Composite graphite negative electrode material with high energy density, and preparation method and application thereof

A technology of high energy density and composite graphite, which is applied in the field of high energy density composite graphite anode materials and its preparation, can solve the problems of complicated preparation steps, increased manufacturing costs, increased production costs, etc., and achieve good processing performance and high first-time efficiency , the effect of high first discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

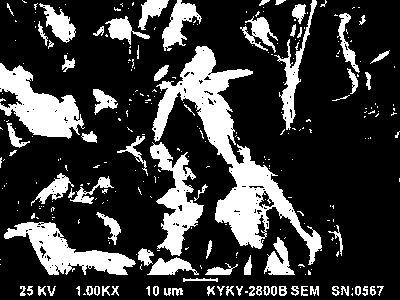

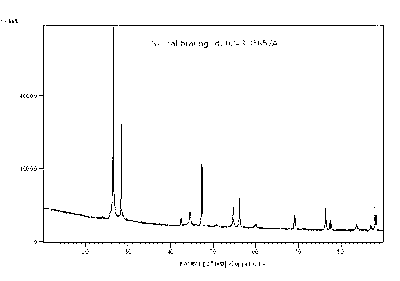

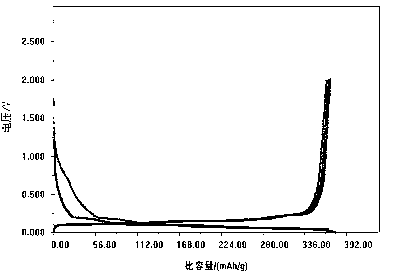

Image

Examples

Embodiment 1

[0061] Example 1 Preparation of composite graphite negative electrode material of the present invention

[0062] The preparation method of composite graphite negative electrode material of the present invention may further comprise the steps:

[0063] (1) Weigh 50Kg D 50 25μm petroleum coke and 50Kg D 50 It is natural graphite of 18 μm, which is placed in a mixer and mixed uniformly to obtain a composite graphite homogeneous mixture;

[0064] (2) Heat 50Kg of medium-temperature coal tar pitch to 100°C, then add the prepared composite graphite homogeneous mixture into medium-temperature coal tar pitch at 100°C, knead under normal pressure and 100°C until the kneading is uniform, and obtain kneading;

[0065] (3) Compress the kneaded mixture into a rectangular block with a size of 5cm×2cm×2cm under a pressure of 60Mpa, and obtain a density of 1.51 g / cm 3 moldings of

[0066] (4) Under the protection of nitrogen, heat up the rectangular block of t...

Embodiment 2

[0068] Example 2 Preparation of composite graphite negative electrode material of the present invention

[0069] The preparation method of composite graphite negative electrode material of the present invention may further comprise the steps:

[0070] (1) Weigh 100Kg D 50 20μm coal-based needle coke and 50Kg D 50 It is natural graphite of 15 μm, which is placed in a mixer and mixed uniformly to obtain a composite graphite homogeneous mixture;

[0071] (2) Heat 150Kg of medium-temperature coal tar pitch to 100°C, then add the prepared composite graphite homogenate into medium-temperature coal tar pitch at 100°C, knead under normal pressure and 100°C until the kneading is uniform, and obtain kneading;

[0072] (3) Compress the kneaded mixture into a rectangular block with a size of 5cm×2cm×2cm under the pressure of 80Mpa, and obtain a density of 1.56 g / cm 3 moldings of

[0073] (4) Under the protection of nitrogen, the rectangular block of the mo...

Embodiment 3

[0076] Example 3 Preparation of composite graphite negative electrode material of the present invention

[0077] The preparation method of composite graphite negative electrode material of the present invention may further comprise the steps:

[0078] (1) Weigh 200Kg D 50 28μm mesophase carbon microspheres and 50Kg D 50 It is natural graphite of 18 μm, which is placed in a mixer and mixed uniformly to obtain a composite graphite homogeneous mixture;

[0079] (2) Heat 125Kg high-temperature coal tar pitch to 120°C, then add the prepared composite graphite homogeneous mixture into high-temperature coal tar pitch at 120°C, knead under normal pressure and 120°C until the kneading is uniform, and obtain kneading;

[0080] (3) Compress the kneaded mixture into a rectangular block with a size of 5cm×2cm×2cm under a pressure of 90Mpa to obtain a density of 1.60 g / cm 3 moldings of

[0081] (4) Under the protection of nitrogen, the rectangular block of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com