Pressure swing adsorption oxygen production device for producing high-purity oxygen by using two-stage PSA (Pressure Swing Adsorption)

A pressure swing adsorption oxygen production, high-purity technology, applied in the direction of oxygen preparation, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of filter element impact, filter element flushing, air pressure increase, etc., to prevent being flushed away Or damage, improve service life, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

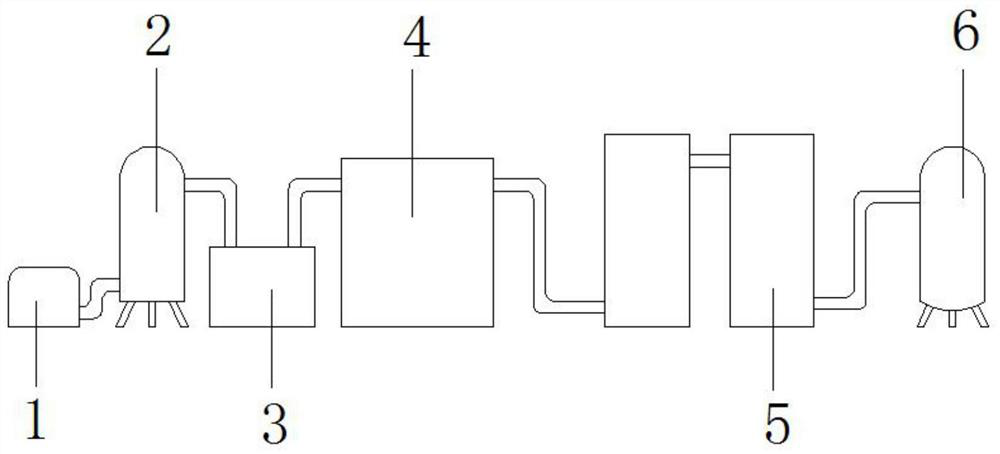

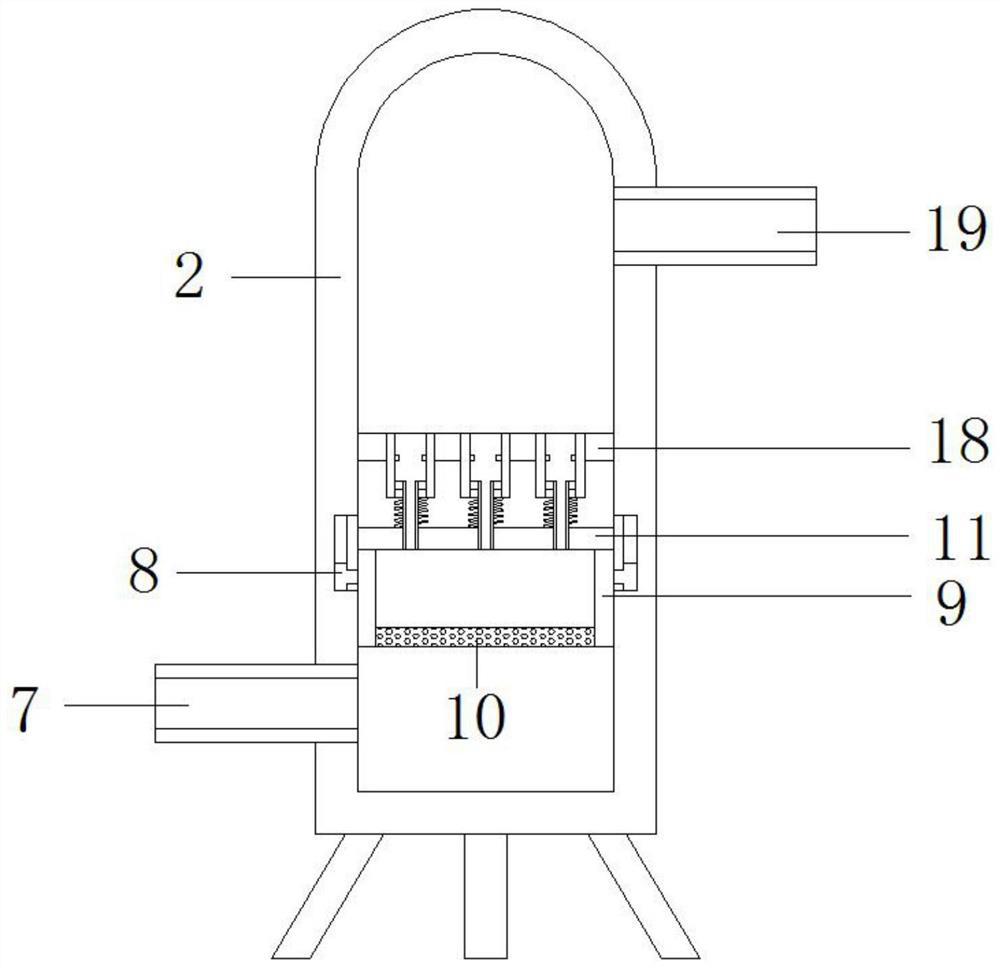

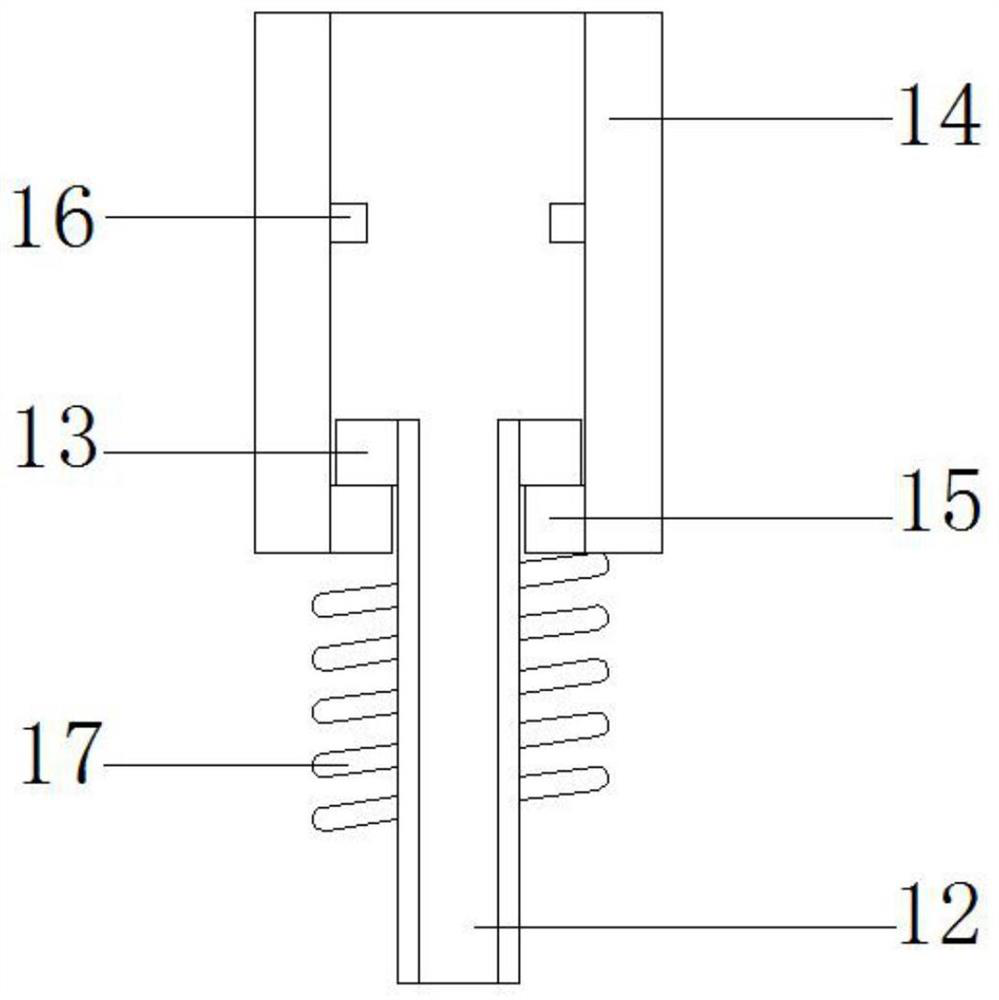

[0020] refer to Figure 1-3 , a pressure swing adsorption oxygen generator using two-stage PSA to produce high-purity oxygen, comprising an air compressor 1, an air buffer tank 2 connected to the outlet of the air compressor 1 through a connecting pipe, and connected to the air buffer tank 2 through a connecting pipe An open freeze dryer 3, a filter group 4 socketed on the inner wall of one side of the freeze dryer 3, an oxygen generator 5 socketed at one end of the filter group 4, and an oxygen buffer tank socketed at the outlet end of the oxygen generator 5 6. The oxygen generator 5 includes two separation towers, and the two separation towers are connected to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com