Manufacturing method of black film, black film and light-emitting device

A production method and black film technology, which are applied in the manufacture of electrical solid-state devices, semiconductor devices, and semiconductor/solid-state devices, etc., can solve the problems of difficulty in forming black films with surface morphology, and achieve the effect of smooth surface and good surface morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

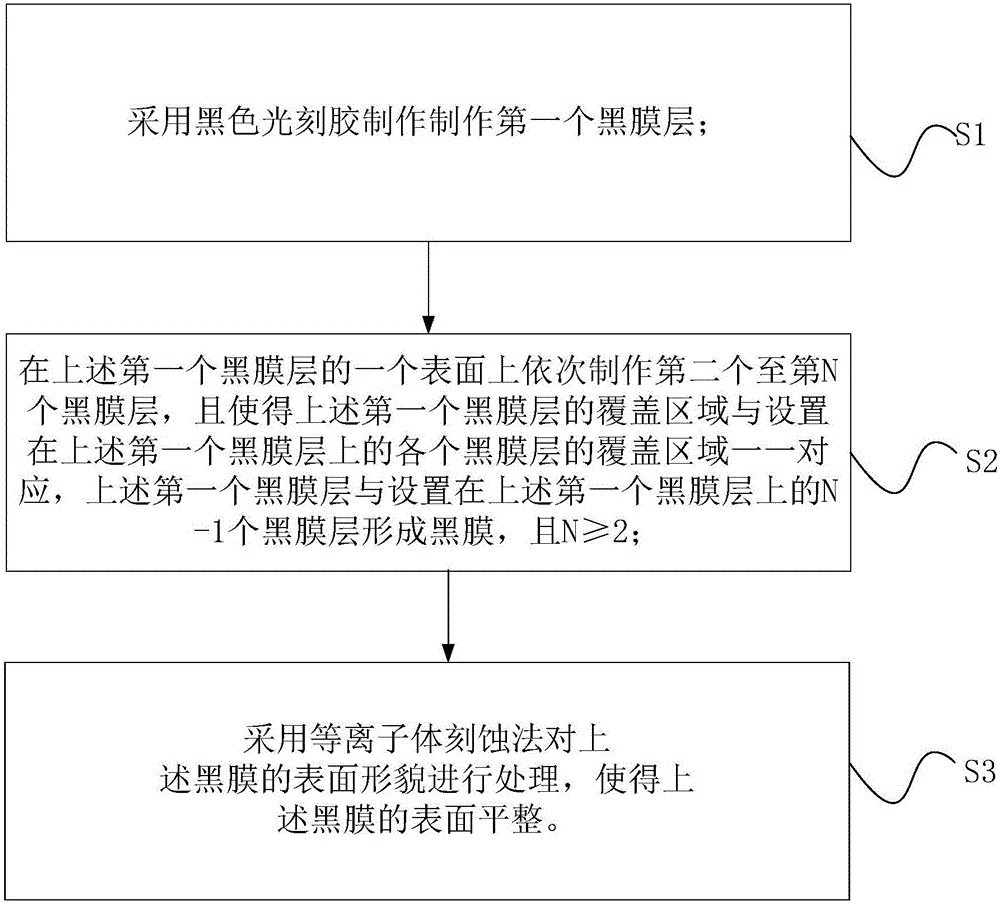

Method used

Image

Examples

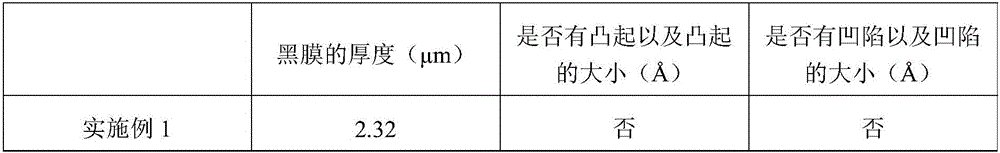

Embodiment 1

[0061] Pre-form a black film with a thickness of 2.3 μm, the specific production process is:

[0062] First, make the first black film layer.

[0063] A black photoresist is arranged on the surface of the substrate, and the thickness of the black photoresist is 1.3 μm; the black photoresist is pre-cured so that the black photoresist forms the first pre-black film layer that does not flow; the mask The plate is placed on the surface of the first pre-black film layer away from the substrate, and the light-transmitting area of the mask plate includes the alignment mark, the light-transmitting area of the mask plate and the coverage area of the first pre-black film layer One-to-one correspondence; use ultraviolet light to expose the first pre-black film layer from the side of the mask away from the first pre-black film layer; developing to dissolve the unexposed areas in the first pre-black film layer; curing the developed first pre-black film layer to form the first black ...

Embodiment 2

[0071] The difference from Example 1 is that in the first gas, Ar and O 2 The molar ratio of the gas is 30:1, the ionization power of the first gas is 700W, and the etching time is 8s. In the second gas, He and N 2 65% of the total volume of the second gas, HF 1% of the total volume of the second gas, and O 2 The molar ratio with Ar is 6:1. And the ionization power of the second gas is 200W, and the etching time is 65s.

Embodiment 3

[0073] The difference from Example 1 is that in the first gas, Ar and O 2 The molar ratio of the first gas is 18:1, the ionization power of the first gas is 350W, and the etching time is 13s. The second gas does not include impurity removal gas, He and N 2 88% of the total volume of the second gas, and O 2 The molar ratio with Ar is 3:1. And the ionization power of the second gas is 500W, and the etching time is 28s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com