Special plasticizer TM8 for automobile interior parts

A technology of automotive interior parts and plasticizers, which is applied in the field of plasticizers and can solve the problem of low odor in the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This embodiment provides a special plasticizer TM8 for automotive interior parts. The raw and auxiliary materials of the plasticizer TM8 include the following components: acid anhydride, alcohol, catalyst, sodium carbonate and filter aid.

[0065] In this embodiment, the sum of the weight of acid anhydride and alcohol is the total feed weight, alcohol in mass ratio: acid anhydride>2.1, the catalyst accounts for 0.1‰-1‰ of the total feed weight, and sodium carbonate accounts for 0.1‰-1‰ of the total feed weight. 0.7‰, filter aid accounts for 0.3‰-1‰ of the total weight of feed;

[0066] The acid anhydride is trimellitic anhydride; the alcohol is n-octanol; the catalyst is isopropyl titanate; the filter aid is diatomaceous earth.

[0067] The preparation process of the special plasticizer TM8 for automotive interior parts is as follows:

[0068] ① Trimellitic anhydride and n-octanol are put into the esterification kettle for esterification reaction, and after the esterif...

Embodiment 2

[0074] The specific plasticizer TM8 for automotive interior parts in the embodiment 1 provided by this embodiment, the raw and auxiliary materials of the plasticizer TM8 include by mass parts: trimellitic anhydride: 1 part, n-octanol: 2.5 parts, catalyst: 0.35 ×10 -3 -3.5×10 -3 Parts, sodium carbonate: 0.35×10 -3 -2.45×10 -3 Parts, diatomaceous earth: 1.05×10 -3 -3.5×10 -3 share.

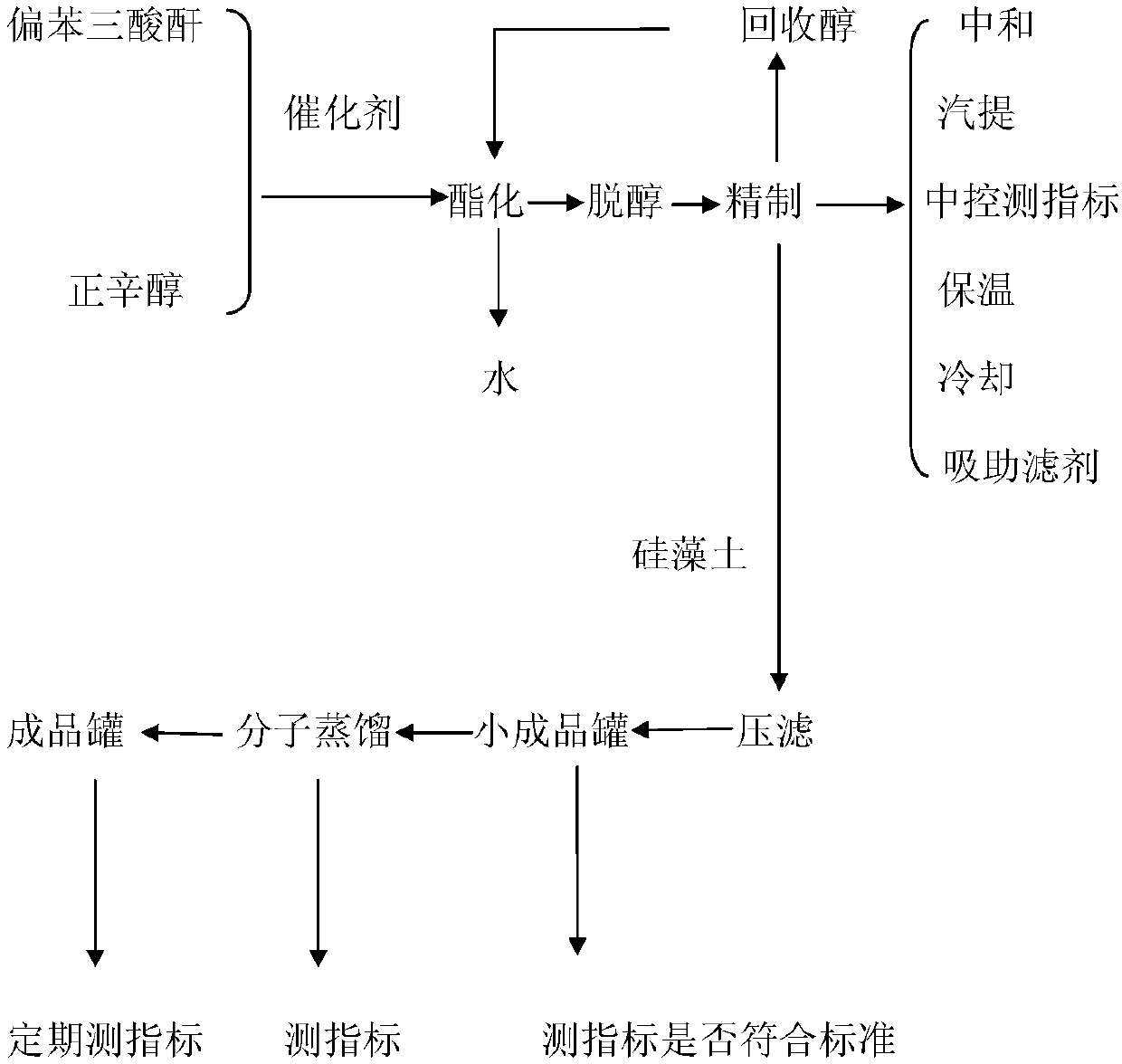

[0075] The preparation process of the special plasticizer TM8 for the above-mentioned automotive interior parts is as follows: figure 1 As shown, it includes the following process: esterification-refining-press filtration-molecular distillation, wherein:

[0076] (1) Esterification

[0077] Check whether all material systems, vacuum systems, heating systems, cooling systems and transmission systems are normal, check whether the bottom valve of the esterification tank is closed, and whether the esterification tail gas is vented;

[0078] Pour n-octanol into the esterification kettle. Afte...

Embodiment 3

[0128] This embodiment also provides a special plasticizer TM8 for automotive interior parts. The plasticizer TM8 is esterified, refined and pressed by trimellitic anhydride, n-octanol, isopropyl titanate, sodium carbonate, diatomaceous earth and auxiliary materials. obtained by filtration;

[0129] The components by mass parts are as follows: by mass parts: trimellitic anhydride: 1 part, n-octanol: 2.5 parts, isopropyl titanate: 0.35×10 -3 -3.5×10 -3 Parts, sodium carbonate: 0.35×10 -3 -2.45×10 -3 Parts, diatomaceous earth: 1.05×10 -3 -3.5×10 -3 parts, accessories: 0.001-0.002 parts, of which:

[0130] The auxiliary materials are mixed with chlorinated paraffin, leveling agent, compound rare earth, lubricant, coupling agent, glass fiber powder, calcium / zinc stabilizer, soybean oil and flame retardant system;

[0131] The components of the auxiliary materials in parts by mass are as follows:

[0132] Chlorinated paraffin: 9-11 parts, leveling agent: 8-10 parts, compound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com