Process for purifying coal tar through centrifugation method and preparing needle coke by using coal tar

A needle coke raw material, coal tar technology, applied in the field of coal chemical industry, can solve the problems affecting the quality of graphite electrodes, limited QI removal efficiency, etc., achieve high separation efficiency, reduce costs, and improve economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

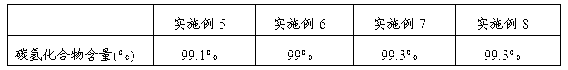

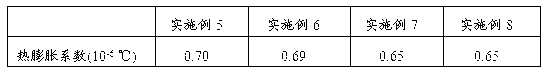

Examples

Embodiment 1

[0042] In the process for purifying coal tar by centrifugal method described in this example, the relative centrifugal force for centrifugal separation is 2500G; the temperature of the coal tar for centrifugal separation is 40°C, the viscosity is 30mpa·s, and the time for centrifugal separation is 2min .

Embodiment 2

[0044] In the process of purifying coal tar by centrifugal method described in this example, the relative centrifugal force for centrifugal separation is 3500G; the temperature of the coal tar for centrifugal separation is 50°C, the viscosity is 100mpa·s, and the time for centrifugal separation is 1.5 min.

Embodiment 3

[0046] In the process for purifying coal tar by centrifugal method described in this example, the relative centrifugal force for centrifugal separation is 2900G; the temperature of the coal tar for centrifugal separation is 200°C, the viscosity is 50mpa·s, and the time for centrifugal separation is 1.5 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com