityBacteriaMutant preparationBiotechnologyMembrane technology

The invention provides a sporolactobacillus inulinus and a method for preparing D-lactic acid by fermenting strains of sporolactobacillus inulinus (CGMCC No. 3997). The method comprises the steps of (1) cultivating seeds for fermentation; (2) fermenting the obtained strains to prepare D-lactic acid; and (3) extracting and refining the D-lactic acid. The strains in the invention have the characteristics of stable high-yield performance and high optical purity as well as wide source of fermentation formula and low cost, wherein the fermentation state is between the anaerobic state and the microaerophilic state, the fermentation period of the strains is 40 to 50 hours, the acidogenic rate by fermentation is 12 to 14 percent, the conversion rate of sugar to acid is 92 to 94 percent, and the optical purity of fermentation is 98 to 99 percent. In the invention, a series of currently advanced membrane technologies and short-path distillation technologies are adopted in the aspects of extraction and purification, thereby ensuring the quality of products and the extraction yield.

Owner:北京朗净汇明生物科技有限公司 +1

Synthesis method of phenolic epoxy resin

The invention relates to a synthesis method of phenolic epoxy resin with light color and low chlorine content. The method comprises steps of preparing alkenyl alkyl phenylate, preparing phenolic resin with double bonds and preparing phenolic epoxy resin, and the like. The phenolic epoxy resin prepared by the method provided by the invention can reach regulated softening point and epoxy value, and the chloridion content is lower than 20 ppm. Since molecular extraction and short path distillation technology are adopted, the volatile matter content of the obtained phenolic epoxy resin is quite low. Meanwhile, since a film evaporation-short path distillation technology is adopted, a solvent generated in the reaction process can be repeatedly used, thereby being beneficial to protecting the environment and reducing the production cost.

Owner:THE NORTHWEST RES INST OF CHEM IND

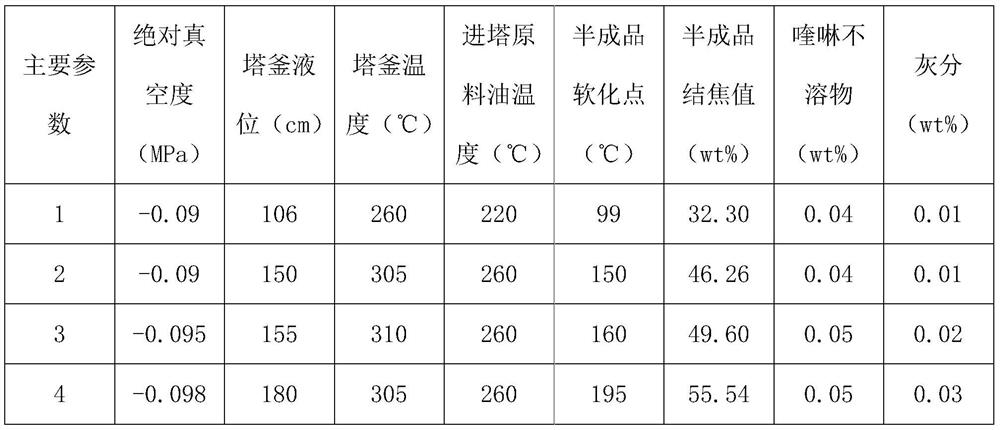

Continuous production method of lithium ion battery negative electrode coating material

PendingCN112592734AWide variety of sourcesRealize industrializationNegative electrodesSecondary cellsMetallurgyPhysical chemistry

The invention discloses a continuous production method of a lithium ion battery negative electrode coating material. The method comprises the following steps: (1) raw material preheating: preheating araw material ethylene tar or ethylene residual oil in a raw material oil storage tank to 70-100 DEG C, and conveying the preheated raw material to a primary condensation preheater and a raw materialoil preheater by using a conveying pump, heating the raw materials to 140-170 DEG C by a primary condensation preheater, and heating the raw materials to 200-300 DEG C by a raw material oil preheater;(2) rectification: conveying the preheated raw materials into a rectifying tower through a conveying pump, and carrying out rectification treatment to obtain asphalt of which the softening point is less than 200 DEG C; (3) distillation: conveying the product into a short-path distiller by using a conveying pump, and obtaining asphalt with the softening point of more than 250 DEG C at a temperature of 320-400 DEG C and the absolute vacuum degree of -0.098 MPa; (4) filtering: melting and filtering the materials at high temperature, wherein the filtering precision is 520 microns; and (5) granulating and storing: granulating and storing the material obtained by filtering in the step (4).

Owner:新疆中碳新材料科技有限责任公司

Recovery of lubricants from used cooling lubricants

In a method for recovering lubricant or lubricant concentrate from a used mixture containing lubricant, the mixture containing lubricant and which is substantially dewatered is subjected to short path distillation at a temperature of at least 150° C. and a pressure of less than 1.5 mbar, in order to obtain a lubricant concentrate which can be recycled into cooling lubricants and which is free of very finely wear debris, metal soaps and polymers.

Owner:HYDRO ALUMINIUM ROLLED PROD GMBH

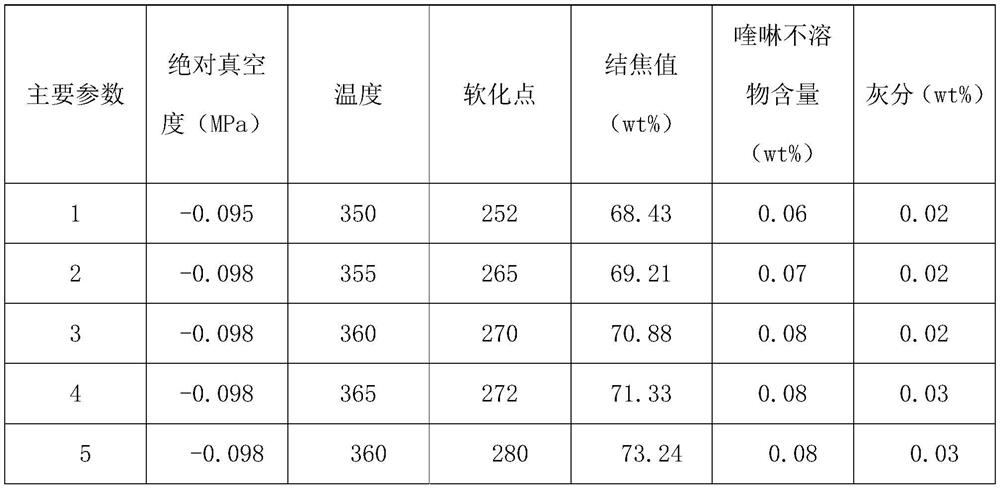

Special plasticizer TM8 for automobile interior parts

InactiveCN108218700AAvoid flushingAvoid cloggingOrganic compound preparationCarboxylic acid esters preparationAlcoholPlasticizer

The invention discloses a special plasticizer TM8 for automobile interior parts. Raw materials and auxiliary materials of the plasticizer TM8 comprise acid anhydride, alcohol, a catalyst, sodium carbonate and a filter aid. A process of the special plasticizer TM8 for the automobile interior parts comprises esterification, purification and filter press purification, and molecular distillation (short-path distillation). In esterification, alcohol is added first, after the temperature of a reactor is less than 80DEG C, 1,2,4-benzeneticarboxylic anhydride is added, then the catalyst is added, whenthe temperature of the material rises to 220DEG C, a negative pressure reaction starts, when an acid value is less than or equal to 0.1mgKOH / g, flash evaporation and dealcoholization start. In purification, steam stripping is performed while temperature rises to 215+ / -10DEG C, and the filter aid diatomite is added so as to purify and stir. In molecular distillation, the vacuum degree reaches lessthan 100pa, and the material inlet temperature is maintained at 215+ / -5DEG C. The raw materials are easy to obtain, the process is advanced, the equipment is simple, the plasticizer is environmentally friendly, has high plasticizing efficiency, resists high and low temperature, has low volatility, has small odor, and is highly stable.

Owner:JIANGSU SENHE CHEM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com