Combined type solid-state distillation device

A solid-state distillation and combined technology, applied in the field of combined solid-state distillation devices, can solve the problems of large heat dissipation area, increased steam pressure drop, and long tail of low-alcohol wine, so as to improve the efficiency of wine distillation, reduce pressure drop, increase scent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

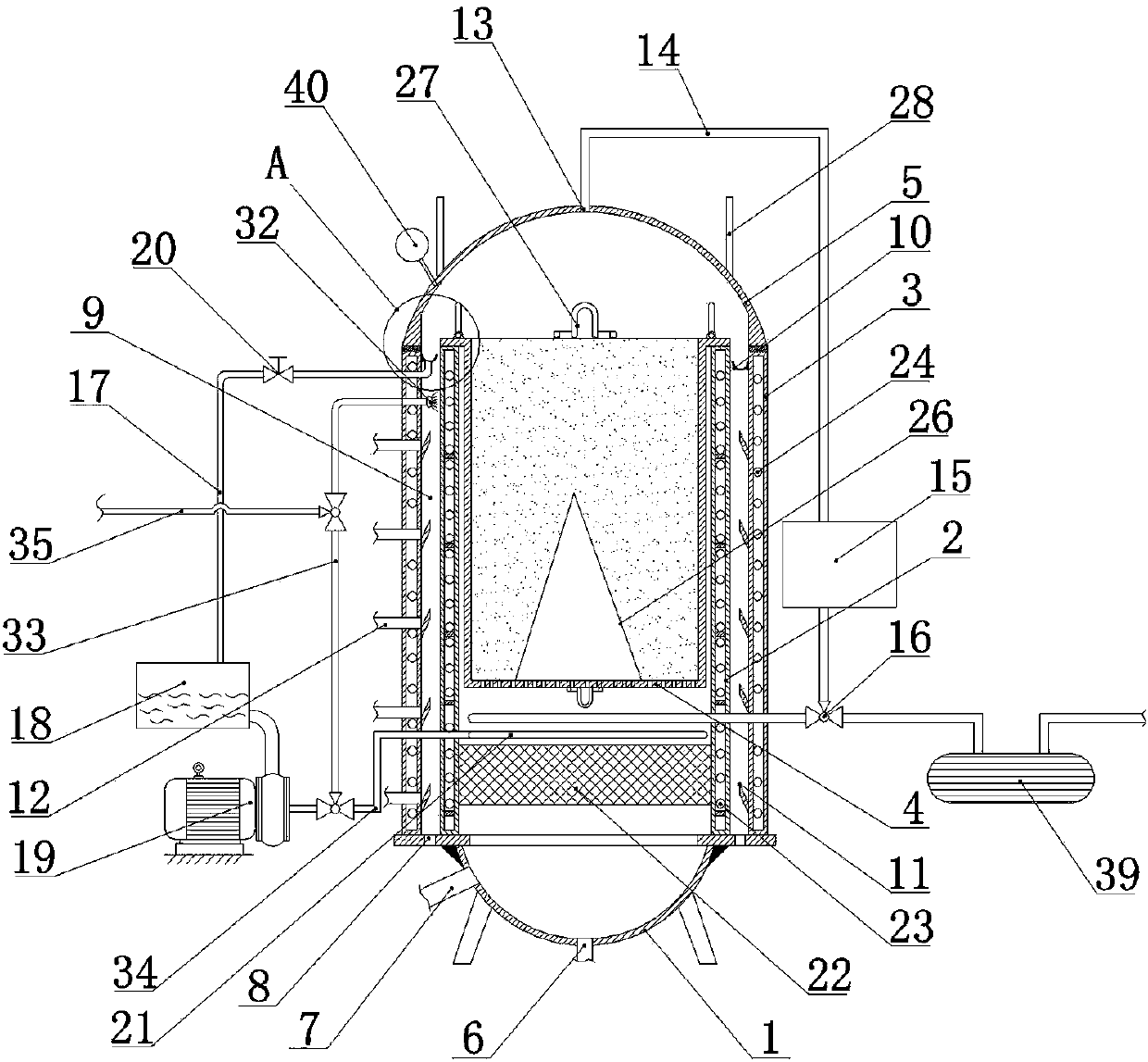

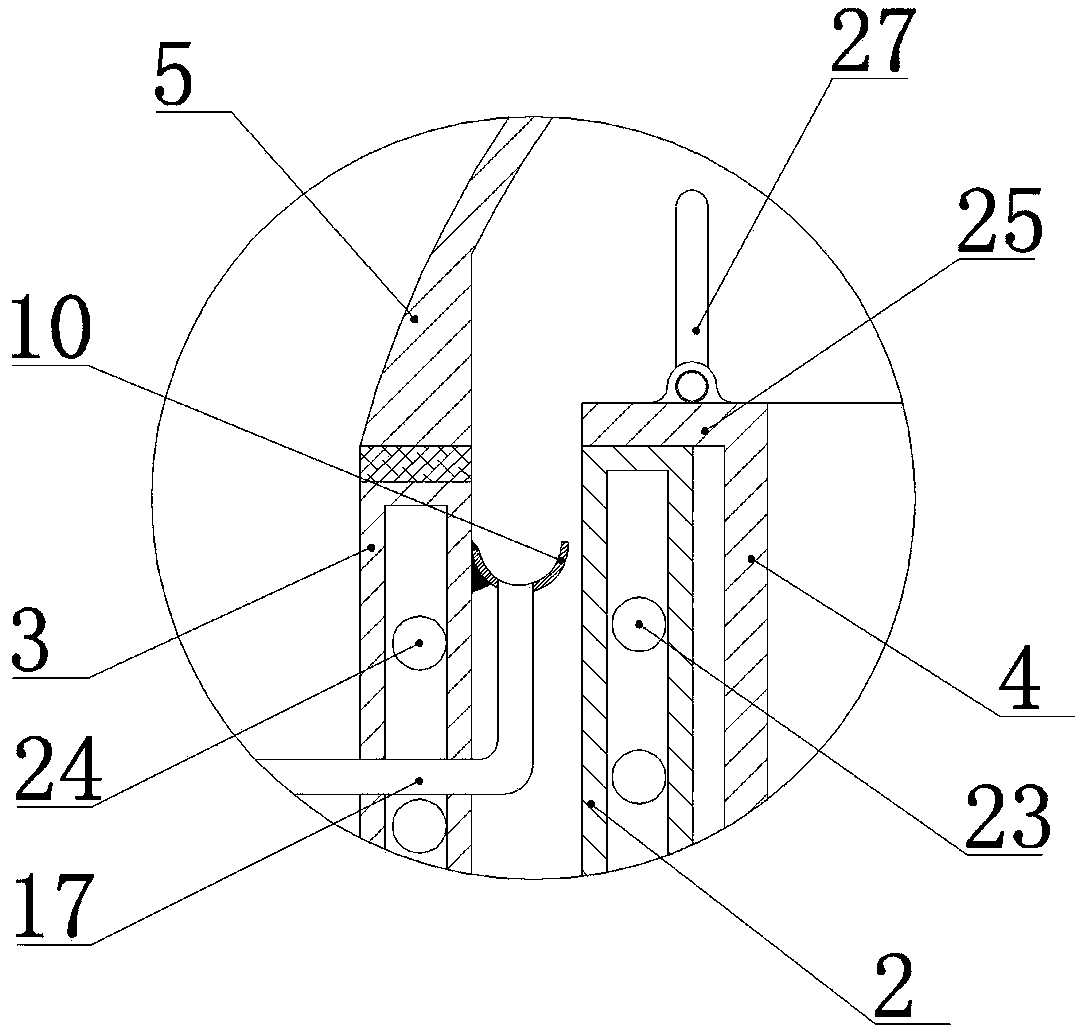

[0039] Embodiment one: see figure 1 , figure 2 , Figure 4 , a combined solid-state distillation device, comprising a base 1, a vaporization wall bucket 2 and a condensation wall bucket 3 arranged on the base 1 and mutually fitted, a pot bucket 4 arranged in the vaporization wall bucket 2 and a boiler bucket 4 arranged in the condensation wall bucket 3 The upper top cover 5, the base 1 is provided with a liquid discharge port 6 and a steam input port 7, the outer side of the top cover 5 is provided with a condensation liquefaction layer, between the vaporization wall bucket 2 and the condensation wall bucket 3 and the base 1, condensation Both the wall barrel 3 and the top cover 5 are matched and sealed. Between the vaporization wall barrel 2 and the condensation wall barrel 3 and the base 1, an interlayer cavity 9 with an open top and a tail liquid discharge hole 8 is formed at the bottom, and the condensation wall The top of the inner wall of the barrel 3 is provided ...

Embodiment 2

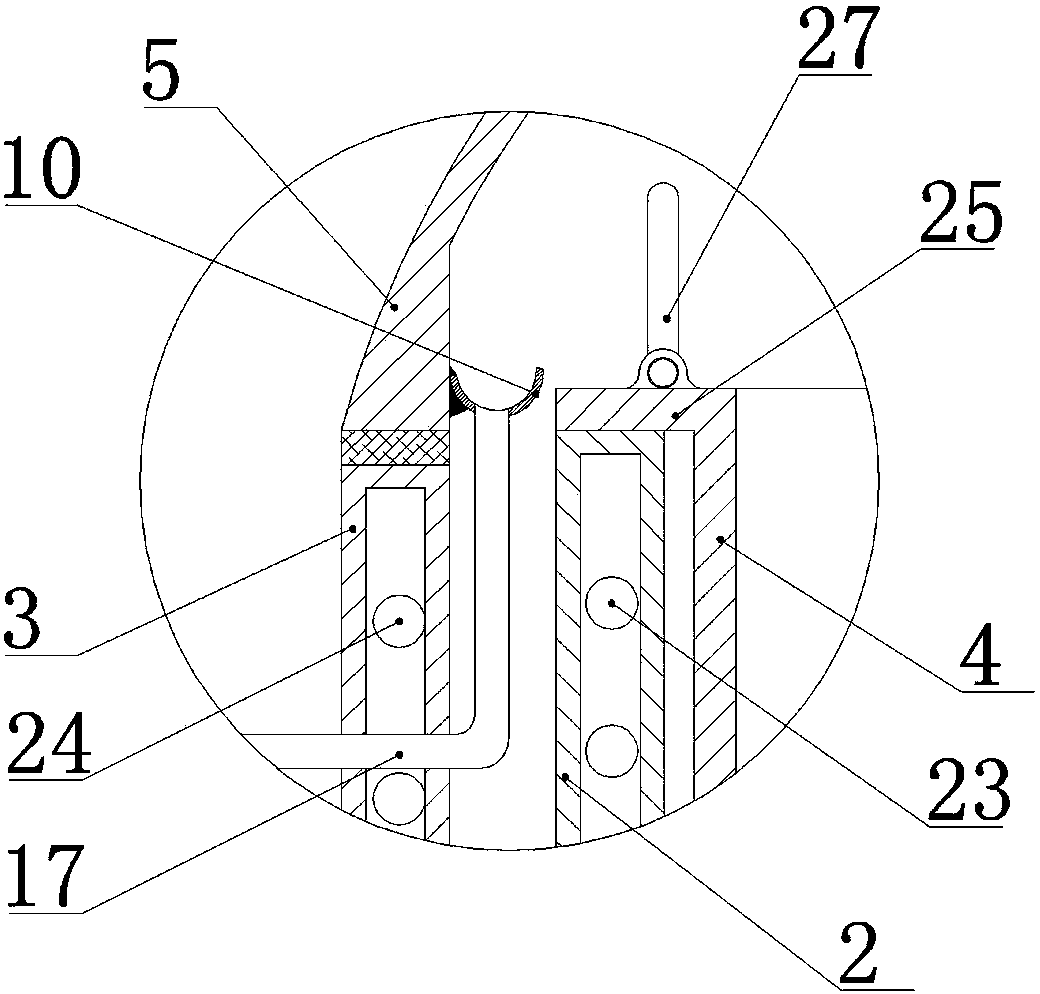

[0041] Embodiment two: see figure 1 , image 3 , Figure 4 , the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the annular flow guide groove 10 is arranged at the lower part of the inner wall of the top cover.

Embodiment 3

[0042] Embodiment three: see Figure 1-Figure 4 , the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that: the top cover 5 is provided with a steam return hole 13, and the steam return hole 13 passes through the steam return hole. The distillation pipeline 14 communicates with the steam compressor 15, and the outlet end of the steam compressor 15 is connected to the distillation retort cavity at the bottom of the pot through the steam recovery pipeline 13. The steam recovery pipeline 13 can also be connected with high-temperature steam through a three-way valve. Generator, which can pass superheated steam, so that lipids can be extracted.

[0043] During the distillation process, it is difficult for the fat in the fermented grains to dissolve directly in the water vapor, which will cause a low extraction rate of the fat in the fermented grains and cause a lot of waste of fat. Therefore, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com