Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1030 results about "Coal tar product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

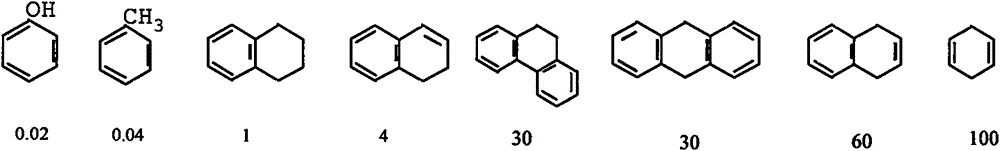

Coal tar is a thick dark liquid which is a by-product of the production of coke and coal gas from coal.

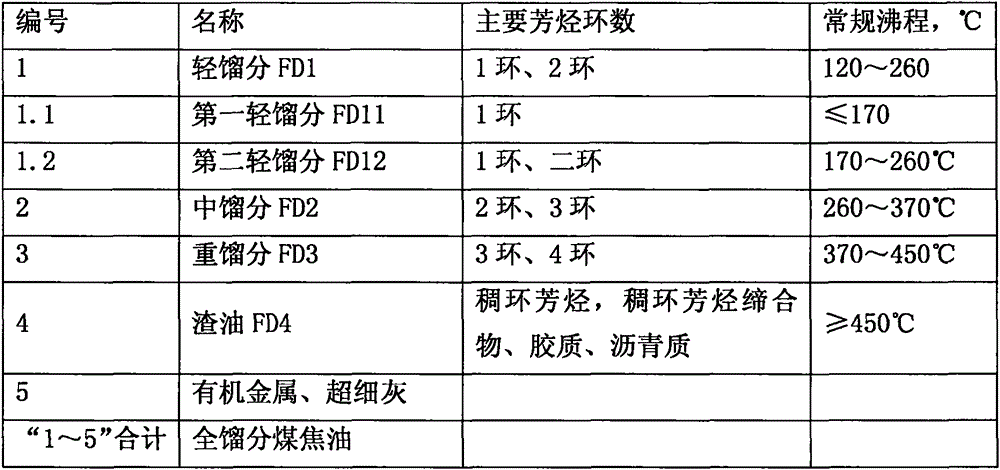

Coal tar whole fraction hydrotreatment process

ActiveCN1766058AImprove operating conditionsSimple processTreatment with hydrotreatment processesFixed bedGasoline

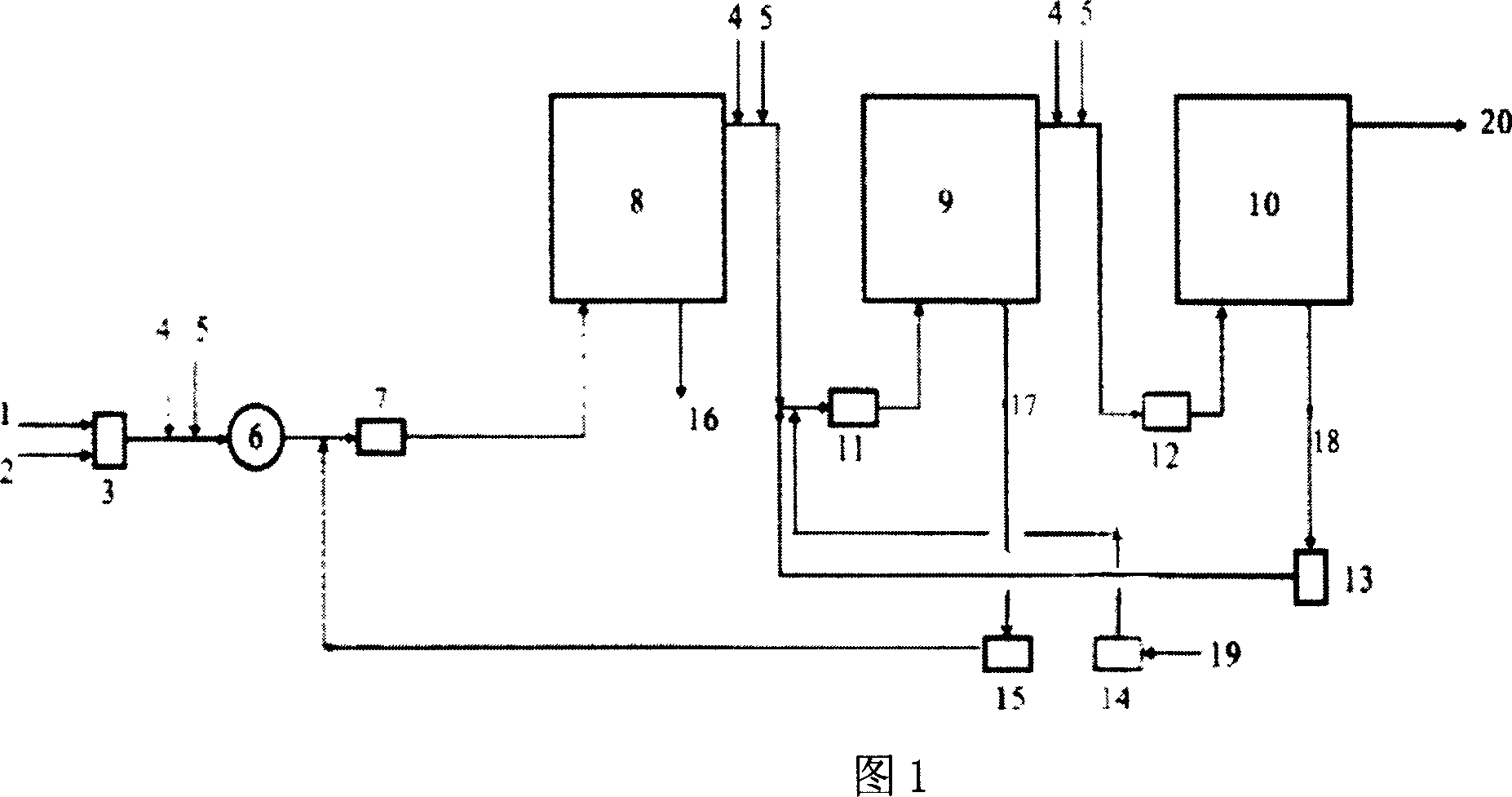

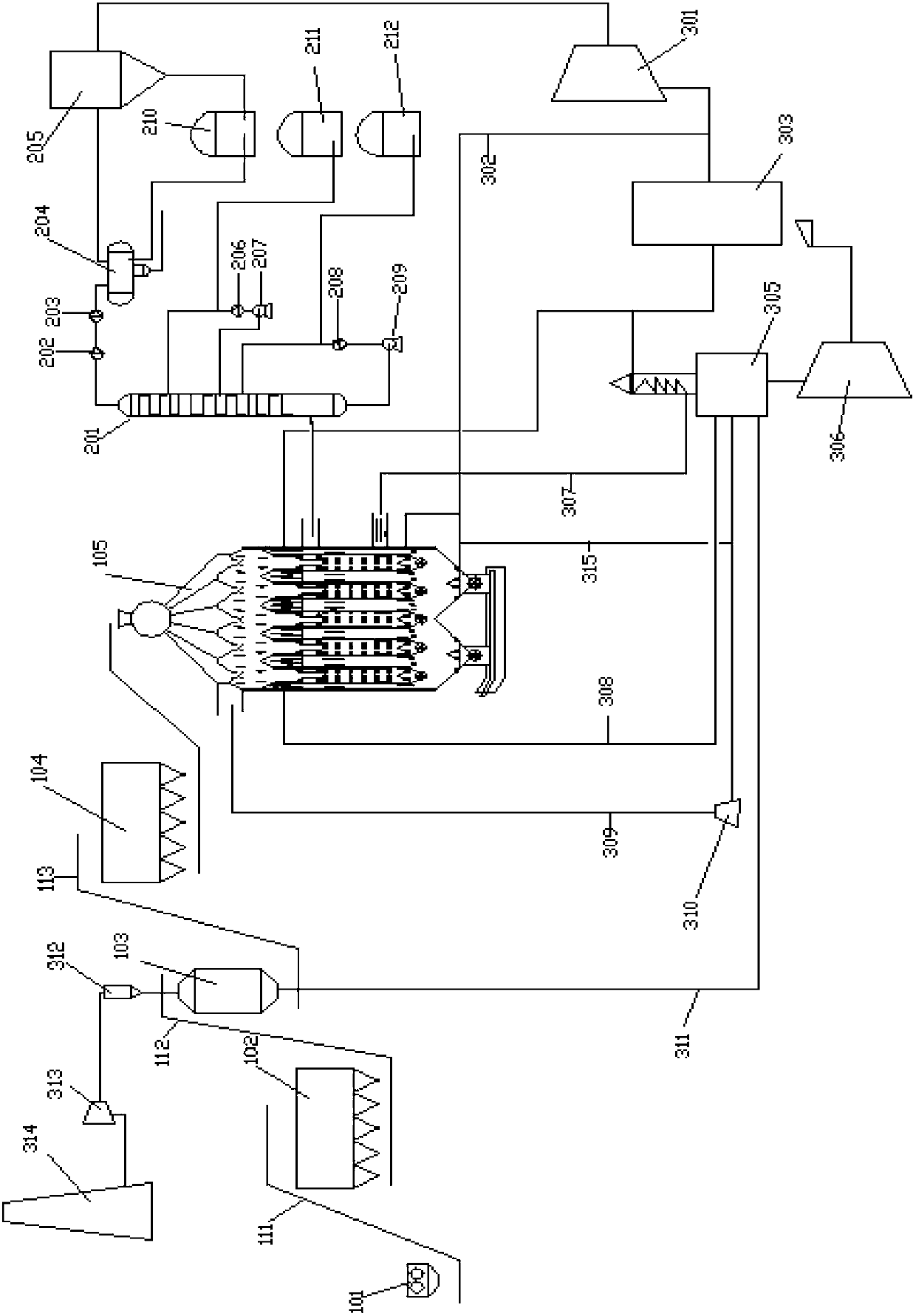

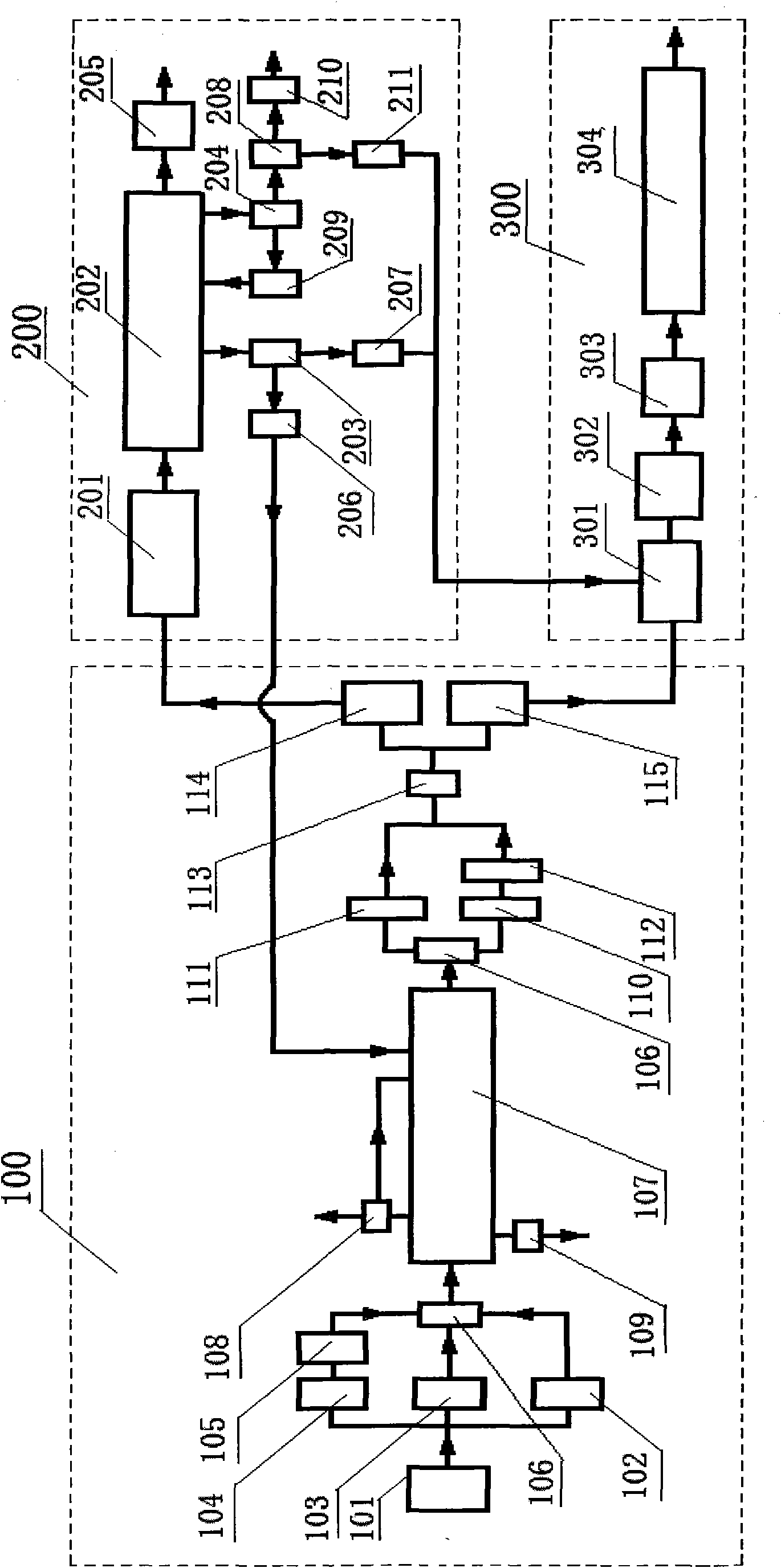

The invention discloses a hydrocracking treatment technique for coal tar total distillate, which comprises: first mixing with homogeneous catalyst, or adding impurity, gum, asphaltene and coal oil total distillate contained much oxygen element directly into suspended-bed hydrogenation device; cutting the stream with distilling plant to discharge water, distillate less than 370Deg that enters fixed bed reactor for hydrorefining reaction to cut gasolene less than 150Deg and diesel oil 150-370Deg, and tail oil less than 370Deg that recycles to said reactor and converts into light oil product. Compared with prior art, this invention is simple, but high conversion rate and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

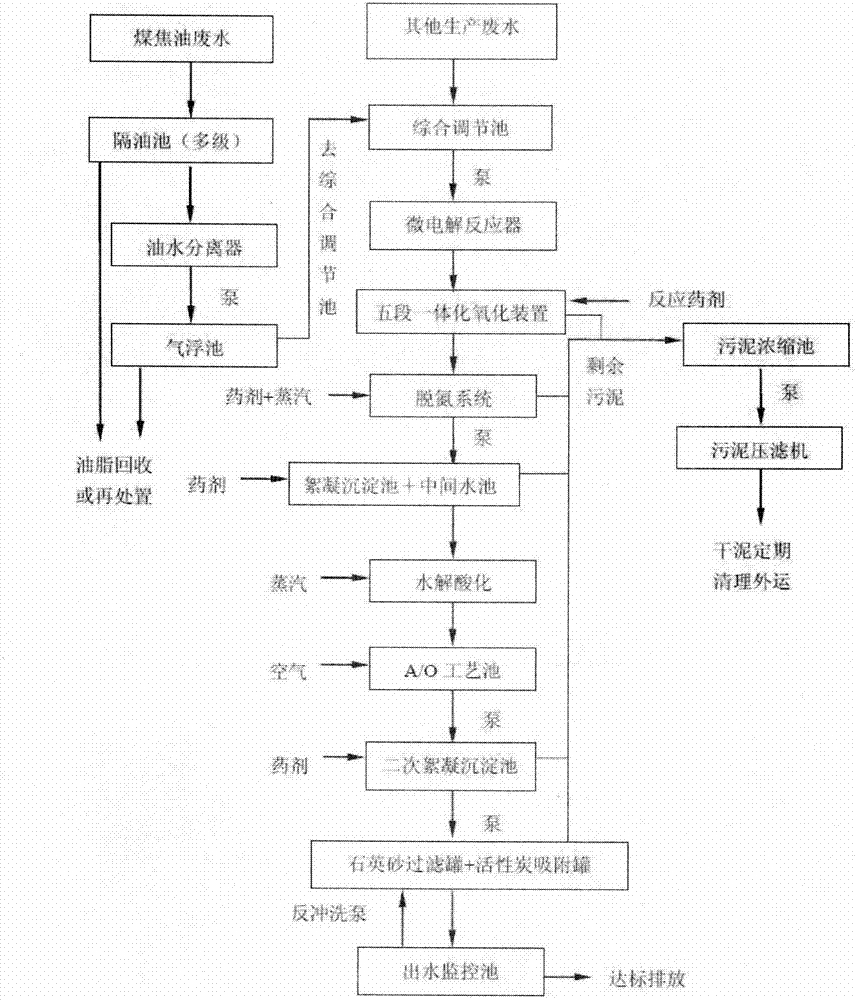

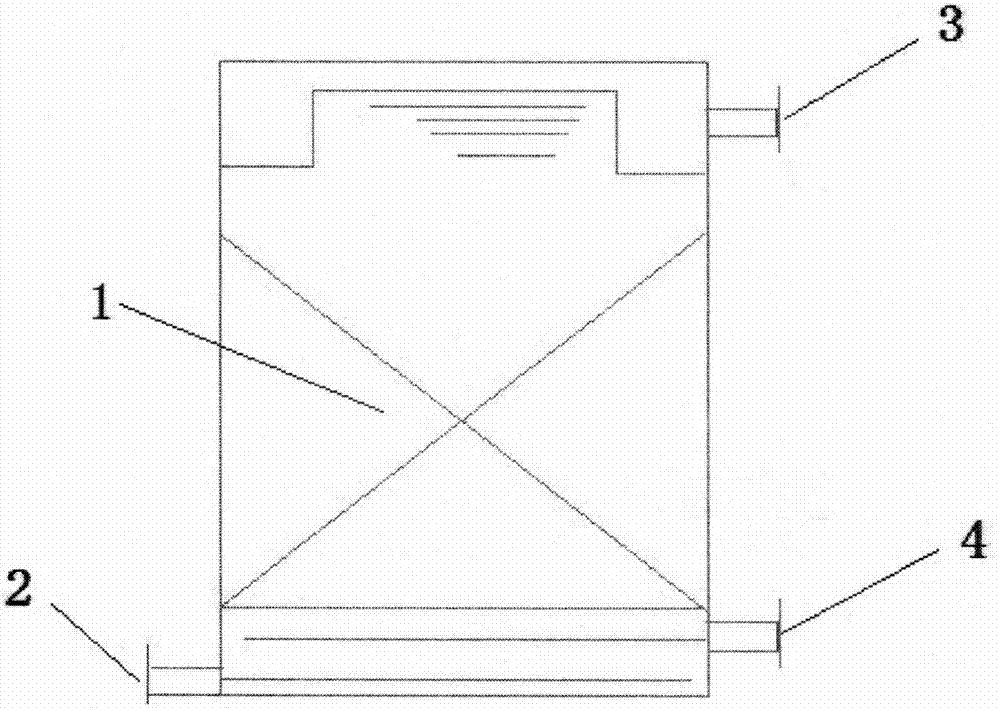

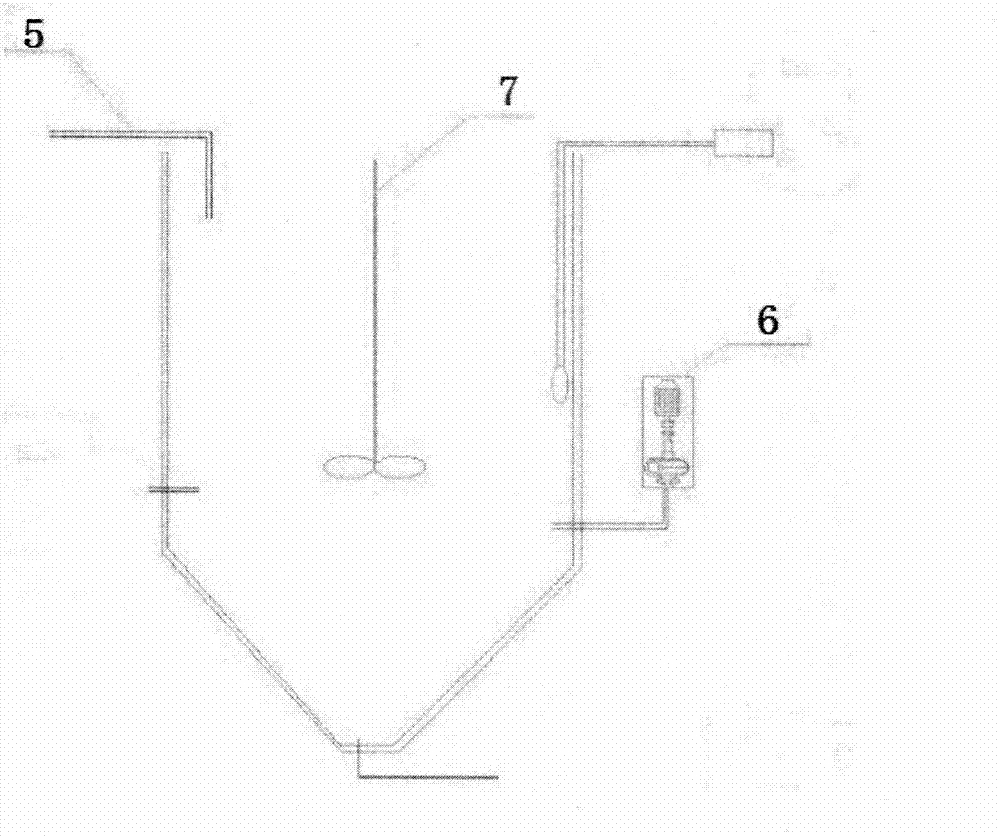

Complete equipment and process for processing coal tar wastewater

InactiveCN103113003AEasy to handleCreate economic valueMultistage water/sewage treatmentChemical oxygen demandElectrolysis

The invention provides complete equipment and process for processing coal tar wastewater, and belongs to the technical field of environmental conservation. The process comprises the following steps of: adopting different removal principles according to different physicochemical properties of heavy oil, light oil and emulsified oil; scientifically and orderly removing the heavy oil, light oil and emulsified oil through three sets of environmental conservation equipment such as a multi-stage oil separator, an oil-water separator and an air floating tank gradually; combining a micro electrolysis reactor with a five-section integrated oxidization device; and firstly destroying a benzene ring by microelectrolysis, and then strongly oxidizing various organic matters through an oxidant, so that the COD (chemical oxygen demand) and the chromaticity are greatly reduced. Ammonia nitrogen can be efficiently removed by a denitrification system; the denitrification system is low on requirements of pH value and temperature, and low in operation cost; the denitrification system is arranged behind the five-section integrated oxidization device; the reaction change of power of hydrogen is fully considered; and the complete equipment complies with the scientific principle, and can be used for reducing feeding of acid and alkali, and lowering the operation cost.

Owner:NANJING ZIDU ENVIRONMENTAL PROTECTION SCI & TECH

Two-tower type pressure reducing coke tar distillation process and apparatus therefor

ActiveCN101475819ASolve the technical problems of dealing with large-scale tarShort processTar working-up by distillationReboilerHeat conducting

The invention relates to a two-tower type process for distilling vacuum tar and a device thereof. The process comprises the following steps: removing the moisture and light oil distillate of raw tar in a pre-dehydration tower and a dehydration tower at normal pressure; performing decompressing operations in a No.1 distillation tower to obtain carbolic oil, naphthalene oil and light washing oil distillate; and performing decompressing operations in a No.2 distillation tower to obtain heavy washing oil, first anthracene oil, second anthracene oil and mid-temperature pitch. The heat for the pre-dehydration tower and the dehydration tower is supplied by heat conducting oil; the heat for the No.1 distillation tower is supplied by heating the mixed oil on the bottom of the tower circularly in a No.1 tubular heating furnace; and the heat for the No.2 distillation tower is supplied by heating the mixed oil on the bottom of the No.1 distillation tower in a No.2 tubular heating furnace and then performing flash distillation on the mixed oil on the bottom of the No.2 tower. The main devices comprise the dehydration tower, the No.1 distillation tower, the No.2 distillation tower, a dehydration tower reboiler, the No.1 tubular heating furnace, the No.2 tubular heating furnace, a heat exchanger for each distillate, a cooler, a steam generator and the like. The process has the advantages of short technological flow, less device investment, and less energy consumption, thus the process is applicable to large scale coal tar processing engineering.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

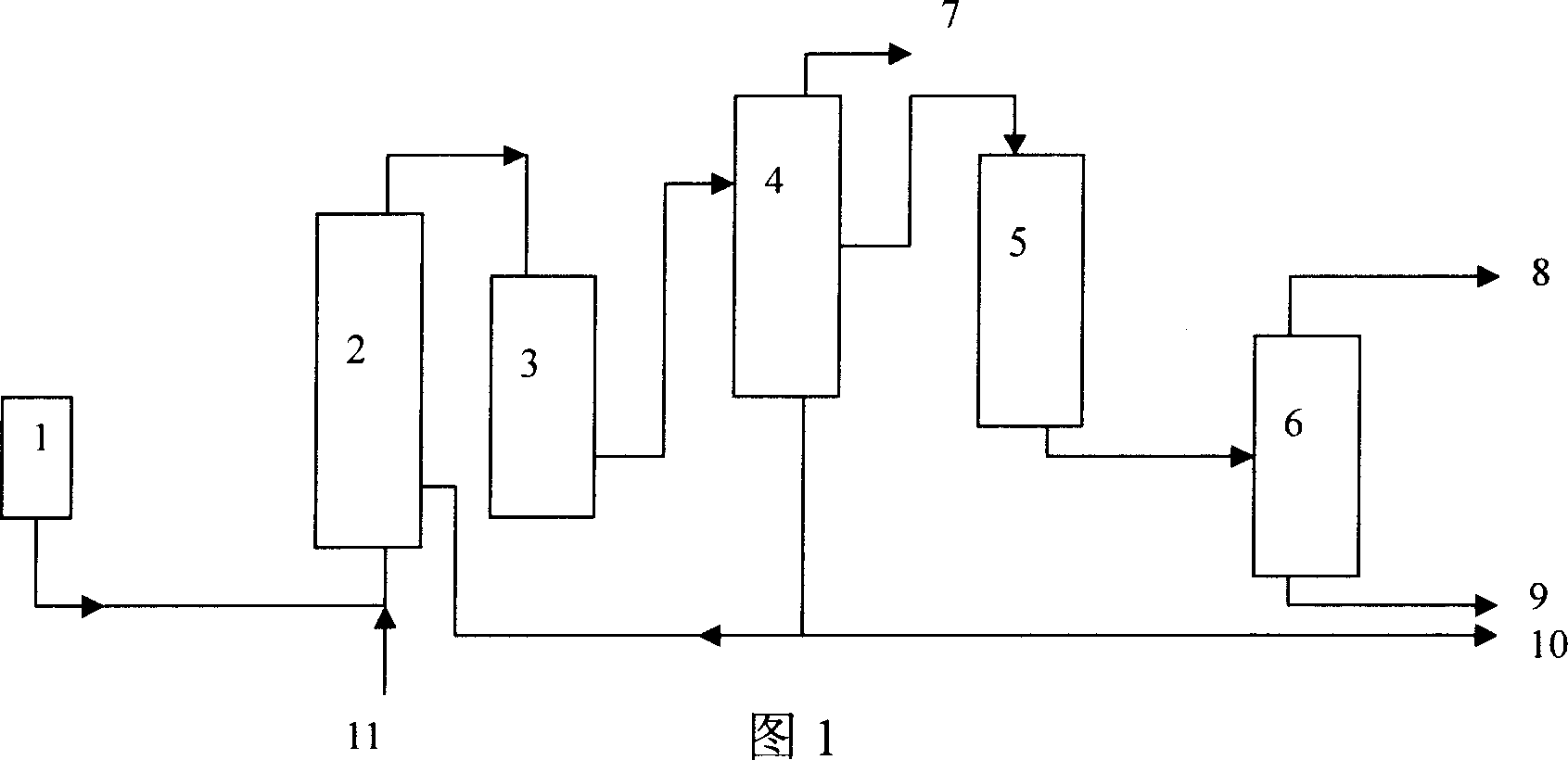

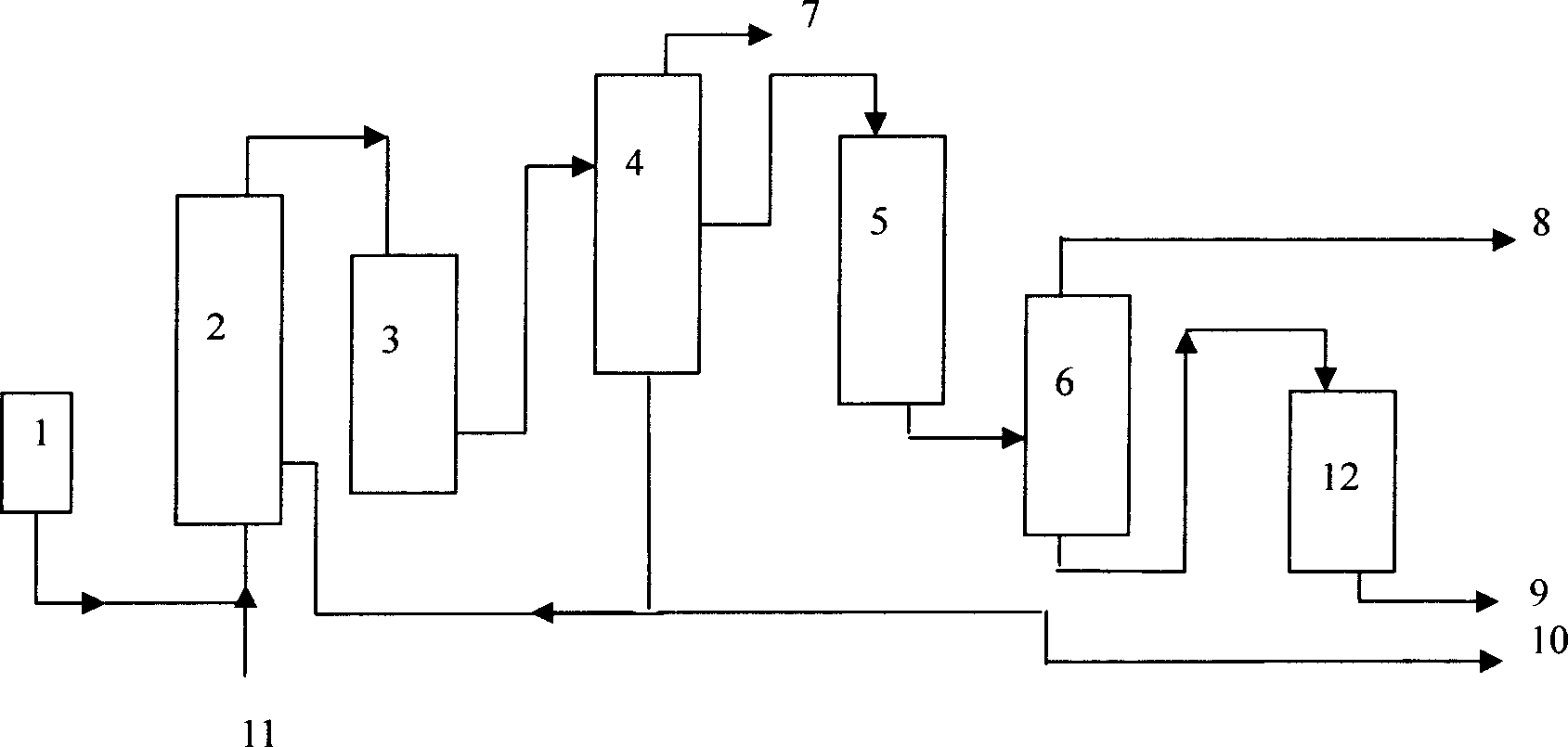

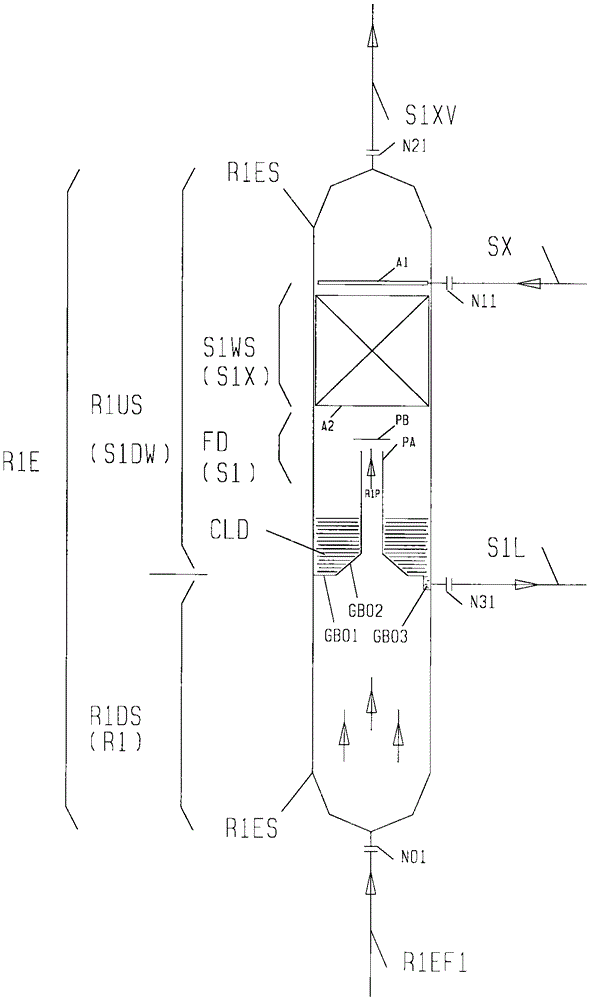

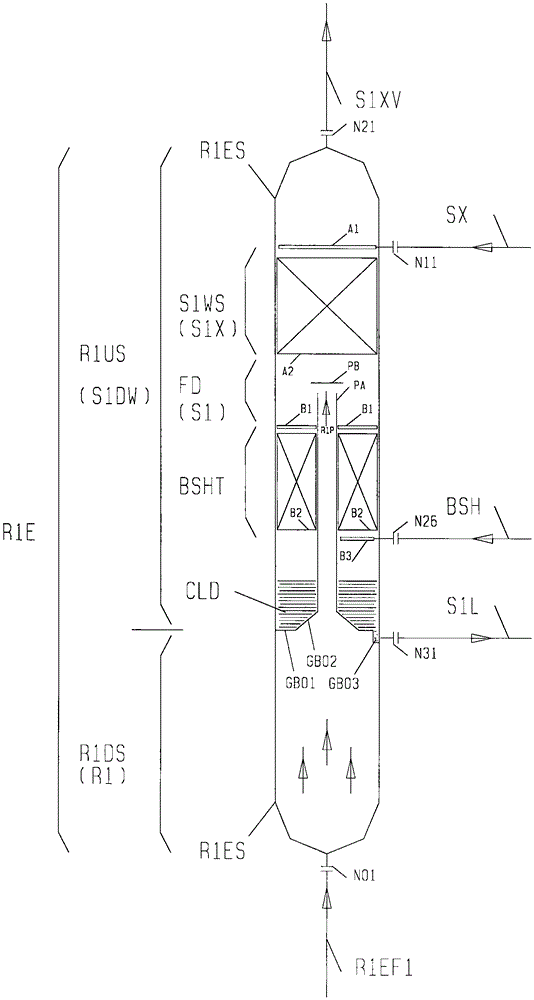

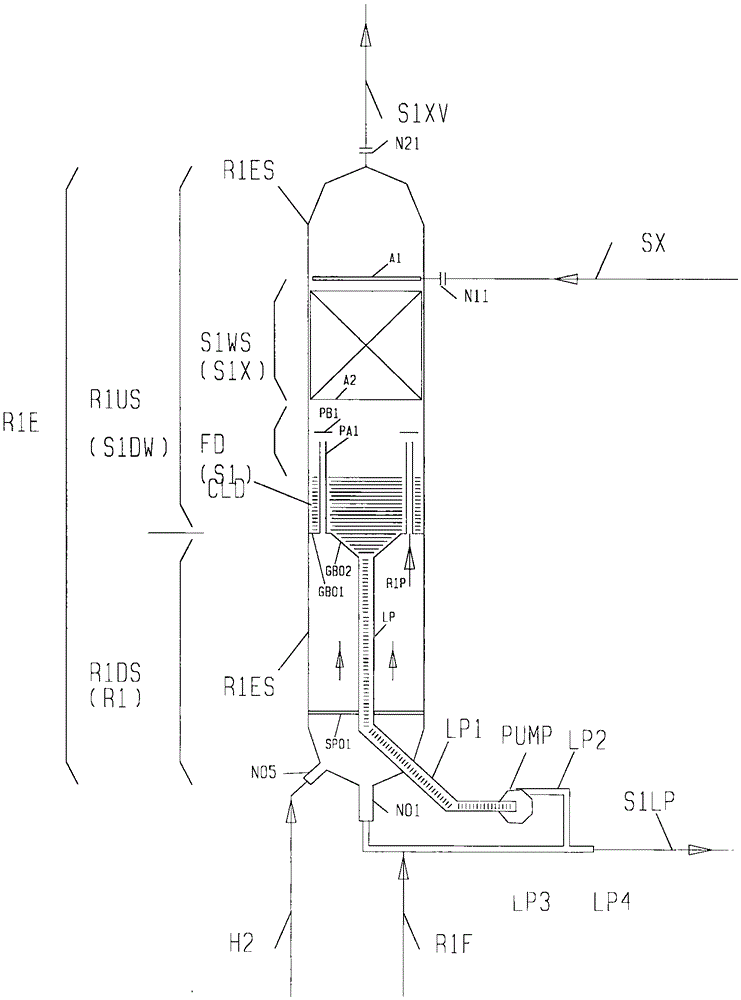

Hydrocarbon material hydrogenation method and combined expanded bed hydrogenation reactor

InactiveCN105602616ATreatment with hydrotreatment processesChemical/physical processesChemistryDistillation

The invention relates to a hydrocarbon material hydrogenation method and a combined expanded bed hydrogenation reactor. The method is suitable for a medium / low-temperature coal tar heavy-fraction hydrogenation thermal cracking process and an oil preparation process from coal by direct hydrogenation, can implement integration of the reaction section and the reaction product R1P comprehensive separation section, and can implement cooling on the R1P immediately to inhibit the heavy component thermal condensation reaction and / or implement washing to lower the solid content or dissolve and rectify the solids in the gas product so as to lower the heavy hydrocarbon content in the gas product. The reactor R1E is provided with a lower section R1DS (expanded bed reaction region) and an upper section R1US (thermal high-pressure separation gas washing region), the R1P enters the R1US and is separated in the flash distillation space into a gas R1PV possibly containing solids and a liquid stream S1L possibly containing solids, the gas R1PV contacts washing oil SX and is washed and separated into rich washing oil SXK and gas S1V, and at least part of the stream S1L or distillate oil thereof returns to the lower section R1DS to perform cyclic reaction.

Owner:何巨堂

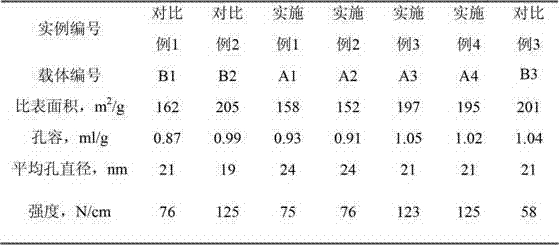

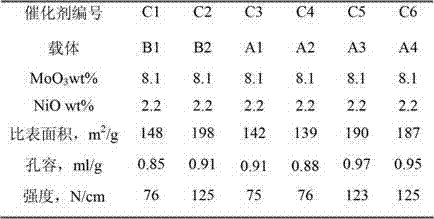

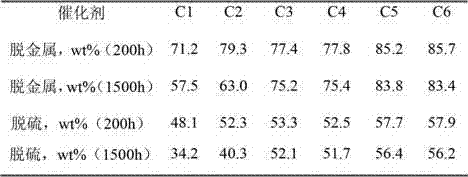

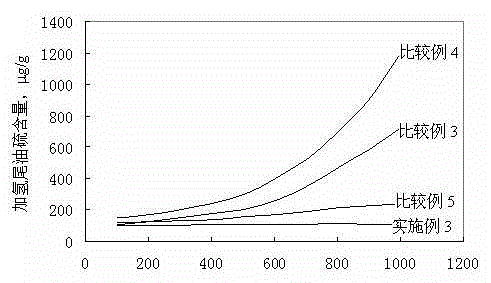

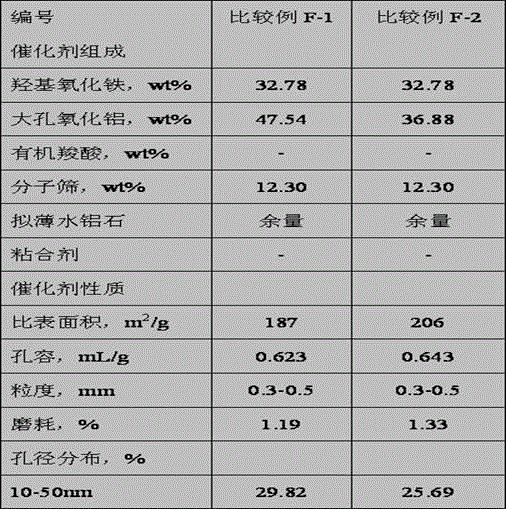

Coal tar hydrodemetalization catalyst and preparation method thereof

ActiveCN102847541AUnobstructed pore structureIncrease profitCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic acidPtru catalyst

The invention discloses a coal tar hydrodemetalization catalyst and a preparation method thereof. The method comprises the steps of: (1) taking or preparing an alumina carrier; (2) treating the alumina carrier from the step (1) with an organic acid solution with pH value lower than 3; then impregnating the alumina carrier subjected to acid treatment with an aluminium nitrate solution; and drying and roasting to obtain a modified alumina carrier; and (3) loading and hydrogenating an active component by an impregnation method to obtain the coal tar hydrodemetalation catalyst. Compared with the prior art, the coal tar hydrodemetalation catalyst provided by the invention has better activity and activity stability, and longer operation cycle.

Owner:上海竣铭化工工程设计有限公司

Electric field purifying process of coal-tar oil

ActiveCN100999675AAvoid poisoningAvoid cloggingWorking-up tarRefining by electric/magnetic meansPtru catalystGasoline

The electric field coal tar purifying process includes the technological steps of preparing mixed oil, the first stage of electric purifying, the second stage of electric purifying, the third stage of electric purifying, draining waste water, etc. The experiments show that the coal tar purifying process of the present invention is superior to available coal tar purifying process, and has the advantages of simple technological process, low running cost, high purifying rate, etc. The present invention can reach coal tar purifying rate over 95 %, and the purified coal tar may be used in producing gasoline and diesel oil through hydromodification with no corrosion to the production apparatus, no catalyst poisoning, no blocking of the reactor bed layer and long production apparatus running period.

Owner:SHENMUFUYOU ENERGY TECH

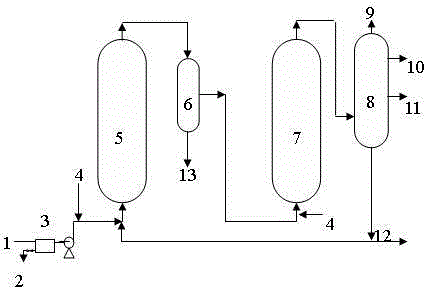

Method for hydrogenation of coal tar via fluidized bed

ActiveCN104593060AConsistent activityEasy to removeTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a method for hydrogenation of coal tar via a fluidized bed. The method comprises the following steps: subjecting a coal tar raw material to hydro-upgrading; carrying out separation to remove water; and then carrying out hydrorefining and fractionation so as to obtain a gasoline fraction, a diesel fraction and hydrogenation tail oil. A hydro-upgrading catalyst used in the method comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina, a molecular sieve and pseudo-boehmite; and a hydrofining catalyst used in the method comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina and a binder. The method provided by the invention adopts cheap iron oxyhydroxide as an active metal component, the hydro-upgrading catalyst and the hydro-refining catalyst are graded, so cost is low. According to the invention, moderate cracking of coal tar is carried out before refining of coal tar, so impurities in coal tar are effectively removed, product distribution and product quality are adjusted, and the running period of a device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

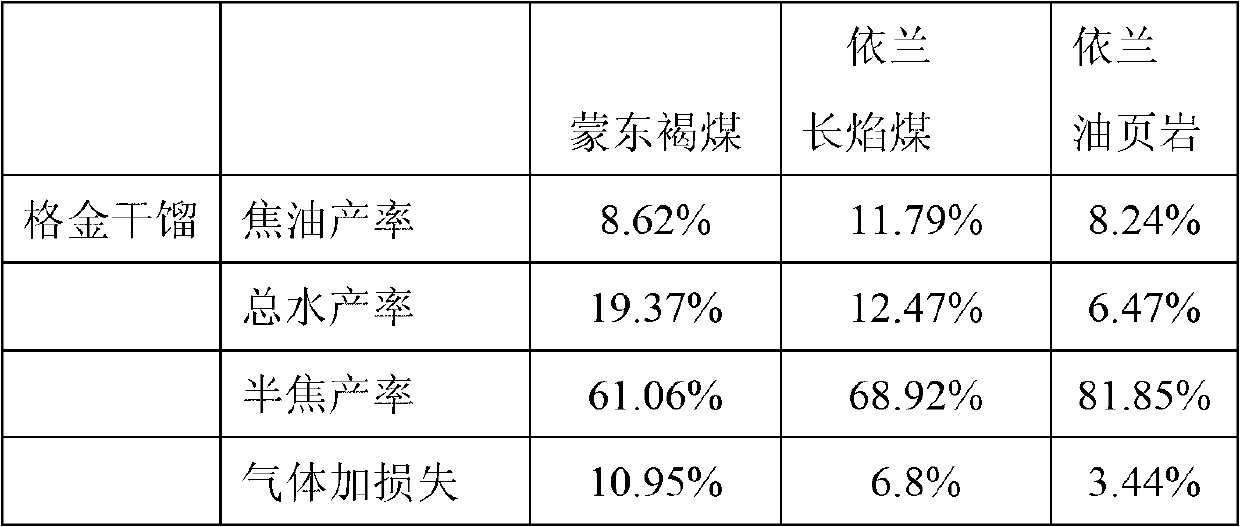

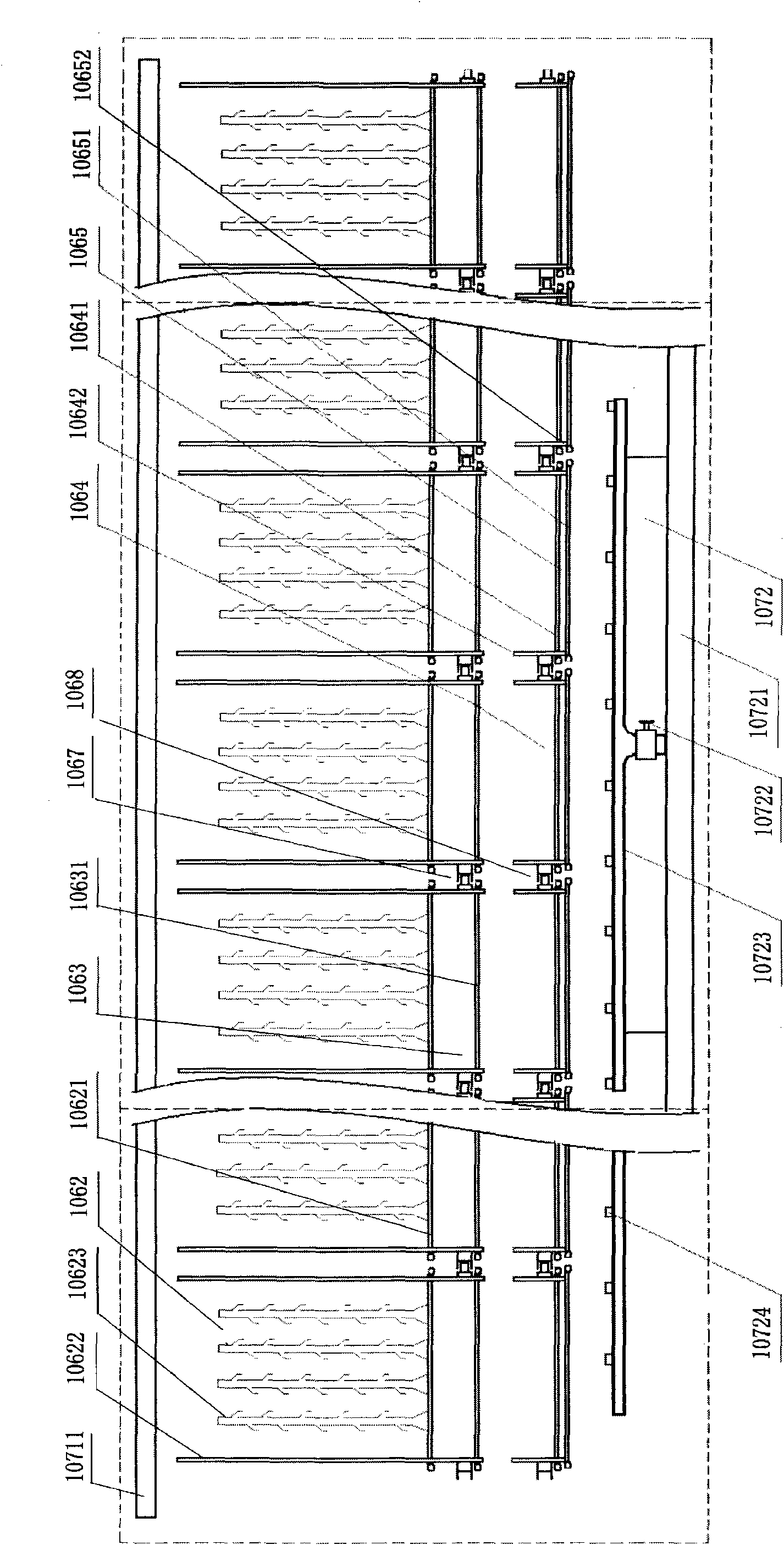

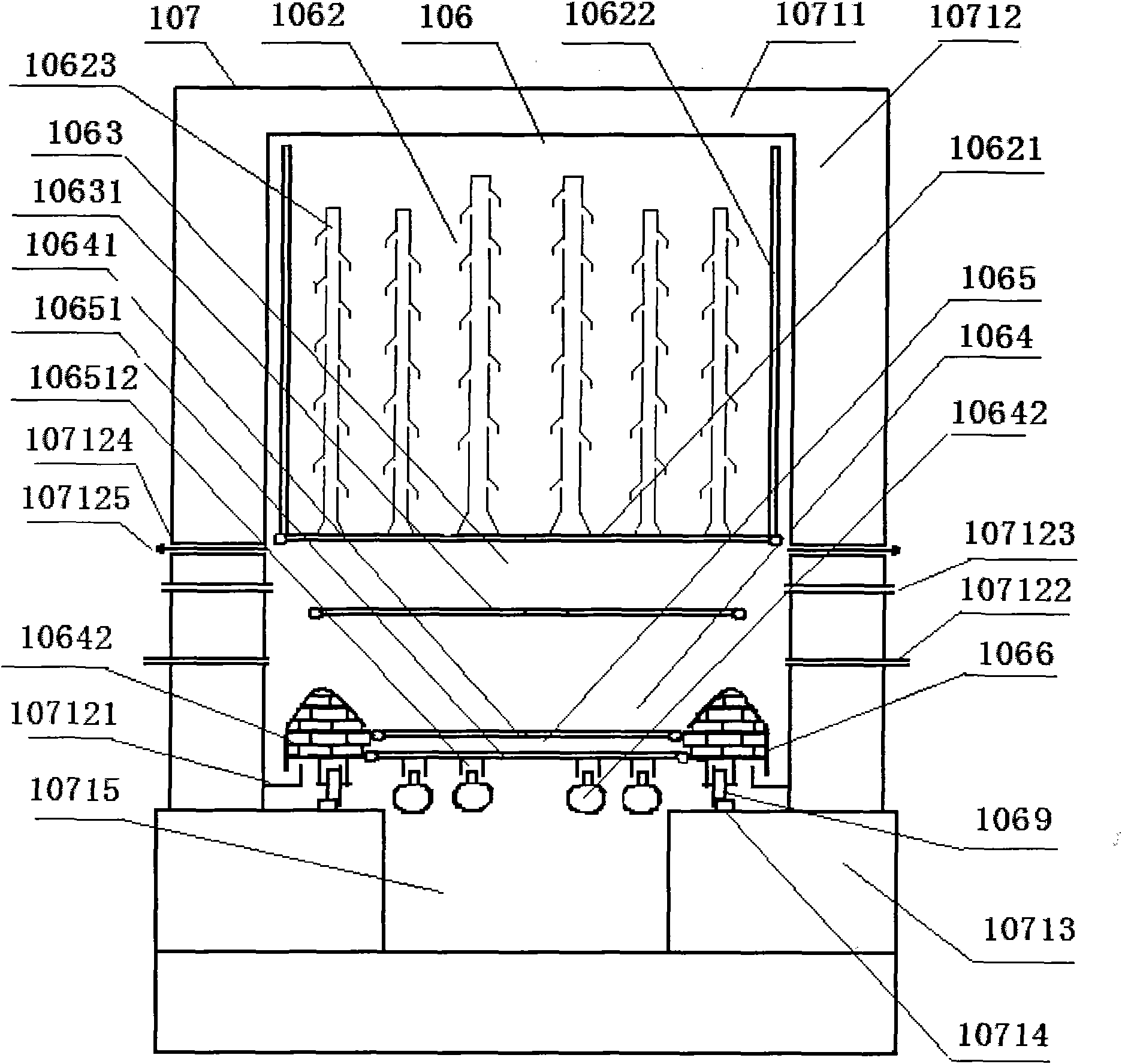

Tunnel pipe thin-layer retort for coal and oil shale and retort process thereof

InactiveCN103013544AImprove heat transfer performanceIncrease profitChemical industrySpecial form destructive distillationThin layerOil shale gas

The invention discloses a tunnel pipe thin-layer retort for coal and oil shale and a retort process thereof, relates to a retort and a process for producing coal tar and shale oil, and solves the problems that the conventional retorts and processes have large heat loss at semicoke cooling sections, the retort time is difficultly controlled accurately, the oil yield is low and the treatment capacity of the single furnace is small. The retort comprises a drying section, a retort section, a high temperature cooling section and a low temperature cooling section, wherein the semicoke cooling section is divided into two sections by a roller feeding machine, heat exchange of cooling wind is carried out at the high temperature semicoke section, the low temperature cooling section is communicated with a tunnel pipe, and drying gas enters the drying section via the tunnel pipe. According to the process, retort oil gas led out from a retort oil gas outlet of a retort furnace is purified and then used as circulation retort gas, and gas led out from a drying gas outlet of the retort furnace is used as the circulation drying gas to carry out retort. With the retort and the retort process, an addition of 20 percent of semicoke residual heat is recovered from per ton raw material, the retort time is accurately controlled, the oil yield is high, and the treatment amount of the single furnace is large; and the retort and the retort process are mainly applied to the field of coal chemical industry.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

Catalyst used for coal tar pitch hydrocracking lightening reaction

InactiveCN102029157AEasy to makeLow costMolecular sieve catalystsHydrocarbon oil crackingPtru catalystMetallic sulfide

The invention relates to a catalyst used for coal tar pitch hydrocracking lightening reaction. The preparation method of the catalyst comprises the following steps: taking an inorganic porous material as a carrier; selecting at least one of alumina, silica gel containing alumina, MCM-41 (mobile crystalline material-41) and SBA-15 (santa barbara amorphous-15); loading one or two of metal elements Fe, Ni, Co and Mo of active components onto the carrier in the form of metallic oxide or metallic sulphide by adopting a vacuum immersion method, wherein the metallic oxide or metallic sulphide content of the active components is 1-20wt% of the catalyst; then drying for 1-14 hours under the conditions that nitrogen is used for protection, normal pressure is kept and the temperature is 70-120 DEG C; and then roasting at the temperature of 500 DEG C for 3 hours. The catalyst in the invention has the advantages of simple preparation process, high catalytic activity, less reaction coking and high cracked light oil yield, thus being especially applicable to hydrocracking lightening of heavy component and pitch in coal tar, and the catalyst in the invention can cause conversion per pass of coal bar pitch to reach more than 70%.

Owner:TONGJI UNIV

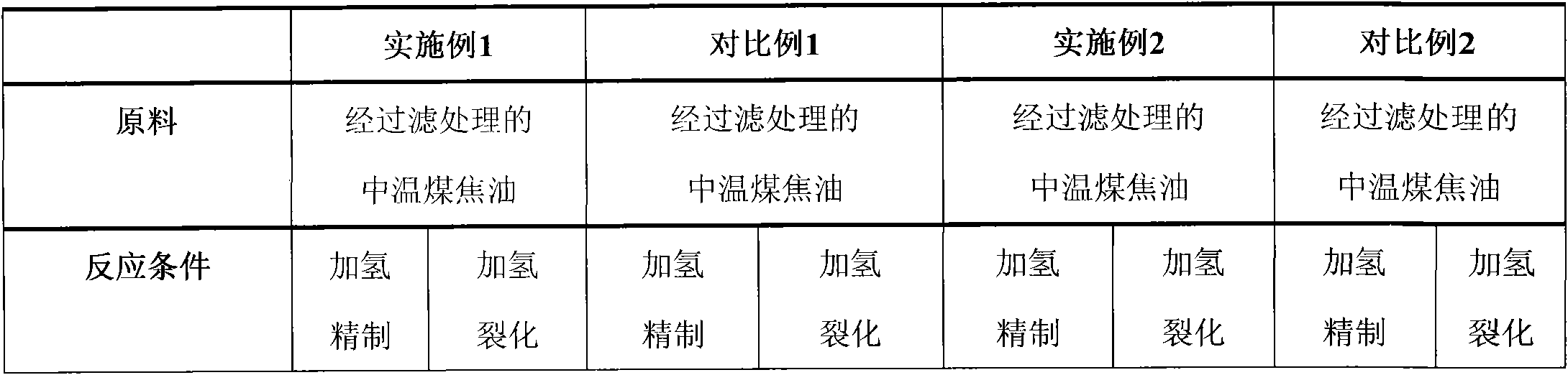

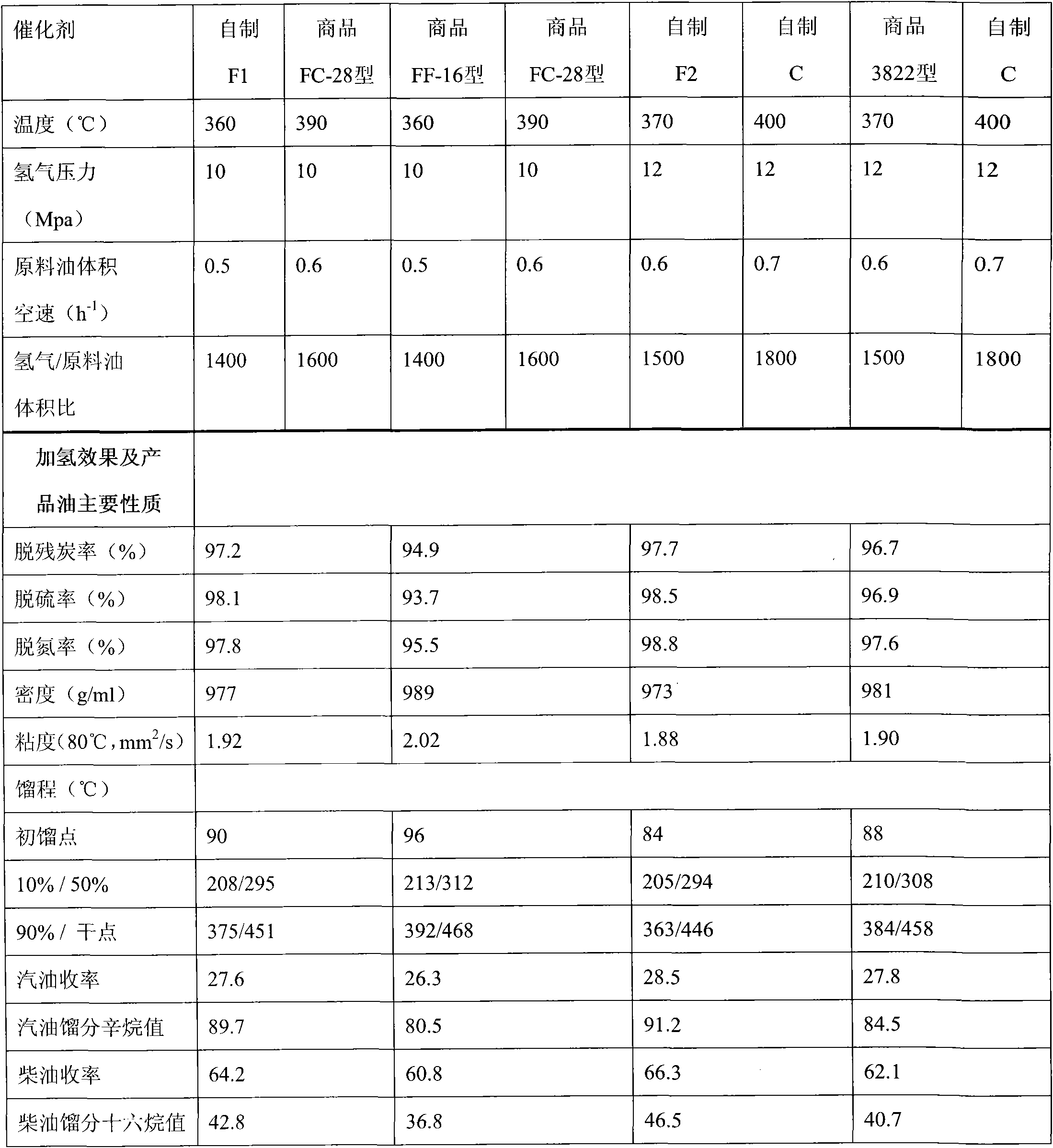

Hydrorefining catalyst for preparing fuel oil from coal tar, preparation method and application method thereof

ActiveCN102068992AImprove operational stabilityImprove handling strengthCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystProcess engineering

The invention provides a hydrorefining catalyst special for new coal tar, a preparation method and an application method thereof, which are used for solving problems existing in the conventional hydrogenation catalyst for coal tar. The hydrorefining catalyst consists of active components, aids and carriers, wherein the active components refer to MoO3 and NiO or MoO3 and CoO; the aids refer to Bi2O3 and K2O; and the carriers refer to alumina and barium oxide. According to calculation by the form of an oxide, the active components, the aids and the carriers account for 15 to 35 percent, 2 to 5 percent and 60 to 83 percent of the total mass of the catalyst respectively. The catalyst is prepared by the following steps of: kneading, grinding, extruding into strips, molding, soaking, performing catalyst post-treatment and the like. New ultrasonic soaking technology is introduced, and the preparation condition of the catalyst is controlled strictly. Compared with the prior art, the catalyst has high surface physical and chemical properties, high purified atom degumming activity, high hydrogenation saturation capability, high stability and high mechanical intensity, and the quality and yield of hydrogenation product oil can be enhanced effectively.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Taphole stemming used for oversize blast furnaces

Belonging to the technical field of refractory materials, the invention relates to taphole stemming used for oversize blast furnaces over 4500m<3>. The taphole stemming used for oversize blast furnaces comprises by weight: 25-50% of brown corundum, 5-20% of silicon carbide, 7-25% of ferro-silicon nitride, 15-30% of a composite carbon material, 5-15% of kaolin, 3-7% of composite refractory material micropowder, and 1-5% of composite metal powder. The stemming is prepared by the steps of: conducting weighing and burdening according to the above ratio of various raw materials, mixing them well and adding a coal tar binder accounting for 15-25% of the total weight of the additionally added dry materials, then conducting rolling and mulling so as to obtain a mud material. The stemming of the invention has good comprehensive performance, stable taphole depth, long tapping time, good erosion and scouring resistance, as well as good construction performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Upflow type hydrogenation thermal cracking method with characteristic of high-aromatic-carbon-rate poor-quality hydrocarbon branching feeding

The invention relates to an upflow type hydrogenation thermal cracking method with a characteristic of high-aromatic-carbon-rate poor-quality hydrocarbon branching feeding. According to the present invention, the upflow type hydrogenation thermal cracking method is suitable for the suspension bed hydrogenation thermal cracking process R10 of coal tar heavy oil having the high contents of metals, polycyclic aromatic hydrocarbons, colloid and asphaltene and having the conventional boiling point of higher than 450 DEG C, wherein the R10 comprises two or a plurality of operation series connecting sub-hydrogenation reaction zones such as a first sub-hydrogenation reaction zone R101, a second sub-hydrogenation reaction zone R102 and the like, poor-quality hydrocarbon HDS is divided into the two-branch raw material such as HDS1 and HDS2 or multi-branch raw material, the HDS1 enters the R101, and the obtained reaction effluent R101P or the stream R101PX containing the hydrogenation generation oil of the R101P enters the R102 and contacts the HDS2, such that the concentration of the fresh raw material HDS2 in the R102 liquid phase can be reduced, the ratio of the hydrogen supply hydrocarbon weight to the fresh raw material HDS weight in the SHS flowing-through reaction zone can be significantly increased when the R101 uses the hydrogen supply hydrocarbon stream SHS, and the thermal condensation coking rate can be reduced.

Owner:洛阳瑞华新能源技术发展有限公司

Modified coal tar, and producing method

InactiveCN1760331AIncrease electrode contentHigh strengthWorking-up pitch/asphalt/bitumen by chemical meansSmall footprintPhenol

A modified coal asphalt with linear resin molecule structure and adjustable softening point is prepared from one or more of coal tar, antracene oil, phenol oil, naphthelene oil and the coal asphalt with softening point lower than 130 deg.C through using acid to regulate pH value, and polymerizing reaction on formaldehyde or tripolyformaldehyde or polyformaldehyde which controlling temp, pressure and time.

Owner:任利华

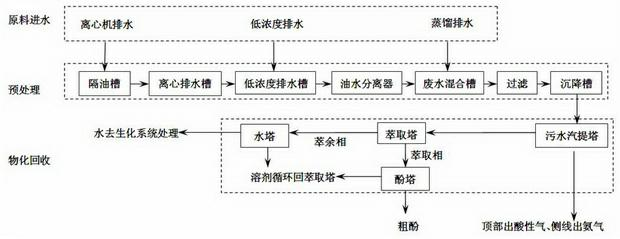

Separation treatment method for waste water in coal tar machining process

InactiveCN102674609AEasy to handleEmission complianceMultistage water/sewage treatmentWater/sewage treatment by heatingWastewaterProcess engineering

The invention discloses a separation treatment method for waste water in a coal tar machining process. The separation treatment method mainly comprises the following steps of: at first, pre-treating the waste water in the coal tar machining process to remove free oil and emulsified oil, and then entering a waste mixing groove; secondly, further removing oil matter by filtering and entering a subside for removing depositions through settling, so as to obtain oil-removed waste water; removing hydrogen sulfide and amine after the oil-removed waste water enters a sewage steam stripping tower, and extracting after acid-removed and amine-removed waste water enters an extraction tower; recovering crude carbolic acid and an extracting agent after an extract phase enters a phenol tower; separating the extracting agent from water after a residual extract phase enters a water tower; and processing after the water enters a follow-up biochemical system. The separation treatment method provided by the invention firstly removes acid and anime of the waste water, provides a good acid-alkali condition for follow-up solvent extraction and dephenolization, and has no need of adding a great amount of the acid and alkali in a treatment process. Meanwhile, byproducts, such as the crude carbolic acid, the anime, the hydrogen sulfide and the like, can be recovered. The water quality of the treated waste water can meet the water inlet requirements of the normal biochemical treatment.

Owner:SOUTH CHINA UNIV OF TECH

Composite type coal tar hydrogenation catalyst and preparation method thereof

ActiveCN102861570AReduce manufacturing costGood catalyticHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCoal tar product

The invention relates to a coal tar hydrogenation catalyst and a preparation method thereof. The catalyst consists of an active ingredient and a carrier. The active ingredient is one or more of molybdenum, nickel, cobalt or tungsten water-soluble salt. The carrier is coal gangue. The content of the active ingredient is 60-90 wt%, and the content of the carrier is 10-40 wt%. The catalysis to forming load of the active ingredient on the coal gangue carrier is effectively achieved through a negative pressure freeze-drying forming process, the coal tar hydrogenation catalyst is used in a coal tar suspended bed hydrocracking technological process and has good hydrogenation activity, the production rate of light oil reaches to more than 96%, the coal gangue is cheap and easily obtained and can be recycled and used repeatedly, and the preparing and using cost of the catalyst can be reduced remarkably.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

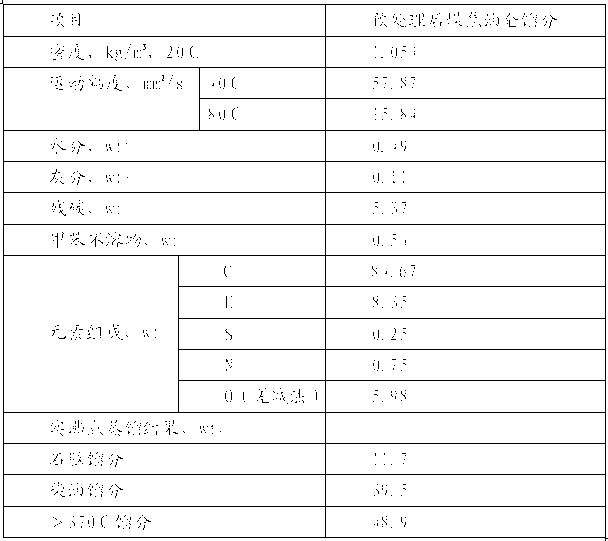

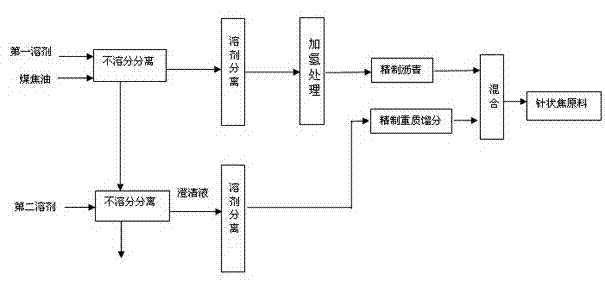

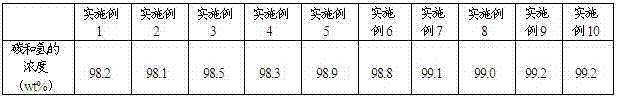

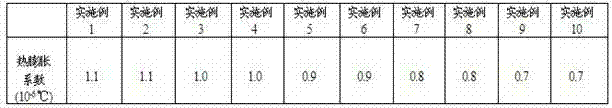

Process for preparing needle coke raw material by using coal tar and through heavy-phase circulation

ActiveCN103087745AHigh yieldEfficient separationTar working-up by chemical refiningTar working-up by solvent extractionCokeProcess engineering

The invention relates to a process for preparing a needle coke raw material by using coal tar and through heavy-phase circulation. The process comprises the steps that: (1) coal tar is sufficiently mixed with a first solvent; first solvent insoluble matters are removed from the mixture with a physical separation method, such that a first clarified liquid is obtained; (2) the first solvent is removed by separation; the obtained residual component is subjected to hydrogenation, such that refined asphalt is obtained; (3) the first solvent insoluble matters and a second solvent are sufficiently mixed; second solvent insoluble matters are removed from the mixture with a physical separation method, such that a second clarified liquid is obtained; (4) the second solvent in the second clarified liquid is removed by separation, such that a refined heavy component is obtained; and (5) the refined asphalt and the refined heavy component are mixed, such that the raw material used for preparing needle coke is obtained. With the process provided by the invention, the obtained needle coke raw material has high polyaromatic condensed polycyclic aromatic content, such that needle coke product yield is effectively improved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Large-scale brown coal quality-improving process and apparatus

InactiveCN102757833AImprove utilizationComprehensive utilization of product quality improvementSolid fuelsSpecial form destructive distillationBrown coalMicrowave

The invention belongs to the technical field of brown coal quality improving, and relates to a large-scale brown coal quality-improving process and a large-scale brown coal quality-improving apparatus. According to the invention, an interrelated large-scale continuous brown coal quality-improving system is composed of three modules which are a tunnel internal-heat drying module, an external-heating microwave destructive distillation module, and a powdery brown coal molding and drying module. Because of large-amount water discharging, a brown coal block large-capillary framework is collapsed, so that the brown coal is naturally broken into small blocks and powder without mechanical disruption. The small-block brown coal is subjected to destructive distillation under high-temperature hot wind external heating and microwave coupling, until the blocks turn into semi-coke; water-containing coal gas, water-containing coal tar, anhydrous gas, and anhydrous coal tar are respectively obtained by destructive distillation. With a binder of the water-containing coal tar and coal tar pitch (one or a mixture thereof), the powdery brown coal is subjected to kneading and aging; the material is processed into granules by using a vacuum extrusion granulator; and the particles are processed by using a low-temperature microwave drying device, so that high-quality brown coal particles with high strength, low moisture absorption, and high heat value are obtained. The brown coal particles can endure long-distance transportation.

Owner:周灿旭

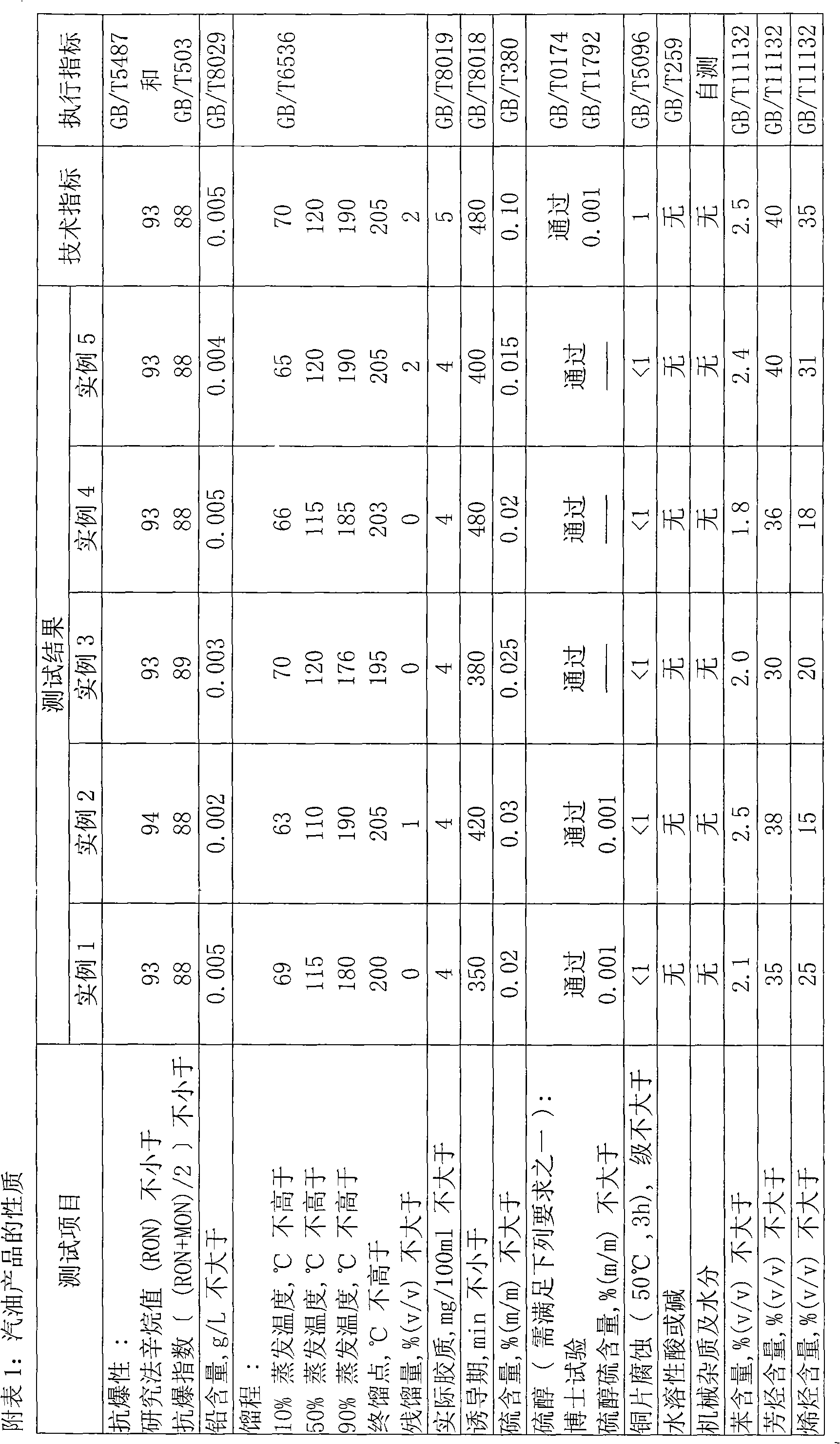

Catalyst for using coal tar to prepare clean fuel oil by catalytic hydrogenation, preparation method and applications

InactiveCN101574659AHigh activityHigh selectivityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFuel oilSilicon oxide

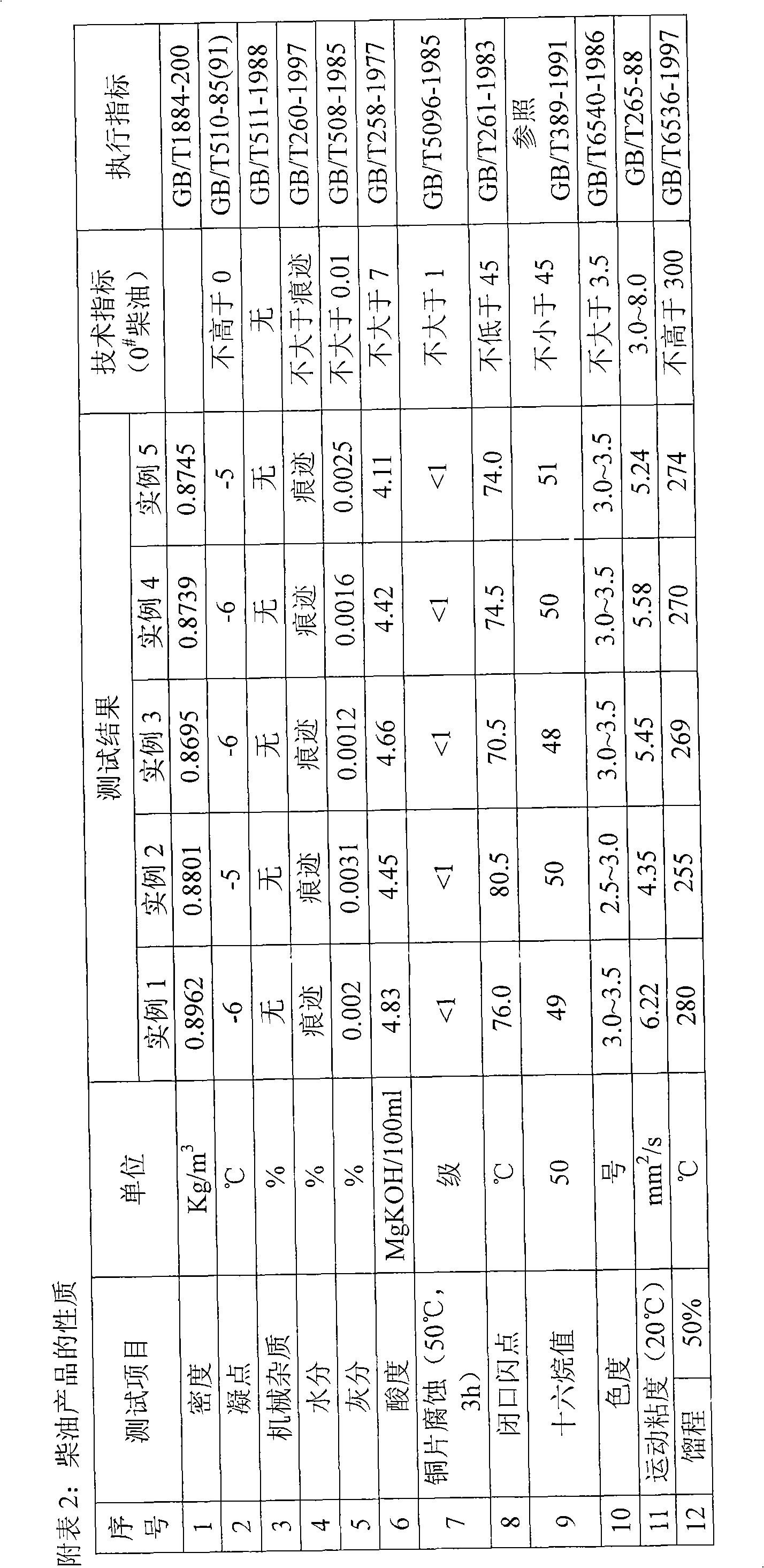

The invention relates to a catalyst for using coal tar to prepare clean fuel oil by catalytic hydrogenation, comprising the following components in percentage by mass: 4 to 15 percent of molybdenum oxide, 3 to 9 percent of nickel oxide, 0.1 to 5 percent of cobalt oxide, 10 to 25 percent of tungsten oxide, 2.5 to 40 percent of silicon oxide and 26 to 65 percent of aluminium oxide. The preparation method of the catalyst comprises the following steps of: firstly, preparing a silicon oxide-aluminium oxide carrier, loading active components of Co, Mo, Ni and W on the carrier by an isosteric dipping method, drying, baking and forming. The catalyst can be used for the preparation of the clean fuel oil by catalytic hydrogenation of the coal tar, gasoline and diesel oil obtained from the prepared fuel oil after being separated respectively meet the national standard of 93# gasoline and 0# diesel oil.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

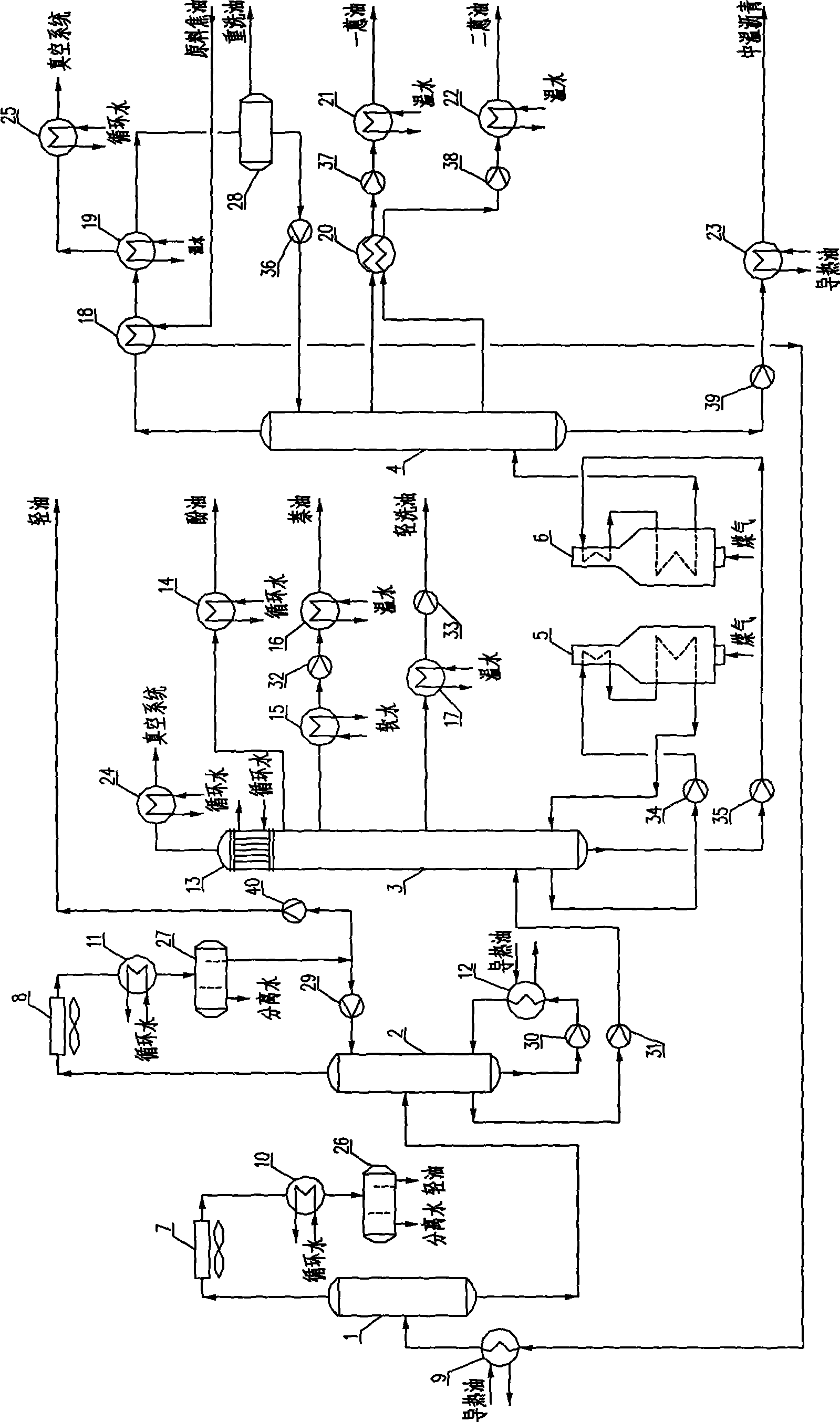

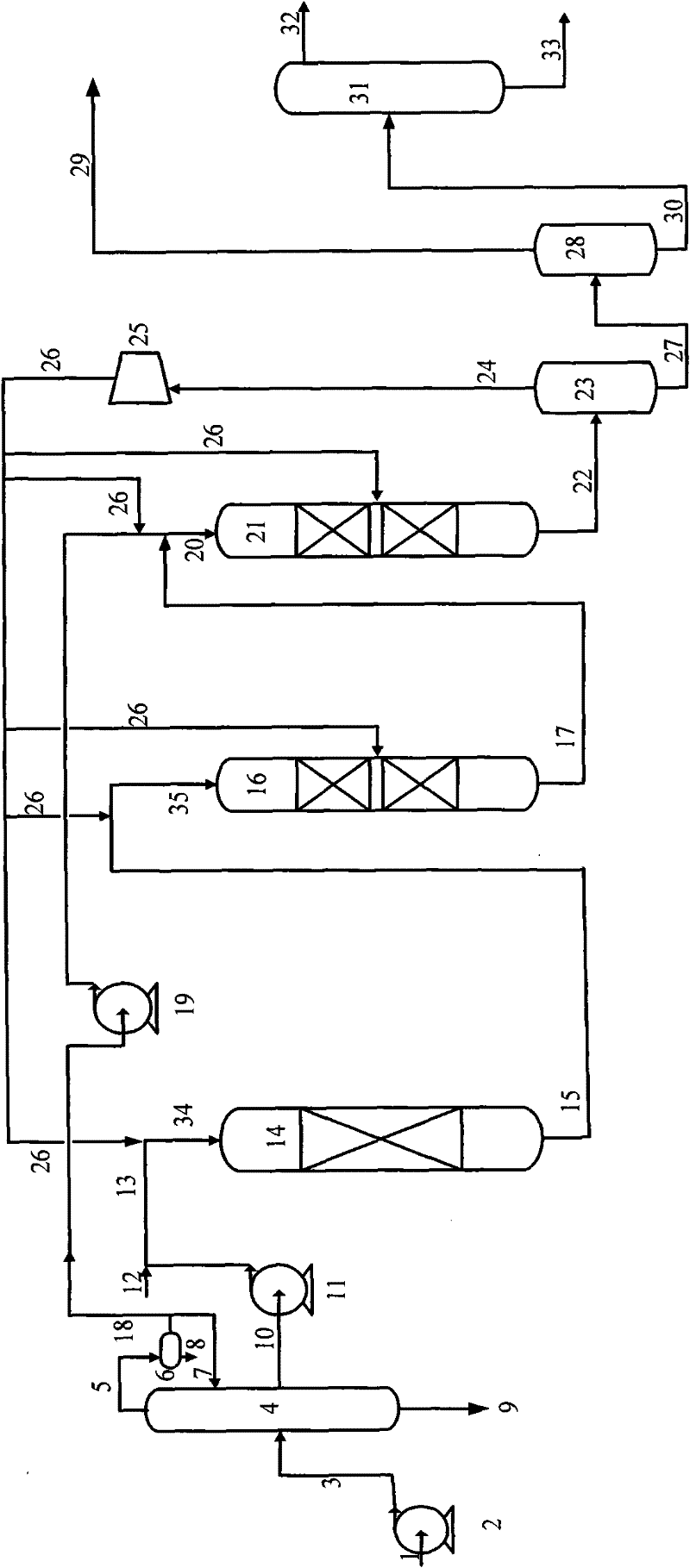

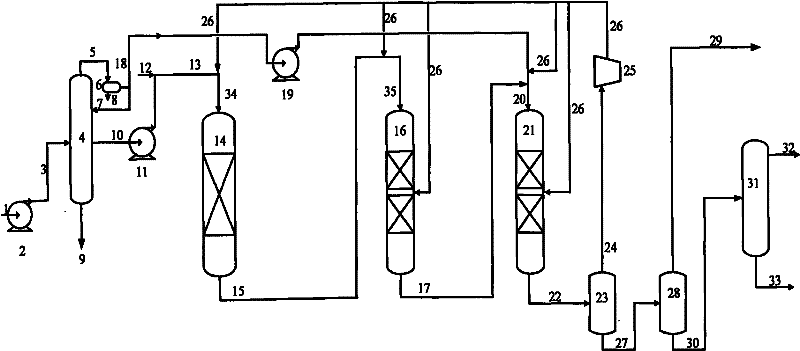

Matching technology method for optimizing feeding of coal tar suspended bed hydrocracker

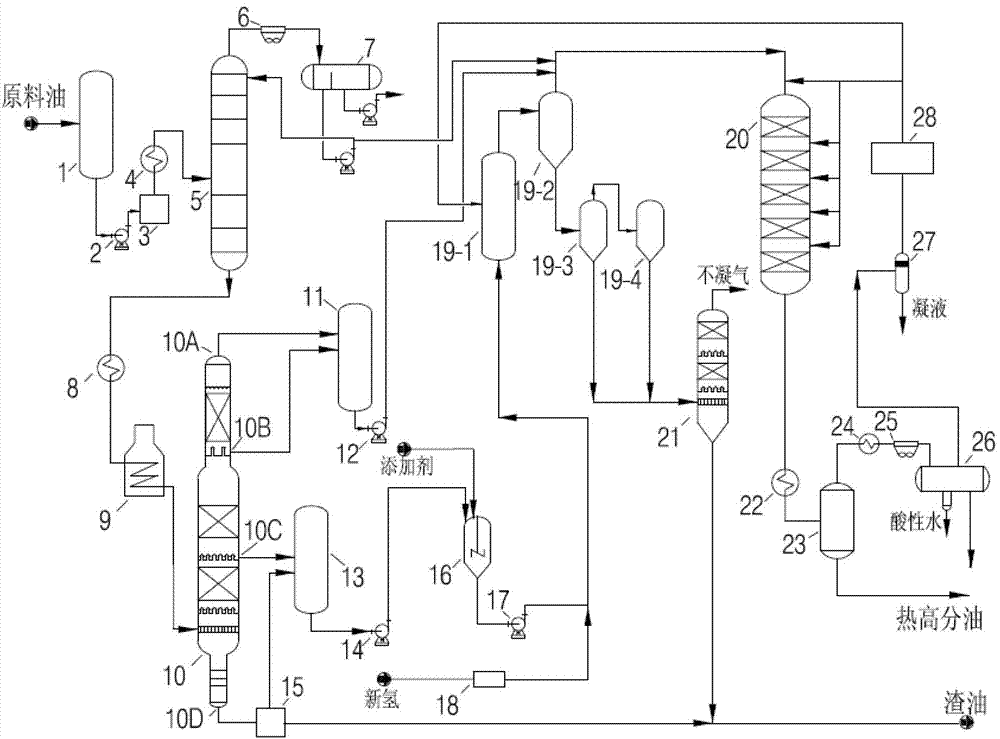

ActiveCN103484159AAvoid crackingReduce solid particlesTreatment with hydrotreatment processesFiltrationFixed bed

The invention relates to a matching technology method and a treatment system for optimizing feeding of a coal tar suspended bed hydrocracker. The method comprises the following steps: filtration and deslagging of coal tar, dehydration treatment through a dehydrating tower, and deep drawing through a vacuum tower. According to the invention, light oil pumped out from the top of the vacuum tower is mixed with diesel fractions pumped out from the vacuum tower siding to be sent to a fixed bed reactor for hydrocracking treatment; the light oil pumped out from the top of the vacuum tower can also be sent to the fixed bed reactor for hydrocracking treatment, and the diesel distillate pumped out from the siding is sent to a phenol-extracting device to be used as a raw material for extracting phenolic substances; wax oil fractions pumped out from the vacuum tower siding are sent to the suspended bed hydrocracker to be used as a raw material for a hydrocracking reaction; heavy oil pumped out from the bottom of the vacuum tower is subjected to filtration, a filtrate is sent to the suspended bed hydrocracker to be used as a raw material for the hydrocracking reaction, and filter residues are sent to a granulating device for granulating. The invention also provides the treatment system, suitable for the method, of the coal tar.

Owner:BEIJING PETROCHEM ENG

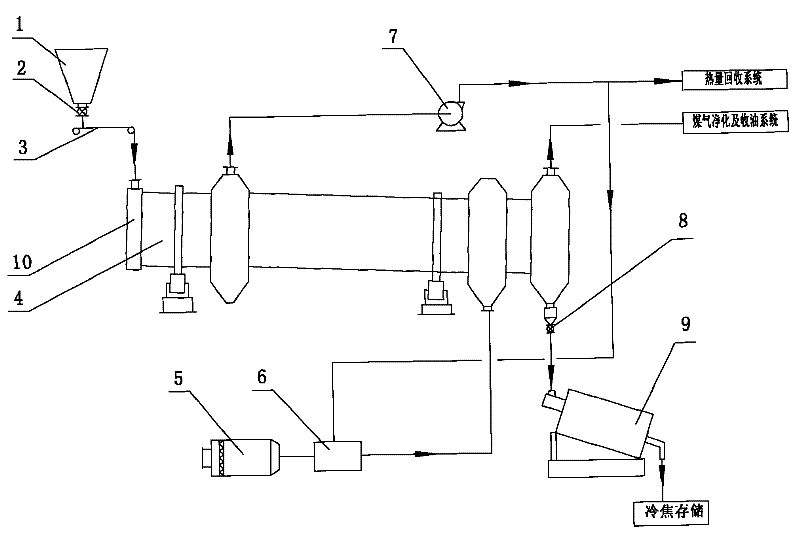

Single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology and system

ActiveCN102358840AImprove thermal efficiencyEasy to handleIndirect heating destructive distillationSpecial form destructive distillationSingle stageSpiral blade

The invention discloses a single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology and a system. The single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology adopts a multi-pipe rotary destructive distillation machine to carry out low-temperature destructive distillation of fine coal. Multiple destructive distillation pipes for dispersing fine coal are arranged in the multi-pipe rotary destructive distillation machine. Spiral blades are arranged in the destructive distillation pipes and have the effects of diversion and disturbance on coal. The single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology and the system can enhance destructive distillation effects, can increase destructive distillation effective areas, have the advantages of large fine coal treatment amount, small destructive distillation gas treatment amount, low content of tar and dust, and high calorific value of gas, can realize recovery of chemical raw materials such as coal tar and the like produced in low-temperature destructive distillation of soft coal and low-order fine coal as completely as possible, can improve a comprehensive utilization rate of coal, and can realize production of semicoke powder and high-calorific value gas from soft coal and low-order fine coal through low-temperature destructive distillation.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

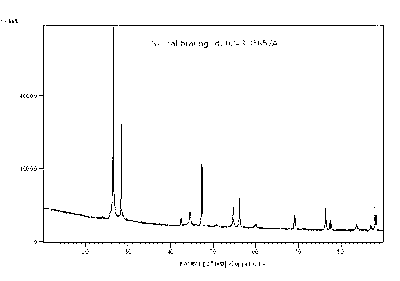

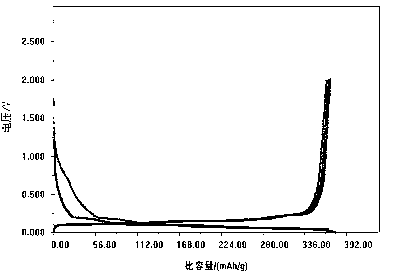

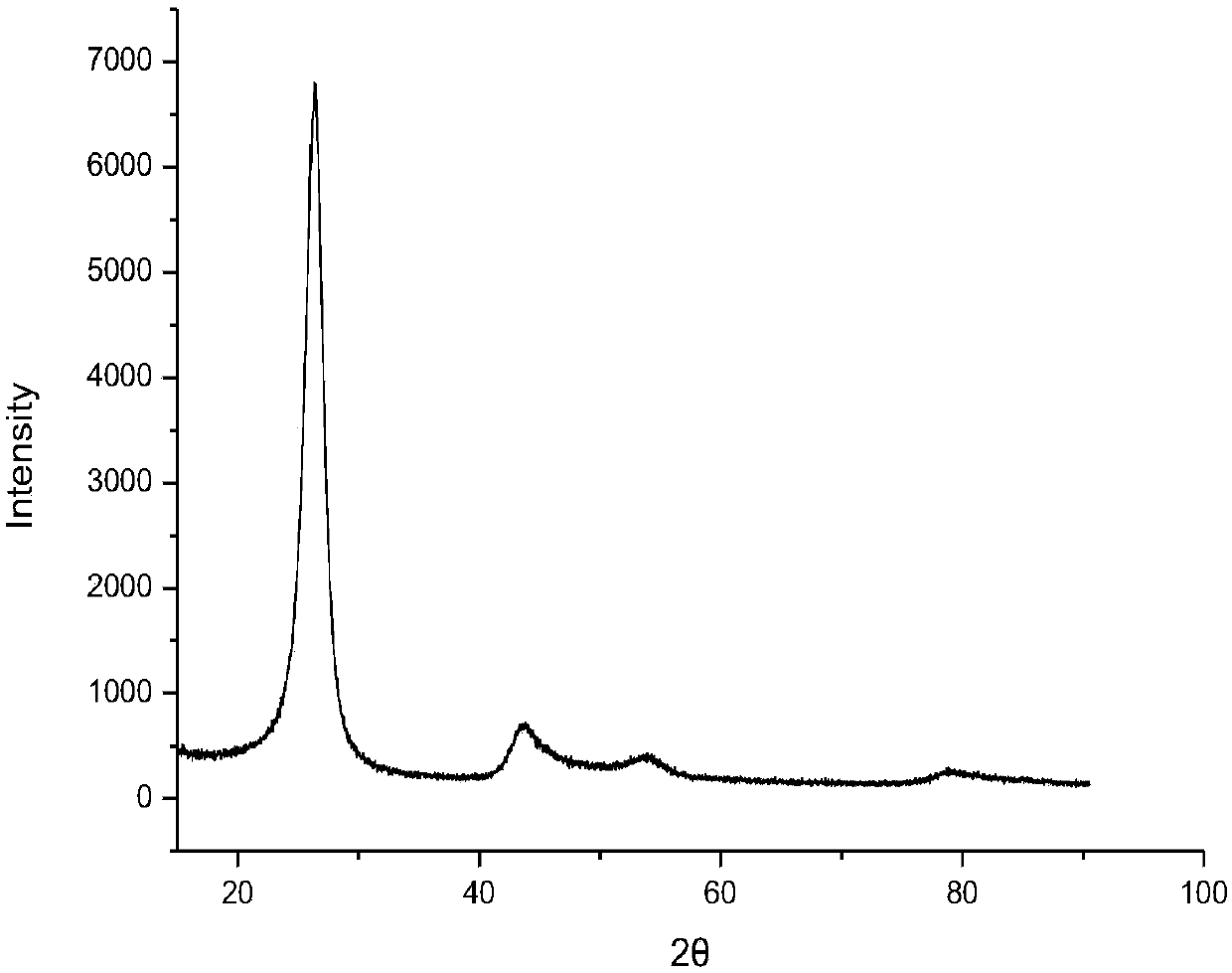

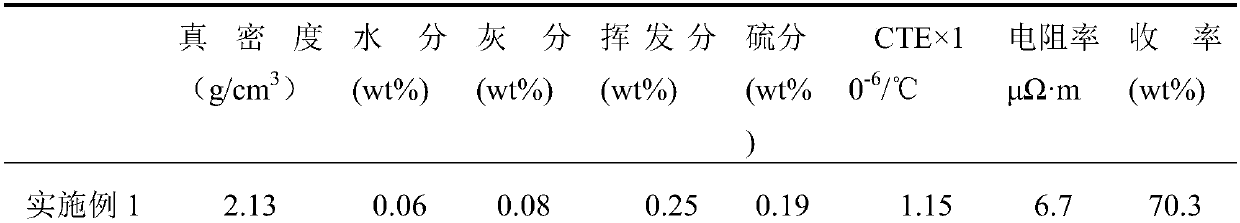

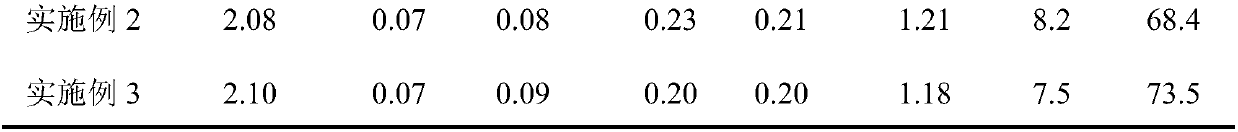

A kind of isotropic graphite negative electrode material and preparation method thereof

InactiveCN102280629ASolve the defect of irreversible capacityImprove the first charge and discharge efficiencyCell electrodesGraphiteSolvent

The invention relates to an isotropic graphite negative electrode material and a preparation method thereof. The negative electrode material is surface-coated artificial graphite prepared by coating and modifying isotropic graphite with a coating agent composed of pitch and / or coal tar The layered isotropic graphite negative electrode material, the weight ratio of the coating agent to the isotropic graphite is 0.03-0.15:1. The preparation method comprises the following steps: weighing 100 parts of isotropic graphite, 3 to 15 parts of coating agent, and 10 to 70 parts of solvent, stirring and mixing evenly at 25 to 350° C., then vacuumizing, removing the solvent, and discharging glue, carbonization, and finally high-temperature treatment under the condition of 2400-3000° C. in an inert protective atmosphere to obtain the negative electrode material. The isotropic graphite negative electrode material has high coulombic efficiency and good cycle performance for the first time. The preparation method is easy to implement industrially.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD

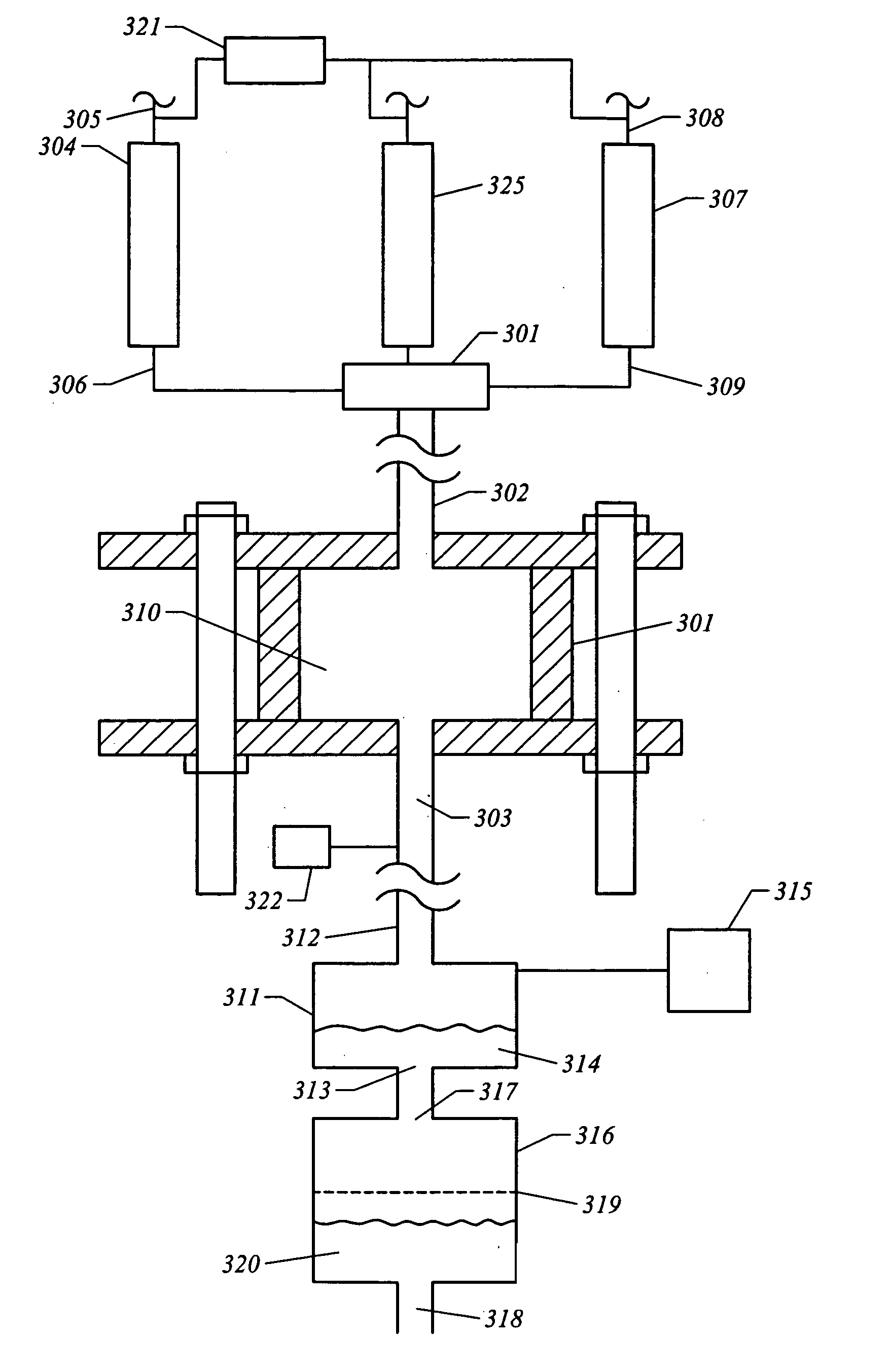

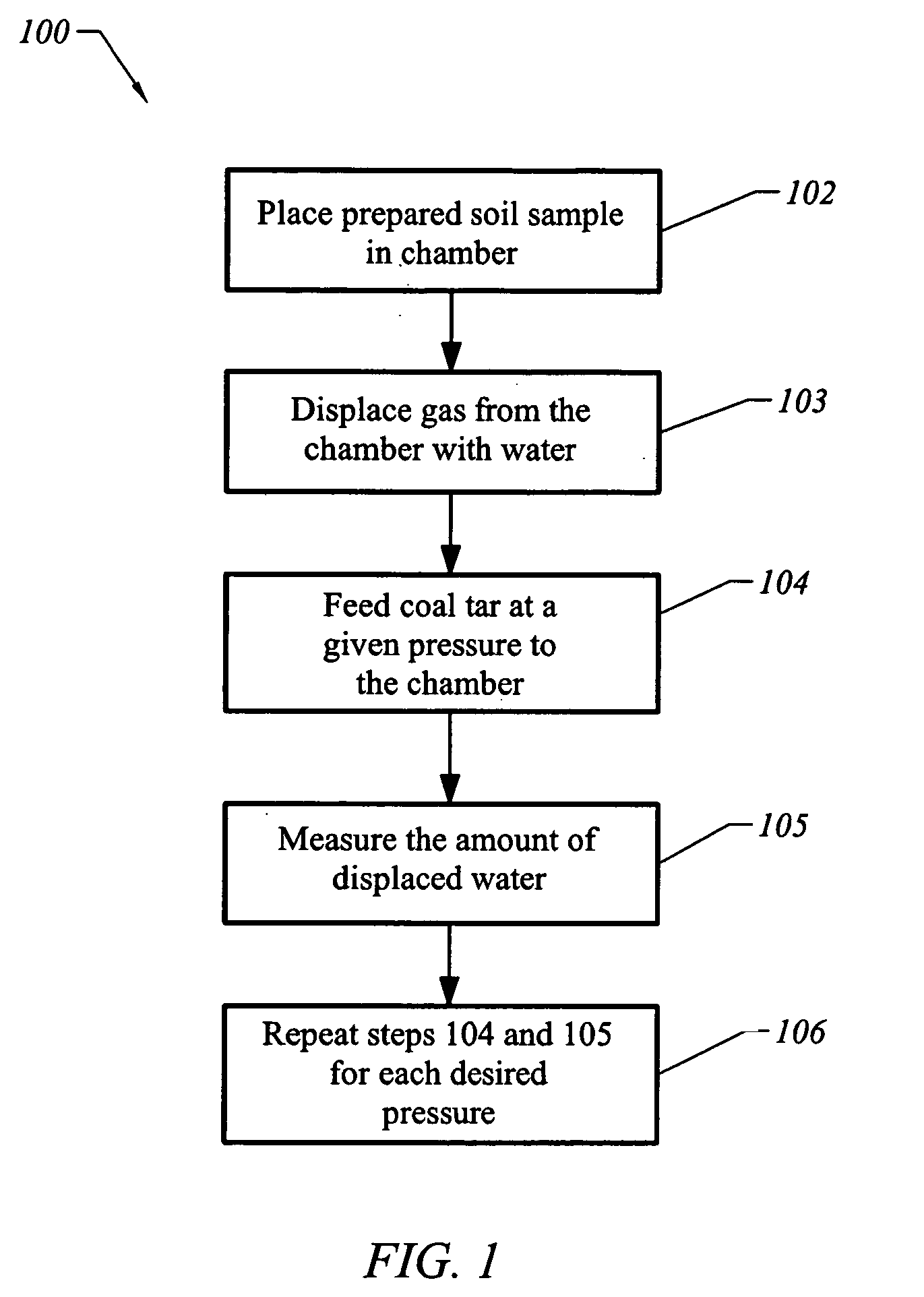

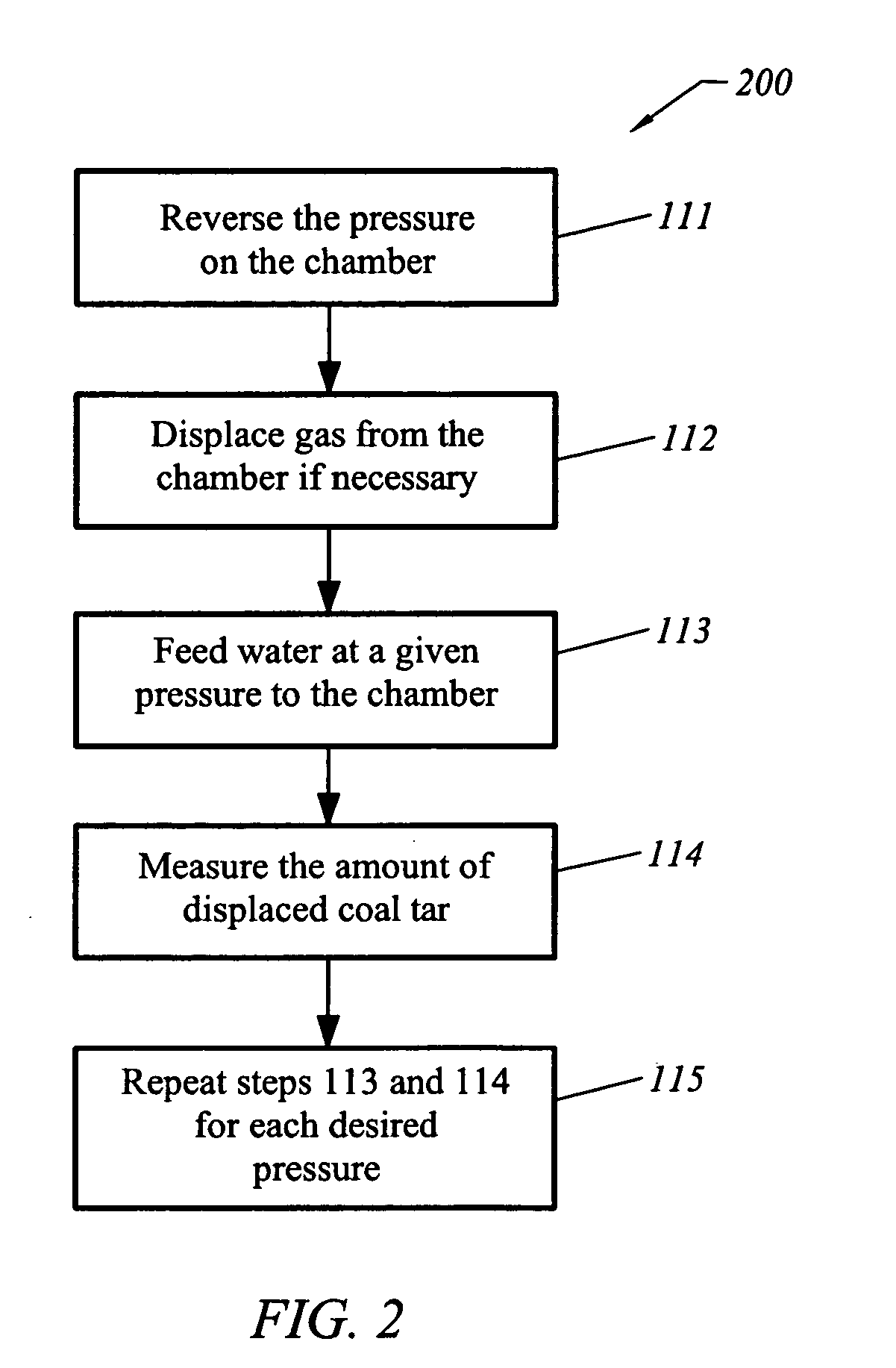

Method and apparatus for characterizing coal tar in soil

The present invention provides a method and apparatus or system for determining an amount of coal tar that can enter, and subsequently be displaced from, a given type of soil for a range of depths of the soil. The method and apparatus also provide verification of the pressure at which coal tar can be displaced from a given type of soil. In particular, the method and apparatus simulate the hydrostatic pressure that a soil sample encounters in the subsurface of the ground. Accordingly, the method and apparatus provide a relationship between the concentration of coal tar in the soil and the pressure required to displace the coal tar from the soil, which allows for an estimation of the amount of coal tar that may be displaced at a particular location or site. Further, the method and apparatus are adaptable for use in the laboratory or the field.

Owner:ELECTRIC POWER RES INST INC +1

Method for improving yield of pyrolysis coal tar of low-rank coals

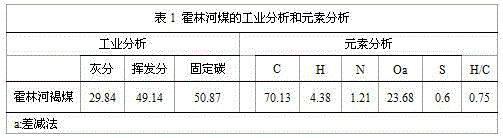

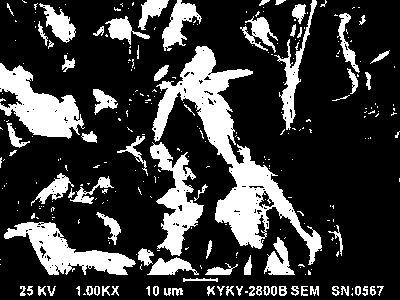

InactiveCN104479711AIncrease added valueHigh yieldLiquid hydrocarbon mixture productionSpecial form destructive distillationProcess engineeringCoal tar product

The invention discloses a method for improving the yield of pyrolysis coal tar of low-rank coals. The method comprises the following steps: (1) drying raw coals; (2) swelling; (3) performing pyrolytic reaction; and (4) collecting coal tar. By adopting the method disclosed by the invention, on the premise that the production cost is considered, a pyrolysis process of the low-rank coals is improved to ensure that the total volatile matter yield is improved by 3-7%, the yield of the coal tar is improved by 3.4%, the added value of the low-rank coals is improved, and a pretreatment solvent can be recovered for recycling.

Owner:HUNAN UNIV OF SCI & TECH

Method for producing activated carbon by thermally activating coal tar dreg/ sludge fermentation body by using microwaves

ActiveCN102381705ALower activation energyReduce manufacturing costActivated carbonIndustrial effluent

The invention discloses a method for producing activated carbon by thermally activating a coal tar dreg / sludge mixed fermentation body by using microwaves. The method comprises the steps of: firstly crushing and grinding coal tar dreg into more than 200 meshes, then, mixing the ground coal tar dreg with sludge, and performing aerobic fermentation for 10-20 days; then, adding zinc chloride servingas an activator into the mixed fermentation body, and infiltrating for 12-24h at 70-80 DEG C, wherein the added zinc chloride is 0.5-4 times more than the mixed fermentation body in mass; and finally, carbonizing and activating for 30-120min in a microwave carbonization furnace under a N2 protection condition to obtain coal tar dreg / sludge mixed activated carbon, washing with water till a neutralcondition is achieved, and drying to obtain a product disclosed by the invention. The method disclosed by the invention has the advantages of simplicity and convenience for operation, easiness for control, low cost, high product synthesis rate and favorable product performance, and can be widely applied to industrial wastewater treatment, refractory wastewater treatment, sound insulation, noise reduction, deodorization, oil absorption, lipid suction and other industries.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Composite graphite negative electrode material with high energy density, and preparation method and application thereof

InactiveCN103000867AIncrease energy densityImprove discharge capacityCell electrodesHigh energyLithium-ion battery

The invention relates to a graphite composite material with high energy density. The composite graphite material comprises artificial graphite, natural graphite and a coating. A mass ratio of the artificial graphite to the natural graphite is 15:1-1:5; a mass ratio of the coating to the composite graphite is 1:5 to 5:1; the composite graphite comprises the artificial graphite and the natural graphite; the coating material is one selected from middle-temperature coal pitch, high temperature coal pitch, secondary coal pitch, petroleum pitch and coal tar, and a combination thereof. The composite graphite negative electrode material provided by the invention has advantages of high energy density, high discharge capacity, high first discharge (388mAh / g), high first efficiency (higher than 95%), high compactness (1.79g / cm<3>) and good processing performance, and meets requirements of high energy density of lithium ion battery material by portable electronic products.

Owner:天津市贝特瑞新能源科技有限公司

Molded coal made from garbage and process for preparing same

The invention provides a molded coal made from garbage and process for preparing same, wherein the molded coal comprises, (1) urban domestic refuse, (2) one or several flammable substances containing fixed carbon, including coal gangue, coal mud, stone coal, pulverized coke, bituminous shale, charcoal powder, coal, graphite powder, carbon black, (3) binder including loess, carclazyte, cement, soluble glass, industrial sewage, asphalt slag, coal tar, industrial maize starch and cellulose. The preparation process comprises the steps of sterilizing, artificial sorting, disintegrating, drying, charging binder, addition agent, mixing, magnetic separating, super fine crushing, modeling and drying.

Owner:CHANGCHUN HONGGUANG CLEAN ENERGY DEV

Method for producing gasoline and diesel oil through hydrogenation of coal tar

ActiveCN102453534AEfficient removalReduce pollutionTreatment with hydrotreatment processesSulfurGasoline

The invention relates to a method for producing gasoline and diesel oil through hydrogenation of coal tar. The method comprises: cutting full-range distillate oil of coal tar into light distillates, medium distillates and heavy distillates, conducting hydrotreatment to the light distillates and medium distillates through segmented feeding, and introducing the medium distillates into a hydrogenating protective reaction area, a first hydrofinishing reaction area and a second hydrofinishing reaction area; leaving the light distillates only to enter the second hydrofinishing reaction area for moderate hydrotreatment. The method of the invention can produce clean diesel oil with low sulfur and high cetane value, and can simultaneously give consideration to produce gasoline blending components, thus providing an application approach with a higher added value for processing and utilization of coal tar and alleviating the current tense supply-demand situation of petroleum-based gasoline and diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing needle coke from compounded and blended components such as washing oil, anthracene oil and asphalt in medium and low temperature coal tar as raw materials

InactiveCN107868671AEasy to handleStrong targetingCoking carbonaceous materialsTar working-up by solvent extractionCarbolineumCalcination

The invention provides a process for producing needle coke from compounded and blended components such as washing oil, anthracene oil and asphalt in medium and low temperature coal tar as raw materials. The process comprises the steps as follows: raw material pretreatment of the medium and low temperature coal tar, fraction cutting of the components such as the washing oil, the anthracene oil andthe asphalt in the medium and low temperature coal tar, blending of the compounding raw materials, and preparation of the needle coke with thermal polymerization and calcination processes. The ideal raw materials for the needle coke are prepared from fractions of the coal tar by compounding and blending, formation of a wide-area ordered fibrous structure from an intermediate phase can be greatly promoted in a thermal polymerization process by means of reasonable raw material components, and a needle coke product with excellent performance is obtained after calcination.

Owner:SHAANXI YULIN ENERGY GRP CO LTD +1

High-efficiency deep desulfurization active carbon and preparation method thereof

ActiveCN104667872AHigh sulfur capacityFast desulfurizationOther chemical processesActive agentFiltration

The invention discloses high-efficiency deep desulfurization active carbon and a preparation method thereof, belonging to the field of modified active carbon materials. The high-efficiency deep desulfurization active carbon is prepared through the steps of by adopting coal or a coconut shell as raw materials, crushing, screening, then adding a coal tar adhesive for extrusion forming, and calcining at 750-950 DEG C to form primary active carbon; carrying out dipping treatment on the primary active carbon, uniformly loading a hydroxide active agent and a cyclodextrin assistant active agent, carrying out secondary high-temperature calcination in the presence of excessive heat water vapors to obtain a high-efficiency desulfurization active carbon product. The active carbon prepared through the method disclosed by the invention has the advantages of high sulphur capacity, high desulfurization speed, long usage period, high strength, good abrasion resistance, good material permeability, no dust and the like, can not only be used for the large-scale deep desulfurization and purification of petrochemical products such as fuel oil, natural gas, gas, liquid hydrocarbon and synthetic ammonia, but also be used for the fields of pharmaceutical gas sterilization, solution filtration and purification, solvent recovery, water purification, gas purification and the like.

Owner:JIANGSU ZHUHAI ACTIVATED CARBON CO LTD

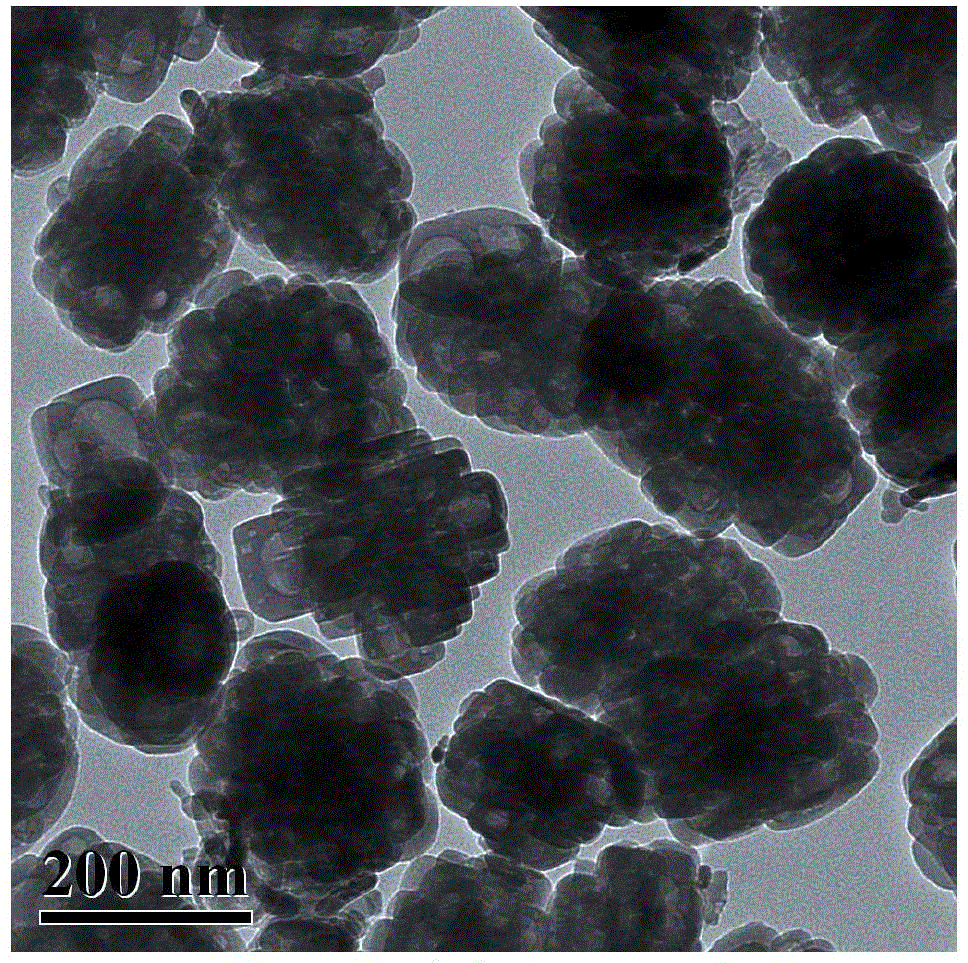

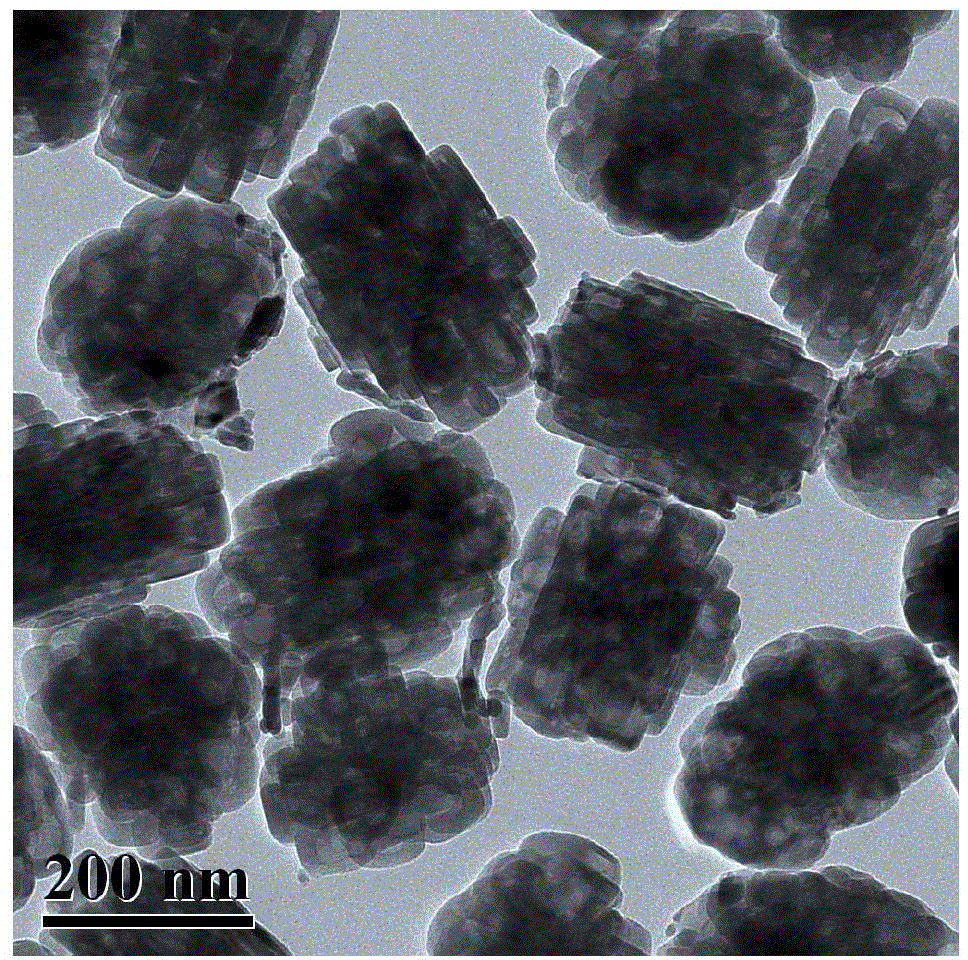

Surface amphiphilic nano-molybdenum disulfide hydrogenation catalyst and preparation method and application thereof

ActiveCN105439203ASurface amphipathicGood dispersionPhysical/chemical process catalystsMolybdenum sulfidesHydrodesulfurizationHigh pressure

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com